Silver powder is a fine granular powder made from silver metal. It has been used across various industries due to its unique properties. This comprehensive guide covers everything you need to know about silver powder, from its manufacturing process and composition to its applications, suppliers, installation, operation and maintenance.

Overview of Silver Powder

Silver powder is composed of tiny silver particles, typically under 10 microns in size. It can be produced through various mechanical and chemical processes that finely divide silver metal into a powdered form.

Some key properties and composition details of silver powder include:

Properties

- High electrical and thermal conductivity

- Antimicrobial qualities

- Stability in high temperatures

- Low toxicity

Typical Composition

- 99%+ pure silver

- Particle sizes under 10 microns

- Various size distributions available

- May contain small amounts of additives

Common Forms

- Spherical silver powders

- Silver flake powders

- Irregular shaped silver particles

- Silver nanoparticles

Applications and Uses of Silver Powder

Silver powder has become an increasingly popular material across a wide range of industries due to its conductive, antimicrobial and stable properties at high temperatures.

Major application areas include:

- Conductive adhesives, pastes and fillers

- Conductive inks and prints

- Plastics, paints and coatings

- Brazing alloys and solders

- Thermal interface materials

- Biomedical products

- Textiles

- Solar cells

- Electronics

Within these broad application areas, more specific uses of silver powder include:

- Electrically conductive tapes, adhesives and epoxies

- EMI/RFI shielding in polymers and coatings

- Conductive tracks in printed circuit boards

- Plating brighteners and grain refiners

- Thermal greases and interface pads

- Radio-opaque polymers in medical devices

- Antimicrobial medical instruments and consumer products

- Conductive fabrics and antistatic textiles

- Crystalline silicon solar cells

- Conductive die attach films

- LED reflectors

Manufacturing Process of Silver Powders

There are a variety of methods used to produce silver powders with the desired composition, particle size and morphology. The five main manufacturing processes include:

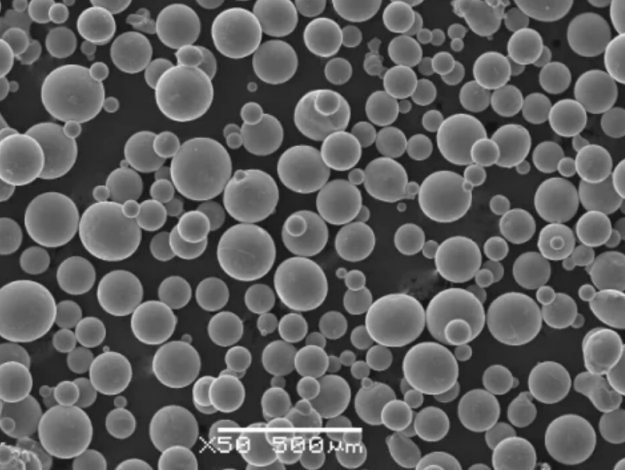

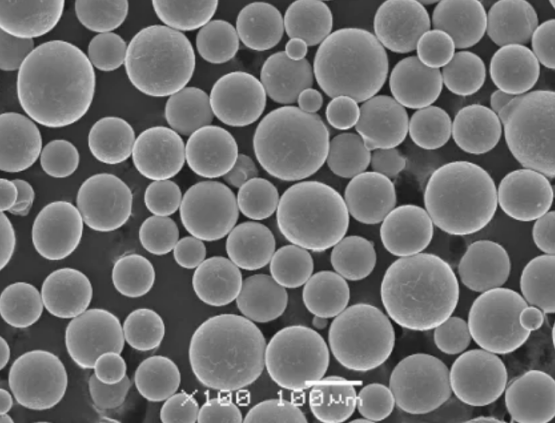

1. Atomization – Molten silver is broken into droplets and rapidly cooled to form small spherical particles. This produces high purity powders suitable for fabrication of contacts and circuits.

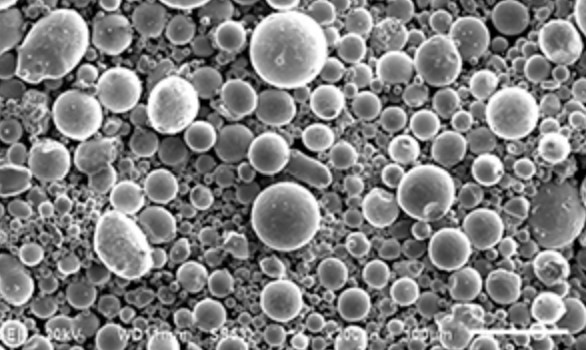

2. Milling – Mechanical milling uses grinding media to break down silver flakes, shot or other feedstock into smaller irregular particles with wider size distribution. Lower cost but higher impurity levels.

