Visão geral de Pó para manufatura aditiva

A manufatura aditiva, também conhecida como impressão 3D, utiliza vários materiais em forma de pó para construir peças e produtos camada por camada. O tipo de pó selecionado depende do processo específico de manufatura aditiva que está sendo usado, bem como das características desejadas da peça acabada.

Alguns dos principais tipos de pós de manufatura aditiva incluem:

- Pós metálicos - Usado em processos de fusão de leito de pó e deposição de energia direcionada. Os materiais comuns incluem titânio, alumínio, aço, ligas de níquel e cobalto-cromo.

- Pós de polímero - Usado em processos de fusão de leito de pó e jateamento de material. Os materiais comuns incluem náilon, ABS, policarbonato, poliestireno e poliuretano termoplástico.

- Pós cerâmicos - Usado em processos de jateamento de aglutinantes e extrusão de materiais. Os materiais comuns incluem sílica, alumina, zircônia e porcelana.

- Areia e pós de fundição - Usado em processos de jateamento de aglutinante para criar moldes e núcleos para fundições de metal. Geralmente à base de sílica.

- Pós biocompatíveis e bioativos - Usado em aplicações médicas. Os materiais comuns incluem titânio, hidroxiapatita e fosfato tricálcico.

As características dos pós de manufatura aditiva podem influenciar significativamente as propriedades, a qualidade, a precisão e o desempenho das peças impressas. As principais propriedades dos pós incluem:

Composição do pó para manufatura aditiva

A manufatura aditiva utiliza materiais metálicos, poliméricos, cerâmicos, areia e outros materiais em pó com composições específicas adaptadas a vários processos de impressão.

Pós metálicos

| Tipo | Composições comuns |

|---|---|

| Ligas de titânio | Ti-6Al-4V, Ti-6Al-7Nb, Ti-Al-Fe, Ti-Al-Mn, Ti-Al-Sn |

| Ligas de alumínio | AlSi10Mg, AlSi12, Scalmalloy |

| Ligas de aço | 17-4PH, 316L, 304L, 4140 |

| Ligas de níquel | Inconel 625, 718; Hastelloy X |

| Cobalto-cromo | CoCrMo |

Pós de polímero

| Tipo | Composições comuns |

|---|---|

| Nylon | Nylon 11, Nylon 12 |

| ABS | Acrilonitrila butadieno estireno |

| Policarbonato | Policarbonato de bisfenol A |

| Poliestireno | PS, PS de alto impacto |

| Poliuretano termoplástico | TPU |

Pós cerâmicos

| Tipo | Composições comuns |

|---|---|

| Sílica | Quartzo fundido, cristobalita |

| Alumina | Al2O3 |

| Zircônia | ZrO2, YSZ (estabilizado com ítria) |

| Porcelana | Mistura de vidro, argila e feldspato |

Areia e pós de fundição

| Tipo | Composições |

|---|---|

| Areia de sílica | Principalmente SiO2, com traços de óxidos metálicos e óxidos não metálicos |

| Areia de zircônio | Silicato de zircônio |

| Areia de olivina | Silicato de ferro e magnésio |

| Areia de cromita | Óxido de cromo e ferro |

Pós bioativos e biocompatíveis

| Tipo | Composições comuns |

|---|---|

| Titânio e ligas | Titânio puro, Ti-6Al-4V |

| Hidroxiapatita | Ca10(PO4)6(OH)2 |

| Fosfato tricálcico | Ca3(PO4)2 |

Pó para manufatura aditiva Propriedades

As principais propriedades dos pós de manufatura aditiva que influenciam a qualidade da peça e o desempenho do processo incluem:

| Propriedade | Descrição | Importância |

|---|---|---|

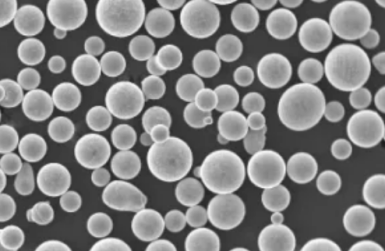

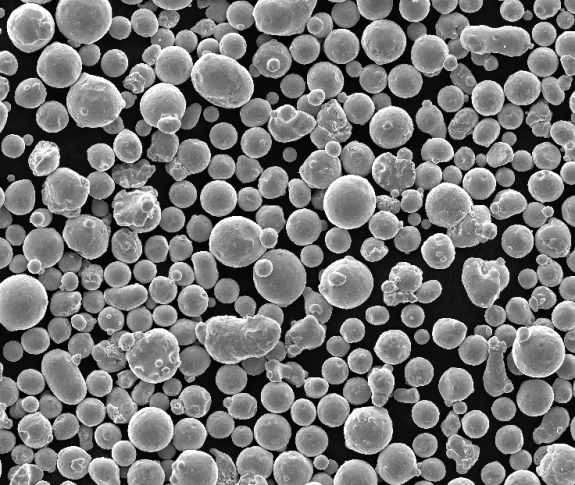

| Distribuição do tamanho das partículas | Faixa e distribuição das dimensões das partículas de pó | Afeta a fluidez do pó, a densidade de empacotamento, a uniformidade da camada e a resolução |

