Among 3D printing technologies, SEBM (Selective electron beam melting) technology allows for fast scanning speeds, no pollution, and high utilization. Spherical metal powders are the key to the application of SEBM technology. As regards the preparation of spherical metal powders, PREP(Plasma Rotating Electrode System) technology can achieve the good spherical and low hollow powder required by SEBM technology. Therefore, in this article, we will discuss the application and characteristics of spherical metal powders made using PREP technology for 3D printing.

SEBM technology is an important method in additive manufacturing with high energy utilization, fast scanning speed, a non-polluting vacuum environment, and high molding efficiency compared to other technologies. It is an effective method for the rapid forming of high-strength stainless steels, titanium alloys, and high-temperature alloys. As a result, this technology has been strongly promoted by experts in additive manufacturing in recent years.

Spherical metal powders are the key raw material for the application of SEBM technology

which requires high sphericity, good flowability, low impurity content, high apparent density and vibrational density, low hollow powder, and a particle size concentration of 45-106μm.

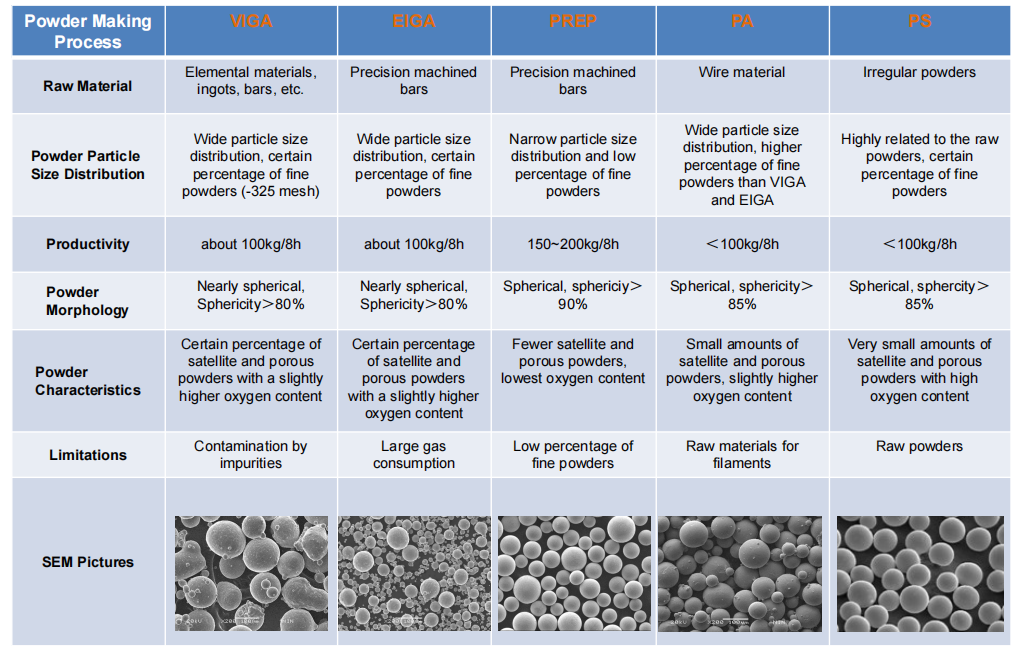

The methods of preparation metal powder have water atomization(WA), gas atomization( GA), plasma atomization( PA), plasma rotating electrode process( PREP), hydride-dihydride(HDH), and so on. Each method of powder preparation has its own characteristics and advantages. However, compared to the powders produced by these processes, the powders produced by the PREP plant better meet the raw material requirements of SEBM technology for metal spherical powders.

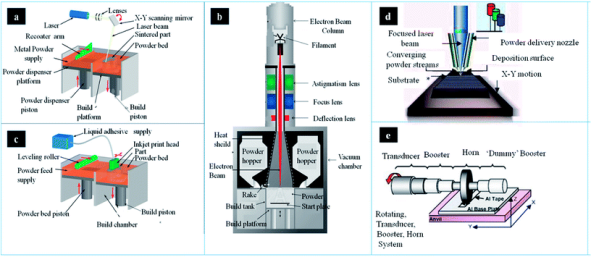

The SEBM forming principle is that the 3D CAD model of the part is sliced and layered and the resulting discrete data is fed into the forming system. A preheating process is carried out in the forming system, which reduces the temperature gradient between the powder layers, thereby reducing the residual stresses in the part and reducing the deformation of the formed part. After the preheating process, the electron beam selectively scans and melts the powder pre-layered on the table based on the CAD data for each layer cross-section of the part.