3. Precipitation – Dissolving silver salts in an electrolyte solution and using chemical reduction agents to precipitate very fine pure silver powder. Allows tight control of particle size and shape.

4. Electroexplosion – Applying a high current across a silver wire causes an explosion that transforms the metal to nanoparticles under 30nm in size.

5. Electrolysis – Using electrolysis to dissolve silver electrodes into a solution and reduce silver cations onto cathode plates to scrape off powder.

Each process results in different powder characteristics that lend themselves to certain applications over others. The choice depends on factors like desired particle shape, purity levels needed, powder density, cost constraints etc.

Types of Silver Powder

There are a few key varieties of silver powder categorized by production method, morphology, structure and particle size:

By Production Method

- Atomized silver powder

- Milled silver powder

- Precipitated silver powder

- Nanoparticles

- Flakes

By Morphology/Shape

- Spherical

- Flakes

- Irregular

By Structure

- Crystalline

- Amorphous

By Particle Size

- Nanoparticles (<100nm)

- Submicron (100nm – 1 micron)

- Micron scale (> 1 micron)

By Additives

- Unalloyed (Pure Silver)

- Silver alloyed with other metals

Each type has distinct properties, cost considerations and best-fit applications that should be evaluated.

Silver Powder Particle Size Specifications

Silver powders are available across a wide range particle size range – from nanoparticles under 100 nm to coarser powders up to 10 microns. Different size grades are used for various applications based on the properties they impart.

Typical size ranges and examples of corresponding applications:

| Particle Size Range | Applications |

|---|---|

| 30 – 50 nanometers | Conductive inks, biomedical |

| 0.5 – 1 micron | PCB fabrication, solar cells |

| 1 – 5 microns | Thermal greases, coatings |

| 5 – 10 microns | Brazing alloys, EMI shielding |

More broadly, finer silver powders below 1 micron are used when smooth finish and high conductivities are needed. Coarser micron-scale powders are cheaper and suited for coatings, pastes, lubricants.

Choosing Silver Powder Particle Size

The optimal silver powder size grade depends on the application requirements and functionality desired. Some key considerations when selecting particle size include:

Desired Properties

- Electrical/thermal conductivity levels

- Stability at elevated temperatures

- Viscosity of paste/liquid

- Density and porosity

- Mechanical strength post-sintering

- Surface smoothness finish

Processing Parameters

- Dispersion ease in medium

- Sintering time and temperatures

- Deposition/coating thickness

- Print resolution for inks

- Mold injection pressures

Cost Considerations

- Cost per gram differences

- Smaller is typically more expensive

- Weigh cost vs performance impact

Evaluating these parameters against application needs assists in narrowing down the most suitable silver powder grades during material selection.

Antimicrobial Properties of Silver Powder

One of the most prominent properties of silver is its antimicrobial effect against bacteria, viruses and fungi. This ability can be imparted by incorporating silver powders into medical instruments, consumer goods and textile products.

A few key notes regarding the microbial fighting properties:

- Effective against range of microbes – especially antibiotic resistant bacteria

- Cations interfere with microbial enzymes and DNA replication

- Requires sustained silver ion release over time

- Concentration levels dictate efficacy rate

- Particle size influences dissolution rate and availability of ions

Increasing antibacterial effect

- Reduce powder size for faster ion dissolution

- Use porous carriers for sustained ion release

- Increase loading percentages of silver powder

- Leverage flow of liquids/sweat to proliferate ions

The antimicrobial advantages make silver powder uniquely suited for items such as odor-preventing textiles, infection-resistant medical tools, clean consumer appliances and contaminated water treatment.

Silver Powder Pricing

Silver powder pricing can range widely based on powder characteristics like purity, particle size/shape, production method, packaging type and order volumes. Some typical price ranges:

| Silver Powder Type | Price Range |

|---|---|

| Nanoparticles | <$100 per gram |

| Submicron | $50 to $500 per kg |

| 1-10 micron | $5 to $50 per kg |

In general, factors that increase cost include:

- Smaller particle sizes

- High purity (>99.9%)

- Precise particle size distributions

- Special powder shapes

- Small order quantities

- Suspensions or dispersions

And factors that decrease powder price:

- Larger micron-scale particles

- Wider size distributions

- Irregular powder morphology

- Lower purity levels

- Economy grade atomization

- Large bulk orders

So when comparing silver powder materials, be sure to balance price against purity needs, size and tolerance requirements.

