In the realm of metal additive manufacturing, the choice of powder is akin to picking a champion for your team. Each contender brings unique strengths and weaknesses to the table, and selecting the right one hinges on the specific needs of your project. Today, we enter the arena to witness the clash of the titans: low alloy steel powder versus a squadron of its metallic adversaries.

We’ll delve into the properties, applications, and battle cries (advantages and disadvantages) of each powder type, equipping you to make a strategic selection for your next 3D printing conquest.

Low Alloy Steel Powder: The Workhorse Warrior

Low alloy steel powder (LASP) is a formidable force in the metal additive manufacturing arena. Think of it as the dependable knight in shining armor, offering a compelling blend of strength, affordability, and versatility. But like any warrior, it has its limitations.

Composition and Characteristics:

LASP is an iron-based powder alloyed with small amounts of elements like manganese, chromium, nickel, and molybdenum. These alloying elements, though minimal, significantly enhance its mechanical properties compared to pure iron powder.

Properties:

- High Strength and Hardness: LASP boasts superior strength and hardness compared to many other metal powders. This makes it an ideal choice for components that need to withstand significant loads and forces, such as gears, sprockets, and tools.

- Good Toughness and Plasticity: While not the most flexible contender, LASP offers a respectable balance between strength and some degree of bendability. This allows parts to absorb some impact without succumbing to brittle fracture.

- Decent Wear and Corrosion Resistance: The presence of alloying elements like chromium can enhance LASP’s resistance to wear and tear, making it suitable for applications exposed to friction and harsh environments.

- Affordable: Compared to some exotic metal powders, LASP is a relatively cost-effective option. This opens doors for projects where budget is a key consideration.

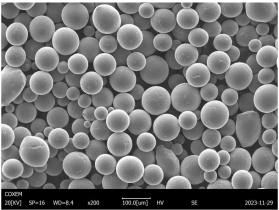

- Wide Range of Printability: LASP exhibits good flowability and laser compatibility, making it suitable for various additive manufacturing techniques like Laser Powder Bed Fusion (LPBF).

Applications:

LASP finds application in a diverse range of industries, including:

- Automotive: Gears, sprockets, engine components

- Aerospace: Brackets, structural elements

- Industrial Machinery: Tools, dies, jigs, fixtures

- Consumer Goods: Sporting equipment, hardware

Specifications, Sizes, Grades, and Standards:

LASP comes in a variety of specifications, sizes, and grades depending on the manufacturer and desired properties. Common standards include ASTM International (ASTM) and the Metal Powder Industries Federation (MPIF). Here’s a glimpse into the variations:

| Parameter | Description |

|---|---|

| Size | Typically ranges from 15 to 150 microns |

| Grade | Can vary based on specific alloying elements and their percentages |

| Standards | Common standards include ASTM A29, ASTM B294, MPIF 05 |

Pros and Cons of Low Alloy Steel Powder

| Advantage | Disadvantage |

|---|---|

| High strength and hardness | Lower ductility compared to some other metal powders |

| Good toughness and plasticity | Can be susceptible to rust and corrosion in extreme environments |

| Affordable | May require post-processing for optimal surface finish |

| Wide range of printability | Not ideal for applications requiring high corrosion resistance |

The Metal Powder Posse: A League of Extraordinary Materials

While LASP reigns supreme in many applications, other metal powders offer distinct advantages for specific needs. Let’s introduce some of the key contenders in the metal powder arena:

1. Stainless Steel Powders (316L, 17-4 PH): These warriors shine in their resistance to corrosion and high temperatures. Imagine them as the stoic guardians, ideal for applications in harsh environments like marine components or medical implants.

2. Tool Steel Powders (M2 High Speed Steel, H13 Tool Steel): Think of these as the berserkers of the group. Tool steel powders boast exceptional hardness and wear resistance, making them perfect for cutting tools, dies, and molds that need to withstand extreme wear and tear.

3. Aluminum Powders (AlSi10Mg, AlSi7Mg): These lightweight champions prioritize agility and speed. Aluminum powders offer excellent strength-to-weight ratios and good corrosion resistance, making them ideal for applications in aerospace and automotive

4. Nickel-based Powders (Inconel 625, Inconel 718): Imagine these as the heat-resistant alchemists. Nickel-based powders excel in high-temperature environments due to their exceptional resistance to oxidation and creep. They find application in jet engines, gas turbines, and other components exposed to extreme heat.