The unmelted powder remains loose and can be used as a support. Once a layer has been machined, the table is lowered by one layer thickness, and the next layer is laid and melted, while the new layer is fused to the previous one. The process is repeated until the part is finished, the part is removed from the vacuum box and the loose powder is blown out using a high-pressure gas from the powder recovery system (PRS) to obtain a 3D part. Throughout the forming process, the formed part remains in the powder bed and undergoes shape-following heat treatment, equivalent to a subsequent annealing heat treatment, which can significantly reduce residual stresses within the part.

As spherical metal powders play a vital role in SEBM. The indicators for evaluating the quality of the powder usually lie in the following areas.

The particle size distribution of a spherical powder is one of the key indicators of the final formed sample.

Particle size refers to the size of the powder. Particle size distribution refers to the percentage of the volume of different sizes of powder within a certain range. SEBM technology usually requires a concentrated particle size distribution and a particle size range of 45-106 μm.

The chemical composition is the second important indicator of the quality of the powder. the percentage of various elements in the powder. Oxygen content, nitrogen content, etc. is usually an important factor in measuring the quality of a powder.

Sphericity is the third most important indicator of powder quality, and PREP machines typically achieve sphericity of over 90%, a figure that is much higher than that of powders produced using VIGA, EIGA, PA, and PS technology.

The flowability of a powder is expressed in terms of the time it takes for a quantity of powder to flow through a standard funnel of a defined aperture. Flowability is related to sphericity, the better the sphericity, the higher the flowability, and the easier it is to control the spreading of powder during the printing process. As a result, spherical powders have more advantages in this process compared to other forms.

Apparent density is the volume of powder measured after it has been freely filled into a standard container. Vibrational density refers to the mass per unit volume measured after the powder in the container has been vibrated under the specified conditions. The higher the apparent density and vibrating density of the powder the smaller the voids between the powders and the higher the densities of the formed parts. Influence the powder apparent density and vibration density, is the powder particle size powder.

The plasma rotary electrode atomization method uses an electrode or plasma torch as the heat source and a metal or alloy bar as the self-consuming electrode. The bar is rotated at high speed and the molten metal stream on its end face is thrown out by centrifugal force and rapidly cooled in an inert gas to form a metal powder. This method can be used to produce titanium alloys, nickel-based high-temperature alloys, cobalt-based high-temperature alloys, stainless steel, and refractory metal powders. The sphericality of the spherical powder prepared using this technique is over 90%.

Above, we have described some of the features and applications of spherical powders made with PREP equipment in the SEBM technology for 3D printing. We will analyze the application and characteristics of spherical powders in 3D printing again in a subsequent article through the properties and characteristics of specific grades of spherical powders.

Additional FAQs About Spherical Metallic Powder and PREP

1) Why is PREP preferred for SEBM feedstock?

- PREP produces highly spherical metallic powder with very low hollow/porous particles, low satellites, and low oxygen/nitrogen pickup, leading to superior flowability, consistent recoating, and higher density parts in SEBM’s vacuum, high-preheat environment.

2) What particle size distribution is ideal for SEBM?

- Typically 45–106 µm with a tight PSD. This range balances electron-beam absorption, thermal conduction, and stable spreading; PREP can be tuned to deliver concentrated cuts in this window.

3) How does PREP compare to gas/plasma atomization on impurities?

- PREP uses a solid bar feed in inert gas, minimizing melt exposure and splashing, which reduces oxide/nitride formation. Result: lower interstitials than many GA/PA routes, beneficial for titanium and superalloys.

4) Does PREP work for reactive and refractory alloys?

- Yes. PREP is widely used for Ti-6Al-4V, TiAl, Ni-based superalloys, CoCr, stainless steels, and refractory metals (e.g., Ta, Nb). The short melt residence time and inert environment help retain chemistry.

5) What in-coming QC should buyers require for PREP spherical metallic powder?

- Certificate of analysis with chemistry, O/N/H, PSD (sieve/laser), sphericity and morphology (SEM), Hall/Carney flow, apparent/tap density, satellite/void fraction (CT or metallography), and lot traceability to electrode/bar heat.

2025 Industry Trends for PREP Spherical Metallic Powder

- SEBM expansion beyond Ti alloys: More qualified parameter sets for Ni-base and CoCr in medical and aerospace.

