Introduction

In today’s technological landscape, surface modification techniques play a crucial role in improving the performance of various materials. One such technique that has gained significant attention is the Plasma Rotating Electrode Process (PREP). This innovative process offers several advantages over conventional surface modification methods and finds applications in diverse industries. In this article, we will explore the intricacies of the Plasma Rotating Electrode Process, its advantages, applications, working principles, equipment setup, key parameters, factors affecting performance, comparison with other techniques, future developments, and safety considerations.

What is the Plasma Rotating Electrode Process?

The Plasma Rotating Electrode Process (PREP) is a surface modification technique that involves the use of a rotating electrode immersed in a plasma environment. The process facilitates the deposition of coatings onto various materials, leading to enhanced surface properties and improved performance. PREP is particularly useful for applications where wear resistance, corrosion resistance, hardness, and other desirable surface characteristics are required.

Advantages of Plasma Rotating Electrode Process

The Plasma Rotating Electrode Process offers several advantages over traditional surface modification techniques. Some of the key benefits include:

- Enhanced Surface Properties: PREP enables the deposition of high-quality coatings with improved hardness, wear resistance, and corrosion resistance.

- Increased Efficiency: The rotating electrode design ensures uniform coating deposition, resulting in improved efficiency and reduced material waste.

- Versatility: PREP can be applied to a wide range of materials, including metals, alloys, ceramics, and composites, making it highly versatile.

- Cost-effective: The process is cost-effective due to its ability to achieve desired coating properties with minimal material and energy consumption.

- Tailored Coating Thickness: PREP allows for precise control over coating thickness, enabling customization based on specific application requirements.

Applications of Plasma Rotating Electrode Process

The Plasma Rotating Electrode Process finds applications in various industries and sectors. Some notable applications include:

- Aerospace: PREP is utilized in the aerospace industry for coating turbine blades, aerospace components, and engine parts to enhance their resistance to high temperatures, wear, and corrosion.

- Automotive: The automotive sector benefits from PREP by applying coatings to engine components, pistons, gears, and other critical parts to improve their performance, durability, and fuel efficiency.

- Medical Devices: PREP is employed in the medical industry to enhance the biocompatibility, wear resistance, and antibacterial properties of medical implants, such as orthopedic implants and dental implants.

- Renewable Energy: The process finds application in the renewable energy sector for coating wind turbine blades, solar panels, and other components to improve their durability, efficiency, and resistance to environmental factors.

- Tooling and Machining: PREP is used in tooling and machining industries to coat cutting tools, molds, and dies, providing them with superior hardness, wear resistance, and extended tool life.

How Does the Plasma Rotating Electrode Process Work?

The Plasma Rotating Electrode Process involves several stages that contribute to the deposition of high-quality coatings. The process can be summarized as follows:

- Plasma Generation: A plasma environment is created using a suitable gas, typically argon or nitrogen, which is ionized to produce a highly energetic state.

- Electrode Rotation: A specially designed electrode, often in the form of a cylindrical rod, is rotated at a controlled speed. The rotation helps ensure uniform coating deposition and prevents uneven buildup.

- Material Selection: The coating material, in the form of wire or powder, is carefully chosen based on the desired surface properties. It is typically composed of the coating material and any necessary alloying elements.

- Coating Deposition: As the rotating electrode comes into contact with the plasma, the coating material is heated, melted, and atomized. The resulting particles are propelled towards the substrate, where they condense and solidify, forming a coating layer.

- Post-treatment: Depending on the specific requirements, the deposited coating may undergo additional processes such as heat treatment, surface finishing, or polishing to optimize its properties.

Equipment and Setup

To perform the Plasma Rotating Electrode Process, certain equipment and setup are required. The key components typically include:

- Rotating Electrode System: This system consists of a motorized rotation mechanism that drives the electrode rotation at a controlled speed. It ensures the uniform deposition of the coating material.

- Plasma Generation System: The plasma generation system comprises a power supply, gas delivery system, and a plasma torch. The power supply generates the plasma, while the gas delivery system controls the flow of the ionizing gas.

- Coating Material Feeding System: The coating material, in the form of wire or powder, is fed into the plasma torch through a dedicated feeding system. It ensures a steady and controlled supply of the coating material.

- Substrate Handling System: The substrate handling system holds and positions the material to be coated, ensuring precise alignment and stability during the deposition process.

Key Parameters for the Plasma Rotating Electrode Process

Several key parameters influence the performance and quality of coatings produced by the Plasma Rotating Electrode Process. These parameters include:

- Rotating Electrode Speed: The rotation speed of the electrode determines the coating deposition rate and affects the coating’s microstructure and properties.

