1. Introduction

Inconel 718 powder is a high-performance superalloy powder that has gained significant popularity in various industries. With its exceptional properties and versatility, it has become a go-to material for applications requiring strength, durability, and resistance to extreme conditions. This article explores the world of Inconel 718 powder, delving into its properties, applications, manufacturing methods, advantages, limitations, and future trends.

2. What is Inconel 718 Powder?

Inconel 718 powder is a powdered form of Inconel 718, a nickel-based superalloy known for its outstanding mechanical properties and resistance to corrosion, oxidation, and high temperatures. It is composed primarily of nickel, chromium, and molybdenum, with small amounts of other elements such as iron, niobium, and titanium. The powder form allows for easier handling and enables advanced manufacturing techniques like additive manufacturing.

3. Properties of Inconel 718 Powder

3.1 High Strength and Durability

Inconel 718 powder exhibits remarkable strength and durability, making it suitable for demanding applications. Its high tensile, fatigue, and rupture strengths allow components made from this powder to withstand extreme mechanical stresses and loads.

3.2 Corrosion and Oxidation Resistance

One of the standout characteristics of Inconel 718 powder is its exceptional resistance to corrosion and oxidation. It remains resistant to corrosive environments, including acids, alkaline solutions, and marine environments. Moreover, it maintains its integrity even at elevated temperatures, making it suitable for high-temperature applications.

3.3 Temperature Resistance

Inconel 718 powder retains its mechanical properties at both low and high temperatures, making it a reliable choice for applications where temperature variations are significant. It can withstand temperatures ranging from cryogenic levels up to 704°C (1300°F), without compromising its performance.

3.4 Fatigue and Creep Resistance

Thanks to its excellent fatigue and creep resistance, Inconel 718 powder is widely used in applications that involve cyclic loading and prolonged exposure to high temperatures. It resists deformation and maintains its structural integrity even under extreme conditions.

3.5 Weldability

Inconel 718 powder offers good weldability, allowing for the fabrication of complex components through various welding techniques. It can be easily joined with other materials to create hybrid structures, expanding its application possibilities.

4. Applications of Inconel 718 Powder

Inconel 718 powder finds applications in a wide range of industries due to its exceptional properties and reliability. Some notable applications include:

4.1 Aerospace Industry

The aerospace industry extensively utilizes Inconel 718 powder for manufacturing turbine engine components, rocket motors, and structural parts of aircraft. Its ability to withstand high temperatures, corrosion, and mechanical stresses makes it a preferred choice for critical aircraft components.

4.2 Automotive Industry

In the automotive industry, Inconel 718 powder is employed in exhaust systems, turbochargers, and other high-temperature components. Its strength, heat resistance, and corrosion resistance contribute to improved performance and durability in demanding automotive applications.

4.3 Oil and Gas Industry

Inconel 718 powder is widely used in the oil and gas industry for downhole tools, wellhead components, and valves. Its resistance to corrosive environments, high temperatures, and high-pressure conditions makes it an ideal material for challenging oil and gas exploration and production environments.

4.4 Power Generation

Inconel 718 powder is utilized in power generation equipment such as gas turbines, steam turbines, and nuclear reactors. Its ability to withstand extreme temperatures, pressure differentials, and corrosive environments ensures reliable performance and longevity in power generation applications.

4.5 Medical Industry

In the medical industry, Inconel 718 powder is employed for surgical implants, prosthetics, and medical instruments. Its biocompatibility, strength, and corrosion resistance make it a suitable material for critical medical applications where durability and compatibility with the human body are crucial.

