El polvo de niobio en morfología esférica ofrece ventajas únicas para diversas aplicaciones que requieren una combinación de alta resistencia, resistencia a la corrosión, superconductividad y otras propiedades especializadas. Esta guía ofrece una visión completa de polvo esférico de niobio composición, propiedades, fabricación, calidades, especificaciones, aplicaciones, precios, proveedores, ventajas e inconvenientes y otros detalles.

Visión general del polvo esférico de niobio

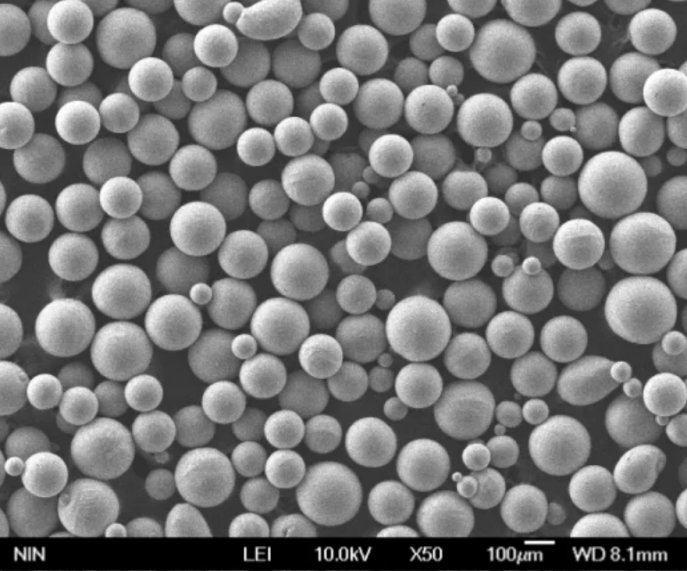

El polvo esférico de niobio consiste en pequeñas partículas esféricas casi perfectas compuestas de niobio metálico con una pureza típica superior a 99%. La forma esférica mejora el flujo y la densidad de empaquetamiento en comparación con el polvo angular.

Entre las propiedades clave que hacen útil el polvo esférico de niobio se incluyen:

- Alta resistencia y módulo

- Excelente resistencia a la corrosión

- Bajo coeficiente de fricción

- Superconductividad a bajas temperaturas

- Resistencia al choque térmico

- Biocompatibilidad y no toxicidad

El polvo esférico fino de niobio se utiliza en revestimientos por pulverización térmica, condensadores, superconductores, fabricación aditiva, implantes biomédicos y otras aplicaciones avanzadas. Esta guía abarca la composición, las propiedades, la fabricación, las especificaciones, las calidades y las aplicaciones de los productos de polvo esférico de niobio.

Composición del polvo esférico de niobio

El niobio, también conocido como columbio, es un metal de transición refractario con número atómico 41. El polvo de niobio comercial suele tener los siguientes límites de impurezas:

| Elemento | Composición por peso |

|---|---|

| Niobio (Nb) | 99,8% mínimo |

| Oxígeno (O) | 2000 ppm máx. |

| Nitrógeno (N) | 100 ppm máx. |

| Carbono (C) | 500 ppm máx. |

| Hidrógeno (H) | 100 ppm máx. |

| Hierro (Fe) | 200 ppm máx. |

| Tántalo (Ta) | 1000 ppm máx. |

| Tungsteno (W) | 100 ppm máx. |

Muchas aplicaciones del niobio exigen un alto grado de pureza. Los grados más estrictos tienen una pureza de 99,99% o superior. El oxígeno y el nitrógeno están controlados, ya que pueden fragilizar el niobio.

Propiedades de Niobio esférico en polvo

Las principales propiedades del polvo esférico de niobio son:

| Propiedad | Descripción |

|---|---|

| Densidad | 8,57 g/cm3 |

| Punto de fusión | 2468°C |

| Conductividad térmica | 53,7 W/m-K (a 20°C) |

| Resistividad eléctrica | 12,4-14 μΩ-cm (a 20°C) |

| Módulo de Young | 105 GPa |

| Resistencia a la tracción | 200-400 MPa |

| Alargamiento | 20-45% |

| Resistencia a la corrosión | Excelente resistencia a muchos ácidos y medios oxidantes |

| Temperatura de superconducción | 9.2 K |

Sus propiedades lo hacen adecuado para usos que requieren resistencia, conductividad y resistencia a la corrosión.

Proceso de fabricación del polvo esférico de niobio

El polvo esférico de niobio se produce mediante atomización con gas, un proceso avanzado de pulvimetalurgia con los siguientes pasos:

| Escenario | Descripción |

|---|---|

| Fundición | El niobio de alta pureza se funde por inducción en vacío o con gas inerte |

| Atomización | La corriente fundida se atomiza con un gas inerte en finas gotitas |

| Solidificación | Las gotitas se solidifican rápidamente en partículas esféricas de polvo al enfriarse |

| Colección | El polvo esférico se recoge en una cámara situada debajo de la boquilla |

| Cribado | Las partículas se tamizan hasta alcanzar los tamaños deseados |

Los parámetros de atomización se controlan para conseguir la distribución del tamaño de las partículas, las características de flujo, la densidad aparente y la pureza requeridas. El gas inerte evita la oxidación.

Tamaños y distribución por tamaños del polvo esférico de niobio

Los polvos esféricos de niobio están disponibles en varias distribuciones de tamaño clasificadas por tamaños de malla estándar:

| Luz de malla | Tamaño de las partículas (μm) |

|---|---|

| -325 | Menos del 44 |

| -230 | 44-63 |

| -170 | 63-90 |

| -140 | 90-125 |

| -100 | 125-149 |

| -325+500 | 15-44 |

| -230+270 | 63-74 |

Las distribuciones de tamaño típicas mantienen un coeficiente de variación por debajo de 30% para tamaños de partícula consistentes. Pueden producirse tamaños más pequeños, inferiores a 10 μm, con técnicas de atomización especiales.

