1. Introduction

In the ever-evolving field of manufacturing, additive manufacturing, also known as 3D printing, has emerged as a groundbreaking technology. It enables the creation of complex objects layer by layer, offering unparalleled design freedom and efficiency. At the heart of this technology lies additive manufacturing powders, the key building blocks that make the magic happen.

2. What is Additive Manufacturing?

Additive manufacturing is a process of fabricating three-dimensional objects by adding material layer by layer, as opposed to traditional subtractive methods that involve cutting, drilling, or shaping a block of material. This transformative technology has found applications in various industries, including aerospace, automotive, healthcare, and consumer goods.

3. The Role of Powders in Additive Manufacturing

Additive manufacturing powders play a pivotal role in the success of the 3D printing process. These powders, composed of various materials such as metals, polymers, and ceramics, serve as the feedstock for creating intricate and precise parts. The choice of powder material significantly impacts the final product’s properties, including strength, durability, and appearance.

4. Types of Additive Manufacturing Powders

4.1 Metal Powders

Metal powders are widely used in additive manufacturing to produce functional and structural components. Metals such as aluminum, titanium, stainless steel, and nickel-based alloys find applications in industries requiring high-performance parts, like aerospace and medical implants.

4.2 Polymer Powders

Polymer powders are popular in additive manufacturing due to their versatility, ease of use, and cost-effectiveness. These powders consist of various thermoplastics, including ABS, PLA, and nylon, and are commonly used in industries such as consumer goods, prototyping, and healthcare.

4.3 Ceramic Powders

Ceramic powders enable the production of objects with exceptional thermal, electrical, and mechanical properties. Additive manufacturing with ceramics finds applications in industries such as electronics, aerospace, and automotive, where high-temperature stability and wear resistance are crucial. Ceramic powders like alumina, zirconia, and silicon carbide are commonly used in additive manufacturing processes.

5. Powder Properties for Additive Manufacturing

To ensure successful additive manufacturing, several powder properties must be carefully considered:

