Copper, a reddish-brown metal prized for its excellent electrical and thermal conductivity, takes center stage in a whole new game when it’s transformed into a fine powder. Copper-based alloy powders are revolutionizing various industries, offering a unique blend of properties that traditional materials often struggle to achieve. But what exactly are these wonder powders, and how do they work their magic? Buckle up, because we’re diving deep into the fascinating world of copper-based alloy powders!

the Composition of Copper-Based Alloy Powders

Imagine a tiny orchestra, each instrument a different metal powder playing its part in harmony. That’s essentially what copper-based alloy powders are. While copper is the star conductor, it often shares the stage with other elements, creating a diverse range of alloys with specific functionalities. Here are some of the key players:

- Tin (Sn): Adding tin to the mix creates bronze, a stronger and harder material compared to pure copper. This makes it ideal for applications requiring wear resistance, like bearings and gears.

- Zinc (Zn): Introducing zinc gives birth to brass, known for its beautiful golden hue and excellent machinability. It’s a popular choice for decorative elements, plumbing fixtures, and electrical components.

- Nickel (Ni): Nickel brings superior strength and corrosion resistance to the table. Copper-nickel alloys are frequently used in marine environments and for high-pressure applications.

- Chromium (Cr): A touch of chromium enhances hardness and wear resistance. Copper-chromium alloys are perfect for electrical contacts and components that experience friction.

- Aluminum (Al): Aluminum, the lightweight champion, can also join the party. Copper-aluminum alloys offer a good balance of strength and conductivity, making them suitable for high-strength power lines.

This is just a glimpse into the vast array of possibilities. By adjusting the proportions of these elements and incorporating others, manufacturers can tailor copper-based alloy powders to meet a wide range of requirements.

Composition of Common Copper-Based Alloy Powders

| Alloy | Composition | Key Properties | Applications |

|---|---|---|---|

| Bronze (CuSn) | Copper (Cu) with Tin (Sn) | High strength, wear resistance, good corrosion resistance | Bearings, gears, bushings, sculptures |

| Brass (CuZn) | Copper (Cu) with Zinc (Zn) | Excellent machinability, good formability, corrosion resistance | Decorative parts, plumbing fixtures, electrical components |

| Copper-Nickel (CuNi) | Copper (Cu) with Nickel (Ni) | High strength, corrosion resistance, good electrical conductivity | Marine applications, high-pressure components, heat exchangers |

| Copper-Chromium (CuCr) | Copper (Cu) with Chromium (Cr) | High hardness, wear resistance, good electrical conductivity | Electrical contacts, friction components |

| Copper-Aluminum (CuAl) | Copper (Cu) with Aluminum (Al) | High strength, good conductivity, lightweight | High-strength power lines, electrical conductors |

Additional Considerations:

The specific composition of a copper-based alloy powder can also include trace amounts of other elements depending on the desired properties and manufacturing process. The particle size and morphology (shape) of the powder also play a crucial role in its performance.

Manufacturing Methods: From Mine to Miniature Marvels

Copper-based alloy powders are born through a series of meticulous processes. Here are some of the most common methods:

