Introduction

In the realm of advanced materials, C103 powder stands tall as a remarkable super alloy with exceptional properties. This article delves into the world of C103 powder, exploring its composition, manufacturing process, applications, advantages, challenges, and future prospects. Join us as we unravel the secrets behind this cutting-edge material and its transformative impact on various industries.

What is C103 Powder?

C103 powder, also known as C103 super alloy, is a high-performance material renowned for its outstanding properties. It falls under the category of refractory metal-based composites and contains tantalum (Ta), hafnium (Hf), and carbon (C) as its primary elements. This unique combination gives rise to a material with exceptional resistance to extreme temperatures, making it a top choice for applications requiring high-temperature performance.

The Composition of C103 Powder

C103 powder’s composition is meticulously crafted to achieve a balance between various critical attributes. It typically consists of approximately 70% tantalum, 27% hafnium, and 3% carbon. The high tantalum content contributes to its remarkable thermal stability, while hafnium enhances its mechanical strength. Carbon plays a vital role in improving the material’s oxidation resistance, making C103 powder a versatile and reliable choice for demanding applications.

Manufacturing Process of C103 Powder

The production of C103 powder involves complex and precise manufacturing techniques. The process often starts with the production of master alloys, which are then converted into powder form using methods like mechanical alloying or gas atomization. The powder is carefully handled to prevent contamination, ensuring that its unique properties remain intact. The resulting C103 powder is then ready for various downstream applications.

Applications of C103 Powder

Aerospace Industry

The aerospace sector is one of the most significant beneficiaries of C103 powder. Its exceptional high-temperature resistance and mechanical properties make it an ideal material for aircraft engine components, such as turbine blades and nozzles. Additionally, C103 powder finds use in rocket propulsion systems, where it withstands the extreme conditions of space travel.

Defense Sector

The defense industry also leverages the prowess of C103 powder in various applications. It is utilized in manufacturing armor-piercing projectiles, ensuring optimal performance even under severe stress and heat. Moreover, C103 powder’s resistance to corrosion and oxidation makes it suitable for critical defense equipment.

Automotive Industry

In the automotive sector, C103 powder is employed to create high-performance engine parts, exhaust systems, and components for racing vehicles. Its ability to endure high temperatures and mechanical stress makes it a favored material in the pursuit of enhanced automotive performance.

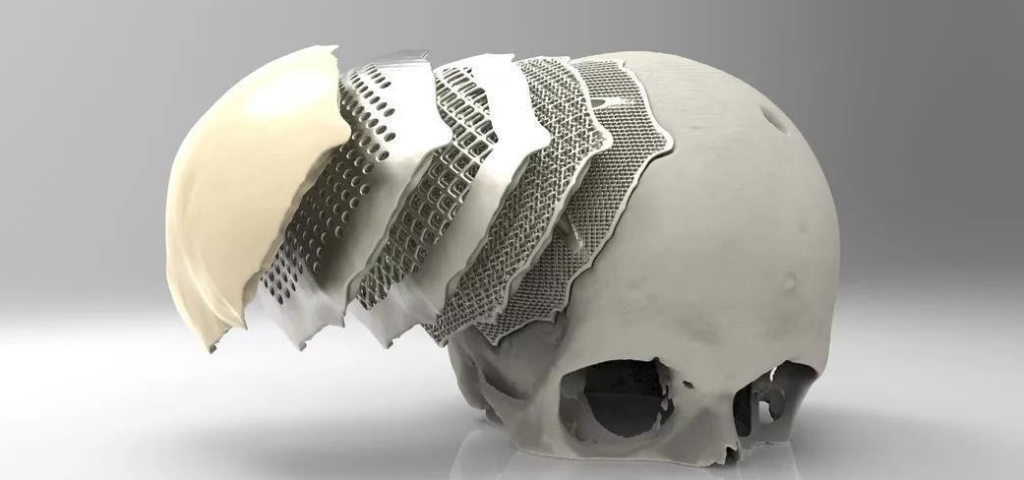

Medical Applications

C103 powder’s biocompatibility and resistance to corrosion open doors for medical applications. It finds usage in surgical instruments, implants, and other medical devices that require both durability and compatibility with the human body.