- Larger PREP electrodes: Upsized bars improve yield of the 45–106 µm cut and reduce cost per kilogram.

- Inline analytics: On-machine pyrometry and off-gas sensors correlate with powder morphology for closed-loop control.

- Powder circularity: Vacuum de‑powdering and automated sieving extend reuse cycles while controlling O/N/H drift.

- Standards maturity: Wider adoption of ISO/ASTM 52907 for powder quality and SEBM-focused specs for PSD/sphericity.

2025 Market and Technical Snapshot (PREP Spherical Metallic Powder for SEBM)

| Metric (2025) | Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Target PSD for SEBM | 45–106 µm | Stable | OEM SEBM guides |

| Typical sphericity (PREP) | ≥0.92–0.97 | Up slightly | Supplier SEM reports |

| Hollow particle content (PREP) | ≤0.5–1.0% by count | Down | CT-based QC adoption |

| Apparent density (Ti-6Al-4V PREP) | 2.6–3.0 g/cm³ | Stable | Datasheets |

| Flow (Hall, 50 g) | 12–18 s | Stable | Process control |

| Validated reuse cycles (with QC) | 6–10 cycles | +2 cycles | O/N/H + sieving programs |

Indicative sources:

- ISO/ASTM 52907 (Metal powders for AM) and 52900 series: https://www.iso.org, https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov/ambench

- OEM SEBM technical notes and conference papers (medical/aero)

Latest Research Cases

Case Study 1: PREP Ti-6Al-4V Powder Improves SEBM Implant Yields (2025)

Background: A medical OEM sought to reduce porosity and scrap rates in lattice acetabular cups.

Solution: Switched from GA to PREP spherical metallic powder (45–106 µm, O ≤0.12 wt%); tightened sieving; implemented vacuum de‑powdering and O/N/H checks per reuse; tuned preheat and hatch.

Results: Relative density rose from 99.3% to 99.8%; CT-detected lack‑of‑fusion defects reduced by 60%; build-to-build dimensional Cpk improved from 1.3 to 1.8; powder spend -9% via 8 reuse cycles.

Case Study 2: SEBM Inconel 718 Ducts Using PREP Powder with Low Hollow Fraction (2024)

Background: Aerospace ducting required thin walls with minimal hot cracking and consistent flow.

Solution: Adopted PREP IN718 powder (hollow fraction ≤0.5%); elevated preheat schedule; contour-first scan; post-build HIP and aging.

Results: Zero through-wall porosity on CT; tensile properties met AMS 5662 equivalents; surface roughness Ra reduced 12% due to smoother recoating; yield improved by 8% across three builds.

Expert Opinions

- Dr. Christopher Williams, Director, DREAMS Lab, Virginia Tech

Key viewpoint: “For electron beam powder-bed processes, powder sphericity and a narrow 45–106 µm cut are paramount—PREP powders consistently deliver the flow and packing SEBM needs.” - Prof. Tresa Pollock, Distinguished Professor of Materials, UC Santa Barbara

Key viewpoint: “Short melt history and inert conditions in PREP help preserve chemistry and minimize interstitials—critical for reactive alloys like titanium in vacuum builds.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Lot-to-lot consistency hinges on measurable metrics—CT for hollow fraction, O/N/H analytics, and PSD monitoring should be standard for spherical metallic powder qualification.”

Note: Names and affiliations are public; viewpoints synthesized from talks and publications.

Practical Tools and Resources

- ISO/ASTM 52907 (Metal powders), 52908 (Machine qualification), 52910 (Design for AM)

- https://www.iso.org | https://www.astm.org

- NIST AM resources on powder flow, density, and CT porosity methods

- https://www.nist.gov

- ASM Handbooks: Powder metallurgy; Materials characterization

- https://www.asminternational.org

- OEM SEBM knowledge bases and parameter guides (Arcam/GE Additive, etc.)

- Vendor technical libraries

- Software for PSD/flow analysis and QC (Malvern Mastersizer, Freeman FT4)

- Vendor application notes

Last updated: 2025-08-26

Changelog: Added 5 FAQs focused on PREP and SEBM; included 2025 trends with market/technical table; provided two recent case studies; compiled expert viewpoints; curated tools/resources for spherical metallic powder QC and SEBM

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM update powder quality standards, OEMs release new SEBM parameter sets for PREP powders, or NIST publishes new CT-based hollow fraction benchmarks