| Morfologia e forma | Relação de aspecto e fatores de forma das partículas de pó | Impacta o espalhamento, a densidade de empacotamento e o fluxo de pó |

| Densidade | Relação entre massa e volume do pó a granel | Determina o peso e a precisão dimensional das peças |

| Fluidez | Capacidade do pó de fluir livremente sob tensão aplicada | Vital para o espalhamento uniforme e o recobrimento das camadas de pó |

| Teor de umidade | Porcentagem de conteúdo de água no pó | A alta umidade causa aglomerações de pó e defeitos de impressão |

| Composição química | Composição elementar e fases presentes | Define as propriedades mecânicas, a microestrutura e o desempenho das peças acabadas |

Aplicações de pós para manufatura aditiva

Os pós de manufatura aditiva são usados para imprimir componentes funcionais nos principais setores:

| Setor | Formulários | Materiais utilizados |

|---|---|---|

| Aeroespacial | Lâminas de turbinas, componentes de aeronaves, motores de foguetes | Ligas de titânio, ligas de níquel, ligas de alumínio, cromo cobalto |

| Automotivo | Prototipagem, produção de peças como engrenagens, suportes | Ligas de alumínio, nylon, ABS |

| Médico | Coifas dentárias, implantes, instrumentos cirúrgicos | Ligas de titânio, cromo cobalto, aço inoxidável |

| Consumidor | Joias, objetos decorativos, luminárias | Metais preciosos, como ouro e prata; polímeros |

Especificações de pós para manufatura aditiva

Os materiais em pó usados em um processo específico de manufatura aditiva estão em conformidade com determinados limites de tamanho, composição e propriedade:

| Processo | Tamanho da partícula | Grau da liga | Padrões |

|---|---|---|---|

| Fusão de leito de pó | 15-45 mícrons | Ti-6Al-4V ELI de acordo com a ASTM F3001 | ASTM F3049, ASTM F2924, ASTM F2971 |

| Jato de aglutinante | 20-60 mícrons | Aço inoxidável 420 ou 316 | ASTM F3301, MPIF 35 |

| Jato de material | 5-25 mícrons | Poliuretano 60-65 Shore D | – |

| Deposição de energia direcionada | 45-150 mícrons | Inconel 718, aço inoxidável 316L | ASTM F3055, ASTM F3302 |

Fornecedores de pós para manufatura aditiva

Há uma rede robusta de fornecedores que oferecem uma ampla variedade de pós para manufatura aditiva de metais, polímeros, cerâmicas e compostos:

| Empresa | Materiais em Pó | Faixa de custo |

|---|---|---|

| Tecnologia LPW | Ligas de titânio, ligas de alumínio, aço inoxidável, ligas de níquel | $100-$500 por kg |

| Sandvik Osprey | Ligas de aço inoxidável, ligas de níquel, ligas de cobalto | $50-$250 por kg |

| Pós e revestimentos avançados | Polímeros à base de nylon, PEEK, PEKK | $80-$600 por kg |

| A empresa ExOne | Aço inoxidável, aço para ferramentas, carboneto de tungstênio, Inconel 625 | $75-$1000 por kg |

| Höganäs | Aço inoxidável, ligas à base de ferro | $30-$150 por kg |

| Kennametal | Carbeto de tungstênio-cobalto, aço inoxidável 17-4PH | $100-$1200 por kg |

| 3DCeram | Cerâmica de alumina, cerâmica de zircônia, sílica | $100-$250 por kg |

Comparação entre Pós de manufatura aditiva

Existem diferenças consideráveis entre as várias opções de pó com relação aos processos de produção, custo, propriedades das peças e qualidade:

| Parâmetro | Pó de polímero | Pó metálico | Pó de cerâmica |

|---|---|---|---|

| Taxa de construção | Médio | Lento | Rápido |

| Resolução | Médio | Alta | Médio a baixo |

| Força da peça | Baixo a médio | Muito alto | Médio a alto |

| Precisão da peça | Médio | Médio a alto | Baixo a médio |

| Acabamento da superfície | Médio | Alta | Baixo a médio |

| Propriedades térmicas | Baixo ponto de fusão, baixa condutividade | Alto ponto de fusão, alta condutividade | Alto ponto de fusão, baixa condutividade |

| Custo por peça | Baixo a médio | Alta | Médio |

| Pós-processamento | Mínimo | Extensivo | Médio |

Vantagens de usar a manufatura aditiva de leito de pó

Algumas das principais vantagens do uso da tecnologia de leito de pó para a fabricação de peças incluem:

