The world of manufacturing is undergoing a significant transformation. Traditional techniques, while well-established and reliable, are facing increasing challenges in an era that demands innovation, customization, and lightweight, high-performance parts. Enter Nickel-based powder 3D printing, a revolutionary technology that’s shaking things up. But how does it stack up against the tried-and-true methods? Buckle up, because we’re diving deep into the fascinating world of nickel-based 3D printing, comparing it head-to-head with traditional manufacturing technologies.

Comparison of Process Characteristics

Traditional Manufacturing: Think of it like baking a cake. You have a mold (think casting or forging), you pour in the “batter” (molten metal), and let it cool and solidify in the desired shape. Common traditional techniques for nickel alloys include:

- Casting: Molten nickel alloy is poured into a mold cavity that replicates the final part’s geometry. Once cooled, the casting is removed, and excess material is machined away.

- Forging: A heated nickel bar is hammered or pressed into a specific shape using dies. This process strengthens the grain structure of the metal.

- Machining: A solid block of nickel alloy is sculpted into the desired shape using computer-controlled cutting tools.

Nickel-Based Powder 3D Printing: Here, imagine building your cake layer by layer. A high-powered laser melts tiny nickel alloy particles together, following a digital blueprint. Let’s break down the process:

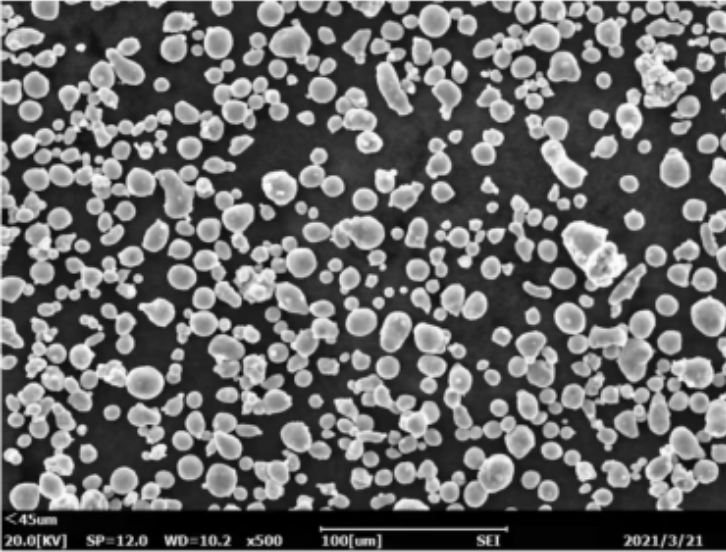

- Powder Preparation: Nickel alloy is atomized into a fine powder with specific particle size and distribution for optimal printing.

- Printing Process: A layer of powder is spread across a build platform. A laser beam selectively melts the powder particles according to the design, creating a single layer of the part. This process repeats, building the object layer by layer.

- Post-Processing: The printed part may undergo heat treatment for stress relief or improved mechanical properties. Support structures used during printing are removed.

At a Glance:

| Feature | Traditional Manufacturing | Nickel-Based Powder 3D Printing |

|---|---|---|

| Process | Subtractive (removing material) or Additive (shaping molten metal) | Additive (building layer by layer) |

| Tooling | Requires complex and expensive molds or dies | Minimal tooling needed, design data drives the process |

| Design Flexibility | Limited by mold or die complexity | Highly complex and intricate geometries are achievable |

| Material Waste | Can be significant, especially with machining | Minimal waste, unused powder can be recycled |

| Production Volume | Ideal for high-volume production runs | More suited for low-volume, custom, or complex parts |

Comparison of Advantages and Disadvantages

Now that we understand the basic processes, let’s see how they fare in a head-to-head battle:

Traditional Manufacturing:

Advantages:

- Cost-effective for high volumes: For mass production of simple parts, traditional methods offer lower per-unit costs.

- Established technology: These methods have been refined over decades, resulting in reliable and predictable outcomes.

- Wide material selection: Traditional techniques can handle a broader range of metal alloys compared to 3D printing.

Disadvantages:

- Limited design complexity: Creating intricate geometries can be difficult and expensive with traditional methods.

- High upfront tooling costs: Molds and dies for casting or forging can be a significant investment.

- Material waste: Significant material removal in machining or excess material from casting can lead to higher costs and environmental impact.

Nickel-Based Powder 3D Printing:

Advantages:

- Unmatched design freedom: Highly complex geometries, internal channels, and lightweight structures are easily achievable.

- Reduced lead time: No need for complex tooling allows for faster production cycles, especially for prototypes or low-volume runs.

- Minimal material waste: Unused powder can be recycled, minimizing material consumption and environmental impact.

- Lightweight parts: The ability to create intricate internal structures allows for significant weight reduction.

