Introduction

In the world of manufacturing, technological advancements continue to push the boundaries of what is possible. One such innovation that has gained significant attention is Metal Injection Molding (MIM) technology. MIM technology combines the versatility of plastic injection molding with the durability and strength of metal to create complex and precise parts. This article delves into the intricacies of MIM technology, exploring its working principles, advantages, applications, limitations, and future prospects.

What is MIM Technology?

MIM technology, also known as Metal Injection Molding, is a manufacturing process that allows the production of intricate metal parts with high precision and accuracy. It involves combining fine metal powders with a thermoplastic binder material to create a feedstock. This feedstock is then injected into a mold cavity, similar to plastic injection molding. The resulting part undergoes a series of post-processing steps, including debinding and sintering, to remove the binder and fuse the metal particles together, respectively.

How Does MIM Technology Work?

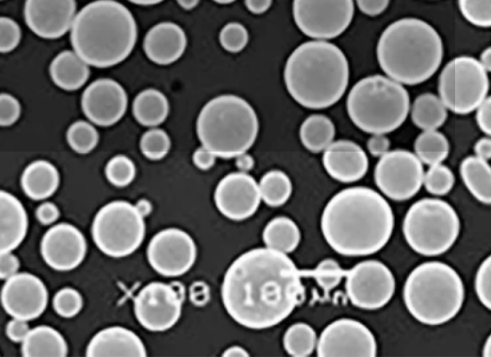

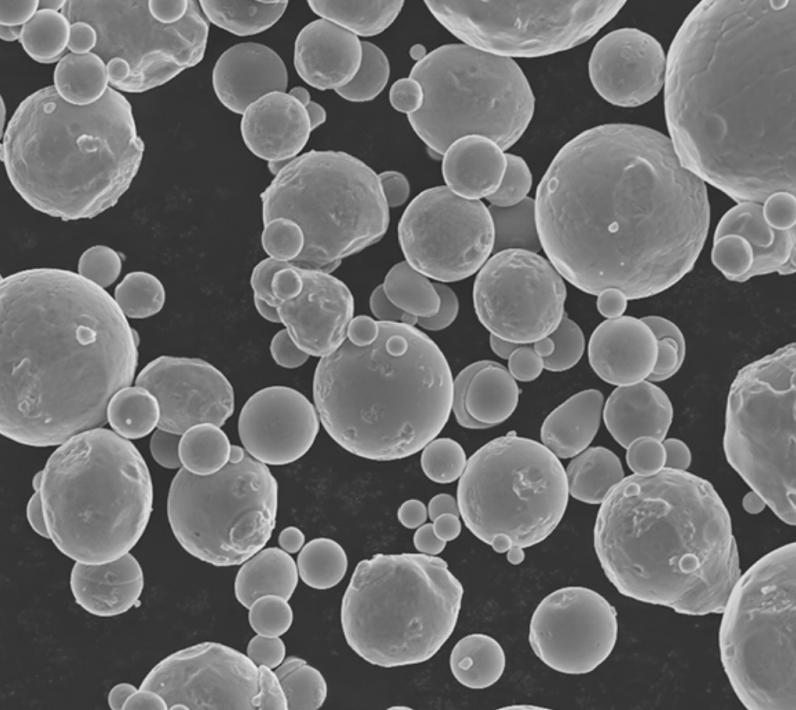

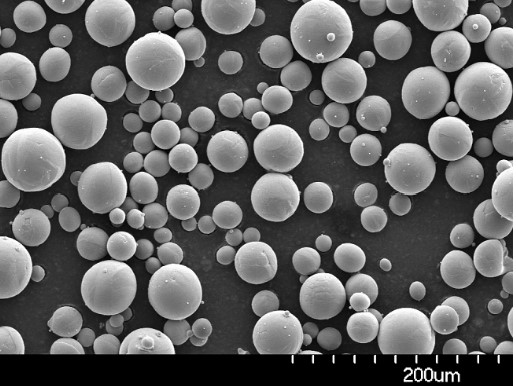

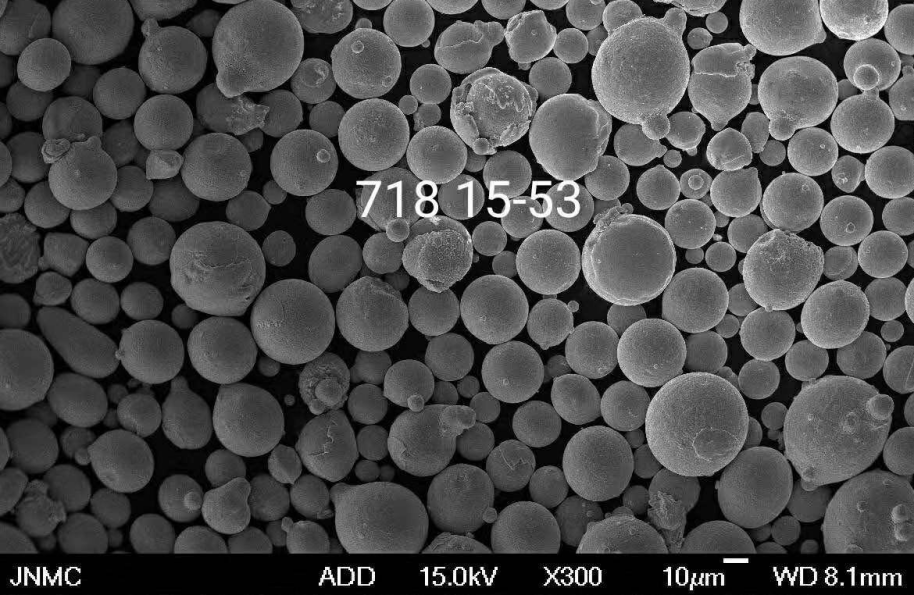

Feedstock Preparation

The first step in the MIM process is the preparation of the feedstock. Fine metal powders, typically less than 20 micrometers in size, are mixed with a thermoplastic binder material. This mixture is subjected to a kneading or extrusion process to ensure homogeneity. The resulting feedstock, with a high metal loading of around 60-70%, is ready for molding.

Molding

Once the feedstock is prepared, it is injected into a mold cavity using specialized molding equipment. The mold is designed to replicate the desired shape of the final part. Under high pressure, the feedstock fills the mold and takes its form. After cooling, the mold is opened, and the green part, still containing the binder, is removed.

Debinding

The green part obtained from the molding process contains a significant amount of binder material. To remove the binder, the green part undergoes a debinding process. This can be done through thermal or solvent debinding methods. Thermal debinding involves subjecting the part to carefully controlled heating to gradually eliminate the binder, leaving behind a porous structure called a brown part.

Sintering

