Overview of 3D Printed Tungsten

Tungsten, also known as wolfram, is a hard, dense metal with a high melting point. It is commonly used in applications that require high temperature strength, hardness, and wear resistance.

3D printing of tungsten and tungsten alloys is an emerging technology that allows for greater design freedom and cost-effective production of complex geometries. Some key details about 3D printed tungsten include:

- Tungsten has a density of 19.3 g/cm3, making it one of the densest metals. This gives 3D printed tungsten components high mass relative to size.

- Pure tungsten has a melting point of 3422°C, allowing it to maintain strength at very high temperatures.

- Tungsten is not easily machined by conventional methods due to its hardness. 3D printing circumvents this issue.

- Both laser powder bed fusion (L-PBF) and binder jetting can be used to 3D print tungsten and its alloys.

- Common applications utilize the heat and wear resistance of 3D printed tungsten components.

Equipment for 3D Printing Tungsten

| Type | Key Characteristics |

|---|---|

| Laser powder bed fusion (L-PBF) | Uses a laser to selectively melt powder material layer-by-layer. Provides high density parts with good mechanical properties. |

| Binder jetting | Deposits a liquid binding agent onto a powder bed to bind particles together. Lower density but more suitable for larger components. |

Materials for 3D Printing Tungsten

| Material | Properties | Applications |

|---|---|---|

| Pure tungsten | Highest melting point, density, hardness. Challenging to process. | Components needing high temperature strength. Radiation shielding. |

| Tungsten carbide | Extreme hardness, wears and cuts other materials. Brittle. | Cutting tools, dies, abrasion/erosion resistance. |

| Tungsten alloys | Tungsten alloys with cobalt, copper, iron, nickel, etc. Varying properties based on composition. | Electrical contacts, electrodes, heat sinks, weights. |

3D Printed Tungsten Specifications

| Parameter | Details |

|---|---|

| Part sizes | Up to several centimeters with L-PBF. Larger parts feasible with binder jetting. |

| Layer thickness | 15-100 μm typical |

| Surface finish | As-printed surface is rough, needs post-processing |

| Accuracy | Can achieve tolerances down to ±0.1-0.15% with proper calibration |

| Densities | ≥90% for L-PBF, ≥60% for binder jetting |

Suppliers of 3D Printed Tungsten

| Supplier | Key Details | Price Range |

|---|---|---|

| Company A | Specializes in L-PBF tungsten. Wide material selection. | $$$$ |

| Company B | Binder jetting and L-PBF. Large part sizes. | $$-$$$ |

| Company C | Research scale L-PBF. Small batch production. | $$$ |

Prices vary based on part size, production volume, material used, and other factors. Expect $50-$150 per cubic centimeter for moderate quantities of pure tungsten.

Applications of 3D Printed Tungsten

| Category | Uses |

|---|---|

| Radiation shielding | Block gamma rays, x-rays, neutrons. Used in medical and nuclear industries. |

| Electrical contacts | Resist arcing and wear. Copper-tungsten alloys common. |

| Ballasts | High density balances and stabilizes systems. |

| Cutting tools | Extreme hardness of tungsten carbide wears down other materials. |

| Fixtures and electrodes | Withstand high temps in furnaces, welding, lighting, and more. |

The high density, hardness, heat and wear resistance make tungsten suitable for many demanding applications. 3D printing enables complex, optimized geometries.

How to Choose a 3D Printed Tungsten Supplier

Choosing a reputable supplier is important when sourcing 3D printed tungsten parts. Here are key factors to consider:

- Experience – Look for an established company with years of experience in AM tungsten. They are more likely to produce high quality components consistently.

- Technical capabilities – The supplier should have in-depth knowledge of parameters, post-processing, etc. to 3D print tungsten well. Ensure they can meet your specifications.

- Quality certifications – Suppliers with ISO 9001 or other standards certification follow rigorous quality processes. This results in more reliable products.

- Industry reputation – Research online reviews and testimonials. Companies with good reputations often provide better customer service as well.

- Customization – Choose a supplier that offers customization if you need complex or unique part geometries.

- Lead time – Expect 1-4 weeks normally. Make sure supplier can deliver in your project timeline.

- Cost – Get price quotes from multiple suppliers. Consider part quantity, size, material, finish level, and other factors affecting cost.

- Customer support – Select a supplier that provides design support, answers questions, and helps resolve any issues.

Weigh factors like capabilities, quality, reputation, price, and service when deciding on a 3D printed tungsten supplier. Share detailed requirements and ask for sample parts to evaluate.

How to Design Parts for Optimal 3D Printed Tungsten Production

When designing components for 3D printed tungsten, consider these design guidelines:

- Minimize overhangs and angles below 30-45° to avoid supports and prevent defects like sagging.

