With the continuous development of 3D printing technology, the market share of 3D printing powder metal materials also continues to be high.

This article mainly introduces the latest progress of aerosolization technology, the current process of preparing metal powder for 3D printing, and analyzes the current status of 3D printing metal powder preparation technology.

3D printing technology is a new type of printing technology, its outstanding advantage is that without mechanical processing or any mold, it can directly generate any shape of parts from computer graphics data, thus greatly reducing the product development cycle, improving productivity and reducing production costs.

3D printing metal powder as the most important raw material for 3D printing of metal parts, its preparation method has attracted a lot of attention, 3D printing Metal powder as the most important part of the metal parts 3D printing industry chain, but also the greatest value.

The world’s leading experts in the 3D printing industry have a clear definition of 3D printing metal powder, which refers to a group of metal particles with a size of less than 1mm. This includes single metal powder, alloy powder and certain refractory compound powder with metallic properties.

At present, 3D printing metal powder materials include cobalt-chromium alloy, stainless steel, industrial steel, bronze alloy, titanium alloy and nickel-aluminum alloy. However, in addition to good plasticity, 3D printed metal powders must also meet the requirements of fine particle size, narrow particle size distribution, high sphericity, good flowability and high bulk density.

Making Process of Metal Powder

At present, the powder preparation method according to the preparation process can be divided into: reduction method, electrolysis method, carbonyl decomposition method, grinding method, atomization method, etc.

Among them, it is more common to use the powder produced by reduction, electrolysis and atomization methods as raw materials for the powder metallurgy industry. However, electrolytic and reduction methods are limited to the production of single metal powders, while for alloy powders these methods are not applicable.

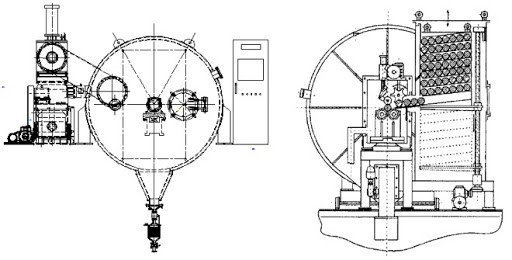

The atomization method can be used for the production of alloy powders, and the modern atomization process can also control the shape of the powder, and the evolving atomization chamber structure has significantly improved the atomization efficiency, which makes the atomization method gradually developed into the main powder production method.

Atomization method meets the special requirements of 3D printing consumables metal powder. Atomization method refers to the mechanical method to crush the molten metal into particles of size less than about 150μm.

Aerosolization is one of the main methods of producing metal and alloy powders. The basic principle of aerosolization is the process of breaking the liquid metal stream into small droplets and solidifying them into powder by high speed airflow. Due to the advantages of high purity, low oxygen content, controllable powder size, low production cost and high sphericity, it has become the main development direction of high performance and special alloy powder preparation technology. However, the gas atomization method also has shortcomings.

The energy of high-pressure air flow is much smaller than that of high-pressure water flow, so the braking efficiency of gas atomization on metal melt is lower than that of water atomization, which makes the atomization efficiency of gas atomized powder lower, thus increasing the preparation cost of atomized powder.

Frequently Asked Questions (FAQ)

1) What is PREP in 3D Printing Metal Powder Making Technology?

- PREP stands for Plasma Rotating Electrode Process. A consumable alloy rod is spun at high speed; its tip is melted by a plasma arc and centrifugal force atomizes the melt into highly spherical, low‑oxygen powder, ideal for LPBF/EBM and DED.

2) How does PREP differ from gas atomization (GA) and water atomization (WA)?

- PREP: top-tier sphericity, cleanliness, narrow satellites, low O/N pickup; lower yield and higher cost. GA (VIGA/EIGA): scalable, excellent sphericity for most alloys; moderate oxygen depending on melt route. WA: highest yield/lowest cost but irregular morphology and higher O—often needs post‑spheroidization for AM.

3) Which alloys benefit most from PREP-made powders?

- Reactive and high-value systems where cleanliness matters: titanium alloys (Ti‑6Al‑4V, Ti‑6242), Ni‑based superalloys (IN718/625), Co‑Cr‑Mo for medical, and specialty refractory alloys where inclusion control is critical.

4) What particle-size distributions are typical from PREP?

- Common LPBF cuts are 15–45 μm or 20–53 μm; EBM often uses 45–105 μm; DED favors 75–150 μm. PREP can be tuned via rotation speed and melt rate to target these PSD bands.

5) What quality tests should verify PREP powder for AM?

- PSD (laser diffraction), morphology/satellites (SEM), flow (Hall/Carney), apparent/tap density (ASTM B212/B703), chemistry O/N/H (ASTM E1019), and inclusion/phase checks. Build coupons validated to ISO/ASTM 52907 practices.