5. Titanium Powders (CP Ti, Ti-6Al-4V): These are the noble warriors, offering a unique blend of strength, low weight, and excellent biocompatibility. Titanium powders are particularly valuable for aerospace components and medical implants due to their weight savings and compatibility with the human body.

6. Copper Powders: Think of these as the electricity conductors of the group. Copper powders boast exceptional thermal and electrical conductivity, making them ideal for applications in heat sinks, electrical components, and electromagnetic shielding.

7. Cobalt Chrome Powders (CoCrMo): Imagine them as the champions of wear resistance. Often used in the medical field for implants like artificial joints, cobalt chrome powders offer exceptional wear resistance and biocompatibility.

8. Tungsten Powders: These heavy hitters pack a punch in terms of density. Tungsten powders are incredibly dense and offer superior properties for radiation shielding and armor applications.

9. Precious Metal Powders (Gold, Silver, Platinum): These are the elite guard, valued for their unique properties and aesthetics. Precious metal powders find application in jewelry, electronics, and even some medical devices due to their conductivity, corrosion resistance, and biocompatibility.

10. Refractory Metal Powders (Tantalum, Molybdenum): Imagine these as the heat shields of the group. Refractory metal powders boast incredibly high melting points, making them ideal for applications in furnaces, crucibles, and other high-temperature environments.

A Tale of Two Titans: A Side-by-Side Comparison

Now that we’ve assembled our metal powder legion, let’s delve deeper into a head-to-head comparison between LASP and some of its prominent rivals:

| Metric | Low Alloy Steel Powder | Stainless Steel Powders (316L) | Tool Steel Powders (M2) | Aluminum Powders (AlSi10Mg) |

|---|---|---|---|---|

| Strength | High | High | Very High | Moderate |

| Hardness | High | Moderate | Very High | Moderate |

| Toughness | Moderate | Moderate | Low | High |

| Ductility | Moderate | Low | Low | High |

| Wear Resistance | Good | Moderate | Very High | Moderate |

| Corrosion Resistance | Moderate | High | Low | High |

| Weight | Heavy | Moderate | Heavy | Light |

| Printability | Good | Good | Moderate | Good |

| Cost | Affordable | Moderate | High | Moderate |

| Metric | Nickel-based Powders (Inconel 625) | Titanium Powders (CP Ti) | Copper Powders | Cobalt Chrome Powders (CoCrMo) | Tungsten Powders |

|---|---|---|---|---|---|

| Strength | High | High | Low | High | Very High |

| Hardness | Moderate | Moderate | Low | High | Very High |

| Toughness | Moderate | High | Low | Moderate | Low |

| Ductility | Moderate | High | High | Low | Low |

| Wear Resistance | Good | Moderate | Low | Very High | High |

| Corrosion Resistance | High | Moderate | Low | Moderate | Low |

| Weight | Heavy | Moderate | Light | Heavy | Very Heavy |

| Printability | Moderate | Moderate | Good | Moderate | Moderate |

| Cost | High | High | Moderate | High | Very High |

Matching Needs with Material

As with any good battle royale, selecting the victor depends on the specific needs of your project. Here are some key considerations to guide your choice:

- Required Strength and Hardness: For applications demanding high load-bearing capacity and resistance to deformation, LASP, tool steel powders, or nickel-based powders might be ideal choices.

- Ductility and Toughness: If your project requires some degree of bendability and impact resistance, aluminum powders or titanium powders could be better suited.

- Wear Resistance: Components exposed to significant friction and wear benefit from tool steel powders, cobalt chrome powders, or tungsten powders.

- Corrosion Resistance: For environments prone to rust or harsh chemicals, stainless steel powders or nickel-based powders offer superior protection.

- Weight Considerations: When weight reduction is a priority, aluminum powders or titanium powders become strong contenders.

- Printability: LASP and aluminum powders generally exhibit good printability across various additive manufacturing techniques. However, some metal powders, like tool steels and nickel-based alloys, can be more challenging to print due to their higher melting points and flowability characteristics. Consider consulting with a metal additive manufacturing expert to determine the most suitable powder for your chosen printing technology.

- Cost: LASP is a budget-friendly option compared to many exotic metal powders like titanium or precious metals. However, factor in the potential costs of post-processing for LASP if a high-quality surface finish is required.

