Introduction

Copper titanium powder is an extremely useful material that offers numerous advantages across a wide variety of applications. This advanced powder is produced by mechanically alloying copper and titanium metal powders in precise ratios using ball milling. The resulting composite powder has unique properties that make it ideal for use in industries such as electronics, aerospace, automotive, and more.

Some of the key benefits of copper titanium powder include excellent thermal and electrical conductivity, low thermal expansion, high strength-to-weight ratio, corrosion resistance, and biocompatibility. This versatile powder can be used to 3D print complex parts, fabricate contacts and terminals, produce thermal management devices, develop high-performance alloys, and even create antimicrobial surfaces.

In this comprehensive guide, we will explore the many benefits and advantages of using copper titanium powder in detail.

High Thermal and Electrical Conductivity

One of the standout properties of copper titanium powder is its exceptional thermal and electrical conductivity. This is largely attributed to the high conductivity of copper combined with the stability of titanium.

Copper has the second highest thermal and electrical conductivity among pure metals, only behind silver. When alloyed with titanium, it retains this superior conductivity. The thermal conductivity of copper titanium alloys ranges from 120 to 220 W/m-K, while the electrical conductivity ranges from 2.2 to 5.8 x 10^7 S/m.

This high conductivity allows copper titanium powder to rapidly transfer heat and electricity. This makes it ideal for applications that involve dissipating heat and transmitting signals/power such as:

- Heat sinks

- Heat exchangers

- Motor armatures

- Electrical contacts and terminals

- Printed circuit boards

- Integrated circuit substrates

- Resistors

- Conductive wires and cables

The excellent conductivity of copper titanium powder provides improved efficiency and performance in electronics and electrical systems while allowing for faster heat dissipation in components prone to overheating.

Low Coefficient of Thermal Expansion

In addition to conductivity, copper titanium alloys also possess a low coefficient of thermal expansion (CTE). This means the material experiences minimal expansion or contraction when subjected to temperature fluctuations.

The CTE of copper titanium alloys ranges from 7 to 10 x 10^-6 K^-1 which is lower than pure titanium (8.6 x 10^-6 K^-1) and significantly lower than pure copper (16.7 x 10^-6 K^-1).

The minimal change in dimensions despite temperature changes makes copper titanium highly dimensionally stable. This is advantageous for applications where preserving original dimensions is critical over a wide operating temperature range.

Some examples include:

- Aeronautical and aerospace components

- Precision instruments

- Optoelectronic devices

- MEMS

- Disk drive components

- Lens mounts

The dimensional stability of copper titanium powder is especially useful for 3D printed parts in high-temperature environments. It allows intricate printed geometries to retain their shape without warping or deforming under thermal cycling.

High Strength-to-Weight Ratio

Copper titanium alloys deliver an exceptional combination of high strength and low density. When consolidated from powder form, copper titanium parts can achieve tensile strengths over 1 GPa while having densities between 4.1-4.5 g/cm3.

This gives copper titanium one of the highest strength-to-weight ratios among metal alloys, exceeding aluminum, magnesium, and even titanium alloys. The high-strength lightweight nature makes copper titanium an excellent choice for applications where reducing weight is critical.

Some examples include:

- Aircraft and aerospace components

- Automotive parts

- Biomedical implants

- Orthopedic devices

- Sporting goods

- High-performance rotating parts

The high strength and low density allow substantial weight savings over traditional alloy options. This leads to improved fuel efficiency, higher speeds, greater load capacity, and reduced wear in moving parts.

Excellent Corrosion Resistance

Copper titanium powder affords good corrosion resistance comparable to stainless steel in most environments. This is due to the passivating oxide layer that forms readily on the titanium in the alloy.

The stable and dense titanium oxide barrier protects the underlying metal from chemical attack. This prevents deterioration from moisture, salts, acids, bases, organic chemicals, and other corrosive compounds.

The corrosion resistance of copper titanium makes it well-suited for uses such as:

- Marine hardware

- Chemical processing equipment

- Biomedical implants

- Surgical tools

- Jewelry

- Cookware

- Decorative trim

- Plating for mirrors and optics

Copper titanium can withstand environmental exposure better than many competing alloys, providing long-lasting performance and aesthetics.

Biocompatibility and Antimicrobial Ability

Copper titanium powder has proven biocompatible and capable of eliminating bacteria. This is due to the presence of both copper and titanium, two metals known for their antimicrobial properties.

Titanium itself is highly biocompatible and resistant to bacterial growth. The titanium oxide layer prevents bacteria from adhering and colonizing the surface. Copper is also toxic to microbes and actively kills bacteria on contact by penetrating cell membranes.