Disadvantages:

- Higher cost per unit: Currently, 3D printing nickel-based alloys can be more expensive than traditional methods for high-volume production.

- Limited material selection: The range of printable nickel alloys is still evolving compared to traditional methods.

- Post-processing requirements: Printed parts may require heat treatment or support structure removal, adding to processing time.

The Verdict: There’s no clear winner here. The choice between traditional manufacturing and nickel-based powder 3D printing depends on your specific needs. For high-volume production of simple parts, traditional methods might be the better option. However, if design complexity, rapid prototyping, or lightweight parts are critical, then nickel-based powder 3D printing emerges as a compelling choice. As 3D printing technology matures, production costs are expected to decrease, making it a more viable option for a wider range of applications.

Applications of Nickel-Based Powder 3D Printing

Nickel alloys are known for their exceptional strength, high-temperature resistance, and corrosion resilience. These properties make them ideal for demanding applications in various industries:

- Aerospace: Nickel-based 3D printing is being used to create lightweight, high-strength components for jet engines, airframes, and spacecraft. The ability to produce intricate cooling channels within parts allows for improved thermal management.

Imagine a jet engine combustor. Traditionally, this critical component is a complex assembly of many parts. Nickel-based 3D printing allows engineers to create a single, intricate combustor with internal cooling channels, reducing weight and complexity while improving performance.

- Oil & Gas: Nickel alloys can withstand harsh downhole environments. 3D printing enables the creation of custom well components, flow control devices, and even downhole tools with complex internal features for enhanced functionality.

Think about a downhole pressure sensor. Traditionally, this would be a complex machined component. 3D printing allows for a lighter, more intricate design with internal channels for fluid flow and pressure measurement, all within a single piece.

- Medical: Biocompatible nickel alloys are finding use in implants and prosthetics. 3D printing allows for customized designs that perfectly match a patient’s anatomy, leading to improved fit and function.

- Automotive: Nickel-based 3D printing is being explored for creating high-performance components like pistons, connecting rods, and even brake calipers. The ability to design lightweight structures with high strength is particularly attractive for the automotive industry.

The Future of Nickel-Based Powder 3D Printing

The future of nickel-based powder 3D printing is bright. As research and development continue, we can expect to see:

- Reduced production costs: Advancements in printing technology and materials are expected to bring down the cost per unit, making 3D printing more competitive for broader applications.

- Expanded material selection: The range of printable nickel alloys will continue to grow, offering engineers more options for specific performance needs.

- Faster printing speeds and larger build volumes: Advancements in printing technology will lead to faster printing times and the ability to create larger and more complex parts.

- Integration with other technologies: 3D printing might be combined with other advanced manufacturing techniques like machining or surface finishing for a complete solution.

FAQ

Here are some frequently asked questions about nickel-based powder 3D printing:

| Question | Answer |

|---|---|

| What are the surface finish characteristics of nickel-based 3D printed parts? | The surface finish can vary depending on the printing process and post-processing techniques. Parts may require additional machining or polishing to achieve a desired surface finish. |

| Can nickel-based 3D printed parts be welded or joined to other components? | Yes, nickel-based 3D printed parts can be welded using specialized techniques. However, the weldability can vary depending on the specific alloy and printing parameters. |

| What are the environmental benefits of nickel-based 3D printing? | Compared to traditional methods, 3D printing offers reduced material waste and lower energy consumption due to minimal material removal. |

| Is nickel-based 3D printing safe? | Nickel powder can be a health hazard if inhaled. Proper safety protocols and ventilation systems are essential when working with nickel powder in a 3D printing environment. |

In Conclusion

Nickel-based powder 3D printing is a transformative technology with the potential to revolutionize various industries. While it may not replace traditional manufacturing entirely, it offers unique advantages for applications requiring complex geometries, lightweight parts, and rapid prototyping. As the technology matures and costs decrease, we can expect to see nickel-based 3D printing play an increasingly significant role in the future of manufacturing.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) Which nickel-based alloys are most used in powder 3D printing today?

- IN718 and IN625 dominate due to balanced weldability and properties. Higher-temperature grades like IN738LC and IN939 are emerging but require tighter oxygen control and post-treatment.

2) How do powder characteristics impact LPBF outcomes vs traditional routes?

- For LPBF, PSD 15–45 μm, high sphericity (>0.93), low satellites, and low O/N/H (e.g., O ≤0.03–0.06 wt%) are critical to density and surface finish. Traditional routes rely less on powder morphology and more on melt cleanliness and mold/die quality.

3) When is Nickel-based Powder AM cost-competitive with casting/forging?

- Low-to-mid volumes, complex internal channels, part consolidation, or high buy-to-fly ratios. Eliminating tooling and reducing machining can offset higher per-kg powder and machine-hour costs.