Conductivity Values of Silver Powders

The high electrical and thermal conductivity imparted by silver powders are among their most valued characteristics across functional applications like conductive adhesives, inks, greases and more.

Typical conductivity ranges:

| Electrical Conductivity | Thermal Conductivity |

|---|---|

| 6.3 x 10^7 S/m (Annealed Bulk) | 429 W/m-K |

| 2.5 x 10^7 to 5.5 x 10^7 (Sintered) | 150 to 250 W/m-K |

| 5 x 10^4 to 4.5 x 10^6 S/m (Unsintered) | 10 to 40 W/m-K |

Factors impacting conductivity:

- Purity levels – high purity enhances conductivity

- Porosity – more porous, lower conductivity

- Particle size – nanoparticles can achieve higher Conductivity

- Sintering quality influences connectivity

When comparing options, smaller nanoparticles often achieve the best conductivity but cost more. Find the balance suitable for application needs and budget.

Major Suppliers of Silver Powders

There are a number of well-established companies that manufacture and supply consistent quality silver powder materials at globally competitive rates. Some of the top silver powder suppliers include:

| Suppliers | Locations | Typical Products |

|---|---|---|

| DOWA | Japan, USA | Submicron spherical |

| DuPont | Global | Organic capped nanoparticles |

| Ferro | Europe, USA | Thick film pastes |

| Fukuda Metal Foil & Powder | Japan, Taiwan | Flakes for pastes |

| Metalor | Switzerland | All types |

| Mitsui Mining & Smelting | Japan | Flakes, spherical |

| Nanoshel | USA | Nanopowders |

| Chang Chun Group | China | Low cost grades |

| Kunshan Sunny | China | Nano, flake, spherical |

| Shoei Chemical | Japan | Variety grades/alloys |

When contacting suppliers, providing application details and target powder specifications will allow them to offer products best suited. Comparing options from a few suppliers is recommended before purchasing.

Installing Silver Powder Into Manufacturing Processes

Incorporating silver powders into product manufacturing requires adapting current processes or developing new methods to effectively handle the material. Here is an overview of typical integration steps:

Typical installation process:

- Choose powder suitable for application

- Set up storage/handling area and equipment

- Establish powder dispersion/mixing protocols

- Add feed mechanisms for continuous processes

- Adapt molding, sintering, annealing processes

- Implement post-processing quality testing

- Refine parameters to meet product specifications

Key installation considerations:

- Containment to prevent powder leaking

- Protect operators from overexposure

- Minimize contamination during transfers

- Achieve homogeneous blending with medium

- Test sintering settings to maximize conductivity

- Control dispensing accuracy and waste

For small batches, manual handling in fume hoods or glove boxes may suffice. Larger volumes justify automated hoppers, conveyors and dosing systems to improve reliability and throughput. Partner with equipment suppliers where necessary to implement custom powder integration.

Safe Handling Precautions for Silver Powders

While silver powders are relatively inert compared to other metals, some basic handling precautions are recommended to minimize risks when processing:

- Use protective apparel – gloves, N95 masks, goggles as needed

- Avoid skin/eye contact to prevent argyria and irritation

- Handle larger quantities in fume hoods

- Seal containers to prevent leakage and ingress of moisture

- Ensure adequate ventilation and breathing protection

- Use explosion-proof electrical equipment for nanopowders

- Follow flammable/combustible powder storage guidelines

- Review SDS sheet thoroughly before use

- Implement standard protocols for spill containment

The very fine particle sizes increase importance of minimizing inhalation and explosion risks during powder transfers. Establish appropriate engineering controls tailored to quantity and location.

Maintaining Silver Powders InStorage and Use

To sustain consistent silver powder quality during storage and ongoing manufacturing use, here are some recommended maintenance practices:

- Store sealed containers away from sunlight in cool dark places

- Limit shelf life to 6-12 months for finer nanoparticles

- Use dessicants to absorb ambient moisture from storage areas

- Dry powders fully before sealing containers

- Refresh stock every 3-6 months to avoid agglomeration

- Discard clumped powder properly if found in stores

- Inspect visually for changes in flowability, color

- Clean powder handling equipment and containers regularly

- Follow supplier recommendations for reconstitution if required

Monitoring storage conditions closely prevents premature degradation and allows stable long term use of silver powders in manufacturing processes.

