Introduction

Additive Manufacturing (AM), also known as 3D printing, is a transformative technology that has been revolutionizing various industries. It allows for the creation of complex and intricate objects by adding layer upon layer of material, making it an innovative alternative to traditional manufacturing methods. One of the key factors enabling the success of AM is the development of AM materials.

What are AM Materials?

AM materials refer to the various types of materials that can be used in additive manufacturing processes. These materials come in different forms, including polymers, metals, ceramics, and composites. Each type of material possesses unique properties and characteristics, making them suitable for diverse applications.

The History of Additive Manufacturing

To understand the significance of AM materials, it’s essential to explore the history of additive manufacturing. The roots of 3D printing can be traced back to the 1980s when the first AM technologies were developed. Over the years, advancements in AM processes and materials have led to a rapid growth in its adoption across industries.

Types of AM Materials

Polymers

Polymers are one of the most commonly used AM materials. They offer versatility, cost-effectiveness, and the ability to create intricate shapes. From consumer products to medical devices, polymers have found applications in various fields.

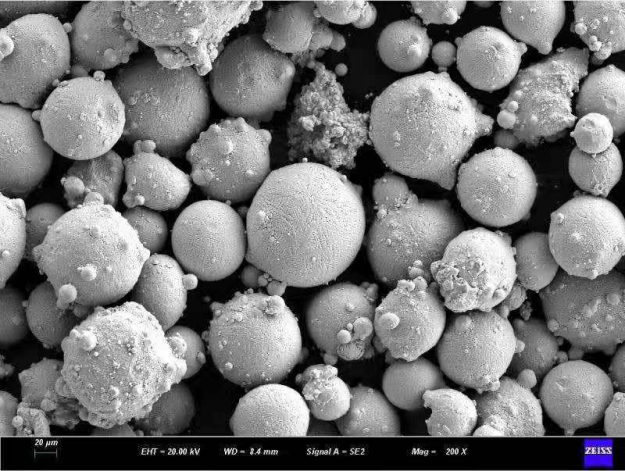

Metals

Metal AM materials have gained immense popularity due to their strength, durability, and excellent thermal and electrical conductivity. Industries such as aerospace and automotive rely on metal AM for lightweight and high-performance components.

Ceramics

Ceramics are valued for their high-temperature resistance and excellent mechanical properties. AM allows for the production of intricate ceramic components that are challenging to achieve through traditional manufacturing methods.

Composites

Composites combine the advantages of different materials to create structures with enhanced properties. AM enables the fabrication of composite materials with complex geometries and tailored characteristics.

Advantages of AM Materials

Design Freedom

AM materials offer unparalleled design freedom, allowing engineers and designers to create shapes and structures that were previously impossible to manufacture.

Reduced Waste

Traditional manufacturing often results in significant material wastage. AM materials help minimize waste by only using the exact amount of material needed for the final product.

Lightweight Structures

In industries where weight is a critical factor, such as aerospace and automotive, AM materials enable the production of lightweight yet robust components.

Customization

AM materials facilitate customization of products, catering to individual needs and preferences. This level of personalization is unparalleled in traditional manufacturing.

Challenges in AM Material Development

While AM materials have opened up new possibilities, several challenges need to be addressed for further advancements.

Material Selection and Properties

Selecting the right AM material with the required properties for a specific application can be complex. Understanding material behavior during the printing process and post-processing is crucial.

Process Optimization

Optimizing the AM process for different materials is essential to ensure the final product’s quality and performance.

Post-Processing and Finishing

Post-processing steps are often necessary to achieve the desired surface finish, mechanical properties, and accuracy.

Applications of AM Materials

AM materials have already made significant impacts in various industries. Some notable applications include:

Aerospace and Aviation

AM materials are used to create lightweight and high-strength components for aircraft, leading to improved fuel efficiency and performance.

Healthcare and Medical Devices

Customized medical implants and prosthetics are now possible, thanks to AM materials, providing better patient outcomes.

Automotive Industry

The automotive sector benefits from AM materials in rapid prototyping, lightweight parts, and on-demand spare parts production.

Consumer Goods

AM materials enable the production of customized consumer products, giving rise to unique and personalized designs.

Future of AM Materials

The future of AM materials holds promising opportunities for further innovation and growth. Continuous research and development will lead to the creation of new materials with enhanced properties, expanding the scope of additive manufacturing.

Sustainability and AM Materials

The sustainability aspect of AM materials is gaining attention. As the technology evolves, efforts are being made to develop more environmentally friendly materials and recycling strategies.

Conclusion

Additive Manufacturing materials have transformed the manufacturing landscape, opening up new possibilities across industries. From aerospace to healthcare, AM materials offer exceptional design freedom, reduced waste, and customization opportunities. While challenges exist, ongoing research and innovation will pave the way for an even more exciting future.

FAQs

- What is Additive Manufacturing (AM)? Additive Manufacturing, also known as 3D printing, is a technology that builds objects layer by layer, adding material rather than subtracting it, as in traditional manufacturing.

- What are the advantages of AM materials in aerospace applications? AM materials in aerospace applications offer lightweight components, reducing fuel consumption and improving overall performance.

- Can AM materials be used to create medical implants? Yes, AM materials are used to create customized medical implants and prosthetics that offer better fit and functionality.

- How does AM material recycling work? AM material recycling involves collecting and reprocessing used or excess AM materials to create new components or products.

- What are the main challenges in AM material development? The main challenges in AM material development include material selection, process optimization, and post-processing techniques to achieve desired properties and quality.