4) What post-processing is typical for AM nickel parts?

- Stress relief, HIP for porosity, solution/age heat treatments (e.g., IN718), machining/EDM for features and surface finish, and NDT (CT, UT, dye penetrant) to meet aerospace/energy specs.

5) Can AM parts match fatigue performance of wrought/cast components?

- Yes, with optimized parameters, HIP, and surface finishing. Internal defect control and surface condition are key; several aerospace-qualified IN718 AM parts meet or exceed conventional baselines under specified conditions.

2025 Industry Trends: Nickel-based Powder AM vs Traditional

- Productivity: Multi-laser LPBF and advanced scan strategies increase build rates 20–60% vs 2023 for IN718/IN625.

- Qualification: Wider adoption of standardized artifacts and digital material passports speeds aerospace/energy approvals.

- Sustainability: Argon recovery in atomization, higher recycled content disclosures (5–20%), and extended powder reuse with tighter QA.

- Design shift: Part consolidation reduces fasteners and leak-paths; conformal cooling in hot-section components improves efficiency.

- Hybrid workflows: AM near-net shapes + finish machining challenge investment casting lead times for complex hardware.

2025 KPI Snapshot (indicative ranges)

| Metric | Traditional (Casting/Forging + Machining) | Nickel-based Powder AM (LPBF) | Notes/Sources |

|---|---|---|---|

| Lead time (tooling to part) | 10–30+ weeks (tooling-dependent) | 2–8 weeks (no tooling) | OEM case studies; supplier data |

| Buy-to-fly ratio | 4:1 to >10:1 (machined) | 1.1:1 to 2:1 | AM part consolidation |

| As-built relative density | N/A (cast ~99.0–99.5%) | 99.6–99.9% (optimized) | CT-confirmed coupons |

| Surface finish Ra (μm) | Casting 3–12; machined ≤1 | LPBF 8–20; post-machined ≤1 | Process and finish dependent |

| LPBF build rate (cm³/h per laser, IN718) | N/A | 35–60 (2025) | Multi-laser + path tuning |

| Oxygen content (wt%, AM-grade powder) | N/A | 0.03–0.06 typical | ISO/ASTM 52907; ASTM E1019 |

| Reuse cycles before blend | N/A | 5–10 with QA | Digital powder passports |

References: ISO/ASTM 52907; ASTM E1019; ASTM B212/B213/B703; NIST AM‑Bench; OEM application notes (EOS, SLM Solutions, GE Additive), industry sustainability reports

Latest Research Cases

Case Study 1: Consolidated IN718 AM Combustor Liner for Lead-Time Reduction (2025)

Background: An aero tier‑1 faced 24‑week lead times and 12‑part assemblies for a small combustor liner.

Solution: Redesigned for LPBF with integrated effusion and conformal channels; used multi‑laser overlap calibration, HIP, and IN718 age hardening.

Results: Part count 12 → 1; lead time −58%; mass −18%; pressure drop −9%; low‑cycle fatigue at 650°C matched spec after surface finishing.

Case Study 2: Argon Recovery and He‑Assist Atomization for IN625 Powder Quality (2024)

Background: A powder supplier sought lower satellites and oxygen with reduced gas cost.

Solution: Installed cryogenic argon recovery and selective helium assist at the nozzle; inline O2 ppm monitoring and PSD control.

Results: Argon consumption −34%; median O 0.061 → 0.045 wt%; satellite count −29%; Hall flow improved by 1.6 s/50 g; customer AM density +0.2% absolute.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Consistent powder metrics—PSD, O/N/H, flow, density—plus digital traceability underpin reproducible Nickel‑based Powder AM across sites.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “In 2025, parameter portability and multi‑laser calibration move nickel AM from prototypes to dependable serial production in hot‑section hardware.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Aligning supplier COAs with ISO/ASTM methods and material passports is compressing qualification timelines in aerospace and energy.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Feedstock characterization for metal AM powders

https://www.iso.org/standard/78974.html - ASTM standards: E1019 (O/N/H), B212/B213/B703 (flow/density), F3301/F3571 (PBF practices)

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM validation

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Nickel‑based Powder applications

https://senvol.com/database - HSE ATEX/DSEAR: Safe handling of combustible metal powders

https://www.hse.gov.uk/fireandexplosion/atex.htm - OEM resources (GE Additive, EOS, SLM Solutions, Renishaw): Parameter guides and application notes

Last updated: 2025-08-27

Changelog: Added 5 FAQs, 2025 KPI comparison table, two recent case studies, expert viewpoints, and curated standards/resources tailored to Nickel‑based Powder AM vs traditional processes.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major OEMs release new Ni alloy parameter sets, or new datasets on powder reuse and argon recovery are published.