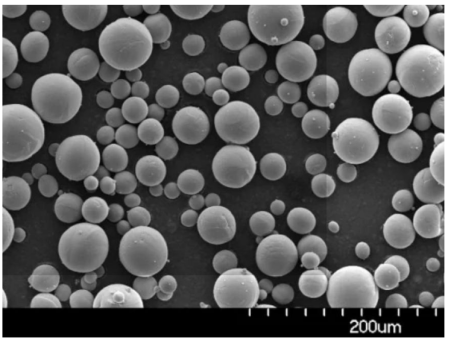

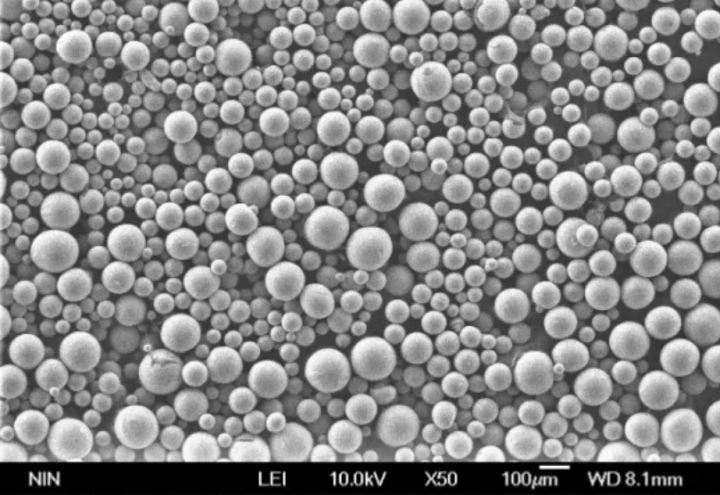

- Atomization: Imagine molten metal being blasted into tiny droplets that solidify mid-air. This is the essence of atomization, which can be achieved using various techniques like water, gas, or centrifugal atomization.

- Chemical Reduction: This method involves a series of chemical reactions that transform copper compounds into fine powders. It offers precise control over the composition but can be less scalable compared to atomization.

- Electrodeposition: Electricity takes center stage in this method, where copper ions are deposited onto a cathode, forming a powdery layer that’s subsequently crushed and sieved.

Each method has its own advantages and limitations. The choice depends on factors like the desired powder characteristics, production volume, and cost.

the Applications of Copper-Based Alloy Powders

Copper-based alloy powders are finding their way into a stunningly diverse range of applications. Here are a few examples:

- Additive Manufacturing (3D Printing): These powders are like tiny building blocks for 3D printers, allowing for the creation of complex, near-net-shape components with superior properties compared to traditional manufacturing techniques.

- Friction Components: The exceptional wear resistance of some copper alloys makes them ideal for bearings, gears, and brakes, ensuring smooth operation and extended lifespan.

- Electrical Applications (Continued): The excellent electrical conductivity of copper-based alloy powders makes them perfect for electrical contacts, connectors, and heat exchangers. Compared to pure copper, some alloys offer improved strength and resistance to arcing, making them ideal for high-performance applications.

- Corrosion Resistance Champions: Mother Nature doesn’t stand a chance against certain copper alloy powders. Their inherent corrosion resistance makes them valuable for components used in harsh environments like marine applications, chemical processing plants, and oil and gas refineries.

- Biocompatible Brilliance: Some copper-based alloy powders boast biocompatible properties, meaning they can coexist peacefully with human tissue. This opens doors for exciting applications in medical implants and devices, potentially improving patient outcomes.

- Aesthetics with a Punch: Let’s not forget about aesthetics! Brass powders, for instance, can be used to create stunning decorative elements with a warm, golden hue. Their excellent machinability allows for intricate designs, adding a touch of elegance to various products.

Specific Metal Powder Models and Applications:

Here’s a deeper dive into some specific metal powder models and their applications:

- Copper (Cu): Pure copper powder is a popular choice for applications requiring high electrical and thermal conductivity, such as heat sinks for electronic devices and high-performance electrical conductors. However, its softness can be a limitation in some applications.

- Bronze (CuSn4): This alloy powder, containing 4% tin, offers a good balance between strength, wear resistance, and conductivity. It’s commonly used for bearings, bushings, gears, and electrical components that require good mechanical properties alongside some level of current flow.

- Brass (CuZn15): Brass with 15% zinc content is a versatile workhorse. Its excellent machinability makes it ideal for complex parts like valves, fittings, and decorative elements. The golden hue adds a touch of sophistication while maintaining good corrosion resistance.

- Copper-Nickel (CuNi20): This alloy powder, containing 20% nickel, shines in marine environments and applications exposed to saltwater. Its exceptional corrosion resistance makes it a valuable material for ship propellers, desalination plants, and heat exchangers in contact with seawater.

- Copper-Chromium (CuCr1Zr): Adding 1% chromium and a trace amount of zirconium to the mix creates a copper alloy powder specifically designed for high wear resistance. This makes it perfect for electrical contacts that experience frequent switching and friction, like automotive relays and circuit breakers.

- AM (Additive Manufacturing) Copper Alloy Powders: These powders are specially formulated for 3D printing processes. They offer good flowability and packing density, ensuring smooth layer formation during printing. The specific composition can vary depending on the desired final properties of the printed part.

