Introduction

In modern engineering, the demand for materials with exceptional properties has led to the development of advanced alloys like tc4 material. This article explores TC4 material, its properties, applications, manufacturing techniques, and a comparison with other titanium alloys. We will also discuss its advantages and disadvantages, as well as its future prospects.

What is TC4 Material?

tc4 material is a titanium alloy that is widely used in various industries due to its outstanding characteristics. It is also known as Ti-6Al-4V, which indicates its composition of 6% aluminum and 4% vanadium. The combination of these elements results in a strong and lightweight material, making it suitable for a wide range of applications.

Properties of TC4 Material

High Strength-to-Weight Ratio

One of the most remarkable features of TC4 material is its high strength-to-weight ratio. This means that despite being lightweight, it exhibits excellent mechanical strength, allowing it to withstand heavy loads and harsh conditions. Such properties make it an ideal choice for industries like aerospace and automotive.

Corrosion Resistance

TC4 material possesses exceptional corrosion resistance, particularly in aggressive environments. This property is crucial in industries where components are exposed to chemicals, seawater, or other corrosive substances, ensuring the longevity and reliability of the products.

Biocompatibility

In addition to its industrial applications, TC4 material is also biocompatible, making it suitable for medical implants. Its ability to integrate well with the human body and resist corrosion in physiological environments makes it a popular choice for orthopedic and dental implants.

Applications of TC4 Material

Aerospace Industry

The aerospace industry extensively utilizes TC4 material in the manufacturing of aircraft components. Its high strength, low weight, and corrosion resistance contribute to fuel efficiency and improved performance of aerospace systems.

Medical Implants

The biocompatibility of TC4 material makes it a valuable resource for producing medical implants, such as joint replacements, bone plates, and dental implants. Its compatibility with human tissues reduces the risk of rejection and promotes faster healing.

Sporting Goods

In the sports industry, TC4 material finds applications in the production of lightweight and durable equipment. It is commonly used in the construction of bicycle frames, tennis rackets, and golf clubs, providing athletes with the advantage of enhanced performance.

Automotive Industry

TC4 material is increasingly adopted in the automotive sector, where reducing the weight of vehicles is a key goal for improving fuel efficiency. Its application in engine parts, exhaust systems, and suspension components helps enhance overall vehicle performance.

Marine Engineering

The marine environment exposes materials to severe corrosion from saltwater and other harsh conditions. TC4 material’s corrosion resistance makes it suitable for marine engineering applications, including shipbuilding and underwater components.

Manufacturing of TC4 Material

TC4 material can be manufactured through various processes, each with its own advantages.

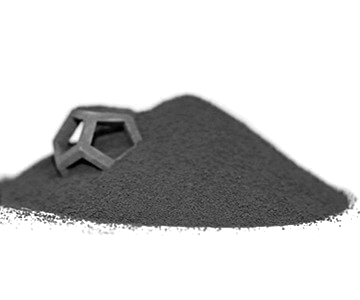

Powder Metallurgy

Powder metallurgy involves the compacting and sintering of titanium alloy powders to form solid components. This process allows for complex shapes and precise control over the final product.

Hot Isostatic Pressing (HIP)

HIP involves subjecting the material to high temperature and pressure, which helps in reducing porosity and improving the material’s properties, resulting in a higher quality product.

Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, enables the fabrication of complex geometries with less material waste. This technique has revolutionized the production of aerospace and medical components.

Forging and Machining

Forging and machining are traditional methods for shaping TC4 material into desired forms. While these methods are time-tested, they may not be as cost-effective as newer manufacturing techniques.

Comparison with Other Titanium Alloys

TC4 vs. Ti-6Al-4V

TC4 is often used interchangeably with Ti-6Al-4V since they have the same chemical composition. However, the naming convention may vary in different regions or industries.

TC4 vs. TC6

TC4 and TC6 are both titanium alloys, but they have distinct compositions and properties. Understanding their differences is essential for selecting the right material for specific applications.

Advantages and Disadvantages of TC4 Material

Advantages

- High strength-to-weight ratio

- Corrosion resistance

- Biocompatibility

- Versatility in manufacturing processes

- Extensive applications across industries

Disadvantages

- High cost compared to some other materials

- Requires specialized handling during manufacturing

Future Prospects

The future of TC4 material looks promising, with ongoing research and advancements in manufacturing techniques. As industries continue to demand materials that offer high performance, TC4’s unique combination of properties will likely make it a preferred choice for diverse applications.

Conclusion

TC4 material, also known as Ti-6Al-4V, is a remarkable titanium alloy with exceptional properties. Its high strength-to-weight ratio, corrosion resistance, and biocompatibility have made it indispensable in various industries, including aerospace, medical, and sports. With advancements in manufacturing techniques, the future prospects of TC4 material are bright, cementing its position as a key player in modern engineering.