- Include small radius fillets in corners to reduce stresses. Sharp corners can crack.

- Design wall thicknesses above ~0.8 mm to ensure full consolidation and prevent fractures.

- Avoid exceedingly fine features and surface details below 0.2-0.3 mm as they may not print accurately.

- Design symmetrical shapes and uniform wall thicknesses where possible to prevent warping and improve accuracy.

- Include tear-drop shaped end holes, slots, and other stress concentrators to minimize cracking.

- Position the part, orient layers, and arrange supports to minimize unsupported overhangs.

- Allow an additional 0.5-1 mm of stock material for post-processing like surface machining or grinding.

- Optimize for printability, functionality, post-processing, and performance requirements. Simpler is often better.

Work closely with your chosen supplier to finalize an optimal design configured for their specific process and parameters. Simpler geometries tend to print most reliably.

How to Post-Process 3D Printed Tungsten Parts

As-printed 3D tungsten components typically require post-processing to improve surface finish and achieve final dimensional accuracy. Common post-processing steps include:

- Support removal – Dissolve or carefully remove any support structures. This may use chemical baths, water jets, or manual tools.

- Surface machining – Conventional machining like turning, milling, and drilling improves precision and surface finish. Use rigid setups and adequate lubricant.

- Grinding – Both manual and automated grinding smooths surfaces. Silicon carbide or diamond abrasives work best for tungsten’s hardness.

- Lapping and polishing – Achieves precision flatness and angstrom-level surface finishes. Can also deburr edges.

- Heat treatment – Annealing relieves stresses and enhances ductility. Hot isostatic pressing further densifies any internal voids.

- Joining – Add threads, fasteners, or other components using welding, brazing, press fitting, adhesives and other methods.

- Coatings – Apply functional coatings like electroplating for corrosion protection, insulation, conductance, etc.

Work with experienced technicians familiar with machining tungsten during post-processing. Follow safety precautions due to risks like tungsten dust exposure.

Installing and Integrating 3D Printed Tungsten Components

3D printed tungsten parts often serve as components integrated into larger systems and assemblies. Here are best practices for installation:

- Handle parts carefully to avoid damage – tungsten is brittle. Use proper fixtures and tensioning.

- Clean surfaces thoroughly – any contamination can hinder performance. Use solvents compatible with tungsten.

- Use thermal management – preheating and controlled cooling prevents thermal shock cracks.

- Apply lubrication if needed – high-temp greases, oils, anti-seize, graphite, etc. Reduce galling and wear.

- Join properly – use suitable methods like press-fitting, brazing, or fasteners. Account for thermal expansion differences.

- Test functionality – cycle the part through operating temps, loads, duty cycles, and other live conditions.

- Monitor wear and lifespan – periodically inspect for any cracking, erosion, or performance deterioration.

Get input from engineers or technicians experienced with tungsten applications to integrate printed components successfully.

Operating and Maintaining 3D Printed Tungsten Parts

To achieve optimal performance from 3D printed tungsten, follow these usage and maintenance guidelines:

- Operate at recommended temperatures – maintain below recrystallization to prevent grain growth and loss of strength.

- Limit shock loading – tungsten is brittle. Avoid hammering, impact, and rapid heating/cooling.

- Check for wear and damage – inspect routinely for any cracks, chips, erosion, or component deformation.

- Clean with solvents – remove any built-up contaminants, debris, oxidation, grease, oils etc.

- Apply fresh high-temp lubrication – replenish dry or depleted lubricant films.

- Tighten fixtures – ensure no loosening over time under vibration or thermal cycling.

- Monitor electrical and thermal conductivity – detect any changes indicating material degradation.

- Consider spares or replacements – have backups available for any critical components prone to wear.

Consult operating manuals and seek guidance from experienced engineers or technicians when using 3D printed tungsten. Follow proper safety precautions.

Pros and Cons of 3D Printed Tungsten

There are both advantages and limitations to using 3D printed tungsten compared to conventional fabrication methods:

Advantages

- Design freedom for complex geometries not possible by machining

- Consolidation of sub-components into single printed parts

- Just-in-time production of custom parts on demand

- Low waste – use only required amount of material

- Lightweighting by optimizing designs for function rather than manufacturability

- Reduce assembly steps by integrating components directly in the print

Disadvantages

- Higher per-part cost for small quantities compared to mass production

- Restricted sizes based on printer build volume

- Lower strength and ductility than wrought tungsten due to porosity

- Post-processing often required to improve finish and tolerances

- High power consumption for melting tungsten’s high temperature metal powder

- Limited supplier base currently offering 3D printed tungsten

Weigh the benefits versus limitations relative to your specific application requirements when deciding on additive or traditional subtractive fabrication.