Together these effects make copper titanium highly antimicrobial and ideal for medical uses such as:

- Surgical tools and implants

- Medical devices and equipment

- Healthcare facility surfaces

- Wound dressings

- Textiles

- Paints and coatings

The antimicrobial properties inhibit the spread of dangerous bacteria like E. coli, S. aureus, and Salmonella in both community and healthcare settings. This helps reduce infections, cross-contamination, and improve medical outcomes.

Wide Range of Alloy Compositions

A major advantage of copper titanium powder is the ability to tailor alloy compositions to achieve specific material properties. By adjusting the ratios of copper and titanium, the thermal, electrical, mechanical, and physical characteristics can be dialed in based on application requirements.

Copper contents typically range from 10% to 50% by weight, with the remainder as titanium. Some common copper-titanium ratios include Cu-10Ti, Cu-15Ti, Cu-30Ti, and Cu-50Ti.

Higher copper concentrations increase conductivity and ductility at the expense of strength and oxidation resistance. More titanium content improves high-temperature performance. Optimal combinations are chosen based on the intended operating conditions and priorities.

The wide alloying range enables copper titanium powder to meet the needs of diverse applications across industries. It can match or exceed the capabilities of conventional alloys through compositional adjustments.

Excellent Printability for Additive Manufacturing

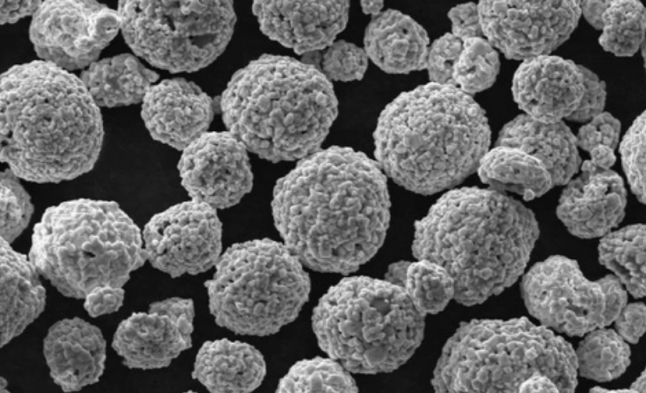

Copper titanium powder is perfectly suited for additive manufacturing (AM) methods like direct metal laser sintering (DMLS) and electron beam melting (EBM). It possesses all the ideal powder characteristics:

- Spherical morphology

- Narrow particle size distribution

- Good flowability

- High packing density

These properties allow the powder to be smoothly and uniformly spread in thin layers during printing. The excellent flow prevents agglomeration and clogging while the spherical shape and distribution maximizes laser/electron beam absorption for superior melting and fusion.

Parts 3D printed from copper titanium powder can achieve exceptional mechanical properties exceeding cast and wrought alloys. Some examples include:

- Tensile strength over 1 GPa

- Yield strength over 500 MPa

- Elongation over 25%

- High hardness over 300 HV

This allows lightweight customized parts with optimized geometries impossible through conventional fabrication routes. Copper titanium is also very amenable to post-processing like heat treatment, hot isostatic pressing, and metal injection molding to further enhance mechanical performance.

Overall, the printability of copper titanium powder makes it viable for complex mission-critical aerospace, automotive, and medical components.

Can Be Combined with Other Particulates

A further advantage of copper titanium powder is the ability to incorporate secondary particulate additives like carbides, nitrides, oxides, borides, and ceramics. Introducing these particles can further augment the properties and capabilities.

For example, adding reinforcements like silicon carbide, tungsten carbide, or titanium carbide can significantly improve hardness, wear resistance, thermal conductivity, and high-temperature strength. Reinforcements are commonly 5-15% by volume.

Oxide ceramics like aluminum oxide, calcium oxide, or magnesium oxide can provide increased oxidation resistance and insulation at elevated temperatures. Diamonds can also be added for enhanced thermal management and dielectric properties.

By combining the tailored base alloy composition with secondary phases, the properties of copper titanium can be highly customized for specialized applications and operating environments. This expands the utility across even more industrial sectors.

Environmentally Friendly and Sustainable

Copper titanium powder offers environmental advantages over competing powder metallurgy materials. Both copper and titanium are earth-abundant metals with much lower environmental footprints than less common alloys based on elements like cobalt, nickel, chromium etc.