The brown part is then subjected to a sintering process. Sintering involves heating the part to a temperature below its melting point but high enough to cause diffusion and bonding of metal particles. As the particles fuse together, the part undergoes shrinkage and densification, resulting in a final fully dense metal component with the desired mechanical properties.

Advantages of MIM Technology

MIM technology offers several advantages over traditional manufacturing methods, making it an attractive choice for various industries. Some key advantages include:

Complex Geometries

MIM technology enables the production of parts with complex geometries, including intricate internal features, undercuts, and fine details. It eliminates the need for costly secondary operations, such as machining or assembly, which are often required with traditional manufacturing methods.

Material Versatility

MIM technology supports a wide range of materials, including stainless steel, titanium alloys, cobalt-chrome alloys, and more. This versatility allows manufacturers to choose the optimal material for their specific application, considering factors such as strength, corrosion resistance, and biocompatibility.

Cost Efficiency

By combining multiple manufacturing steps into a single process, MIM technology offers cost savings in terms of reduced labor, shorter production cycles, and minimal material waste. It eliminates the need for expensive tooling often associated with other manufacturing techniques.

High Precision and Accuracy

MIM technology enables the production of parts with tight tolerances and high dimensional accuracy. The use of molds ensures consistency and repeatability, resulting in reliable and precise components.

Surface Finish

MIM parts have excellent surface finish straight out of the molding process, reducing the need for additional polishing or finishing operations. This saves time and cost in achieving the desired surface quality.

Applications of MIM Technology

The versatility and capabilities of MIM technology make it applicable in various industries. Some notable applications include:

Automotive Industry

MIM technology finds extensive use in the automotive industry for producing components such as transmission gears, fuel injection nozzles, and sensors. Its ability to manufacture complex shapes and maintain dimensional accuracy makes it an ideal choice for automotive parts with demanding requirements.

