Overview of Additive Manufacturing Powder

Additive manufacturing, also known as 3D printing, utilizes various materials in powder form to construct parts and products layer by layer. The type of powder selected depends on the specific additive manufacturing process being used, as well as the desired characteristics of the finished part.

Some of the key types of additive manufacturing powders include:

- Metal Powders – Used in powder bed fusion and directed energy deposition processes. Common materials include titanium, aluminum, steel, nickel alloys, and cobalt-chrome.

- Polymer Powders – Used in powder bed fusion and material jetting processes. Common materials include nylon, ABS, polycarbonate, polystyrene, and thermoplastic polyurethane.

- Ceramic Powders – Used in binder jetting and material extrusion processes. Common materials include silica, alumina, zirconia, and porcelain.

- Sand and Casting Powders – Used in binder jetting processes to create molds and cores for metal castings. Usually silica-based.

- Biocompatible and Bioactive Powders – Used in medical applications. Common materials include titanium, hydroxyapatite, and tricalcium phosphate.

The characteristics of additive manufacturing powders can significantly influence the properties, quality, accuracy, and performance of printed parts. Key powder properties include:

Additive Manufacturing Powder Composition

Additive manufacturing utilizes metallic, polymeric, ceramic, sand, and other powder materials with specific compositions tailored to various printing processes.

Metal Powders

| Type | Common Compositions |

|---|---|

| Titanium alloys | Ti-6Al-4V, Ti-6Al-7Nb, Ti-Al-Fe, Ti-Al-Mn, Ti-Al-Sn |

| Aluminum alloys | AlSi10Mg, AlSi12, Scalmalloy |

| Steel alloys | 17-4PH, 316L, 304L, 4140 |

| Nickel alloys | Inconel 625, 718; Hastelloy X |

| Cobalt-chrome | CoCrMo |

Polymer Powders

| Type | Common Compositions |

|---|---|

| Nylon | Nylon 11, Nylon 12 |

| ABS | Acrylonitrile butadiene styrene |

| Polycarbonate | Bisphenol A polycarbonate |

| Polystyrene | PS, High impact PS |

| Thermoplastic Polyurethane | TPU |

Ceramic Powders

| Type | Common Compositions |

|---|---|

| Silica | Fused quartz, cristobalite |

| Alumina | Al2O3 |

| Zirconia | ZrO2, YSZ (yttria stabilized) |

| Porcelain | Mix of glass, clay and feldspar |

Sand and Casting Powders

| Type | Compositions |

|---|---|

| Silica sand | Mostly SiO2, with traces of metal oxides and nonmetal oxides |

| Zircon sand | Zirconium silicate |

| Olivine sand | Magnesium iron silicate |

| Chromite sand | Iron chromium oxide |

Bioactive and Biocompatible Powders

| Type | Common Compositions |

|---|---|

| Titanium and alloys | Pure titanium, Ti-6Al-4V |

| Hydroxyapatite | Ca10(PO4)6(OH)2 |

| Tricalcium phosphate | Ca3(PO4)2 |

Additive Manufacturing Powder Properties

The key properties of additive manufacturing powders that influence part quality and process performance include:

| Property | Description | Significance |

|---|---|---|

| Particle size distribution | Range and distribution of powder particle dimensions | Affects powder flowability, packing density, layer uniformity, resolution |

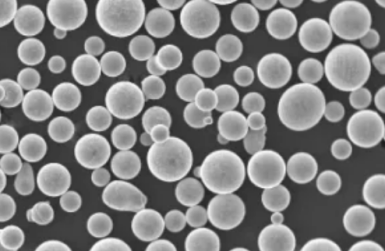

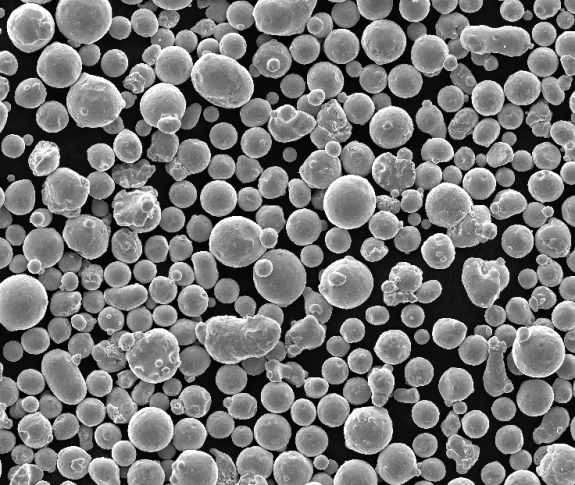

| Morphology and shape | Aspect ratio and shape factors of powder particles | Impacts spreading, packing density, powder flow |

