Introduction

In the world of advanced materials, tantalum powder holds a special place due to its unique properties and versatile applications. This article delves into the fascinating world of tantalum powder, exploring its characteristics, production methods, applications, and sustainability aspects. Join us on this journey to discover the significance of tantalum powder in modern industries.

What is Tantalum Powder?

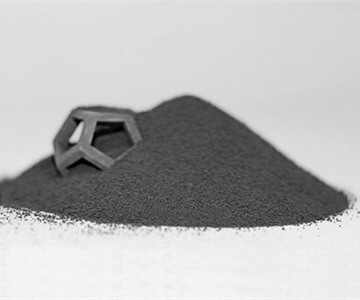

Tantalum powder is a fine, grayish metal powder derived from tantalum, a rare and dense transition metal found in nature. It is often used as a key ingredient in various alloys and compounds due to its remarkable properties. Tantalum is known for its high melting point, excellent corrosion resistance, and biocompatibility, making it a valuable material in several industries.

Tantalum Powder Properties and Characteristics

High Melting Point

One of the most notable features of tantalum powder is its exceptionally high melting point. With a melting point of approximately 3,020 degrees Celsius (5,468 degrees Fahrenheit), tantalum can withstand extreme temperatures, making it suitable for applications in high-temperature environments such as jet engines and nuclear reactors.

Corrosion Resistance

Tantalum exhibits outstanding corrosion resistance, making it highly desirable for applications involving aggressive environments. It resists attack from various acids, including hydrochloric acid and sulfuric acid, making it invaluable in chemical processing equipment and other corrosive environments.

Ductility

Despite its robust nature, tantalum is also quite ductile. It can be easily formed into different shapes and sizes, allowing manufacturers to create intricate components for a wide range of applications.

Biocompatibility

Tantalum possesses excellent biocompatibility, making it suitable for medical implants and devices. When used in the human body, tantalum exhibits minimal adverse reactions, reducing the risk of implant rejection and enhancing patient outcomes.

Applications of Tantalum Powder

Electronics and Capacitors

Tantalum powder is a critical component in manufacturing tantalum capacitors, widely used in the electronics industry for energy storage and signal filtering. These capacitors find applications in smartphones, computers, and various electronic devices, contributing to their compact size and improved performance.

Aerospace Industry

The aerospace industry relies on tantalum powder for its high strength, thermal stability, and resistance to fatigue. Tantalum alloys are used in jet engine components, aircraft frames, and other critical parts, ensuring safe and reliable operations at high altitudes and extreme temperatures.

Medical Implants

Tantalum’s biocompatibility makes it an ideal material for medical implants, such as hip replacements and dental implants. Its ability to integrate with the human body’s bone tissue promotes faster healing and reduces the risk of complications.

Additive Manufacturing

With the rise of additive manufacturing or 3D printing, tantalum powder has found its way into the production of intricate and custom-designed parts. Additive manufacturing techniques allow for the creation of complex geometries, making tantalum an attractive option for various industries.

Tantalum Powder Production and Processing

Mining and Extraction

Tantalum is primarily obtained from tantalite ore, which is often found alongside niobium in geological deposits. The mining and extraction process involves various stages, including exploration, excavation, and ore processing.

Refining Process

Once the tantalite ore is obtained, it undergoes a refining process to separate tantalum from other minerals and impurities. This refining process is crucial to obtaining high-purity tantalum suitable for various applications.

Powder Production Methods

Tantalum powder is produced through several methods, including the sodium reduction process, the magnesium reduction process, and the electrolysis method. Each method has its advantages and produces tantalum powder with specific properties suitable for different applications.

Tantalum Supply and Demand

The supply and demand dynamics of tantalum play a significant role in its availability and pricing. As a rare metal, tantalum faces challenges in meeting the growing demand from various industries. Understanding these dynamics is crucial for manufacturers and consumers alike.

Environmental and Ethical Considerations

The extraction and processing of tantalum raise important environmental and ethical concerns. From mining’s impact on local ecosystems to the issue of conflict minerals, responsible sourcing and sustainable practices are essential in the tantalum industry.

Advantages and Challenges of Using Tantalum Powder

Advantages

Tantalum powder’s unique properties offer several advantages, such as high-temperature resistance, corrosion resistance, and biocompatibility. These advantages have enabled tantalum to find a place in critical applications, contributing to technological advancements.

Challenges

Despite its remarkable characteristics, tantalum also faces challenges, including its scarcity, high production costs, and ethical concerns related to conflict minerals. Addressing these challenges is crucial for ensuring a sustainable supply chain and responsible consumption.

Tantalum Recycling and Sustainability

Given the limited availability of tantalum, recycling plays a vital role in meeting demand while reducing environmental impact. Recycling processes for tantalum ensure the recovery of valuable materials, promoting sustainability in the tantalum industry.

Future Trends and Outlook

The tantalum industry is continually evolving, driven by advancements in technology and increasing demand from various sectors. Exploring the potential applications and emerging trends can provide insights into the future prospects of tantalum powder.

Conclusion

Tantalum powder’s exceptional properties and versatile applications make it a sought-after material in various industries. Its high melting point, corrosion resistance, and biocompatibility have enabled advancements in electronics, aerospace, medical, and additive manufacturing fields. As we look to the future, responsible sourcing, recycling, and sustainability will play a crucial role in ensuring a stable tantalum supply chain.

FAQs

- What is tantalum powder used for?

- How is tantalum powder produced?

- What are the advantages of using tantalum powder in electronics?

- Is tantalum powder environmentally friendly?

- How does tantalum contribute to the aerospace industry?