- Plasma Gas Composition: The choice of plasma gas, such as argon or nitrogen, influences the ionization process, plasma temperature, and interaction with the coating material.

- Coating Material Composition: The composition of the coating material, including alloying elements, determines the resulting coating’s properties, such as hardness, wear resistance, and corrosion resistance.

- Plasma Power: The power input to the plasma torch affects the plasma temperature, which in turn influences the melting, atomization, and deposition of the coating material.

- Substrate Preparation: Proper cleaning and surface preparation of the substrate are essential for promoting good adhesion between the coating and the substrate.

Factors Affecting the Performance of Plasma Rotating Electrode Process

Several factors can influence the performance and quality of coatings produced by the Plasma Rotating Electrode Process. These factors include:

- Material Selection: The choice of coating material, including its composition and purity, significantly impacts the resulting coating’s properties and performance.

- Process Parameters: Optimizing the process parameters, such as rotating electrode speed, plasma gas composition, and plasma power, is crucial to achieve desired coating characteristics.

- Surface Preparation: The quality of substrate surface preparation, including cleaning, surface roughness, and preheating, affects the adhesion and integrity of the deposited coating.

- Coating Thickness and Uniformity: Control over coating thickness and uniformity is essential to ensure consistent performance and prevent any potential defects or variations.

- Post-treatment Processes: Additional heat treatment, surface finishing processes, or polishing may be required to further optimize the coating’s properties and surface characteristics.

Comparison with Other Surface Modification Techniques

The Plasma Rotating Electrode Process offers unique advantages when compared to other surface modification techniques. Let’s briefly compare it with some commonly used methods:

- Plasma Spraying: Unlike plasma spraying, which typically produces porous coatings, the Plasma Rotating Electrode Process allows for the deposition of dense and uniform coatings with precise control over thickness and composition.

- Physical Vapor Deposition (PVD): PVD techniques such as sputtering and evaporation are widely used for thin film deposition. However, the Plasma Rotating Electrode Process offers a cost-effective alternative for depositing thicker coatings with superior adhesion and mechanical properties.

- Chemical Vapor Deposition (CVD): CVD is commonly used to deposit coatings with excellent purity and conformal coverage. In contrast, the Plasma Rotating Electrode Process offers greater flexibility in coating composition and thickness, making it suitable for a wider range of applications.

- Electroplating: While electroplating is effective for depositing metallic coatings, the Plasma Rotating Electrode Process can be used with a variety of coating materials, including ceramics, alloys, and composites, offering enhanced versatility.

- Laser Cladding: Laser cladding is another surface modification technique that utilizes a high-energy laser beam to melt and fuse a coating material onto a substrate. The Plasma Rotating Electrode Process, with its rotating electrode design, provides more uniform coating deposition and can cover larger surface areas efficiently.

Future Developments and Research

The field of Plasma Rotating Electrode Process continues to evolve, with ongoing research and development aimed at expanding its capabilities and exploring new applications. Some areas of future development and research include:

- Advanced Coating Materials: Researchers are exploring novel coating materials with tailored properties, such as self-healing coatings, multi-functional coatings, and coatings with improved thermal stability.

- Nanocomposite Coatings: The integration of nanoparticles into coating materials shows promising potential for enhancing specific properties, such as mechanical strength, tribological performance, and electrical conductivity.

- Process Optimization: Continued efforts are being made to optimize process parameters, electrode design, and plasma generation techniques to further improve coating quality, deposition efficiency, and reduce energy consumption.

- Industry-Specific Applications: Further exploration of industry-specific applications, such as electronics, energy storage, and biomedical devices, will unlock new opportunities for utilizing the Plasma Rotating Electrode Process.

- Sustainability and Environmental Impact: Research is focused on developing environmentally friendly coating materials, optimizing energy usage, and minimizing waste generation to ensure sustainability in the Plasma Rotating Electrode Process.

Case Studies and Success Stories

The Plasma Rotating Electrode Process has demonstrated remarkable success in various industries. Here are a few case studies highlighting its effectiveness:

- Aerospace Coatings: PREP has been utilized in the aerospace industry to coat turbine blades, resulting in improved resistance to high-temperature oxidation and erosion, leading to enhanced engine performance and efficiency.

- Automotive Components: The application of PREP coatings on automotive engine components, such as pistons and cylinder liners, has shown significant improvements in wear resistance, leading to extended engine life and reduced maintenance costs.

- Biomedical Implants: PREP has been employed to coat medical implants, such as orthopedic implants and dental implants, with biocompatible and wear-resistant coatings, promoting better integration with the human body and ensuring longer implant lifespan.