FAQ

Here are answers to some common questions about 3D printed tungsten:

Q: What alloys of tungsten can be 3D printed?

A: Common alloys include tungsten heavy alloys with nickel, copper, or iron and tungsten carbide grades with 6-15% cobalt binder. Small amounts of other alloying elements can also be added.

Q: What industries use 3D printed tungsten components?

A: Aerospace, defense, automotive, medical, energy, lighting, and other sectors use 3D printed tungsten where high strength, hardness, and temperature resistance are needed.

Q: How strong and durable are 3D printed tungsten parts?

A: When processed correctly, 3D printed tungsten can reach over 90% density and 500 HV hardness. Fatigue strength is lower than wrought forms but suitable for many applications.

Q: What safety precautions are needed for tungsten powder?

A: Tungsten powder should be handled in well-ventilated areas with dust collection systems. Respirators, gloves, and protective clothing are recommended when working with tungsten powder.

Q: Does 3D printed tungsten require heat treating or annealing?

A: Annealing around 1000-1200°C relieves stresses from the layer-by-layer buildup and improves ductility. HIP can further densify any internal voids.

Q: What surface finishes can be achieved on 3D printed tungsten?

A: As-printed surface roughness averages 15-20 μm Ra but machining and polishing can attain under 1 μm Ra finishes if required.

Q: Can you weld or braze 3D printed tungsten components?

A: Yes, welding or brazing of 3D printed tungsten is possible using suitable tungsten-compatible filler metals and procedures. Joint design must account for residual stresses.

Q: How long does it take to 3D print tungsten parts?

A: Print speeds are typically 5-20 mm/hr for tungsten depending on parameters, so a small part may take 5-40 hours. Larger parts can take multiple days to build.

know more 3D printing processes

Frequently Asked Questions (FAQ)

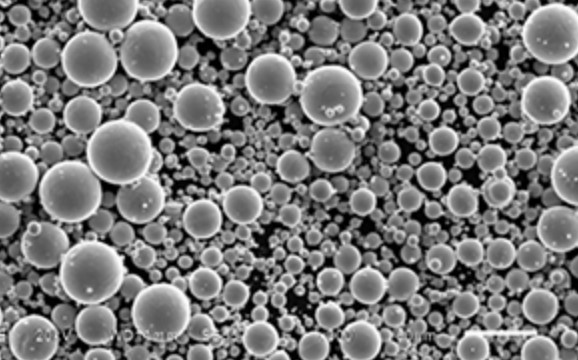

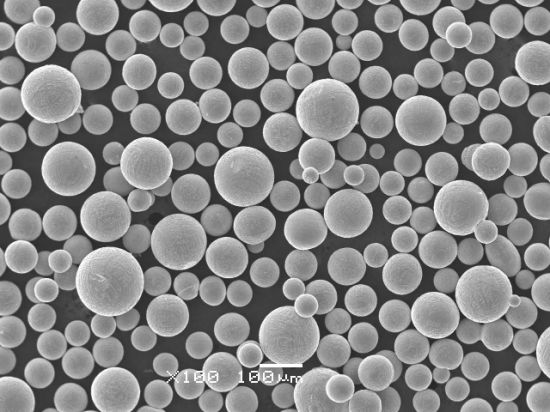

1) What powder specifications are critical for successful 3D Printed Tungsten in L-PBF and binder jetting?

- Spherical morphology, tight PSD (L-PBF: 15–45 μm; Binder Jet: 20–80 μm), low oxygen (≤0.05–0.10 wt% for structural parts), low carbon, and good flowability/tap density. For binder jetting, sinterability and green strength after debind are key.

2) How close can 3D Printed Tungsten get to wrought properties?

- With optimized parameters plus HIP, L-PBF tungsten commonly achieves ≥97–99% relative density, hardness 450–600 HV, and tensile strengths approaching wrought for some alloys; ductility remains lower due to grain morphology and residual impurities.

3) What design tactics reduce cracking in 3D Printed Tungsten?

- Elevated preheat (platform 600–900°C for L-PBF), lattice or graded sections to lower thermal gradients, generous fillets, minimized sharp corners, and scan strategies that avoid long continuous vectors.

4) When should I choose a tungsten heavy alloy (W-Ni-Fe/Cu) over pure tungsten?

- Select WHA when improved toughness and machinability are required, or when joining and impact loads are expected; use pure tungsten for maximum high-temperature strength, radiation shielding efficiency, or sputter/thermal applications.

5) What post-processing steps most improve performance?