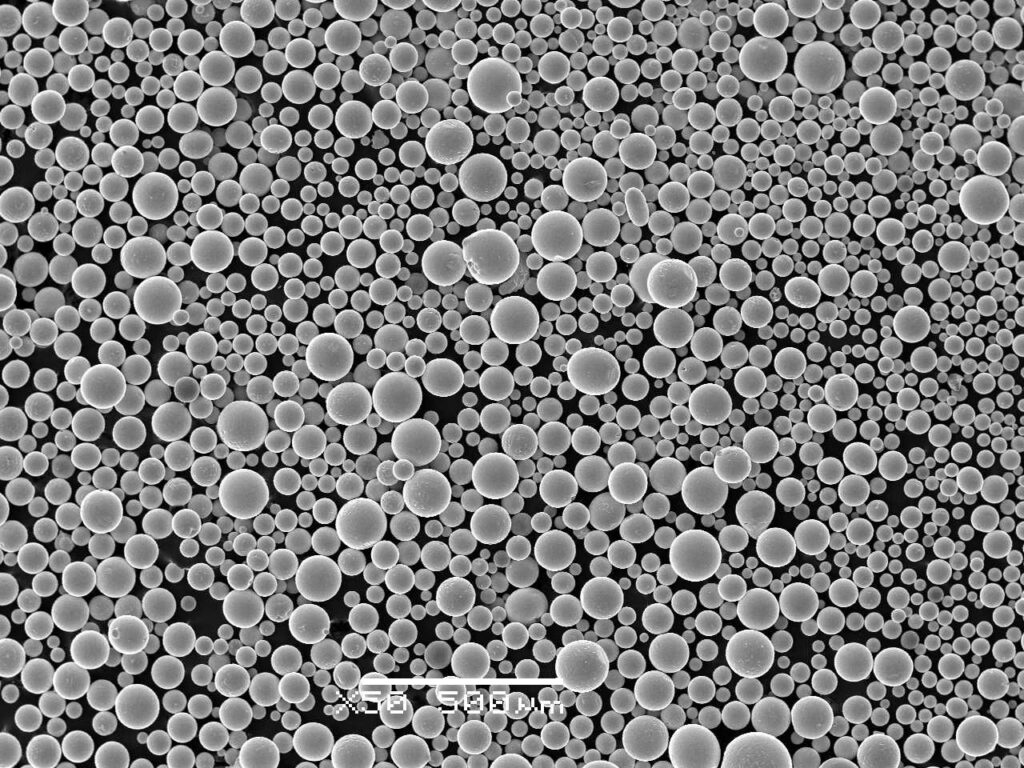

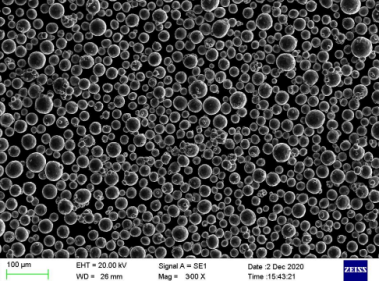

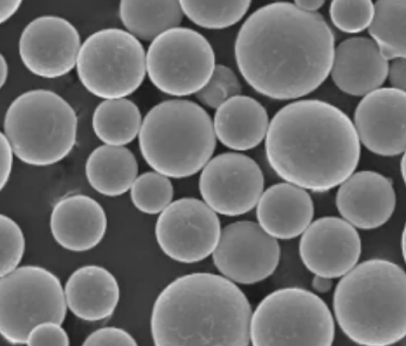

5.1 Particle Size and Distribution

The particle size and distribution of the powder have a direct impact on the printed object’s resolution and surface quality. Fine powders with a narrow size distribution are preferred for achieving high levels of detail and accuracy.

5.2 Powder Flowability

Good powder flowability is essential for uniform powder spreading and layer formation during the 3D printing process. Powders with poor flowability can lead to defects, such as uneven layer thickness or incomplete filling of complex geometries.

5.3 Powder Density

Powder density affects the packing efficiency and porosity of the printed parts. Optimal powder density ensures the desired mechanical properties and dimensional accuracy of the final product.

5.4 Powder Morphology

Powder morphology, including shape and surface characteristics, influences powder flowability, packing behavior, and interparticle interactions. Spherical or irregularly shaped powders have different flow and compaction characteristics.

5.5 Chemical Composition

The chemical composition of the powder material determines the properties of the final printed part. Different alloys or polymers offer unique mechanical, thermal, and electrical characteristics, allowing for a wide range of applications.

5.6 Contamination and Purity

Contamination in powders can lead to defects and compromised material properties. It is crucial to ensure high levels of purity and minimize impurities, such as foreign particles, oxides, or moisture.

5.7 Moisture Content

Moisture content in powders can adversely affect the printing process and the quality of the printed parts. Controlling and monitoring moisture levels is vital to prevent defects like porosity and cracking.

6. Powder Preparation for Additive Manufacturing

To optimize powder performance in additive manufacturing, proper powder preparation techniques are employed:

6.1 Atomization

Atomization is the primary method for producing metal powders used in additive manufacturing. It involves the conversion of molten metal into fine droplets through processes like gas or water atomization.

6.2 Gas or Water Atomization

Gas atomization involves spraying molten metal with high-pressure gas, resulting in the formation of fine powder particles. Water atomization, on the other hand, utilizes water jets to break up the molten metal stream into droplets that solidify into powder.

6.3 Powder Blending and Sieving

Powder blending ensures homogeneity and consistency of the powder composition, especially in the case of metal alloys. Sieving is performed to remove oversized or undersized particles, ensuring a desired particle size range.

7. Powder Handling and Storage

Proper handling and storage of additive manufacturing powders are critical to maintain their quality and performance:

7.1 Environmental Control

Powders should be stored in controlled environments, free from moisture, contaminants, and temperature fluctuations. Humidity and temperature can affect powder properties, such as flowability and reactivity.

7.2 Moisture Control

Moisture absorption by powders can lead to powder clumping, agglomeration, and reduced flowability. Storage conditions with low humidity levels and moisture-resistant packaging help mitigate moisture-related issues.

7.3 Contamination Prevention

Strict cleanliness measures must be implemented to prevent cross-contamination between different powder materials. Dedicated storage containers, handling equipment, and procedures should be in place to avoid mixing powders.

7.4 Segregation Prevention

Powder segregation, where particles separate based on size or density, can occur during handling or storage. Regular gentle mixing or blending of powders helps prevent segregation and ensures a consistent powder composition for reliable printing results.

8. Quality Control in Additive Manufacturing Powders

Maintaining quality control in additive manufacturing powders is crucial for achieving consistent and reliable print outcomes:

8.1 Testing and Characterization

Thorough testing and characterization of powders help assess their suitability for additive manufacturing. Techniques such as particle size analysis, flowability testing, chemical analysis, and mechanical testing ensure compliance with desired specifications.

8.2 Certification and Standards

Certification programs and industry standards play a vital role in ensuring the quality and reliability of additive manufacturing powders. Adhering to recognized certifications and standards provides confidence in the material’s performance and compatibility.

8.3 Traceability

Establishing traceability systems helps track the origin, processing, and handling of additive manufacturing powders. This traceability ensures accountability and allows for identification and resolution of any quality issues that may arise.

