Overview

Silicon alloy powders are materials composed primarily of silicon with added alloying elements like iron, aluminum, magnesium, copper, and nickel. Silicon has valuable semiconducting properties but in its pure form is brittle. When combined with other metals in powder form, silicon alloys gain improved strength, hardness, wear resistance, high temperature performance, and other enhanced properties while retaining useful electrical characteristics.

Silicon alloy powders are used to manufacture precision components, tools, and wear parts via powder metallurgy techniques like metal injection molding, hot isostatic pressing, additive manufacturing, and sintering. Key applications include the automotive sector, aerospace, electronics, and industrial machinery. Silicon alloy powders provide an economic and flexible approach to producing intricate or net-shape components with tailored metallurgical properties.

This guide provides a detailed overview of various types of silicon alloy powders, their composition, properties, production methods, applications, and suppliers. It includes multiple tables comparing parameters between different silicon alloys and summarizing key specifications. The guide is intended to help engineers, product designers, procurement managers, and researchers understand silicon alloy powder materials and select the optimal grade for their manufacturing needs.

Types of Silicon Alloy Powders

There are many binary, ternary, and higher-order alloy variations using silicon and metallic elements. Some of the most common silicon alloy powder types include:

Silicon Alloy Powder Types

| Alloy | Primary Elements | Key Properties | Common Applications |

|---|---|---|---|

| Ferrosilicon | Iron, silicon | High hardness, magnetism | Automotive, electronics |

| Silumin | Aluminum, silicon | Lightweight, strong | Aerospace, automotive |

| Silicast | Aluminum, silicon, magnesium | Wear resistance, low density | Aerospace, automotive |

| Kovar | Iron, nickel, cobalt, silicon | Thermal expansion match with glass | Electronics packaging |

| CuSil | Copper, silicon | Electrical conductivity, lubricity | Electronics, brushes |

| Nichrome | Nickel, chromium, silicon | Heat and corrosion resistance | Heating elements |

Ferrosilicon Alloy Powders

Ferrosilicon alloys contain varying ratios of iron and silicon, sometimes with minor additions of carbon or magnesium. Key characteristics include:

- High hardness and strength

- Pyrophoric nature due to iron content

- Less brittle than pure silicon

- Used in powder metallurgy, welding rods, and battery anodes

Typical compositions include FeSi 75, FeSi 90, FeSiMg with silicon content ranging from 15% to 90% balanced by iron. Smaller silicon particles in an iron matrix improve magnetism.

Silumin Alloy Powders

Silumins are alloys of aluminum and silicon with typical compositions between 5-20% Si balanced by Al. Properties include:

- Low density but high strength

- Good castability and machinability

- Used in automotive and aerospace components

Grain refiners like titanium or boron are often added. Silumins offer a lightweight metal alloy option.

Silicast Alloy Powders

Silicasts are ternary alloys containing aluminum, silicon, and magnesium. Key properties:

- Low density but high hardness and wear resistance

- Content ranges of Si (4-15%), Mg (0.5-5%), and balance Al

- Used for high performance pistons and aerospace applications

Silicast alloys are valued for wear properties combined with lower density versus ferrous alloys.

Kovar Alloy Powders

Kovar is a nickel-cobalt ferrous alloy containing silicon that matches the thermal expansion coefficient of borosilicate glass. It has:

- Composition of Fe 54%, Ni 29%, Co 17%, Si 0.5%

- Dense, uniform microstructure

- Excellent bond with glass, ceramics

- Used for glass-to-metal seals in electronics packaging

The silicon content in Kovar allows it to match glass expansion behavior through a wide temperature range.

CuSil Alloy Powders

CuSil alloys combine 70-97% copper with 1.5-15% silicon. Properties include:

- Retains copper’s high electrical and thermal conductivity

- Improved lubricity and wear resistance

- Used for brushes, welding electrodes, and high current contacts

Silicon increases hardness and mechanical strength compared to pure copper.

Nichrome Alloy Powders

Nichrome refers to nickel-chromium alloys with additions of silicon or aluminum up to 5%. It offers:

- Excellent high temperature oxidation resistance

- High electrical resistivity for heating elements

- Mechanical strength maintained at elevated temperatures

Nichrome silicon grades provide improved flow characteristics suited for powder processing.