Choosing Silver Powder Suppliers

When selecting silver powder suppliers, consider evaluating across these aspects before finalizing:

Product Quality & Reliability

- Powder composition, purity levels

- Consistent particle size distribution

- R&D expertise around silver powder manufacture

- Stringent quality testing protocols

- Records of reliable supply history

- Evidence of strict process controls

- Reviews of product quality from current buyers

Customization Capabilities

- Ability to fine tune particle sizes/distributions

- Range of powder varieties produced

- Special coatings or modified powder engineering

- Custom blending with stabilizers/additives

- Small trial batch friendly

Pricing & Conditions

- Pricing transparency and minimums required

- Volume based discounts available

- All inclusive vs extra add-on costs

- Order and lead time flexibility

- Payment and shipping terms

Evaluating across these parameters helps identify the most suitable silver powder partner for your long term product needs.

Pros and Cons of Using Silver Powders

Here is an overview summary comparing some general pros (benefits) and cons (limitations) to consider when using silver powders:

Pros

- Achieve high electrical conductivity

- Imparts anti-microbial properties

- Withstands high temperature environments

- Enables conductive adhesives and inks

- Relatively chemically inert material

- Suitable bond material for composites

Cons

- Expensive compared to copper

- Requires protection against tarnishing

- Poor mechanical strength in pure form

- Powder form requires safe handling

- Some variability in particle distribution

- Not as versatile as nano carbon options

For most applications, silver powders present substantial opportunities to engineer electrical conductivity, thermal stability and antimicrobial efficacy into the end product with appropriate risk management during handling.

FAQs

Q: Does silver powder tarnish over time with handling?

A: Yes, silver reacts slowly with atmospheric compounds like sulfur and chlorine which causes a tarnished appearance over time. Storing in sealed containers with dessicants helps. Incorporating into polymers and composite bonds protects powders from these reactions during use.

Q: Is silver powder flammable or explosive?

A: Micron-scale silver powders have no fire hazard. But nanoparticles under 100nm can be combustible and even explosive under the right fuel-oxidant conditions. Use inert gas blanketing when storing and transporting nanopowder.

Q: What is the shelf life of silver powder batches?

A: Properly stored sealed containers maintain quality for over a year typically. Finer nanoparticles may degrade within 6-12 months. Heat and sunlight accelerates decline while cooled dark storage optimizes shelf life.

Q: Does silver powder need surface treatment before incorporation?

A: In some cases surface modification of the powder using coatings or stabilizers helps enhance dispersion or adhesion with the medium it is added to. Evaluate if native powder hydrophilicity causes issues.

Q: What industries use silver powders extensively?

A: Electronics, coatings/paints, adhesives, thermoset plastics, printed circuit boards, solar cells, glass manufacturing, textiles and biomedical devices utilize silver powders across many of their products.

know more 3D printing processes

Additional FAQs on Silver Powder

1) What particle morphology is best for conductive inks vs. adhesives?

- Inks: submicron spherical or flake blends (e.g., 200–800 nm spheres + micro‑flakes) optimize printability and low percolation thresholds.

- Adhesives/pastes: 1–5 μm spheres or flakes with controlled aspect ratio improve packing density and bulk conductivity after cure/sinter.

2) How do surface treatments affect silver powder performance?

Organic capping agents (e.g., PVP) improve dispersion and shelf life for nano/submicron powders; silanes or carboxylates aid polymer compatibility; Ag‑coatings with Pd/Au thin films enhance sulfur resistance for harsh environments.

3) What sintering temperatures are typical for silver powders in electronics?

Conventional: 200–300°C for micron powders in epoxy matrices. Pressure‑assisted or nano‑enabled sintering can achieve strong joints at 120–200°C, suitable for temperature‑sensitive substrates.

4) How do I control sulfide/tarnish formation in sulfurous environments?

Use anti‑tarnish coatings, encapsulate within polymers, select low‑sulfur packaging, include scavengers in formulations, and avoid rubber/latex sulfur sources in storage/processing.

5) What tests should be on a Certificate of Analysis (CoA) for silver powder?

Assay (%Ag), PSD (D10/D50/D90), morphology notes, specific surface area (BET), moisture, impurities (Cl, S, Pb, Bi), tap/apparent density, and if applicable, capping agent content and ionic residue.

2025 Industry Trends in Silver Powder

- Low‑temp sintering for power electronics: Ag nano/meso powders enable die-attach at ≤180°C with high thermal conductivity for SiC/GaN modules.

- Sulfur‑robust coatings: Thin Au/Pd shells or alloyed Ag improve anti‑tarnish performance in automotive and telecom applications.

- Printable hybrid systems: Ag–Cu and Ag–carbon hybrids reduce cost while maintaining conductivity in flexible electronics.

- Sustainability: Increased recycled Ag feedstocks and material passports with traceability; EPDs requested by OEMs.