Beyond the Battlefield: Considerations for Success

While material selection is a crucial step, it’s just one piece of the puzzle. Here are some additional factors to consider for a successful metal additive manufacturing project:

- Part Design: Designing your part specifically for additive manufacturing can unlock the full potential of the technology. This might involve incorporating internal lattice structures for weight reduction or designing features that are difficult or impossible to achieve with traditional manufacturing techniques.

- Process Parameters: Optimizing the laser power, scan speed, and other process parameters for your chosen metal powder is essential for achieving the desired mechanical properties and surface finish of your printed part. Collaboration with an experienced AM service provider can be invaluable in this stage.

- Post-Processing: Depending on the metal powder and application, post-processing techniques like heat treatment, hot isostatic pressing (HIP), or machining might be necessary to achieve the final desired properties and dimensional accuracy.

FAQ

Q: What is the difference between metal powder and metal filament used in 3D printing?

A: Metal powders are primarily used in powder bed fusion (PBF) additive manufacturing techniques, where a laser beam selectively melts the powder particles layer by layer to build the desired 3D object. Metal filaments, on the other hand, are used in Fused Deposition Modeling (FDM) for metals, where a metal-filled wire is fed through a heated nozzle and deposited layer-by-layer to create the object. Metal FDM is a relatively new technology with limitations compared to PBF, but it offers potential advantages like wider material compatibility and lower cost.

Q: How safe is it to handle metal powders?

A: Metal powders can pose health risks if inhaled, so proper safety precautions are crucial. This includes using a ventilated enclosure during printing, wearing appropriate personal protective equipment (PPE) like gloves and respirators, and following safe handling practices as recommended by the powder manufacturer.

Q: What are the future trends in metal powder technology?

A: The metal powder landscape is continuously evolving. We can expect advancements in areas like:

- Development of new metal powder alloys with improved properties like higher strength-to-weight ratios or enhanced corrosion resistance.

- Advancements in powder manufacturing techniques to produce finer and more uniform powder particles, leading to improved printability and surface finish.

- Increased focus on sustainability, with the development of recycled metal powders or powders with lower environmental impact.

The Final Verdict: A Symphony of Strengths

The choice of metal powder isn’t a duel, but rather an orchestra of possibilities. Each metal powder brings a unique set of strengths to the table, and the optimal selection hinges on the specific requirements of your project. By understanding the properties, applications, and limitations of various metal powders, you can make an informed decision and unlock the true potential of metal additive manufacturing.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) What makes Low Alloy Steel Powder (LASP) a good baseline choice in AM?

- Balanced strength, hardness, and cost; good printability in LPBF; widely available grades to match heat treatment targets, making LASP a value leader for structural and wear parts.

2) When should I select stainless steel powder over LASP?

- Choose 316L/17‑4 PH when corrosion resistance is critical (marine, medical housings) or when post-weld/print passivation and hygiene matter more than ultimate strength-to-cost.

3) How does LASP compare to tool steel powders for wear applications?

- Tool steels (H13, M2) deliver superior hot hardness and abrasion resistance but are harder to print and machine. LASP with appropriate heat treatment and surface finishing can meet moderate wear needs at lower cost.

4) What powder characteristics most affect LASP print success?

- Narrow PSD (typically 15–45 μm for LPBF), high sphericity/low satellites, low residual oxygen, consistent flow (Hall/Carney), and stable apparent/tap density. These drive layer uniformity and reduce lack‑of‑fusion defects.

5) Can I reuse LASP safely in production?

- Yes, with closed-loop inert handling and sieving between builds. Track O/N/H, PSD shift, flow, and density per ISO/ASTM 52907; many shops allow 6–10 reuse cycles with 20–50% virgin blending.

2025 Industry Trends: Low Alloy Steel Powder vs Other Powders

- Cost-performance optimization: Hybrid routes (water atomized + RF plasma spheroidization) make AM-grade LASP competitive for Binder Jetting and LPBF.

- Parameter portability: OEM multi-laser LPBF machines ship validated LASP parameter sets, lowering qualification time relative to Ni/Ti systems.

- Sustainability: Powder circularity programs extend reuse cycles to 8–12, while argon recovery cuts gas consumption by 25–40% at atomizers.

- QC automation: Inline optical/AI inspection reduces satellites and hollow particles across steel powder lines; digital material passports improve traceability.