Production of Silicon Alloy Powders

Silicon alloy powders are manufactured using techniques similar to other metal powder productions such as:

- Atomization

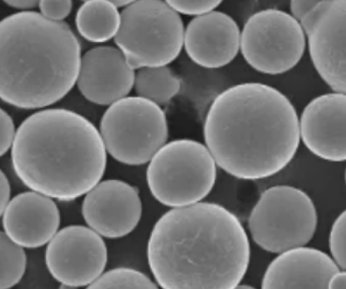

- Water atomization sprays molten alloy into water

- Gas atomization uses inert gas jets

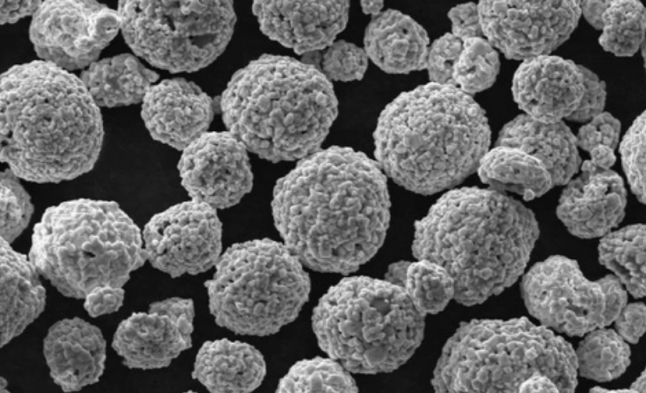

- Produces spherical powders optimal for pressing

- Mechanical milling

- Ball milling or attritor milling

- Irregular powder shapes and wide size distributions

- Electrolytic deposition

- Electrolytically coats a cathode with alloy powder

- Very fine powder sizes possible

- Chemical reduction

- Reduction of silicon and metal salts into alloy powder

- Cost-effective, used for ferrosilicon production

- Plasma atomization

- Use plasma torch to generate ultrafine metallic powders

- Clean, inert process environment

- Nanoscale or microscale particles

Alloy powders are screened to the desired particle size ranges and can be further processed with annealing, lubrication, or coating.

Properties of Silicon Alloy Powders

Silicon alloys exhibit a wide range of physical, mechanical, thermal, electrical, magnetic, and chemical properties based on their composition and microstructure.

Silicon Alloy Powder Properties

| Property | Effects | Measurement |

|---|---|---|

| Particle size | Sintering behavior, compact density | Laser diffraction, sieving |

| Particle shape | Powder flowability, pressing density | Microscopy, image analysis |

| Alloy composition | Mechanical strength, conductivity, magnetism | Inductively coupled plasma, X-ray fluorescence |

| Apparent density | Compactibility, pressing density | Hall flowmeter, Scott volumeter |

| Tap density | Compressibility, die fill density | ASTM B527 |

| Flow rate | Powder handling, fill density | Hall flowmeter |

| Thermal stability | Sintering response, microstructure | Differential scanning calorimetry |

| Oxygen content | Sintering atmosphere needs | Inert gas fusion analysis |

| Magnetic permeability | For soft magnetic compacts | Hysteresisgraph, BH analyzer |

Silicon percentage influences strength, brittleness, electrical resistivity, and thermal properties. Alloying elements impart distinct characteristics – aluminum for strength, nickel for magnetism, etc.

Powder morphologies like gas atomized spherical shapes provide maximum density whereas irregular milled particles improve pressing behavior.

Apparent density indicates compacting response. Hall flow rate and Carr index correlate with powder flow properties during pressing. Thermal analyzers identify potential Solid State sintering temperatures.

Applications of Silicon Alloy Powders

Thanks to their tunable physical, mechanical, and electromagnetic properties, silicon alloy powders are used across many industries to manufacture finished parts and components.

Major Applications of Silicon Alloys

| Industry | Example Applications | Desired Properties |

|---|---|---|

| Automotive | Gears, pistons, engine parts | High temperature strength, wear resistance |

| Aerospace | Turbine blades, structural parts | Strength-to-weight ratio, creep resistance |

| Electronics | Magnet cores, packaging, contacts | Electrical conductivity, soft magnetic behavior |

| Industrial | Cutting tools, dies, bearings | Hardness, fracture toughness, lubricity |

| Ordnance | Penetrators, ordnance cases | Density, ductility, impact resistance |

| Chemical | Valves, pumps, reactors | Corrosion resistance, high temperature behavior |

Powder metallurgy techniques allow net-shape or near-net shape fabrication of intricate components not easily produced by casting or machining.

Automotive uses include engine components subjected to extreme pressures and temperatures. Aerospace applications demand lightweight, high-performance alloys.

Electrical contacts rely on copper/silicon alloys to combine conductivity with mechanical durability. Industrial tools and dies apply hardness and wear properties of ferrosilicon or silicast alloys.

Silicon alloy powders enable tailoring of physical, chemical, thermal, electrical, and magnetic characteristics not achievable with single metal powders.

Specifications of Silicon Alloy Powders

Silicon alloy powders are available under various national and international standard powder specifications that define the particle size range, permissible impurity levels, alloy composition limits, and other parameters specific to the grade.