- Cutting Tools: Tooling and machining industries have benefited from PREP coatings on cutting tools, drills, and inserts, providing superior hardness, wear resistance, and extended tool life, resulting in improved productivity and cost savings.

- Renewable Energy Applications: PREP coatings have been successfully applied to wind turbine blades and solar panels, enhancing their durability, resistance to environmental factors, and overall energy generation efficiency.

Safety Considerations

While working with the Plasma Rotating Electrode Process, it is crucial to prioritize safety. Here are some key safety considerations:

- Personal Protective Equipment (PPE): Operators should wear appropriate PPE, including safety glasses, gloves, and protective clothing, to minimize the risk of injury from plasma, sparks, or coating materials.

- Proper Ventilation: Adequate ventilation systems should be in place to ensure the removal of potentially hazardous fumes, gases, and particulate matter generated during the process.

- Equipment Maintenance and Inspection: Regular maintenance and inspection of equipment, including electrical components and gas supply systems, should be conducted to ensure safe operation and prevent potential hazards.

- Training and Awareness: Operators should receive proper training on the handling of equipment, safe operating procedures, and emergency protocols to mitigate risks and respond effectively in case of accidents.

- Hazardous Material Handling: Coating materials, such as powders or wire, should be stored and handled safely to prevent accidents or exposure to harmful substances.

Conclusion

The Plasma Rotating Electrode Process (PREP) offers a powerful and versatile solution for enhancing the performance of various materials through surface modification. With its ability to deposit high-quality coatings with improved hardness, wear resistance, and corrosion resistance, PREP finds applications in aerospace, automotive, medical, renewable energy, and tooling industries, among others. The process’s unique advantages, such as increased efficiency, cost-effectiveness, and tailored coating thickness, make it an attractive option for industries seeking superior surface properties. Ongoing research and development in the field will continue to expand its capabilities and open up new possibilities for the Plasma Rotating Electrode Process in the future.

FAQs

1. Can the Plasma Rotating Electrode Process be used on non-metallic materials? Yes, the Plasma Rotating Electrode Process can be applied to a wide range of materials, including metals, alloys, ceramics, and composites, offering versatility in surface modification.

2. What are the key parameters to consider for optimizing the Plasma Rotating Electrode Process? Key parameters to consider include rotating electrode speed, plasma gas composition, coating material composition, plasma power, and substrate preparation, as these factors significantly influence coating quality and performance.

3. How does the Plasma Rotating Electrode Process compare to other surface modification techniques? The Plasma Rotating Electrode Process offers advantages such as the ability to deposit dense and uniform coatings, cost-effectiveness, versatility in coating materials, and control over coating thickness, setting it apart from other techniques like plasma spraying, physical vapor deposition, chemical vapor deposition, electroplating, and laser cladding.

4. Are there any safety considerations when working with the Plasma Rotating Electrode Process? Yes, safety considerations include wearing appropriate PPE, ensuring proper ventilation, conducting regular equipment maintenance and inspection, providing training and awareness, and handling hazardous materials safely.

5. What are some future developments in the field of Plasma Rotating Electrode Process? Future developments include exploring advanced coating materials, nanocomposite coatings, process optimization, industry-specific applications, and sustainability initiatives to improve the process’s capabilities, efficiency, and environmental impact.

Additional FAQs About the Plasma Rotating Electrode Process (PREP)

1) What metal powders are most successfully made via the Plasma Rotating Electrode Process?

