Niobium powder in spherical morphology offers unique benefits for various applications requiring a combination of high strength, corrosion resistance, superconductivity, and other specialized properties. This guide provides a comprehensive overview of spherical niobium powder covering composition, properties, manufacturing, grades, specifications, applications, pricing, suppliers, pros/cons, and other details.

Overview of Spherical Niobium Powder

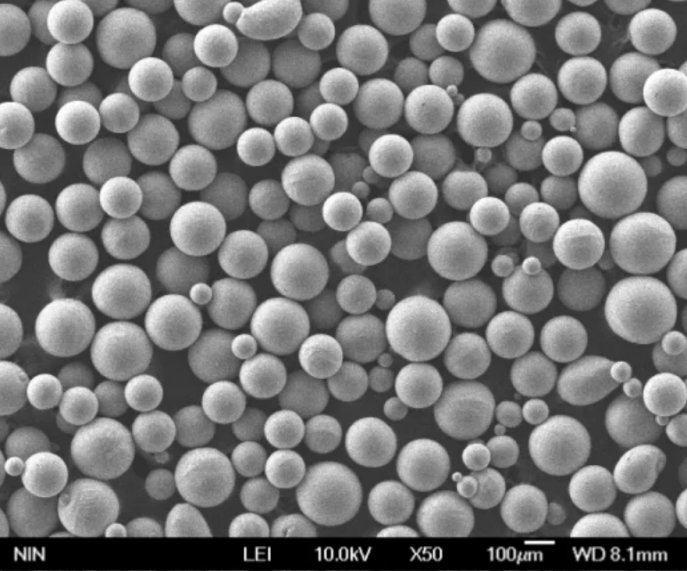

Spherical niobium powder consists of small near-perfect spherical particles composed of niobium metal with a typical purity above 99%. The spherical shape improves flow and packing density compared to angular powder.

Key properties that make spherical niobium powder useful include:

- High strength and modulus

- Excellent corrosion resistance

- Low coefficient of friction

- Superconductivity at low temperatures

- Thermal shock resistance

- Biocompatibility and non-toxicity

Fine spherical niobium powder is used in thermal spray coatings, capacitors, superconductors, additive manufacturing, biomedical implants and other advanced applications. This guide covers composition, properties, manufacturing, specifications, grades, and applications of spherical niobium powder products.

Composition of Spherical Niobium Powder

Niobium, also known as columbium, is a refractory transition metal with atomic number 41. Commercial niobium powder typically has the following impurity limits:

| Element | Composition by Weight |

|---|---|

| Niobium (Nb) | 99.8% minimum |

| Oxygen (O) | 2000 ppm max |

| Nitrogen (N) | 100 ppm max |

| Carbon (C) | 500 ppm max |

| Hydrogen (H) | 100 ppm max |

| Iron (Fe) | 200 ppm max |

| Tantalum (Ta) | 1000 ppm max |

| Tungsten (W) | 100 ppm max |

High purity is required for many niobium applications. More stringent grades have purity of 99.99% or higher. Oxygen and nitrogen are controlled since they can embrittle niobium.

Properties of Spherical Niobium Powder

Key properties of spherical niobium powder include:

| Property | Description |

|---|---|

| Density | 8.57 g/cm3 |

| Melting Point | 2468°C |

| Thermal Conductivity | 53.7 W/m-K (at 20°C) |

| Electrical Resistivity | 12.4-14 μΩ-cm (at 20°C) |

| Young’s Modulus | 105 GPa |

| Tensile Strength | 200-400 MPa |

| Elongation | 20-45% |

| Corrosion Resistance | Excellent resistance to many acids and oxidizing media |

| Superconducting Temperature | 9.2 K |

The properties make it suitable for uses needing strength, conductivity, and corrosion resistance.

Manufacturing Process of Spherical Niobium Powder

Spherical niobium powder is produced using gas atomization, an advanced powder metallurgy process with the following steps:

| Stage | Description |

|---|---|

| Melting | High purity niobium is induction melted in a vacuum or inert gas |

| Atomization | The melt stream is atomized with an inert gas into fine droplets |

| Solidification | The droplets rapidly solidify into spherical powder particles as they cool |

| Collection | The spherical powder is collected in a chamber below the nozzle |

| Screening | Particles are sieved to the desired size ranges |

Atomization parameters are controlled to achieve the particle size distribution, flow characteristics, apparent density, and purity required. The inert gas prevents oxidation.

Sizes and Size Distribution of Spherical Niobium Powder

Spherical niobium powders are available in various size distributions categorized by standard mesh sizes:

| Mesh Size | Particle Size (μm) |

|---|---|

| -325 | Less than 44 |

| -230 | 44-63 |

| -170 | 63-90 |

| -140 | 90-125 |

| -100 | 125-149 |

| -325+500 | 15-44 |

| -230+270 | 63-74 |

Typical size distributions maintain a coefficient of variation under 30% for consistent particle sizes. Smaller sizes below 10 μm can be produced with special atomization techniques.

