1. Introduction

Metal powders play a vital role in various industries, serving as key components in the production of a wide range of products. From automotive parts to electronics and construction materials, the demand for high-quality metal powders continues to grow. Finding reliable metal powder suppliers is crucial for businesses looking to source these essential materials. In this article, we will explore the world of metal powder suppliers, discuss the different types of metal powders, delve into the production processes involved, and highlight the factors to consider when choosing a supplier.

2. What is Metal Powder?

Metal powder refers to fine particles of metallic elements or alloys. These powders are produced by various methods such as atomization, reduction, and electrolysis. Metal powders possess unique properties that make them highly desirable in many industries. They exhibit excellent thermal conductivity, electrical conductivity, and high melting points, which make them suitable for diverse applications.

3. Applications of Metal Powder

Metal powders find applications in numerous industries, including automotive, aerospace, electronics, healthcare, and manufacturing. They are used for manufacturing components such as gears, bearings, filters, magnets, and electrical contacts. Metal powders are also employed in additive manufacturing processes like 3D printing, where intricate and complex parts can be produced with high precision.

4. Types of Metal Powder

Metal powder suppliers said that Metal powders can be broadly classified into two categories: ferrous and non-ferrous.

4.1 Ferrous Metal Powder

Ferrous metal powders consist of iron or iron-based alloys. These powders are commonly used in applications requiring high strength, durability, and magnetic properties. Examples of ferrous metal powders include iron powder, stainless steel powder, and alloy powders like steel-nickel.

4.2 Non-Ferrous Metal Powder

Non-ferrous metal powders comprise metals other than iron. They exhibit excellent corrosion resistance, conductivity, and lightweight properties. Non-ferrous metal powders include aluminum powder, copper powder, bronze powder, and titanium powder.

5. Metal Powder Production

The production of metal powder involves several processes. The choice of method depends on the desired properties and applications of the powder.

5.1 Atomization Process

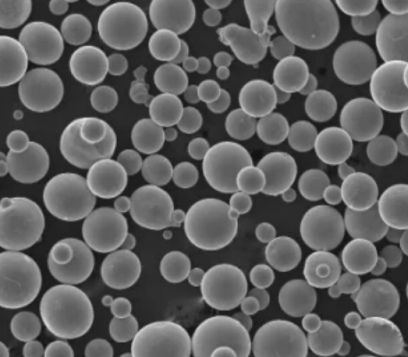

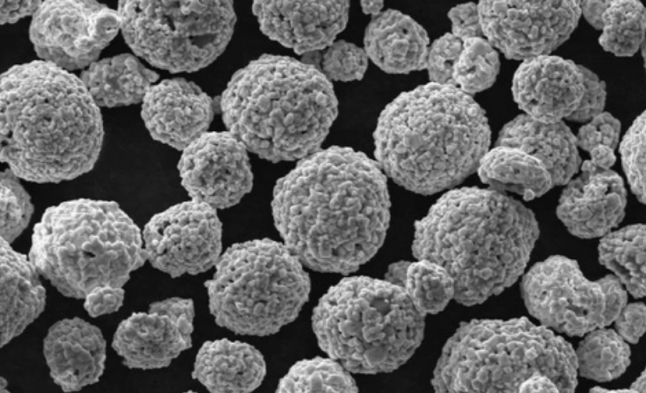

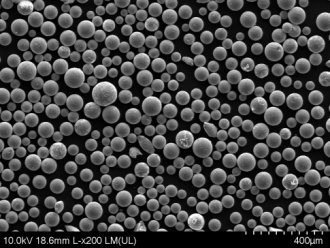

Atomization is the most common method used for producing metal powders. In this process, molten metal is atomized into fine droplets using gas or water jets. These droplets rapidly solidify into powder particles as they cool down. Atomization ensures a uniform particle size distribution and can be used for both ferrous and non-ferrous metals.

5.2 Reduction Process

metal powder suppliers said that The reduction process involves the chemical reduction of metal compounds to obtain metal powders. Metal oxides or salts are reacted with reducing agents such as hydrogen or carbon to produce metal powders. This method is commonly used for obtaining highly pure and fine metal powders. The reduction process is often used for the production of iron powder and other metals like tungsten, molybdenum, and cobalt.

5.3 Electrolysis Process

metal powder suppliers said that The electrolysis process involves the deposition of metal powders from an electrolytic solution. A metal salt solution is electrolyzed, and metal powders are formed on the cathode. This process is commonly used for producing highly pure and specialized metal powders such as copper powder and silver powder.

6. Factors to Consider When Choosing Metal Powder Suppliers

When selecting metal powder suppliers, several factors should be taken into consideration to ensure the procurement of high-quality materials that meet specific requirements. Here are some key factors to consider:

6.1 Quality Control Measures

metal powder suppliers said that Reliable suppliers should have robust quality control measures in place to ensure consistent and reliable product quality. Look for suppliers that follow strict quality standards, such as ISO certifications, and have well-equipped laboratories for quality testing.