- Capacidade de criar geometrias complexas e leves que não são possíveis com fundição ou usinagem

- Desperdício mínimo de matéria-prima, pois o pó não utilizado é reciclado

- Não requer ferramentas ou moldes dedicados, permitindo uma prototipagem rápida

- As peças apresentam alta resistência, durabilidade e resistência ao calor e à corrosão, combinando com materiais forjados

- A porosidade e a microestrutura podem ser facilmente controladas

- Vários materiais e ligas, até mesmo composições graduadas, podem ser impressos

- Possibilidade de produção just-in-time com prazos de entrega mínimos

Limitações da manufatura aditiva de leito de pó

Algumas desvantagens associadas à manufatura aditiva de leito de pó que precisam ser consideradas:

- Altos custos operacionais e de equipamentos em comparação com outros processos

- O pós-processamento adicional, como a prensagem isostática a quente, geralmente é essencial

- Os procedimentos e equipamentos de manuseio de pó requerem atenção especial

- A impressão de determinados polímeros flexíveis e materiais semelhantes à borracha apresenta desafios

- Não é ideal para cenários de volume muito alto e produção em massa

- As restrições de tamanho impostas pelas dimensões da câmara de construção podem exigir o reprojeto de peças grandes

Perguntas frequentes

P: Qual é o pó metálico mais comumente usado na manufatura aditiva?

R: As ligas de titânio, como Ti-6Al-4V, são um dos pós metálicos mais populares, devido à sua alta relação resistência/peso e biocompatibilidade. Ligas de alumínio, aços inoxidáveis, cobalto-cromo e superligas de níquel também são muito usados.

P: Quão finos são os pós usados nos processos de AM?

R: A faixa de tamanho típica é de 10 a 100 mícrons, embora alguns processos possam usar pós nano ultrafinos de 1 a 10 mícrons. Os pós mais finos, abaixo de 20 mícrons, resultam em melhor resolução e precisão.

P: O que afeta o preço dos pós de manufatura aditiva?

R: Os custos da matéria-prima, a composição, o tipo de liga, as características das partículas, como distribuição de tamanho, fluidez e morfologia, os níveis de pureza e o volume de compra determinam os preços. As ligas complexas são mais caras do que as mais simples.

P: O formato das partículas de pó é importante para a manufatura aditiva?

R: Sim, os pós esféricos com boa fluidez, densidade de empacotamento e capacidade de espalhamento têm um desempenho muito melhor do que os pós altamente irregulares ou angulares durante a impressão. O formato das partículas influencia a densidade, a uniformidade da camada e o acabamento da superfície.

P: Qualquer pó pronto para uso pode ser usado nos processos de AM?

R: Nem sempre - a maioria dos processos exige pós personalizados com composições, tamanhos e formatos adaptados especificamente para aplicações de impressão 3D para garantir o fluxo e a fusão ideais. Somente fabricantes estabelecidos com controle de qualidade rigoroso são recomendados.

P: Como o pó metálico não utilizado é reutilizado ou reciclado na manufatura aditiva?

R: Após as impressões, o pó não sinterizado é filtrado para remover grandes aglomerados e, em seguida, misturado com pequenas quantidades de pó fresco, para manter a fluidez, a densidade e a composição dentro de limites rígidos. Essa reciclagem de pó reduz substancialmente os custos e o desperdício.

P: O que causa problemas de delaminação de camadas na impressão 3D em leito de pó?

R: A ligação insuficiente entre as camadas resulta de pré-aquecimento inadequado, distribuição desigual de pó, entrada de energia inadequada, gradientes térmicos desfavoráveis ou densidade de empacotamento de partículas ruim, entre outros motivos comuns. É fundamental otimizar os parâmetros do processo.

P: Os pós metálicos da manufatura aditiva são perigosos e inflamáveis?

Muitos pós reativos elementares e de ligas são altamente inflamáveis quando finamente divididos. A ventilação adequada, o aterramento elétrico do equipamento, os sistemas de exaustão especializados, a detecção de faíscas e a supressão de incêndios são medidas de segurança essenciais. O armazenamento e o manuseio de pós também precisam de precauções especiais.