| Density | Mass to volume ratio of the bulk powder | Determines weight and dimensional accuracy of parts |

| Flowability | Ability of powder to flow freely under applied stress | Vital for uniform spreading and recoating of powder layers |

| Moisture content | Percentage water content in the powder | High moisture causes powder agglomerations and printing defects |

| Chemical composition | Elemental composition and phases present | Defines mechanical properties, microstructure, and performance of finished parts |

Additive Manufacturing Powder Applications

Additive manufacturing powders are used to print functional components across major industries:

| Industry | Applications | Materials Used |

|---|---|---|

| Aerospace | Turbine blades, aircraft components, rocket engines | Titanium alloys, nickel alloys, aluminum alloys, cobalt chrome |

| Automotive | Prototyping, production of parts like gears, brackets | Aluminum alloys, nylon, ABS |

| Medical | Dental copings, implants, surgical instruments | Titanium alloys, cobalt chrome, stainless steel |

| Consumer | Jewelry, decorative objects, lighting fixtures | Precious metals like gold, silver; polymers |

Additive Manufacturing Powder Specifications

Powder materials used in specific additive manufacturing process conform to certain size, composition, property thresholds:

| Process | Particle Size | Alloy Grade | Standards |

|---|---|---|---|

| Powder bed fusion | 15-45 microns | Ti-6Al-4V ELI per ASTM F3001 | ASTM F3049, ASTM F2924, ASTM F2971 |

| Binder jetting | 20-60 microns | 420 or 316 stainless steel | ASTM F3301, MPIF 35 |

| Material jetting | 5-25 microns | 60-65 Shore D polyurethane | – |

| Directed energy deposition | 45-150 microns | Inconel 718, 316L stainless steel | ASTM F3055, ASTM F3302 |

Additive Manufacturing Powder Suppliers

There is a robust network of suppliers offering a wide array of metal, polymer, ceramic and composite additive manufacturing powders:

| Company | Powder Materials | Cost Range |

|---|---|---|

| LPW Technology | Titanium alloys, aluminum alloys, stainless steel, nickel alloys | $100-$500 per kg |

| Sandvik Osprey | Stainless steel alloys, nickel alloys, cobalt alloys | $50-$250 per kg |

| Advanced Powders & Coatings | Nylon-based polymers, PEEK, PEKK | $80-$600 per kg |

| The ExOne Company | Stainless steel, tool steel, tungsten carbide, Inconel 625 | $75-$1000 per kg |

| Höganäs | Stainless steel, iron-based alloys | $30-$150 per kg |

| Kennametal | Tungsten carbide-cobalt, 17-4PH stainless | $100-$1200 per kg |

| 3DCeram | Alumina ceramic, zirconia ceramic, silica | $100-$250 per kg |

Comparison Between Additive Manufacturing Powders

There are considerable differences between various powder options regarding production processes, cost, part properties and quality:

| Parameter | Polymer Powder | Metal Powder | Ceramic Powder |

|---|---|---|---|

| Build rate | Medium | Slow | Fast |

| Resolution | Medium | High | Medium to low |

| Part strength | Low to medium | Very high | Medium to high |

| Part accuracy | Medium | Medium to high | Low to medium |

| Surface finish | Medium | High | Low to medium |

| Thermal properties | Low melting point, low conductivity | High melting point, high conductivity | High melting point, low conductivity |

| Cost per part | Low to medium | High | Medium |

| Post-processing | Minimal | Extensive | Medium |

Advantages of Using Powder Bed Additive Manufacturing

Some of the major advantages of using powder bed technology for manufacturing parts include:

- Ability to create complex, lightweight geometries not possible with casting or machining

- Minimal raw material waste since unused powder is recycled

- Does not require dedicated tooling or molds, allowing rapid prototyping

- Parts show high strength, durability, heat and corrosion resistance matching wrought materials

- Porosity and microstructure can be easily controlled

- Multiple materials and alloys, even graded compositions are printable

- Just-in-time production with minimal lead times is enabled

Limitations of Powder Bed Additive Manufacturing

Some drawbacks associated with powder bed additive manufacturing that need to be considered:

- High equipment and operational costs compared to other processes

- Additional post-processing like Hot Isostatic Pressing is often essential

- Powder handling procedures and equipment require special attention

- Printing of certain flexible polymers and rubber-like materials poses challenges

- Not ideal for very high volume and mass production scenarios

- Size constraints posed by build chamber dimensions may require redesigning large parts

FAQ

Q: What is the most commonly used metal powder for additive manufacturing?