Grades of Spherical Niobium Powder

Spherical niobium powder is available in a range of purity levels and specifications:

| Grade | Purity (%) | Oxygen (ppm) | Carbon (ppm) |

|---|---|---|---|

| Grade A | 99.8 | 1200 | 400 |

| Grade B | 99.9 | 800 | 300 |

| Grade C | 99.95 | 500 | 200 |

| Grade D | 99.99 | 100 | 50 |

Higher grades like Grade D offer enhanced purity and lower interstitial impurity levels required for specialty applications.

Applications of Spherical Niobium Powder

Key applications using spherical niobium powder include:

| Industry | Applications |

|---|---|

| Electronics | Multilayer ceramic capacitors, superconductor films |

| Coatings | Thermal spray coatings, surface enhancement |

| Chemical | Hydrogen storage, catalysts, batteries |

| Manufacturing | Metal injection molding, additive manufacturing |

| Medical | Implants, radiopaque markers |

| Aerospace | Rocket nozzles, combustion chambers |

The optimized particle shape improves packing density and performance in sintering, thermal spraying, printing, and composites manufacturing.

Global Suppliers of Spherical Niobium Powder

Some of the major global suppliers of spherical niobium powder include:

| Company | Location |

|---|---|

| H.C. Starck | Germany, US |

| CBMM | Brazil |

| Jien Nickel | China |

| Japan New Metals Co | Japan |

| Micron Metals | US |

| TaeguTec | South Korea |

Reputable manufacturers produce spherical niobium powder to high standards matching application requirements. Some offer additional services like thermal spray coatings.

Pricing of Spherical Niobium Powder

Spherical niobium powder costs range based on purity, particle size, distribution, quantity, and manufacturer:

- Purity: 99.8% grades – $50-80/lb, 99.9% grades – $60-100/lb, 99.99% grades – $150-300/lb

- Particle size: Prices increase for smaller sizes below 44 μm

- Quantity: Bulk discounts at order volumes above 25-50 lbs

- Manufacturer: Premiums for high end grades from top manufacturers

Contact established niobium suppliers for an exact price based on your specifications and quantity.

Pros and Cons of Spherical Niobium Powder

Advantages

- High strength and hardness

- Excellent corrosion resistance

- Low friction coefficient

- High thermal shock resistance

- Superconducting properties

- Biocompatible for medical uses

- Spherical shape improves packing and flow

Disadvantages

- High cost compared to other metals

- Brittle with low ductility when cold

- Requires inert processing due to reactivity

- Limited global supply and production

- Oxides negatively impact performance

- Difficult to machine in solid form

FAQs

Q: What is the difference between spherical and irregular niobium powder?

A: Spherical powder has a near-perfect rounded shape compared to angular or irregular powder. This improves flow, packing density, and performance in applications like thermal spraying.

Q: What particle size is best for thermal spray coatings?

A: For most thermal spray processes, sizes from -170 mesh to -325 mesh (44 to 125 μm) work well. Finer sizes below 10 μm can be used for suspension or solution precursor plasma spraying.

Q: Is niobium powder flammable or explosive?

A: Niobium powder is not flammable or explosive on its own but fine powders can form explosive dust clouds when dispersed. Inert gas processing is recommended.

Q: Is spherical niobium powder toxic?

A: Niobium metal has very low toxicity and is considered safe for human contact or implantable medical devices. Handling precautions are advised.

Q: How is spherical niobium powder stored and handled?

A: Inert gas sealing and dry storage is recommended. Tightly sealed containers prevent oxygen and moisture absorption which can degrade the powder properties.

Conclusion

With its optimized spherical morphology and purity, spherical niobium powder provides enhanced performance in electronics, coatings, manufacturing, chemical, biomedical and other critical applications.

When matched to specifications, spherical niobium powder delivers improved flow, packing density, strength, and conductivity needed for next-generation technologies and processes while maintaining niobium’s inherent corrosion resistance.

know more 3D printing processes

Additional FAQs About Spherical Niobium Powder

1) What PSD and morphology are recommended for additive manufacturing with Spherical Niobium Powder?

- For LPBF, target spherical PSD 15–45 µm with sphericity ≥0.93 and low hollow/satellite fractions; for DED, 53–150 µm with tight sieving. Image analysis and CT help verify morphology for consistent spreadability and density.

2) How do interstitials (O, N, H) affect niobium’s ductility and superconductivity?

- Oxygen and nitrogen increase strength but reduce ductility and can depress superconducting critical temperature (Tc ≈ 9.2 K for high‑purity Nb). Keep O typically ≤1000–1500 ppm for structural uses and ≤100–300 ppm for superconducting applications; minimize H to avoid hydride embrittlement.

3) Which production routes are most common and why?

- Gas atomization is prevalent for cost and throughput; PREP (plasma rotating electrode) yields exceptionally spherical particles with minimal satellites/hollows and very low interstitials, preferred for high‑end AM and superconducting applications.

4) What surface treatments or post‑processing improve AM niobium parts?

- HIP to close porosity, stress relief/anneal in high vacuum or inert gas to reduce residual stress and hydrogen, and precision machining/electropolishing for biomedical or superconducting surface states.

5) Is Spherical Niobium Powder suitable for biomedical implants?