Clases de niobio esférico en polvo

El polvo esférico de niobio está disponible en distintos niveles de pureza y especificaciones:

| Grado | Pureza (%) | Oxígeno (ppm) | Carbono (ppm) |

|---|---|---|---|

| Grado A | 99.8 | 1200 | 400 |

| Grado B | 99.9 | 800 | 300 |

| Grado C | 99.95 | 500 | 200 |

| Grado D | 99.99 | 100 | 50 |

Los grados superiores, como el grado D, ofrecen mayor pureza y menores niveles de impurezas intersticiales, necesarios para aplicaciones especiales.

Aplicaciones del polvo esférico de niobio

Entre las principales aplicaciones del polvo esférico de niobio figuran las siguientes:

| Industria | Aplicaciones |

|---|---|

| Electrónica | Condensadores cerámicos multicapa, películas superconductoras |

| Revestimientos | Revestimientos por pulverización térmica, mejora de superficies |

| Química | Almacenamiento de hidrógeno, catalizadores, pilas |

| Fabricación | Moldeo por inyección de metales, fabricación aditiva |

| Médico | Implantes, marcadores radiopacos |

| Aeroespacial | Toberas de cohetes, cámaras de combustión |

La forma optimizada de las partículas mejora la densidad de empaquetamiento y el rendimiento en sinterización, pulverización térmica, impresión y fabricación de compuestos.

Proveedores mundiales de Niobio esférico en polvo

Algunos de los principales proveedores mundiales de polvo esférico de niobio son:

| Compañía | Ubicación |

|---|---|

| H.C. Starck | Alemania, EE.UU. |

| CBMM | Brasil |

| Jien Níquel | China |

| Japan New Metals Co | Japón |

| Micron Metales | US |

| TaeguTec | Corea del Sur |

Los fabricantes de renombre producen polvo esférico de niobio de alta calidad que se ajusta a los requisitos de la aplicación. Algunos ofrecen servicios adicionales, como recubrimientos por pulverización térmica.

Precios de Niobio esférico en polvo

Los costes del polvo esférico de niobio varían en función de la pureza, el tamaño de las partículas, la distribución, la cantidad y el fabricante:

- PurezaCalidad 99,8% - $50-80/lb, calidad 99,9% - $60-100/lb, calidad 99,99% - $150-300/lb

- Tamaño de las partículas: Los precios aumentan para los tamaños inferiores a 44 μm

- Cantidad: Descuentos por volumen en pedidos superiores a 25-50 lbs.

- Fabricante: Primas para las calidades superiores de los mejores fabricantes

Póngase en contacto con proveedores de niobio establecidos para obtener un precio exacto basado en sus especificaciones y cantidad.

Ventajas e inconvenientes del niobio esférico en polvo

Ventajas

- Gran resistencia y dureza

- Excelente resistencia a la corrosión

- Bajo coeficiente de fricción

- Alta resistencia al choque térmico

- Propiedades superconductoras

- Biocompatible para usos médicos

- La forma esférica mejora el empaquetado y el flujo

Desventajas

- Coste elevado en comparación con otros metales

- Quebradizo con baja ductilidad en frío

- Requiere tratamiento inerte debido a su reactividad

- Oferta y producción mundiales limitadas

- Los óxidos afectan negativamente al rendimiento

- Difícil de mecanizar en estado sólido

preguntas frecuentes

P: ¿Qué diferencia hay entre el polvo de niobio esférico y el irregular?

R: El polvo esférico tiene una forma redondeada casi perfecta en comparación con el polvo angular o irregular. Esto mejora el flujo, la densidad de empaquetado y el rendimiento en aplicaciones como la pulverización térmica.

P: ¿Qué tamaño de partícula es mejor para los revestimientos por pulverización térmica?

R: Para la mayoría de los procesos de pulverización térmica, los tamaños de -170 mallas a -325 mallas (44 a 125 μm) funcionan bien. Los tamaños más finos por debajo de 10 μm pueden utilizarse para la pulverización de plasma de precursores en suspensión o solución.

P: ¿Es inflamable o explosivo el polvo de niobio?

R: El polvo de niobio no es inflamable ni explosivo por sí mismo, pero los polvos finos pueden formar nubes de polvo explosivas al dispersarse. Se recomienda el tratamiento con gas inerte.

P: ¿Es tóxico el polvo esférico de niobio?

R: El niobio metálico tiene una toxicidad muy baja y se considera seguro para el contacto humano o los dispositivos médicos implantables. Se aconseja tomar precauciones de manipulación.

P: ¿Cómo se almacena y manipula el polvo esférico de niobio?

R: Se recomienda el sellado con gas inerte y el almacenamiento en seco. Los recipientes herméticamente cerrados evitan la absorción de oxígeno y humedad, que pueden degradar las propiedades del polvo.

Conclusión

Con su morfología esférica optimizada y su pureza, el polvo esférico de niobio ofrece un mayor rendimiento en electrónica, revestimientos, fabricación, química, biomedicina y otras aplicaciones críticas.

Cuando se ajusta a las especificaciones, el polvo esférico de niobio proporciona un flujo, una densidad de empaquetamiento, una resistencia y una conductividad mejorados, necesarios para las tecnologías y los procesos de próxima generación, al tiempo que mantiene la resistencia a la corrosión inherente al niobio.