A: Titanium alloys like Ti-6Al-4V are one of the most popular metal powders, due to their high strength to weight ratio and biocompatibility. Aluminum alloys, stainless steels, cobalt chrome, and nickel superalloys are also very commonly used.

Q: How fine are the powders used in AM processes?

A: The typical size range is 10-100 microns, though some processes can use ultrafine 1-10 micron nano powders. Finer powders below 20 microns result in better resolution and accuracy.

Q: What affects the pricing of additive manufacturing powders?

A: Raw material costs, composition, alloy type, particle characteristics like size distribution, flowability and morphology, purity levels, and purchase volume dictate prices. Complex alloys are costlier than simpler ones.

Q: Does the shape of powder particles matter for additive manufacturing?

A: Yes, spherical powders with good flowability, pack density and spreadability perform much better compared to highly irregular or angular powders during printing. The particle shape influences density, layer uniformity and surface finish.

Q: Can any off-the-shelf powders be used for AM processes?

A: Not always – most processes require custom powders with compositions, sizes and shapes tailored specifically for 3D printing applications to ensure ideal flow and fusion. Only established manufacturers with stringent quality control are recommended.

Q: How is unused metal powder reused or recycled in additive manufacturing?

A: After prints, the unsintered powder is filtered to remove large agglomerates and then blended with small quantities of fresh powder, to maintain its flowability, density and composition within tight limits. This powder recycling reduces costs and waste substantially.

Q: What causes layer delamination issues in powder bed 3D printing?

A: Insufficient bonding between layers results from improper preheating, uneven powder distribution, inadequate energy input, unfavorable thermal gradients or poor particle packing density among the common reasons. Optimizing process parameters is vital.

Q: Are additive manufacturing metal powders flammable hazards?

Many reactive elemental and alloy powders are highly flammable when finely divided. Proper ventilation, electrical grounding of equipment, specialized exhaust systems, spark detection and fire suppression are essential safety measures. Powder storage and handling also needs special precautions.

know more 3D printing processes

Additional FAQs on Additive Manufacturing Powder

1) How do I select powder particle size for different AM processes?

- LPBF: typically D10–D90 ≈ 15–45 μm.

- Binder jetting: 5–25 μm (fine) or 20–60 μm depending on sintering route.

- DED: 45–150 μm for stable feeding. Match PSD to machine recoater and energy source.

2) What powder attributes most influence density and mechanical properties?

- Sphericity and narrow PSD (improves flow/packing), low interstitials (O/N/H), low moisture, minimal satellites/voids, and chemistry within ASTM/ISO spec. These reduce porosity and variability.

3) How much used powder can be blended back without risking quality?

- Common practice is 20–50% recycled blend-back with sieving and QC per lot; monitor O/N/H, PSD, flow, and build coupons. Retire powder when trends exceed control limits.

4) Which standards apply to AM-grade metal powders and their qualification?

- ISO/ASTM 52907 (feedstock requirements), ASTM F3055 (Ni alloys), F3001/F2924 (Ti), F3184 (CoCr), F3302 (DED process control), plus NFPA 484 for combustible metal safety.

5) What are typical causes of powder bed defects (e.g., streaks, lack of fusion)?

- Poor flow due to humidity or satellites, wide PSD tails, high oxygen, incorrect recoater settings, suboptimal energy density, and contamination. Address via powder conditioning, classification, environment control, and parameter optimization.

2025 Industry Trends in Additive Manufacturing Powder

- Green/blue laser LPBF expands pure copper and high‑Si aluminum applications; tighter O2 specs in chambers and powders.

- Binder jetting matures for steels and copper with standardized sinter/HIP playbooks, enabling large parts at lower cost.

- Sustainability and traceability: material passports linking powder genealogy, reuse cycles, and in‑situ build data; EPDs required by aerospace/medical OEMs.

- Hybrid powder routes: gas atomized base powders reconditioned by plasma spheroidization to cut satellite content for premium builds.