6.2 Material Certifications

metal powder suppliers said that Check if the supplier provides material certifications and test reports, which validate the composition, purity, and other relevant properties of the metal powders. Material certifications are essential for industries with stringent quality requirements, such as aerospace and medical sectors.

6.3 Production Capacity and Lead Times

Evaluate the supplier’s production capacity and lead times to ensure they can meet your demand requirements. Timely delivery of metal powders is crucial to avoid disruptions in production schedules.

6.4 Technical Support and Expertise

Choose suppliers that offer technical support and have a team of experts who can provide guidance on material selection, process optimization, and troubleshooting. This support can be invaluable in ensuring the successful implementation of metal powders in your applications.

6.5 Pricing and Cost Efficiency

metal powder suppliers said that Consider the pricing structure and cost efficiency offered by different suppliers. While competitive pricing is important, it should not compromise the quality and reliability of the metal powders. Assess the overall value provided by the supplier in terms of quality, technical expertise, and customer service.

6.6 Environmental Sustainability

In today’s environmentally conscious world, it is essential to consider the sustainability practices of metal powder suppliers. Look for suppliers that prioritize environmental sustainability by implementing measures such as waste reduction, recycling, and responsible sourcing of raw materials.

7. Conclusion

Metal powder suppliers play a crucial role in ensuring a steady supply of high-quality materials for industries that rely on metal powders. By understanding the different types of metal powders, production processes, and key factors to consider when choosing suppliers, businesses can make informed decisions and forge strong partnerships. It is essential to prioritize quality, technical expertise, production capacity, and environmental sustainability when selecting a supplier. By doing so, businesses can meet their material requirements and drive innovation in their respective industries.

FAQs

1. Are metal powders safe to handle?

Yes, metal powders are generally safe to handle with proper precautions. However, certain metal powders can be hazardous if mishandled or inhaled. It is crucial to follow safety guidelines provided by the supplier and use appropriate protective equipment, such as gloves and masks, when working with metal powders.

2. Can metal powders be recycled?

Yes, metal powders can be recycled. Many metal powder suppliers have implemented recycling programs to minimize waste and promote sustainability. Recycling metal powders not only helps reduce environmental impact but also provides cost savings for businesses.

3. How can I ensure the consistency of metal powder quality from a supplier?

To ensure consistency in metal powder quality, it is essential to work with reputable suppliers who have robust quality control measures in place. Requesting material certifications and test reports can provide assurance of the composition and quality of the metal powders. Regular communication with the supplier and periodic audits can also help maintain a strong quality partnership.

4. Can metal powders be customized for specific applications?

Yes, metal powders can be customized for specific applications. Experienced suppliers often offer custom powder formulations to meet unique requirements. By understanding the specific needs of your application and collaborating closely with the supplier, you can obtain tailored metal powders that optimize performance and efficiency.

5. How do I determine the appropriate metal powder for my application?

Choosing the right metal powder for your application involves considering factors such as mechanical properties, chemical compatibility, and desired end-use characteristics. It is advisable to consult with the supplier’s technical experts who can provide guidance based on their expertise and knowledge of various metal powders. Conducting thorough testing and evaluation of different powders in your specific application conditions can also help determine the most suitable choice.

Additional FAQs About Metal Powder Suppliers

1) What should a Certificate of Analysis (CoA) from metal powder suppliers include?

- At minimum: chemistry, PSD (D10/D50/D90), flow (Hall/Carney), apparent/tap density, moisture, O/N/H (as applicable), sphericity/satellite % (for AM), and lot traceability. Increasingly, CT‑measured hollow fraction is added for AM powders.

2) How do I benchmark supplier consistency across lots?

- Use SPC on critical metrics (PSD, flow, O/N/H), require rolling 12‑month capability reports (Cp/Cpk), and run small validation builds or sinter coupons on each new lot. Define refresh/reject thresholds contractually.

3) Are water‑atomized powders acceptable for additive manufacturing?

- Often yes for Binder Jetting (then sinter/HIP). For PBF/DED, gas or vacuum gas atomized powders with high sphericity and low oxides deliver better spreadability and density.

4) How can buyers reduce total cost without sacrificing quality?

- Optimize PSD cut to application, buy under multi‑lot agreements, allow recycled revert within limits, and leverage local warehousing to cut freight. Avoid over‑specifying purity or PSD tighter than process needs.

5) What safety frameworks should metal powder suppliers follow?

- NFPA 484 for combustible metal dusts, ATEX/DSEAR for explosive atmospheres, and documented Dust Hazard Analysis (DHA). Verify housekeeping, grounding/bonding, and explosion protection in supplier audits.