- Healthcare textiles: Durable wash‑stable antimicrobial finishes using bound Ag particles and controlled ion release.

| 2025 Metric (Silver Powder/Applications) | Typical Range/Value | Why it matters | Source |

|---|---|---|---|

| Sheet resistance (inkjet Ag on PET after 150–180°C cure) | 20–60 mΩ/sq at 10 μm | Flexible circuits performance | Vendor datasheets; peer-reviewed print electronics |

| Thermal conductivity (Ag die-attach sintered layer) | 150–250 W/m·K | Power device reliability | Power electronics journals |

| Ionic impurities (Cl−, S) in electronics-grade Ag | ≤50–200 ppm total | Corrosion/EM reliability | Supplier specs; IPC guidance |

| Typical PSD for conductive pastes | D50 ≈ 0.5–3 μm (micron); 50–300 nm (nano) | Packing and sinter kinetics | ASM Handbook; supplier notes |

| Indicative price (electronics-grade micron Ag) | $300–$1,200/kg | Budgeting | Market trackers/supplier quotes |

Authoritative references and further reading:

- ASM Handbook, Volume 2A: Aluminum, Copper & Silver systems: https://www.asminternational.org

- IPC/JEDEC materials guidance and reliability documents: https://www.ipc.org and https://www.jedec.org

- NIST materials data: https://www.nist.gov

- EPA antimicrobial silver information: https://www.epa.gov

Latest Research Cases

Case Study 1: Low‑Temperature Sintered Silver Die‑Attach for SiC Modules (2025)

Background: An automotive inverter supplier needed high thermal conductivity attach at ≤180°C to protect components.

Solution: Formulated a bimodal silver powder system (80% 0.8–1.5 μm + 20% 80–150 nm) with proprietary organics to promote necking at low temperatures; nitrogen reflow and brief pressure assist.

Results: Bondline thermal conductivity 185–210 W/m·K; shear strength >40 MPa; passed 1,000 power cycles (−40/175°C) and 500 h HAST with minimal resistance drift.

Case Study 2: Anti‑Tarnish Silver Flake Ink for Outdoor Telecom Housings (2024)

Background: A telecom OEM required stable conductivity in sulfur‑rich urban atmospheres.

Solution: Silver flakes surface‑modified with ultrathin Pd (<1 wt%) plus polymer overcoat; printed and cured at 160°C on coated aluminum panels. Results: <10% increase in sheet resistance after 90 days in 3 ppm H2S exposure; adhesion per ASTM D3359 5B; maintained EMI shielding >60 dB (100 MHz–1 GHz).

Expert Opinions

- Prof. George Grüner, Distinguished Professor (Emeritus), UCLA, Printed and Flexible Electronics

Key viewpoint: “Bimodal silver particle distributions remain the most reliable route to low‑temperature, high‑conductivity prints due to enhanced packing and sinter neck formation.” - Dr. Katharina Arndt, Head of Materials Chemistry, Fraunhofer IFAM

Key viewpoint: “Surface chemistry—capping agents, ionic residues, and anti‑tarnish layers—controls dispersion, corrosion, and final conductivity as much as particle size.” - Richard Kershaw, Technical Manager, International Precious Metals Institute (IPMI)

Key viewpoint: “Traceability and recycled content are becoming procurement requirements for silver powders without compromising electronics‑grade purity.”

Citations for expert profiles:

- UCLA Engineering: https://www.seas.ucla.edu

- Fraunhofer IFAM: https://www.ifam.fraunhofer.de

- IPMI: https://www.ipmi.org

Practical Tools and Resources

- Standards and testing

- ASTM B822 (PSD by laser diffraction), ASTM D3359 (adhesion), ASTM B962 (tap density), ISO 22196 (antibacterial activity), IPC‑TM‑650 methods for electronics

- Data and design

- ASM Handbooks: https://www.asminternational.org

- NIST materials data: https://www.nist.gov

- Processing and QC

- LECO analyzers for impurities and O/N/H: https://www.leco.com

- Rheometers and zeta potential measurement for dispersion optimization (vendor labs/university cores)

- Market and sourcing

- London Bullion Market Association pricing context: https://www.lbma.org.uk

- Supplier catalogs with technical datasheets (DuPont, DOWA, Metalor, Mitsui)

Last updated: 2025-08-21

Changelog: Added 5 targeted FAQs, 2025 trends with metrics table and sources, two recent silver powder case studies, expert viewpoints with citations, and practical tools/resources.

Next review date & triggers: 2026-02-01 or earlier if standards for conductive inks/pastes change, major OEMs release new low‑temp sinter Ag datasets, or silver powder pricing/availability shifts >10% QoQ.