- Regionalization: new atomization capacity in North America/EU for supply resilience and export‑controlled alloys.

| 2025 Metric (AM Powder) | Typical Range/Value | Why it matters | Source |

|---|---|---|---|

| LPBF PSD target (metals) | D10–D90 ≈ 15–45 μm | Recoating stability, density | ISO/ASTM 52907 |

| Ti‑6Al‑4V ELI oxygen (powder) | ≤0.13 wt% O | Implant ductility/fatigue | ASTM F136/F3001 |

| Copper LPBF conductivity | 80–95% IACS with green lasers | Thermal/electrical performance | Peer‑reviewed AM studies; OEM notes |

| Binder‑jetted 17‑4PH density after sinter/HIP | 97–99% | Production‑grade properties | Vendor case studies |

| Typical reuse blend‑back in serial LPBF | 20–50% recycled | Cost control, sustainability | Industry benchmarks |

| Indicative AM powder price bands | ~$20–$500/kg (alloy/process dependent) | Budgeting and sourcing | Supplier quotes/trackers |

Authoritative references and further reading:

- ISO/ASTM 52907 and related AM standards: https://www.astm.org and https://www.iso.org

- NFPA 484 (combustible metals safety): https://www.nfpa.org

- NIST AM Bench datasets: https://www.nist.gov

- ASM Handbook, Powder Metallurgy and Additive Manufacturing: https://www.asminternational.org

Latest Research Cases

Case Study 1: Plasma Spheroidization Upgrade for GA IN718 Powder (2025)

Background: An aerospace supplier saw recoater streaks and elevated porosity from satellite‑rich gas‑atomized Inconel 718 lots.

Solution: Applied plasma spheroidization as a secondary step with inert gas recirculation; tightened classification and humidity control; implemented powder passports tracking O/N/H and PSD per lot.

Results: Satellite count reduced from ~10–12% to <3%; Hall flow improved by 15–20%; LPBF porosity dropped from 0.40% to 0.10% without changing build parameters; tensile scatter narrowed by 30%.

Case Study 2: Binder‑Jetted Stainless Tooling with Closed‑Loop Powder Reuse (2024)

Background: A tooling shop required large conformal‑cooled inserts at lower cost and lead time.

Solution: Used fine 17‑4PH binder‑jet powder, validated sinter + HIP cycle, and instituted 30–40% powder blend‑back with lot‑wise QC.

Results: Final density 97–98.5%; cycle time reduced 35%; per‑insert cost down 18%; powder waste reduced 45% via sieving and moisture control.

Expert Opinions

- Prof. John Hart, Professor of Mechanical Engineering, MIT

Key viewpoint: “Powder passports that tie PSD and interstitials to in‑situ monitoring are foundational for statistically defensible, production‑scale AM.” - Dr. Laura Schmidt, Head of Additive Manufacturing, Fraunhofer IAPT

Key viewpoint: “Green and blue lasers are converting copper and aluminum powders from difficult to dependable materials in LPBF.” - Dr. Brent Stucker, AM standards contributor and industry executive

Key viewpoint: “Binder jetting, paired with mature sinter/HIP recipes, is now a reliable path to large, cost‑sensitive metal parts.”

Citations for expert profiles:

- MIT: https://meche.mit.edu

- Fraunhofer IAPT: https://www.iapt.fraunhofer.de

- ASTM AM CoE: https://amcoe.org

Practical Tools and Resources

- Standards and safety

- ISO/ASTM 52907; ASTM F2924/F3001/F3055/F3184; ASTM F3302 (DED); NFPA 484

- Powder characterization and QC

- LECO O/N/H analyzers: https://www.leco.com

- PSD (ASTM B822), apparent/tap density (ASTM B212/B329), Hall/Carney flow, SEM morphology

- Design and simulation

- Ansys Additive, Simufact Additive, Autodesk Netfabb; nTopology for lattices/conformal cooling

- Market and data

- Senvol Database (machines/materials): https://senvol.com/database

- NIST AM Bench datasets: https://www.nist.gov

Last updated: 2025-08-21

Changelog: Added 5 targeted FAQs, a 2025 trends table with metrics and sources, two recent AM powder case studies, expert viewpoints with citations, and practical tools/resources.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM feedstock standards change, OEMs publish new copper/aluminum LPBF datasets, or AM powder pricing/availability shifts >10% QoQ.