9. Challenges in Additive Manufacturing Powders

Despite the significant advancements in additive manufacturing powders, several challenges remain:

9.1 Powder Reuse and Recycling

Efficient powder reuse and recycling strategies are necessary to minimize waste and reduce costs. Developing methods to recover and reprocess unused or excess powders can contribute to sustainability and cost-effectiveness.

9.2 Material Compatibility

Not all materials are suitable for additive manufacturing. Compatibility between powders and printing processes must be considered to ensure optimal results. Material development and testing are ongoing to expand the range of printable materials.

9.3 Powder Degradation

Repeated usage and exposure to environmental factors can lead to powder degradation. Factors such as oxidation, moisture absorption, and particle breakage can impact powder performance and require careful monitoring and handling.

9.4 Cost and Availability

Certain powders, especially specialized or rare materials, can be expensive and may have limited availability. Balancing the cost and availability of powders with desired material properties is a challenge that the industry continues to address.

10. Future Trends in Additive Manufacturing Powders

The field of additive manufacturing powders is continually evolving, and several exciting trends are shaping its future:

- Advancements in powder atomization techniques to produce powders with tailored properties and improved quality.

- Development of new materials, including hybrid powders and composites, expanding the range of applications.

- Integration of smart materials with functionalities like sensing, self-healing, or shape-memory properties, enabling innovative designs and applications.

- Enhanced powder recycling and sustainability measures to reduce waste and promote a circular economy.

- Continued research and development in powder characterization and quality control techniques for more precise and reliable printing processes.

11. Conclusion

Additive manufacturing powders are indispensable components that drive the success of 3D printing technology. The careful selection, handling, and preparation of powders, along with quality control measures, ensure optimal print outcomes. Despite challenges, ongoing research and advancements in powder materials and processing techniques promise a future of expanded possibilities and applications in additive manufacturing.

FAQs (Frequently Asked Questions)

What are additive manufacturing powders?

Additive manufacturing powders are materials, such as metals, polymers, or ceramics, in powdered form, used as the feedstock for 3D printing processes.

How do powder properties affect additive manufacturing?

Powder properties, such as particle size, density, flowability, and chemical composition, directly impact the resolution, strength, and overall quality of the printed objects.

What are the challenges in additive manufacturing powders?

Some challenges include powder reuse and recycling, material compatibility, powder degradation, and balancing cost and availability of specialized powders.

What is the future of additive manufacturing powders?

The future trends include advancements in powder atomization, development of new materials and composites, integration of smart materials, improved powder recycling and sustainability measures, and ongoing research in powder characterization and quality control.

Additional FAQs About Additive Manufacturing Powders

1) What powder characteristics most influence print quality across AM processes?

- Particle size distribution (PSD), morphology/sphericity, flow (Hall/Carney), apparent/tap density, and interstitials (O/N/H). These affect recoating uniformity, green density, sintering/fusion behavior, and final porosity.

2) How should powder reuse be managed without degrading properties?

- Set reuse limits (often 5–10 cycles for LPBF; 2–3 for BJ), sieve between builds, trend O/N/H, PSD, flow, and density; refresh with virgin powder at defined thresholds. Keep genealogy and lot traceability.

3) When are water‑atomized powders acceptable versus gas/vacuum atomized?

- Water‑atomized: ideal for Binder Jetting and press‑and‑sinter/MIM due to cost; typically higher oxide and irregular shape. Gas/vacuum atomized (including VGA/EIGA/PREP): preferred for LPBF/EBM for sphericity, low satellites, and lower oxygen.

4) What storage conditions best preserve powder quality?

- Dry, inert, and cool environments with sealed packaging (low dew point Ar/N2), desiccants, and minimal handling. Avoid condensation and cross‑contamination; use dedicated tools per alloy family.

5) Which certificates and standards should buyers require from suppliers?

- Certificate of Analysis (chemistry, PSD D10/D50/D90, flow, apparent/tap density, O/N/H; for AM: sphericity/satellite %, CT hollow fraction), ISO/ASTM 52907/52908 compliance, and relevant ASTM/MPIF test reports.

2025 Industry Trends for Additive Manufacturing Powders

- Transparency on CoAs: Routine reporting of image‑based sphericity/satellite % and CT‑measured hollow fractions alongside O/N/H and PSD.

- Sustainability and cost: Argon recirculation, higher revert use, and regional atomization reduce LCA and stabilize pricing.

- Binder jet scale‑up: Bimodal PSD steels/Cu achieving 97–99.5% density post‑sinter; HIP reserved for critical parts.

- Materials expansion: Corrosion‑optimized stainless grades, high‑conductivity Cu alloys, and refractory blends broaden end‑use.