Choosing a Copper-Based Alloy Powder

The selection of the ideal copper-based alloy powder hinges on several factors, including:

- The desired end application: Consider the specific requirements of your project. Does it prioritize strength, conductivity, corrosion resistance, or a combination of these properties?

- Manufacturing process: Different methods might favor powders with specific characteristics like particle size and morphology.

- Cost: The cost of the powder can vary depending on the complexity of the alloy and the manufacturing method.

- Availability: Some alloy powders might be less readily available compared to others.

It’s crucial to consult with material suppliers and potentially conduct pilot testing to determine the most suitable copper-based alloy powder for your specific needs.

The Pros and Cons Copper-Based Alloy Powders

Advantages of Copper-Based Alloy Powders:

- Tailored Properties: By adjusting the composition, copper-based alloy powders can be engineered to possess specific properties, offering a high degree of customization.

- Complex Geometries: Additive manufacturing allows for the creation of intricate shapes with these powders, pushing the boundaries of traditional manufacturing techniques.

- Reduced Waste: Powder-based processes often generate less waste compared to conventional methods, contributing to a more sustainable manufacturing approach.

- Lightweight Potential: Some copper alloys, particularly those with aluminum, offer a good balance of strength and weight reduction, making them attractive for aerospace and automotive applications.

Challenges and Limitations:

- Cost: Manufacturing copper-based alloy powders can be more expensive compared to traditional materials like steel.

- Powder Characteristics: Particle size, shape, and flowability can significantly impact the success of powder-based manufacturing processes.

- Post-Processing: Depending on the application, some copper alloy powders might require additional post-processing steps to achieve the desired properties.

- Limited Availability: While the range of available copper alloy powders is expanding, some specific compositions might be less readily available compared to common materials.

- Environmental Impact: The extraction and processing of copper can have environmental consequences. Choosing recycled copper content in the powder can help mitigate this impact.

Overall, copper-based alloy powders offer a compelling combination of benefits, making them a valuable material for various industries. However, understanding the limitations and carefully considering the application requirements are crucial for successful implementation.

FAQ

Q: What are the advantages of using copper-based alloy powders compared to solid copper?

A: Copper-based alloy powders offer several advantages:

- Tailored properties: Alloys can be designed to achieve specific properties like higher strength, improved wear resistance, or enhanced corrosion resistance, which might not be possible with pure copper.

- Complex geometries: Additive manufacturing with powders allows for the creation of intricate shapes that are difficult or impossible to achieve with traditional machining techniques.

- Reduced waste: Powder-based processes often generate less scrap material compared to subtractive manufacturing methods used with solid copper.

Q: What are some of the limitations of copper-based alloy powders?

A: Some limitations to consider include:

- Cost: Manufacturing copper alloy powders can be more expensive than traditional materials.

- Powder characteristics: Particle size, shape, and flowability can significantly impact the success of powder-based manufacturing processes.

- Post-processing: Depending on the application, some copper alloy powders might require additional steps like heat treatment or hot isostatic pressing (HIP) to achieve the desired properties.

Q: How are copper-based alloy powders used in 3D printing?

A: Copper alloy powders specifically formulated for additive manufacturing processes are used in 3D printing. These powders offer good flowability and packing density, ensuring smooth layer formation during printing. The specific composition of the powder can vary depending on the desired final properties of the printed part.

Q: What are some of the environmental considerations when using copper-based alloy powders?

A: Copper extraction and processing can have environmental consequences. Here are some ways to minimize the impact:

- Choose powders with recycled copper content: Look for suppliers offering copper alloy powders that incorporate recycled copper.

- Minimize waste: Implement strategies to minimize powder waste during the manufacturing process.

Q: Where can I find more information about copper-based alloy powders?

A: Several resources can provide more information:

- Metal powder suppliers: Many metal powder suppliers offer detailed information about the copper alloy powders they provide, including specifications, properties, and applications.

- Additive manufacturing industry publications: Publications and websites focused on additive manufacturing often feature articles and resources on metal powders, including copper-based alloys.

- Professional organizations: Organizations like the Metal Powder Industries Federation (MPIF) offer resources and information on metal powders.

By understanding the properties, applications, and limitations of copper-based alloy powders, you can leverage their unique capabilities to create innovative and high-performance products in various industries.