The primary materials can be continually recycled from end-of-life products. Copper titanium scrap can be easily reprocessed back into powder feedstock via atomization. The high value recycling potential increases sustainability and protects scarce resources.

Parts fabricated using AM methods also have a smaller environmental impact than traditional processes like casting and machining. 3D printing reduces material waste, energy use, and carbon emissions. It enables on-demand production of only the required amount of material.

Overall, the eco-friendly and renewable nature of copper titanium powder makes it an attractive choice as manufacturers aim to reduce environmental impacts.

Cost-Effectiveness

Despite the impressive characteristics, copper titanium powder remains very cost-effective compared to many competing advanced alloys. The base elements of copper and titanium are relatively inexpensive commercial metals.

The mechanical alloying production method is a high-yield and low-cost powder metallurgy process. It does not require complex chemical reactions or expensive raw materials. Parts can be economically produced in AM machines at industrial-scale.

The result is that copper titanium powder can match or outperform the properties of far more expensive metal powders like nickel alloys, refractory metals, and superalloys. This makes it accessible for cost-sensitive industries and large-scale production.

Applications of Copper Titanium Powder

The combination of properties make copper titanium powder suitable for a diverse range of applications across industries such as:

Aerospace

- Jet engine components – blades, nozzles, housings

- Structural airframe parts

- Guidance systems

- Thermal management devices

- Aircraft wiring

Automotive

- Turbocharger wheels

- Exhaust components

- Rotors and armatures

- Bushings and bearings

- Brake pads

- Headlight connectors

Biomedical

- Surgical tools

- Orthopedic implants – knees, hips

- Dental implants

- External prosthetics

- Medical electrodes

Electrical

- Connectors and contacts

- Circuit board vias

- Resistors

- Cables and wiring

Marine

- Propellers and impellers

- Corrosion-resistant fasteners

- Pipeline components

- Superconducting ship magnets

Summary

In summary, copper titanium powder has emerged as an advanced engineering material that offers exceptional thermal, electrical, mechanical, and antimicrobial properties. It outperforms conventional alloys in conductivity, strength, stability, biocompatibility, and printability.

The wide range of achievable alloy compositions enables the properties of copper titanium powder to be tailored for diverse applications across critical industries. It also has sustainability and cost benefits over many competing alloy options.

As metal additive manufacturing continues proliferating, so will the use cases and capabilities of this multipurpose alloy. Copper titanium powder is an essential material helping enable the next generation of lightweight, efficient, and high-performance components across sectors.

FAQ

Here are some common questions about the advantages of copper titanium powder:

What makes copper titanium advantageous for thermal management?

The high thermal conductivity, low thermal expansion, and good oxidation resistance make copper titanium ideal for thermal management applications. It rapidly conducts heat away from sources and has dimensional stability in temperature cycling.

Why is the strength-to-weight ratio of copper titanium powder useful?

The combination of high strength and low density gives copper titanium one of the highest strength-to-weight ratios which allows substantial weight reduction. This improves performance in aerospace, automotive, and other weight-critical uses.

How does copper titanium improve corrosion resistance versus pure copper?

Pure copper corrodes readily but the titanium in the alloy forms a stable protective oxide layer that greatly increases corrosion resistance, comparable to stainless steel. This allows uses in harsh environments.

What makes copper titanium suitable for biomedical implants?

Both copper and titanium have antimicrobial properties that fight bacteria growth. Titanium also forms a biocompatible oxide layer. This prevents infection and improves safety in surgical implants.

How are properties adjusted in copper titanium powder alloys?

By varying the ratio of copper (10-50% wt.) to titanium, the thermal, electrical, and mechanical properties can be tuned to match different design requirements.

Why is copper titanium good for 3D printing?

The spherical powder morphology, flowability, and laser absorption are ideal for powder bed fusion 3D printing. This enables complex geometries with enhanced mechanical properties compared to conventional processing.

Does copper titanium have sustainability benefits?

Copper and titanium are abundant and recyclable metals. AM methods also produce less waste. This improves sustainability compared to other engineering alloys based on scarcer elements.

What are some automotive uses for copper titanium?

Copper titanium is used in turbocharger wheels, exhaust components, brake pads, rotors, and other high heat parts that benefit from its thermal stability, strength, and conductivity.

Can copper titanium be alloyed with other materials?

Yes, particulates like carbides, nitrides, ceramics etc. can be incorporated to further augment properties like hardness, wear resistance, and high temperature performance.

Is copper titanium powder cost-effective?

Copper titanium powder is inexpensive compared to many advanced alloys because copper and titanium are abundant commercial metals and processing uses efficient methods.