- In‑process monitoring: Closed‑loop gas‑to‑metal ratio and melt superheat control reduce satellites and improve yield.

2025 Market and Technical Snapshot (Additive Manufacturing Powders)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Gas‑atomized 316L price | $10–$18/kg | −2–5% | Supplier/distributor indices |

| Gas‑atomized 17‑4PH price | $12–$20/kg | −2–5% | PSD/alloy dependent |

| Ti‑6Al‑4V AM‑grade price | $150–$280/kg | −3–7% | Aerospace/medical grades |

| Common PSD cuts (LPBF/BJ/DED) | 15–45 or 20–63 µm / 20–80+ µm / 53–150 µm | Stable | OEM guidance |

| Sphericity (image analysis) | ≥0.93–0.98 | Slightly up | Supplier CoAs |

| Satellite fraction (image) | ≤3–6% | Down | Atomization tuning |

| CT hollow particle fraction | 0.5–1.5% | Down | VGA/EIGA adoption |

| Validated LPBF reuse cycles | 5–10 | Up | O/N/H trending + sieving |

| Binder jet sintered density (steels) | 97–99.5% | Up | Bimodal PSD/HIP optional |

Indicative sources:

- ISO/ASTM 52907 (Metal powders), 52908 (AM process qualification): https://www.iso.org | https://www.astm.org

- ASTM B214/B213/B212/B962 (powder tests), MPIF 35 (MIM properties): https://www.astm.org | https://www.mpif.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; Additive Manufacturing; Stainless/Titanium/Nickel): https://www.asminternational.org

- NFPA 484 (Combustible metal dusts): https://www.nfpa.org

Latest Research Cases

Case Study 1: Low‑Oxygen 316L for LPBF Medical Components (2025)

Background: A medical OEM needed tighter corrosion/fatigue performance and smoother as‑built surfaces for implant‑adjacent tools.

Solution: Adopted vacuum gas‑atomized 316L (O 0.04 wt%, sphericity 0.96, PSD 20–63 µm); implemented electropolish + passivation; HIP only for thick sections.

Results: Non‑HIP coupons achieved 99.9% density; pitting potential improved by 120 mV (ASTM G150); HCF life increased 1.6× at R=0.1; Ra reduced from 10.5 to 3.2 µm.

Case Study 2: Binder Jet 17‑4PH Gears via Bimodal PSD (2024)

Background: An industrial drivetrain supplier targeted cost‑down on mid‑volume gears without sacrificing strength.

Solution: Engineered bimodal water‑atomized 17‑4PH; solvent debind + H2/N2 sinter; H900‑equivalent aging; selective HIP for safety‑critical SKUs.

Results: 98.8–99.3% final density; tensile met spec; dimensional Cp/Cpk +25%; cost −22% vs. subtractive; throughput +30%.

Expert Opinions

- Prof. Diran Apelian, Distinguished Professor (emeritus), Metal Processing

Key viewpoint: “Powder quality ceiling is set upstream—melt cleanliness and stable atomization dynamics matter more than aggressive post‑screening.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Sphericity, satellite %, and CT‑measured hollows on CoAs are now leading indicators for PBF defect propensity and should be standard.” - Prof. Todd Palmer, Materials Science, Penn State (AM/steels)

Key viewpoint: “For precipitation‑hardening steels like 17‑4PH, disciplined heat treatment and nitrogen/oxygen control are pivotal to reach target strength and corrosion resistance.”

Note: Viewpoints synthesized from public literature and talks; affiliations are publicly known.

Practical Tools and Resources

- Standards and test methods

- ISO/ASTM 52907, 52908; ASTM B214 (sieve), B213 (flow), B212 (apparent density), B962 (tap density); MPIF 35 (MIM): https://www.iso.org | https://www.astm.org | https://www.mpif.org

- Metrology and safety

- NIST powder characterization resources; LECO O/N/H analyzers; industrial CT for hollow/satellite quantification: https://www.nist.gov

- NFPA 484 guidance for combustible metal powders: https://www.nfpa.org

- Technical references

- ASM Digital Library (Powder Metallurgy; Additive Manufacturing; Stainless/Titanium/Nickel): https://www.asminternational.org

- Buyer’s QC checklist

- CoA completeness (chemistry, PSD, flow, densities, O/N/H, sphericity, satellites, hollows), genealogy/traceability, SPC dashboards, sample builds/sinter coupons, local inventory and refresh policies

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; created a 2025 market/technical snapshot table with sources; included two recent case studies; compiled expert viewpoints; curated tools/resources for Additive Manufacturing Powders

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM/MPIF standards update, major OEMs revise AM powder specs, or new NIST/ASM datasets link morphology/interstitials to defect rates and fatigue/corrosion performance