Other Industrial Uses

Beyond the mentioned applications, C103 powder also proves valuable in various industrial settings, such as chemical processing, high-temperature furnaces, and electronics manufacturing.

Advantages of C103 Powder

C103 powder comes with a plethora of advantages that make it stand out among other materials. Some of its key benefits include:

High Temperature Resistance

C103 powder can withstand extreme temperatures, making it a reliable choice for applications in high-temperature environments.

Excellent Mechanical Properties

The combination of tantalum and hafnium imparts outstanding mechanical strength to C103 powder, enabling it to endure heavy loads and stress.

Corrosion Resistance

The material’s resistance to corrosion and oxidation ensures its longevity even in harsh environments.

Low Thermal Expansion

C103 powder exhibits low thermal expansion characteristics, making it suitable for applications requiring dimensional stability under varying temperatures.

Electrical Conductivity

With its good electrical conductivity, C103 powder finds use in electrical and electronic applications.

Challenges and Limitations of C103 Powder

Despite its remarkable properties, C103 powder does have certain limitations. For instance, the high cost of raw materials, particularly tantalum and hafnium, can make C103 powder a more expensive option compared to other materials. This cost factor may restrict its widespread adoption in certain industries, particularly those with budget constraints.

Additionally, the manufacturing process of C103 powder is complex and requires specialized equipment and expertise, further contributing to its cost. The powder’s sensitivity to contamination during production also poses challenges in ensuring consistent quality.

Moreover, while C103 powder exhibits exceptional resistance to corrosion, it may not be suitable for highly aggressive chemical environments. Careful consideration and material selection are essential to ensure its optimal performance in such conditions.

Future Prospects of C103 Powder

As technology continues to advance, the demand for high-performance materials like C103 powder is expected to grow. Ongoing research and development efforts aim to improve the manufacturing process, making it more cost-effective and scalable. This could potentially lead to wider adoption of C103 powder in various industries, including those that were previously hesitant due to cost considerations.

Furthermore, as new applications and industries emerge, the unique properties of C103 powder may find novel uses. Advancements in additive manufacturing techniques, such as 3D printing, could also open up new possibilities for designing and fabricating complex components using C103 powder.

Safety Precautions

While C103 powder boasts impressive characteristics, it is essential to handle it with care, especially during its production and processing. Dust generated during the handling of C103 powder may pose inhalation hazards, so appropriate safety measures and personal protective equipment should be used to minimize exposure.

Additionally, given the presence of tantalum and hafnium, which are heavy metals, proper waste management and disposal practices should be followed to prevent environmental contamination.

Conclusion

In conclusion, C103 powder stands as a remarkable super alloy with unparalleled high-temperature resistance, excellent mechanical properties, and corrosion resistance. Its versatile nature has led to applications in diverse industries, including aerospace, defense, automotive, medical, and more. While it does face challenges and limitations, ongoing research and technological advancements offer promising prospects for its future.

C103 powder continues to play a pivotal role in advancing technology and meeting the demands of modern engineering. As industries strive for higher performance and reliability, C103 powder remains a reliable and cutting-edge choice.

FAQs

- Is C103 powder cost-effective for all applications?While C103 powder offers exceptional properties, its cost can be a limiting factor for certain applications. Industries with budget constraints may need to evaluate the trade-offs between performance and cost when considering C103 powder.

- What makes C103 powder suitable for high-temperature applications?C103 powder’s composition, which includes tantalum and hafnium, provides it with excellent high-temperature resistance and mechanical strength, making it ideal for use in extreme environments.

- Can C103 powder be used in medical implants?Yes, C103 powder’s biocompatibility and resistance to corrosion make it suitable for medical applications, including surgical instruments and implants.

- What safety precautions should be taken when handling C103 powder?When handling C103 powder, it is essential to use appropriate personal protective equipment to minimize inhalation hazards. Proper waste management and disposal practices should also be followed to prevent environmental contamination.

- Is C103 powder compatible with 3D printing?Advancements in additive manufacturing techniques, including 3D printing, hold promise for using C103 powder in designing and fabricating complex components for various applications. However, further research and development are ongoing in this area.