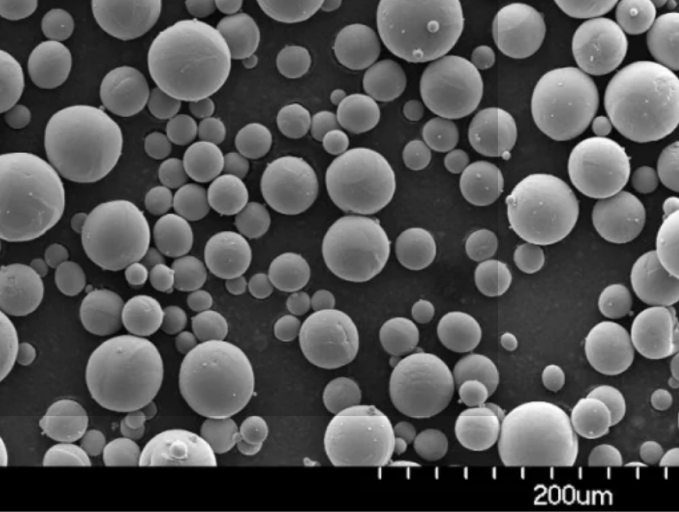

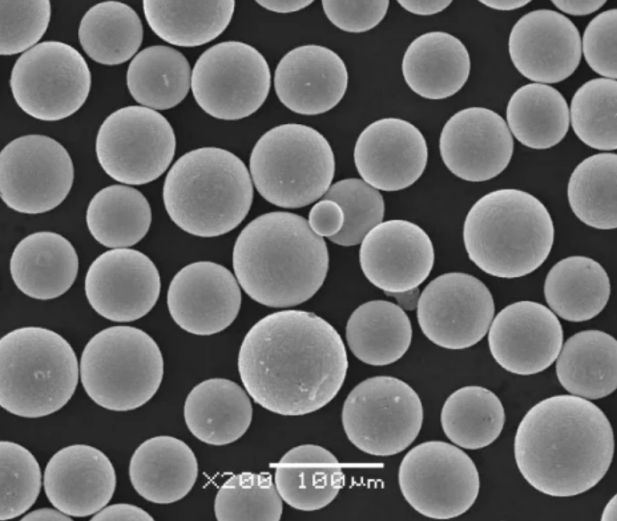

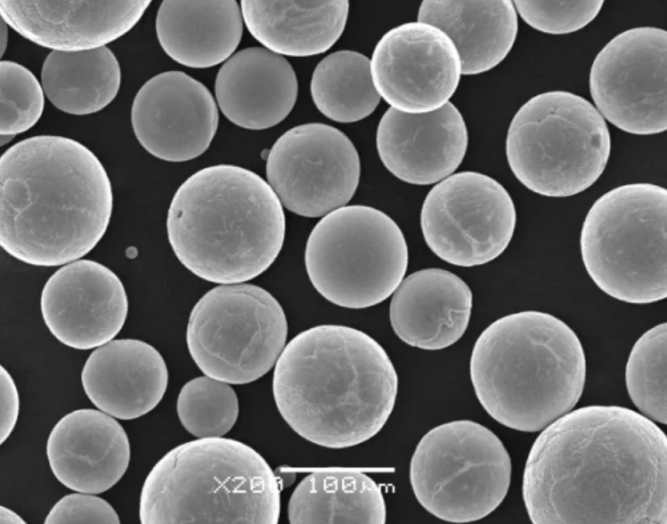

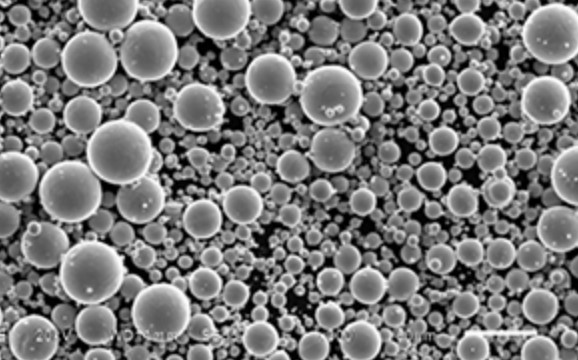

- Reactive and high-performance alloys benefit most: Ti-6Al-4V, CP-Ti, Ni-based superalloys (IN718, IN625), CoCrMo, stainless steels (316L, 17-4PH), and specialty alloys (NiTi, high-entropy alloys). PREP yields high sphericity, low satellites, and low O/N/H.

2) How does PREP powder quality compare to gas atomization for AM?

- PREP typically delivers higher sphericity (≥0.95), narrower PSD, fewer satellites, and markedly lower hollow fractions, improving flowability and PBF spreadability. Gas atomization offers higher throughput and lower cost per kg but may have more satellites/hollows.

3) What key parameters control PREP particle size distribution (PSD)?

- Electrode rod diameter, rotation speed (rpm), plasma power/enthlapy, standoff distance, and chamber atmosphere (inert purity). Higher rpm and smaller rods trend to finer PSD; plasma power influences melt film thickness and droplet breakup.

4) How do you minimize oxygen and nitrogen pickup in PREP?

- Use high-purity inert gases (Ar/He), maintain low chamber pressure and dew point, preclean/etch electrodes, and ensure robust seals/pumpdown. Hot-zone shielding and gettering further reduce interstitial uptake.

5) What typical acceptance criteria do AM users apply to PREP powders?

- Sphericity ≥0.92–0.97, satellites <5% by image analysis, hollows <1–2% by CT, PSD matched to process (LPBF 15–45 µm; EBM 45–106 µm), O/N/H within alloy spec (e.g., Ti O ≤0.15 wt% for AM grades), and Hall/Carney flow within OEM windows.