5. Manufacturing Methods of Inconel 718 Powder

Inconel 718 powder can be produced through several manufacturing methods, each offering unique advantages and considerations. The common methods include:

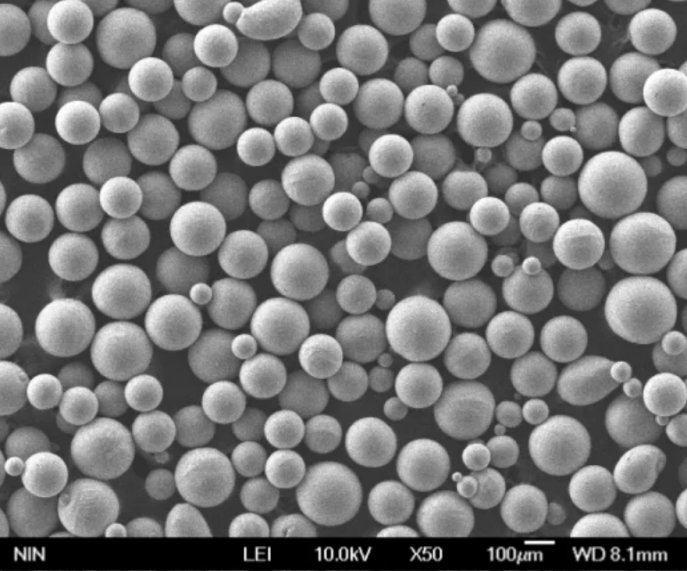

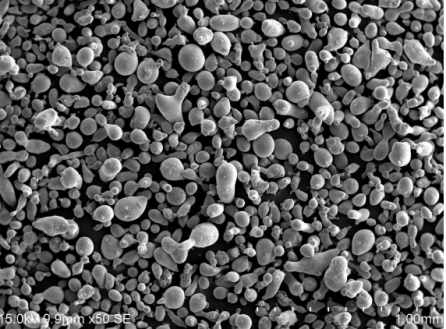

5.1 Gas Atomization

Gas atomization involves melting the alloy and then atomizing it using a high-pressure gas stream. The resulting powder particles are spherical in shape and exhibit excellent flowability, making them suitable for various manufacturing techniques.

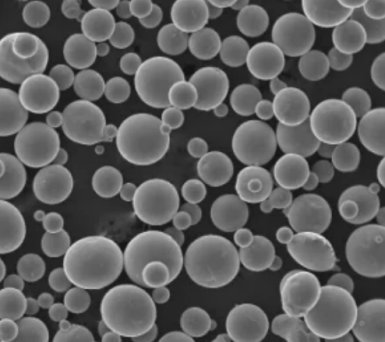

5.2 Plasma Atomization

In plasma atomization, an electric arc is used to melt the alloy, and a high-velocity gas stream atomizes the molten material. The resulting powder particles have a dendritic structure and can be customized for specific applications.

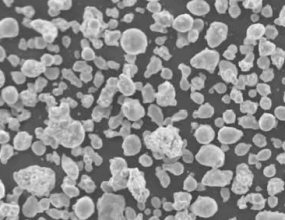

5.3 Water Atomization

Water atomization involves melting the alloy and then atomizing it with water jets. This method produces irregularly shaped particles that are often used in applications where enhanced mechanical properties are desired.

5.4 Mechanical Alloying

Mechanical alloying combines elemental powders of the alloy, which are then milled together to create a homogenous mixture. The resulting powder can exhibit improved properties, such as fine grain size and enhanced mechanical strength.

5.5 Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a revolutionary method for producing components using Inconel 718 powder. This technique allows for the creation of complex geometries with precise control, enabling designers and engineers to unleash their creativity.

6. Advantages of Inconel 718 Powder

Utilizing Inconel 718 powder for advanced manufacturing offers several advantages:

6.1 Design Freedom

Inconel 718 powder allows for the creation of complex geometries and intricate designs that are not feasible with traditional manufacturing techniques. This design freedom enables engineers to optimize components for performance and functionality.

6.2 Cost Savings

Additive manufacturing with Inconel 718 powder can lead to cost savings by reducing material waste. The ability to build components layer by layer minimizes the need for extensive machining and reduces material consumption.

6.3 Rapid Prototyping

Inconel 718 powder and additive manufacturing enable rapid prototyping, allowing designers to iterate and test designs quickly. This accelerates the product development cycle and facilitates innovation and continuous improvement.