2025 Industry Trends in PREP and Atomization for AM Powders

- Clean-melt expansion: More EIGA/VPA melt feeds combined with PREP reduce oxygen baselines by 10–20% vs 2023.

- Yield optimization: New electrode clamping and arc stabilization increase PREP fine-fraction yield by 3–6 percentage points.

- Hybrid routes: WA steel powders upgraded via RF plasma spheroidization approach GA flow at lower cost for Binder Jetting.

- Digital QA: Inline optical/AI satellite detection and digital material passports standardize lot traceability across sites.

- Sustainability: Argon recovery on PREP/GA lines cuts inert gas consumption by 25–40%; powder circularity extends reuse cycles to 8–12.

2025 KPI Snapshot: PREP vs GA vs WA (AM-relevant ranges)

| Metric (AM-grade) | PREP | Gas Atomization (VIGA/EIGA) | Water Atomization |

|---|---|---|---|

| Sphericity (aspect ratio) | 0.95–0.98 | 0.94–0.97 | 0.85–0.92 |

| Oxygen content, Ti-6Al-4V (wt%) | 0.05–0.10 | 0.06–0.12 (EIGA lower end) | 0.10–0.20+ |

| Hall flow (s/50 g, steels/Ni) | 15–18 | 15–20 | 20–35 (pre‑spheroidization) |

| Typical LPBF PSD (μm) | 15–45 | 15–45 | 15–45 (after spheroidization) |

| Fine-fraction yield (<53 μm) | Low–Moderate | Moderate–High | High |

| Relative powder cost | High | Medium | Low |

| Notes/Sources | ISO/ASTM 52907, OEM datasheets | Wohlers 2025, plant reports | Post‑processing often required |

Key references:

- ISO/ASTM 52907:2023 powder characterization https://www.iso.org/standard/78974.html

- ASTM B212/B213/B703; ASTM E1019 O/N/H https://www.astm.org/

- NIST AM‑Bench datasets https://www.nist.gov/ambench

- Wohlers Report 2025 market insights https://wohlersassociates.com/

Latest Research Cases

Case Study 1: PREP Ti‑6Al‑4V with EIGA Feedstock Lowers Oxygen and Boosts Fatigue (2025)

Background: An aerospace supplier observed fatigue scatter using GA Ti powder on multi‑laser LPBF platforms.

Solution: Switched to EIGA billets as PREP electrodes; optimized rotation speed and arc stability; implemented closed‑loop inert powder handling and AI melt-pool control; HIP + stress relief per AMS guidance.

Results: Oxygen stabilized at 0.06–0.08 wt%; porosity fell from 0.35% to 0.12%; HCF median life (R=0.1) +24%; first‑pass yield +17% across 8 reuse cycles.

Case Study 2: RF Spheroidization Upgrade Path for WA 17‑4PH vs PREP Baseline (2024)

Background: An automotive Tier‑1 weighed PREP quality vs cost for Binder Jetting brackets.

Solution: Benchmarked PREP 17‑4PH against WA powder upgraded via RF plasma spheroidization; tuned PSD (D10–D90: 10–45 μm) and sintering curves with dilatometry.

Results: PREP achieved best flow (Hall 15.8 s/50 g) and lowest satellites; RF‑upgraded WA reached 17.5 s/50 g with Hausner 1.27, meeting dimensional Cpk at 12–18% lower powder cost. Decision: PREP for safety‑critical; RF‑upgraded WA for cost‑sensitive parts.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Viewpoint: “Powder route matters, but consistent characterization—PSD, flow, and O/N/H per ISO/ASTM 52907—is what translates PREP’s cleanliness into reliable AM parts.” Source: NIST AM workshops https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Viewpoint: “PREP remains the gold standard for reactive alloys; integration with clean-melt feeds like EIGA closes the loop on inclusions and oxygen control for flight hardware.” Source: AM conference proceedings https://www.utwente.nl/ - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Viewpoint: “In 2025, digital material passports and round‑robin datasets are shortening qualification cycles for PREP powders across platforms.” Source: ASTM AM CoE https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Powder characterization for AM

https://www.iso.org/standard/78974.html - ASTM standards for powder and chemistry testing: B212/B213/B703, E1019

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets and validation problems

https://www.nist.gov/ambench - Senvol Database: Compare machines/materials, including PREP powder options

https://senvol.com/database - HSE ATEX/DSEAR: Safe handling of reactive metal powders

https://www.hse.gov.uk/fireandexplosion/atex.htm - Open-source tools: Thermo‑Calc (CALPHAD for alloy design), pySLM (scan strategies), AdditiveFOAM (thermal/porosity modeling), ImageJ (particle morphology)

Last updated: 2025-08-27

Changelog: Added 5 FAQs on PREP and atomization, 2025 KPI comparison table with sources, two recent case studies, expert viewpoints, and curated tools/resources aligned with ISO/ASTM standards.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major PREP/EIGA capacity changes, or new OEM AM parameter sets affecting powder qualification.