- HIP to close internal porosity, stress relief/anneal (typically 1,000–1,200°C in vacuum/inert), precision grinding/polishing, and, where needed, diffusion bonding or brazing to integrate with other materials.

2025 Industry Trends: 3D Printed Tungsten

- High-temperature platforms: Wider availability of L-PBF systems with build plate preheat ≥800°C reduces cracking in pure tungsten.

- Binder jet maturation: Improved debind/sinter cycles deliver 92–96% density WHA components at lower cost for larger parts.

- Radiation and semiconductor tooling demand: Growth in custom shielding, collimators, wafer handling, and plasma-facing fixtures.

- Powder quality passports: Mandatory lot-level O/N/H, PSD, flow, and reuse count in COAs for regulated sectors.

- Sustainability: Hydrogen-enabled reduction lines and argon recirculation in atomization cut CO2e/kg and gas use.

2025 KPI Snapshot for 3D Printed Tungsten (indicative ranges)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| L-PBF build plate preheat (°C) | 400–700 | 700–900 | Reduces thermal stress/cracking |

| L-PBF relative density (pure W, %) | 94–98 | 97–99.5 | Parameter + HIP optimization |

| Binder jet final density (WHA, %) | 88–93 | 92–96 | Enhanced sinter cycles/additives |

| Oxygen in AM-grade W powder (wt%) | 0.08–0.15 | 0.04–0.10 | Improved inert handling/52907 |

| As-printed Ra (μm, vertical) | 18–30 | 14–22 | Contour + scan tuning |

| HIP time reduction vs 2023 (%) | — | 15–25 | Better powder and preheat |

References: ISO/ASTM 52907, ASTM E1019/E1409/E1447 (O/N/H), peer-reviewed AM tungsten studies, OEM application notes, NIST AM‑Bench

Latest Research Cases

Case Study 1: Crack-Resistant Pure Tungsten Heat Shields via High-Preheat L-PBF (2025)

Background: A fusion research lab needed thin-walled tungsten heat shields with minimal cracking and high dimensional stability.

Solution: Implemented 850°C plate preheat, short island scan strategy, and low-oxygen spherical powder (D50 ≈ 30 μm, O ≤ 600 ppm); post-HIP at 1,400°C and vacuum stress relief.

Results: Relative density 99.2%; cracking rate <2% of surface area (−70% vs prior process); warpage reduced 40%; service life in thermal cycling +28%.

Case Study 2: Binder Jet Tungsten Heavy Alloy Collimators for Medical Imaging (2024)

Background: An imaging OEM sought complex internal channels and reduced machining for patient-specific collimators.

Solution: Binder jetting W‑Ni‑Fe with tailored binder and catalytic debind; stepped sinter with support setters; selective machining on interfaces.

Results: Final density 94.5%; dimensional accuracy ±0.25%; internal channel surface roughness improved 22% after vibratory finishing; unit cost −18% vs machined WHA blocks.

Expert Opinions

- Prof. Susmita Bose, Materials Scientist, Washington State University

Key viewpoint: “High preheat and oxygen control are pivotal for pure tungsten in L-PBF; they determine crack suppression more than laser power alone.” - Dr. Brent Stucker, AM Industry Executive and Researcher

Key viewpoint: “Binder jetting of tungsten heavy alloys is maturing into serial production where geometry complexity and cost outweigh the absolute density of L-PBF.” - Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Powder passports linking PSD and O/N/H to CT porosity and mechanical data are accelerating cross-site qualification for 3D Printed Tungsten parts.” https://www.nist.gov/

Practical Tools/Resources

- ISO/ASTM 52907: Metal powder feedstock characterization

https://www.iso.org/standard/78974.html - ASTM E1019/E1409/E1447: Methods for O/N/H analysis in refractory metal powders

https://www.astm.org/ - NIST AM‑Bench: Datasets and benchmarks relevant to refractory metals in AM

https://www.nist.gov/ambench - IAEA Radiation Shielding Resources: Design considerations for high‑Z materials

https://www.iaea.org/ - Plansee Knowledge Base: Tungsten materials processing and data

https://www.plansee.com/ - OEM technical notes (GE Additive, ExOne/Desktop Metal) on L‑PBF and binder jet tungsten process windows

Last updated: 2025-08-27

Changelog: Added targeted FAQs, a 2025 KPI table for 3D Printed Tungsten, two recent case studies (L‑PBF heat shields; binder jet collimators), expert viewpoints, and curated tools/resources.

Next review date & triggers: 2026-03-31 or earlier if new high-preheat L‑PBF platforms ship, ISO/ASTM standards change, or substantial advances in binder jet tungsten densities are published.