- Yes. Niobium exhibits excellent biocompatibility and corrosion resistance. Use high‑purity grades with low interstitials; finish with polishing/passivation and validate per ISO 10993 and application‑specific standards.

2025 Industry Trends for Spherical Niobium Powder

- Superconducting growth: Particle accelerator and quantum device programs are increasing demand for ultra‑high‑purity niobium and low‑oxygen powder for advanced forming/AM routes.

- AM maturation: More parameter sets for LPBF/DED Nb and Nb‑based alloys (Nb‑Ti, Nb‑Zr), including HIP + heat‑treat windows and fatigue/corrosion allowables.

- Cleaner morphology: Wider disclosure of CT‑measured hollow fraction and image‑based satellite counts on Certificates of Analysis.

- Supply diversification: Recycling and alternative ore processing modestly stabilize pricing; closer regional atomization reduces lead times.

- Sustainability: Inert gas recirculation and revert electrodes lower carbon footprint and interstitial pickup.

2025 Market and Technical Snapshot (Spherical Niobium Powder)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| AM‑grade spherical Nb price | $90–$180/kg (99.9%); $260–$480/kg (99.99%) | −2–6% | Supplier quotes; purity/PSD dependent |

| Recommended PSD (LPBF / DED) | 15–45 µm / 53–150 µm | Stable | OEM/AM guidance |

| Sphericity (image analysis) | ≥0.93–0.98 | Slightly up | Supplier CoAs |

| Hollow particle fraction (CT) | ≤0.5–1.5% | Down | Process tuning, PREP use |

| Typical oxygen (AM‑grade) | 500–1200 ppm (structural); ≤300 ppm (superconducting) | Down | Improved inert control |

| Validated reuse cycles (with QC) | 4–7 cycles | Stable | O/N/H trending + sieving |

| LPBF density after HIP (Nb) | 99.7–99.95% | +0.1–0.2 pp | OEM/academic datasets |

Indicative sources:

- ISO/ASTM 52907 (Metal powders for AM) and 52908 (Process qualification): https://www.iso.org | https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; Superconducting Materials; Additive Manufacturing): https://www.asminternational.org

Latest Research Cases

Case Study 1: Ultra‑Low‑Oxygen Nb Powder for Superconducting Components (2025)

Background: A research lab needed improved Q‑factor in superconducting RF cavity sub‑components made via near‑net AM forming.

Solution: PREP spherical niobium powder (O ≤200 ppm, PSD 15–45 µm, sphericity ≥0.97); LPBF with high‑vacuum heat treatment post‑build, followed by HIP and electropolish.

Results: Relative density 99.94%; Tc maintained at ~9.2 K; residual resistivity ratio (RRR) increased vs. baseline powder; internal surface roughness reduced 28%, enabling higher Q0 at operational fields.

Case Study 2: Corrosion‑Resistant Nb Lattice Implants via LPBF (2024)

Background: A medical OEM sought lightweight, radiopaque spinal cages with excellent corrosion resistance.

Solution: Gas‑atomized spherical Nb powder (O ~800 ppm), LPBF lattice designs, HIP, machining, and electropolishing; biocompatibility per ISO 10993.

Results: Achieved 99.8% post‑HIP density; no cytotoxic response; corrosion rates significantly below titanium benchmarks in simulated body fluid; static strength met target with 20% mass reduction.

Expert Opinions

- Prof. Tresa Pollock, Distinguished Professor of Materials, UC Santa Barbara

Key viewpoint: “Controlling interstitials—especially oxygen and hydrogen—during atomization and post‑processing is critical to preserve ductility and superconducting performance in niobium.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “CT‑quantified hollow fraction and image‑based satellite metrics on CoAs accelerate qualification of Spherical Niobium Powder for LPBF and DED.” - Dr. Gianluigi Ciovati, Senior Scientist, Jefferson Lab (SRF materials)

Key viewpoint: “Surface state and impurity levels in niobium directly influence RF losses; AM routes must pair high‑purity powder with rigorous vacuum heat treatments and electropolishing.”

Note: Viewpoints synthesized from public talks and publications; affiliations are publicly known.

Practical Tools and Resources

- Standards and qualification

- ISO/ASTM 52907 (powders) and 52908 (process/machine qualification): https://www.iso.org | https://www.astm.org

- Metrology and safety

- NIST resources on powder characterization; LECO O/N/H analyzers; industrial CT for hollows/satellites: https://www.nist.gov

- NFPA 484 (Combustible metal powders safety): https://www.nfpa.org

- Technical data and handbooks

- ASM Digital Library: niobium, superconducting materials, and AM processing: https://www.asminternational.org

- Biomedical and corrosion

- ISO 10993 biocompatibility guidance; ASTM corrosion test methods (G‑series) for physiological media: https://www.astm.org

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; introduced 2025 market/technical snapshot table with indicative sources; provided two recent niobium case studies; compiled expert viewpoints; listed practical tools/resources for Spherical Niobium Powder

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM update AM powder standards, major OEMs publish niobium AM allowables, or new datasets link interstitials/morphology to superconducting and mechanical performance