2025 Industry Trends for Plasma Rotating Electrode Process

- Premium AM feedstock: PREP increasingly chosen for mission-critical aerospace/medical parts where defect population and fatigue life dominate qualification.

- Process intensification: Higher-power plasma torches and adaptive rpm control improve yield into target PSD bands.

- Quality disclosure: Certificates of Analysis now commonly include CT-measured hollow fraction and image-based satellite counts.

- Sustainability: Greater use of revert electrodes and closed-loop gas handling to cut cost and carbon footprint.

- Regionalization: More PREP capacity added in APAC/EU to reduce lead times and export risks.

2025 Market and Technical Snapshot (PREP Powders)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| PREP Ti-6Al-4V price | $160–$260/kg | -4–8% | Supplier quotes; capacity additions |

| PREP IN718 price | $120–$200/kg | -3–6% | Alloy/PSD dependent |

| Sphericity (image analysis) | ≥0.94–0.98 | Slightly up | Supplier CoAs |

| Hollow particle fraction (CT) | ≤0.5–1.5% | Down | Process tuning |

| Satellite fraction | ≤2–5% | Down | Improved torch dynamics |

| Typical PSD yield into LPBF cut | 55–70% | Up | Adaptive rpm/rod diameter |

| O content (Ti alloys) | ≤0.08–0.15 wt% | Down | Inert purity/control |

Indicative sources:

- ISO/ASTM 52907 (Metal powders for AM) and 52908 (Process qualification): https://www.iso.org | https://www.astm.org

- NIST AM Bench and powder metrology resources: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; Additive Manufacturing): https://www.asminternational.org

Latest Research Cases

Case Study 1: PREP Ti-6Al-4V Feedstock Lowers PBF Defects (2025)

Background: An aerospace supplier needed improved fatigue life for lattice brackets with stringent CT acceptance.

Solution: Switched from gas-atomized to PREP Ti-6Al-4V (sphericity ≥0.96; hollows ≤0.7%; PSD 15–45 µm). Implemented 250°C plate preheat and contour-first strategy; HIP + stress relief.

Results: CT-detected defect volume −58%; density 99.93% post-HIP; HCF life (R=0.1) improved 2.0× vs. prior baseline; first-pass yield +9%.

Case Study 2: PREP IN718 Enables Stable DED Repairs (2024)

Background: Energy OEM sought consistent bead geometry and low porosity in DED repair of turbine cases.

Solution: PREP IN718, PSD 53–150 µm, satellite fraction <3%; optimized carrier gas and wire-to-powder ratio; post-deposition solution + age per AMS 5662/5663 equivalents.

Results: Porosity <0.3% by metallography; hardness and tensile met specification; bead height variability −25%; rework time −18%.

Expert Opinions

- Prof. Tresa Pollock, Distinguished Professor of Materials, UC Santa Barbara

Key viewpoint: “Powder cleanliness and morphology from PREP—especially low hollow and satellite content—translate directly to fewer lack‑of‑fusion initiators and better fatigue performance in AM parts.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Including CT-based hollow fraction and image-quantified satellites on CoAs is becoming a best practice for qualifying PREP powders in regulated industries.” - Dr. Christina Salvo, Materials Engineer, Aerospace AM Programs

Key viewpoint: “Adaptive PREP controls that tune rpm and plasma power to the electrode diameter significantly boost yield into the target LPBF cut without sacrificing sphericity.”

Practical Tools and Resources

- Standards and guidance

- ISO/ASTM 52907 (Metal powders), 52908 (Machine/process qualification): https://www.iso.org | https://www.astm.org

- Metrology and safety

- NIST powder characterization and AM Bench: https://www.nist.gov

- NFPA 484 (Combustible metal powders safety): https://www.nfpa.org

- Technical databases and handbooks

- ASM Digital Library and Handbooks (AM; PM; Heat Treating): https://www.asminternational.org

- QC instrumentation for PREP powders

- PSD/shape: laser diffraction + image analysis/SEM

- Interstitials: LECO O/N/H analyzers

- Flow: Hall/Carney funnels, FT4 rheometer

- CT scanning for hollows and satellite quantification

Last updated: 2025-08-26

Changelog: Added 5 PREP-specific FAQs; introduced 2025 market/technical snapshot with data table and sources; provided two recent case studies; compiled expert viewpoints; listed practical tools/resources for Plasma Rotating Electrode Process

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM update powder QA standards relevant to PREP, major OEMs publish new PREP material cards, or NIST/ASM release updated datasets on hollow/satellite impacts in AM fatigue performance