Silicon Alloy Powder Specifications

| Alloy | Applicable Standards | Particle Size | Apparent Density | Flow Rate |

|---|---|---|---|---|

| Ferrosilicon | ASTM A483 | -150 +400 mesh | 2.5-3.1 g/cc | 25-35 s/50g |

| Silumin | EN 1706 | -325 mesh | 1.5-2.2 g/cc | 35-45 s/50g |

| Silicast | DIN 1718 | 10-45 microns | 2.8-3.2 g/cc | 28-32 s/50g |

| Kovar | JIS Z 3265 | -270 mesh | 4.8-5.2 g/cc | 22-28 s/50g |

| CuSil | QSIL051 | -325 mesh | 3.2-4.1 g/cc | 30-40 s/50g |

| Nichrome | AMS 7759 | 10-50 microns | 4.2-4.8 g/cc | 26-32 s/50g |

Key criteria like particle size distribution, flow rate, apparent density, and composition ranges help define application suitability.

International standards organizations and professional societies like ASTM, ISO, DIN, JIS, AMS, and AWS maintain metallic powder specifications covering major alloys.

Specifications assist with quality control during manufacturing and provide customers repeatable powder performance.

Silicon Alloy Powder Suppliers

Many major metal powder producers offer standard and custom silicon alloy powder compositions suitable for pressing, sintering, metal injection molding, additive manufacturing, and thermal spray.

Silicon Alloy Powder Suppliers

| Supplier | Silicon Alloys Offered | Production Capacity | Pricing |

|---|---|---|---|

| Höganäs | Ferrosilicon, Nichrome, Silicast | 50,000 tonnes/year | $$/kg |

| CNPC Powder | Ferrosilicon, CuSil, Kovar | 30,000 tonnes/year | $/kg |

| Guizhou Zhenhua | Ferrosilicon | 10,000 tonnes/year | $/kg |

| Vale Metals | Silumin, Nichrome | 20,000 tonnes/year | $$/kg |

| Metal Powders India | Ferrosilicon, Silumin | 5,000 tonnes/year | $/kg |

| JFE Steel | Silicast, Kovar | 35,000 tonnes/year | $$/kg |

Pricing depends on alloy composition, particle size, purity levels, order quantity, and geographical location. Expect to pay premiums for highly engineered alloys used in critical applications versus commodity ferrosilicon grades.

Choosing the Right Silicon Alloy Powder

Selecting the optimal silicon alloy powder requires matching the composition and powder properties to your manufacturing process and final component performance requirements.

Key selection criteria include:

- Alloy composition – Determines physical, mechanical, thermal, electrical properties

- Particle size and shape – Impacts powder flow and compacted density

- Apparent and tap density – Relates to pressing behavior and green strength

- Flow characteristics – Important for automated powder handling

- Purity levels – Affects final properties and microstructure

- Cost factors – Raw materials, production method, quality standards

Work with powder producers early in the design process to narrow suitable alloy choices and powders optimized for your process. Multiple options may meet the technical requirements so focus on maximizing value.

FAQ

Here are answers to some frequently asked questions about silicon alloy powders:

What are the main advantages of silicon alloys versus pure metals?

Silicon alloys retain desirable electrical properties like conductivity or semiconducting behavior while improving mechanical performance. Alloying increases hardness, strength, thermal stability, and wear resistance compared to pure silicon or other base metals.

How do ferrosilicon properties vary with silicon content?

As silicon content increases from 15% Si to 90% Si in ferrosilicons, hardness increases but so does brittleness. Electrical resistivity also rises dramatically with higher silicon levels. 75% Si represents a good compromise between magnetism, ductility, and hardness.

What powder size is recommended for metal injection molding?

For most alloy systems, a powder size range of 10-25 microns provides optimal flow when bindered as well optimal particle packing and sintered density. Finer powders improve green strength but compromise flow behavior.

What causes lower apparent density versus tap density in powders?

Tap density measured under vibration reflects the densest packing state achievable whereas apparent density includes interparticle voids that reduce packing efficiency. Irregular angular powder morphologies exhibit a larger gap between apparent and tap densities.

How are copper and nickel silicons different from ferrosilicons?

CuSil and NiSi alloys retain the high electrical and thermal conductivity of copper and nickel versus the insulating properties of iron. This makes them preferable for applications like brushes and contacts requiring combined metallurgical and conductive characteristics.

What is the benefit of gas atomization versus mechanical milling?

Gas atomization produces spherical, flowing powders suited for automated die fill whereas milling creates irregular particles with higher green strength. Gas atomized powders have lower R:G density ratios but give better sintered uniformity.

Conclusion

Silicon alloy powders enable high performance metal components combining electrical, magnetic, and engineering properties unattainable through pure metals. By selecting the optimal composition, powder characteristics, and fabrication process, engineers can develop components with unique capabilities and value. The versatility of silicon alloys will continue driving advances and innovations across industries.