2025 Industry Trends for Metal Powder Suppliers

- Transparency-first CoAs: Image-based sphericity/satellite %, CT hollow fraction, and O/N/H trending are becoming standard for AM-grade powders.

- Regional capacity and lead-time: New atomization lines in North America/EU/APAC shorten delivery and reduce logistics risk.

- Sustainability: Argon recirculation, higher revert content, and LCA reporting appear in bids; customers request EPDs.

- Modality shift: Binder Jetting growth for steels/Cu; PBF demand steady for Ti/Ni.

- In‑process control: Closed‑loop melt superheat and gas‑to‑metal ratio control improve morphology and reduce satellites.

2025 Market and Technical Snapshot (Metal Powder Suppliers)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Gas‑atomized 316L price | $10–$18/kg | −2–5% | Supplier indices |

| Gas‑atomized Ti‑6Al‑4V price | $150–$280/kg | −3–7% | Alloy/PSD dependent |

| Water‑atomized steel (BJ/MIM) | $4–$9/kg | Flat to −2% | Volume dependent |

| Common AM PSD cuts (PBF) | 15–45 µm, 20–63 µm | Stable | OEM guidance |

| Sphericity (image analysis) | ≥0.93–0.98 | Slightly up | CoA expansion |

| Satellite fraction (image) | ≤3–6% | Down | Process tuning |

| CT hollow particle fraction | 0.5–1.5% | Down | VGA/EIGA, CT QC |

| Validated reuse cycles (AM) | 5–10 | Up | O/N/H trending + sieving |

Indicative sources:

- ISO/ASTM 52907 (Metal powders), 52908 (AM process qualification): https://www.iso.org | https://www.astm.org

- MPIF standards and buyer guides: https://www.mpif.org

- NIST AM Bench, powder metrology: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; AM): https://www.asminternational.org

- NFPA 484 (Combustible metal dusts): https://www.nfpa.org

Latest Research Cases

Case Study 1: Supplier Qualification Playbook for AM‑Grade 17‑4PH (2025)

Background: An industrial OEM experienced variable density and roughness with multi‑supplier 17‑4PH powders.

Solution: Implemented a dual‑source framework requiring CoA with PSD, sphericity, satellite %, O/N/H, and CT hollows; instituted Cp/Cpk thresholds and small build validation per lot.

Results: Scrap rate −38%; average surface roughness (as‑built) improved 12%; changeover time between suppliers reduced by 50% due to harmonized specs.

Case Study 2: Reducing Satellite Fraction in 316L via Gas‑to‑Metal Ratio Control (2024)

Background: A service bureau reported recoater stops linked to high satellite content.

Solution: Supplier upgraded atomization lance and added closed‑loop gas‑to‑metal ratio and melt superheat control; air‑elutriation post‑classification.

Results: Satellite fraction cut from 7.9% to 3.2% (image analysis); Hall flow improved 15%; PBF relative density increased from 99.4% to 99.8%; unplanned stoppages −42%.

Expert Opinions

- Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “CT‑quantified hollow fraction and satellite metrics on CoAs are now leading indicators for PBF defect initiation—buyers should insist on them.” - Prof. Diran Apelian, Distinguished Professor (emeritus), Metal Processing

Key viewpoint: “Melt cleanliness and stable atomization dynamics—superheat and gas‑to‑metal ratio—set the ceiling on powder quality more than after‑the‑fact screening.” - Dr. Christina Varin, Powder Metallurgy R&D Director, European PM Center

Key viewpoint: “For Binder Jetting, engineered bimodal PSDs and controlled oxide surfaces are enabling near‑wrought densities after sinter and optional HIP.”

Note: Viewpoints synthesized from public talks and publications; affiliations are publicly known.

Practical Tools and Resources

- Standards and testing

- ISO/ASTM 52907, 52908; ASTM B214 (sieve), B213 (flow), B212 (apparent density), B962 (tap density); MPIF 35 (MIM properties): https://www.iso.org | https://www.astm.org | https://www.mpif.org

- Safety and compliance

- NFPA 484 guidance; ATEX/DSEAR resources for Dust Hazard Analysis (DHA): https://www.nfpa.org

- Metrology and QC

- NIST powder characterization; LECO O/N/H analyzers; industrial CT for hollow/satellite quantification: https://www.nist.gov

- Supplier due diligence checklist

- CoA completeness (chemistry, PSD, flow, densities, O/N/H, sphericity, satellites, hollows), lot genealogy/traceability, SPC dashboards, local inventory/lead time, return/refresh policies

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; created 2025 market/technical snapshot table with indicative sources; added two supplier-focused case studies; compiled expert viewpoints; listed practical tools/resources for sourcing from Metal Powder Suppliers

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM/MPIF standards update, major OEMs revise AM/MIM powder specs, or new NIST/ASM datasets link morphology/interstitials to build yield and fatigue performance