6.4 Reduced Waste

Traditional manufacturing methods often generate significant amounts of waste material due to subtractive processes. However, with Inconel 718 powder and additive manufacturing, the production process is more efficient, resulting in reduced waste. The powder is selectively deposited, minimizing material usage and minimizing the environmental impact.

6.5 Complex Geometries

Inconel 718 powder, when used in additive manufacturing, enables the production of intricate and complex geometries that are challenging or impossible to achieve with traditional methods. This opens up new possibilities for component design and functionality.

7. Limitations of Inconel 718 Powder

While Inconel 718 powder offers numerous advantages, it also has some limitations that need to be considered:

7.1 High Cost

Inconel 718 powder is relatively expensive compared to traditional manufacturing materials. The cost of the powder, coupled with the specialized equipment and processing techniques required, can increase the overall manufacturing cost.

7.2 Material Handling

Due to its high density and sensitivity to oxygen and moisture, Inconel 718 powder requires careful handling and storage to prevent contamination and maintain its properties. Specialized equipment and facilities are often necessary to ensure proper material handling.

7.3 Surface Finish

Components manufactured with Inconel 718 powder may have a rougher surface finish compared to those produced using traditional methods. Additional post-processing steps, such as machining or polishing, may be required to achieve the desired surface quality.

7.4 Post-Processing Challenges

Inconel 718 powder components may require additional post-processing steps, such as heat treatment or stress relieving, to optimize their mechanical properties and remove residual stresses. These post-processing steps add complexity and time to the manufacturing process.

7.5 Environmental Impact

The production of Inconel 718 powder and the additive manufacturing process have environmental implications. The energy consumption, emissions, and waste generated during production and post-processing stages need to be carefully managed to minimize the environmental impact.

8. Future Trends and Developments

The field of Inconel 718 powder and additive manufacturing is continually evolving. Some key trends and developments to watch for include:

- Enhanced Powder Quality: Continuous research aims to improve the powder quality, consistency, and flowability, enabling more reliable and efficient manufacturing processes.

- Material Optimization: Researchers are exploring the use of alloying elements and heat treatment techniques to enhance the mechanical properties and performance of Inconel 718 powder components.

- Process Optimization: Ongoing efforts are focused on optimizing the additive manufacturing process parameters to improve the build quality, reduce defects, and enhance overall efficiency.

- New Applications: As the understanding of Inconel 718 powder and additive manufacturing grows, new applications and industries are expected to emerge, expanding the reach and impact of this advanced manufacturing technology.

- Sustainability Initiatives: The industry is actively working on developing sustainable practices, such as recycling and reusing powders and optimizing energy consumption, to minimize the environmental footprint of Inconel 718 powder manufacturing.

9. Conclusion

Inconel 718 powder is a remarkable material that has revolutionized advanced manufacturing. Its exceptional properties, including high strength, corrosion resistance, temperature resistance, and weldability, make it a preferred choice for industries such as aerospace, automotive, oil and gas, power generation, and medical. While it offers several advantages, such as design freedom and cost savings, it also has limitations and requires careful material handling and post-processing considerations. As research and development continue, the future of Inconel 718 powder and additive manufacturing looks promising, with ongoing advancements and new applications on the horizon.

FAQs

1. Is Inconel 718 powder suitable for high-temperature applications?

Yes, Inconel 718 powder exhibits excellent temperature resistance and can withstand high temperatures without compromising its mechanical properties.

2. Can Inconel 718 powder be welded?

Yes, Inconel 718 powder offers good weldability, allowing for the fabrication of complex components through various welding techniques.

3. What are the main industries that use Inconel 718 powder?

Inconel 718 powder finds applications in industries such as aerospace, automotive, oil and gas, power generation, and medical.

4. What are the advantages of using Inconel 718 powder for additive manufacturing?

Using Inconel 718 powder for additive manufacturing offers advantages such as design freedom, cost savings, rapid prototyping, reduced waste, and the ability to create complex geometries.

5. How is Inconel 718 powder produced?

Inconel 718 powder can be produced through methods such as gas atomization, plasma atomization, water atomization, mechanical alloying, and additive manufacturing (3D printing). Each method has its own advantages and considerations.