- Application shift: LASP increasingly replaces cast/tool steel in jigs, fixtures, drivetrain prototypes, and medium-wear components after optimized heat treatment.

2025 Snapshot: Comparative KPIs for Common AM Powders

| KPI (AM-grade) | Low Alloy Steel Powder | 316L Stainless | H13 Tool Steel | AlSi10Mg | Inconel 718 |

|---|---|---|---|---|---|

| Typical LPBF PSD (μm) | 15–45 | 15–45 | 15–45 | 15–45 | 15–45 |

| Relative density achievable (%) | 99.5–99.8 | 99.6–99.9 | 99.3–99.7 | 99.0–99.6 | 99.5–99.9 |

| Post-print heat treat complexity | Moderate | Low–Moderate | High | Moderate | High |

| Corrosion resistance | Moderate | High | Low–Moderate | High | High |

| Wear/hot hardness | Moderate | Low–Moderate | Very High | Low–Moderate | Moderate |

| Material cost (USD/kg, 2025 est.) | 20–45 | 25–60 | 40–80 | 30–70 | 90–140 |

| Reuse cycles (pre-blend) | 6–10 | 6–10 | 4–8 | 6–10 | 6–10 |

| Notes/Sources | ISO/ASTM 52907, ASTM B specs | Ditto | Ditto | Ditto | Wohlers 2025, OEM datasheets |

References: ISO/ASTM 52907:2023; ASTM B212/B213/B703, E1019; NIST AM‑Bench; Wohlers Report 2025

Latest Research Cases

Case Study 1: Hybrid WA + RF Plasma Spheroidization Enables AM-Grade LASP for Binder Jetting (2025)

Background: An industrial OEM needed cost-effective steel parts with tight sintering windows, where gas-atomized LASP pricing strained margins.

Solution: Upgraded water-atomized LASP via RF plasma spheroidization; tightened classification; optimized debind/sinter curves and shrink compensation.

Results: Hausner ratio improved 1.36→1.26; Hall flow achieved 16.9 s/50 g; dimensional Cpk +0.4; tensile met design targets; powder cost 12–20% lower than GA baseline.

Case Study 2: LPBF LASP vs 17‑4 PH for Corrosion-Exposed Fixtures (2024)

Background: A contract manufacturer evaluated whether LASP could replace 17‑4 PH for production fixtures exposed to coolant and mild chlorides.

Solution: Parallel LPBF builds, identical scan strategies; LASP received quench and temper; 17‑4 PH aged to H900. Salt spray and wear tests conducted.

Results: LASP matched stiffness and wear at 15% lower cost but failed chloride pitting threshold reached by 17‑4 PH. Decision: Use LASP for dry or protected fixtures; retain 17‑4 PH for wet service.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “For Low Alloy Steel Powder, consistent PSD and oxygen control per ISO/ASTM 52907 predict build stability more than incremental laser power tweaks.” Source: NIST AM workshops https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “Validated multi-laser strategies and robust heat-treatment playbooks let LASP displace conventional tool steels in many jigs and fixtures.” Source: AM conference proceedings https://www.utwente.nl/ - Dr. Anushree Chatterjee, Director, ASTM International Additive Manufacturing Center of Excellence

Key viewpoint: “In 2025, digital material passports tied to standard tests are accelerating cross-platform powder qualification for steel families.” Source: ASTM AM CoE https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Metal powder characterization for AM

https://www.iso.org/standard/78974.html - ASTM standards for powders and testing: B212/B213/B703 (density/flow), E1019 (O/N/H)

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM validation

https://www.nist.gov/ambench - Senvol Database: Compare materials (including Low Alloy Steel Powder) and machines

https://senvol.com/database - HSE ATEX/DSEAR: Safe handling and explosion protection for metal powders

https://www.hse.gov.uk/fireandexplosion/atex.htm - Open-source utilities: pySLM (scan strategy), AdditiveFOAM (thermal/porosity modeling), Thermo‑Calc (CALPHAD for alloy design), ImageJ (morphology analysis)

Last updated: 2025-08-27

Changelog: Added 5 FAQs focused on LASP selection and reuse, 2025 comparative KPI table, two recent case studies, expert viewpoints, and curated tools/resources with standards links.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major cost/capacity shifts for steel powders, or new OEM parameter sets alter LASP qualification practices.