Medical and Dental

In the medical and dental fields, MIM technology is employed to fabricate surgical instruments, orthodontic brackets, dental implants, and other critical components. The ability to produce intricate and customized designs with biocompatible materials is advantageous for these applications.

Electronics

MIM technology plays a vital role in the electronics industry by producing connectors, sensors, and microelectromechanical systems (MEMS). The precise and repeatable manufacturing process ensures high-quality components, meeting the stringent demands of the electronics market.

Firearms

MIM technology is widely used in firearm manufacturing to produce components such as triggers, hammers, and magazine parts. The process allows for cost-effective production of intricate firearm parts with consistent quality and performance.

Limitations and Challenges of MIM Technology

While MIM technology offers numerous advantages, it also faces certain limitations and challenges. These include:

Material Selection

The availability of suitable feedstock materials is crucial for successful MIM production. Not all metals can be processed using MIM, and the choices are somewhat limited compared to traditional manufacturing methods.

Size Limitations

MIM technology is more suitable for small to medium-sized parts. As part size increases, issues related to shrinkage and distortion become more prominent, posing challenges in maintaining dimensional accuracy.

Post-Processing Requirements

The debinding and sintering stages require careful control of parameters such as temperature, time, and atmosphere. These post-processing steps can be time-consuming and add complexity to the overall production process.

Cost of Equipment

The initial investment for MIM equipment can be significant, especially for small and medium-sized enterprises. The costs associated with molds, debinding furnaces, and sintering furnaces should be carefully considered before implementing MIM technology.

Future Outlook of MIM Technology

The future of MIM technology appears promising as ongoing research and development efforts aim to address the limitations and challenges of the current technology. Some areas of focus for the future of MIM technology include:

- Material Expansion: Researchers are exploring new materials and alloy systems that can be processed using MIM. This will expand the range of applications and industries that can benefit from MIM technology.

- Size Scaling: Efforts are being made to optimize the MIM process for larger parts. By refining the debinding and sintering processes and developing innovative mold designs, the size limitations of MIM can be overcome, allowing for the production of larger components.

- Process Optimization: Ongoing research aims to enhance the efficiency and control of each stage of the MIM process. This includes advancements in feedstock preparation, molding techniques, and post-processing methods, resulting in improved part quality and reduced production time.

- Cost Reduction: As MIM technology becomes more widely adopted and the demand for MIM components increases, economies of scale will drive down the overall costs associated with MIM production. This will make MIM technology more accessible to a broader range of industries and manufacturers.

- Integration with Other Technologies: MIM technology can be combined with other additive manufacturing processes, such as 3D printing and metal deposition, to create hybrid manufacturing solutions. These integrated approaches have the potential to further expand the design possibilities and capabilities of MIM technology.

In conclusion, MIM technology is revolutionizing the manufacturing industry by enabling the production of complex metal parts with high precision and efficiency. Its advantages, including the ability to produce intricate geometries, material versatility, cost efficiency, and excellent surface finish, make it a preferred choice for various industries such as automotive, medical, electronics, and firearms. While MIM technology faces certain limitations and challenges, ongoing research and development efforts are paving the way for future advancements and wider adoption. With continuous innovation, MIM technology is expected to play an increasingly significant role in the manufacturing landscape.

FAQs

What materials can be used in MIM technology? MIM technology supports a wide range of materials, including stainless steel, titanium alloys, cobalt-chrome alloys, and more.

Is MIM technology suitable for large-scale production? While MIM technology is more suitable for small to medium-sized parts, ongoing research aims to optimize the process for larger components.

Are MIM parts as strong as traditionally manufactured parts? Yes, MIM parts exhibit comparable strength to traditionally manufactured parts, thanks to the dense and uniform metal structure achieved through the sintering process.

How does MIM compare to other additive manufacturing processes? MIM offers distinct advantages, such as high dimensional accuracy and surface finish, which make it suitable for producing complex metal parts. Other additive manufacturing processes, like 3D printing, may have different strengths and applications.

Can MIM technology be used for prototyping? Yes, MIM technology can be utilized for prototyping, allowing engineers and designers to assess the form, fit, and function of metal components before moving to mass production.