Introduction to EBM Technology

In the fast-paced world of manufacturing and engineering, technological advancements are revolutionizing the way products are made. One such groundbreaking technology is Electron Beam Melting (EBM). This article delves into the world of EBM technology, exploring its principles, applications, advantages, challenges, and its impact on various industries. We will also discuss the future prospects of EBM and its role in shaping a sustainable future.

What is EBM Technology?

EBM, short for Electron Beam Melting, is a cutting-edge additive manufacturing technology that enables the creation of complex three-dimensional objects. Unlike traditional manufacturing methods, EBM utilizes an electron beam to selectively melt and fuse metal powders, layer by layer, to build a final product. This process is often referred to as powder bed fusion, making it an integral part of the additive manufacturing family.

Understanding the Principles of EBM

To grasp the essence of EBM technology, it is essential to understand its fundamental principles. At its core, EBM relies on the use of high-energy electron beams that are emitted from an electron gun. These beams are precisely directed onto a thin layer of metal powder, causing the powder particles to rapidly melt and fuse together. By repeatedly scanning and adding more layers, the object gradually takes shape with exceptional accuracy.

Energy Source: Electron Gun

The electron gun serves as the primary energy source in EBM technology. It emits a focused stream of high-energy electrons, which are responsible for melting the metal powder.

Powder Bed

The metal powder used in EBM serves as the raw material for building the object. The powder bed provides a layer upon which the electron beam operates.

Selective Melting

EBM involves selective melting, where the electron beam targets specific areas on the powder bed to create the desired shape, leaving other areas untouched.

Layer-by-Layer Approach

The layer-by-layer approach is a fundamental aspect of EBM, where each successive layer is added on top of the previous one until the object is complete.

The History of EBM Technology

The roots of EBM can be traced back to the 1980s when it was first conceptualized and developed. The technology was primarily pioneered by a Swedish company called Arcam AB. Over the years, EBM has undergone significant refinements and improvements, leading to its adoption in diverse industrial applications.

Early Developments

The initial stages of EBM technology were marked by experiments with various electron beam sources and metal powders to achieve optimal results.

Arcam AB’s Contribution

Arcam AB, founded in 1997, played a pivotal role in the advancement of EBM technology. Their continuous research and development efforts contributed to making EBM a commercially viable manufacturing method.

How EBM Technology Works

To comprehend the intricacies of EBM, it’s crucial to grasp the step-by-step process of how this innovative technology works.

Digital Design

The first step in EBM involves creating a digital design of the object to be manufactured. This design serves as the blueprint for the entire manufacturing process.

Preparing the Powder Bed

The metal powder, chosen based on the material requirements, is spread evenly on the build platform, creating the first layer.

Electron Beam Melting

The electron gun emits high-energy beams, selectively melting the metal powder according to the digital design.

Adding Layers

After each layer is melted and solidified, the build platform moves down, and a new layer of metal powder is spread on top. The process is repeated until the entire object is fabricated.

Applications of EBM in Various Industries

EBM’s capabilities have opened up new avenues in various industries. Let’s explore some of the key applications of EBM technology.

Applications of EBM in Various Industries (contd.)

Aerospace and Aviation

The aerospace and aviation industries have been early adopters of EBM technology. EBM allows for the creation of complex, lightweight, and high-strength components for aircraft and spacecraft. This has led to improved fuel efficiency, reduced emissions, and enhanced performance.

Healthcare and Medical Devices

In the medical field, EBM has revolutionized the production of customized implants and prosthetics. Its ability to create intricate and patient-specific designs ensures better compatibility and functionality, leading to improved patient outcomes.

Automotive Industry

In the automotive sector, EBM is used to manufacture lightweight and durable components, such as engine parts, gears, and brackets. This aids in increasing vehicle efficiency, reducing emissions, and enhancing overall performance.

Tooling and Prototyping

EBM is increasingly utilized in tooling and prototyping processes. It enables rapid and cost-effective production of molds, patterns, and prototypes, saving time and resources in the product development cycle.

Advantages and Benefits of EBM Technology

EBM technology offers several advantages over traditional manufacturing methods, making it an attractive choice for various industries.

Design Freedom

EBM enables the fabrication of complex geometries that would be challenging or impossible to achieve through conventional techniques. This design freedom opens up possibilities for innovation and optimization in product development.

Material Efficiency

EBM is known for its excellent material utilization, reducing waste and minimizing overall material costs. The layer-by-layer approach ensures that only the required amount of material is used to build the object.

Reduced Lead Times

The additive nature of EBM technology allows for quicker production cycles compared to subtractive methods. This reduced lead time accelerates product development and time-to-market.

Improved Performance

Components manufactured using EBM often exhibit superior mechanical properties, such as strength and fatigue resistance, leading to enhanced product performance and durability.

Challenges and Limitations of EBM

While EBM technology has significant potential, it also faces certain challenges and limitations that must be addressed.

Surface Finish and Post-Processing

The surface finish of EBM-produced parts may not always meet the required standards, necessitating post-processing steps, which can add time and cost to the production process.

Material Selection and Availability

The range of materials compatible with EBM is still relatively limited compared to traditional manufacturing methods. Expanding material options is essential to cater to diverse industry needs.

Machine Size and Cost

EBM machines, especially for large-scale production, can be costly to acquire and maintain. Smaller manufacturers may find it challenging to invest in EBM technology.

Process Optimization

Optimizing the EBM process to achieve consistent results across different materials and applications requires ongoing research and development.

The Future of EBM Technology

The future of EBM technology holds great promise, with ongoing research and innovation poised to overcome current limitations and unlock new possibilities.

Material Advancements

Research into new materials and alloys compatible with EBM is expected to expand the application range of this technology across industries.

Integration with Industry 4.0

As part of the Industry 4.0 revolution, EBM technology is likely to integrate with smart manufacturing systems, enabling more automated and interconnected production processes.

Multi-Material Printing

Advancements in EBM technology may lead to the ability to print objects using multiple materials in a single build, further enhancing design flexibility and performance.

Increased Accessibility

As EBM technology matures and becomes more prevalent, the costs associated with machines and materials are likely to decrease, making it more accessible to a broader range of manufacturers.

EBM Technology in Healthcare and Medicine

The medical field is witnessing significant transformations due to EBM technology. Let’s explore its impact in healthcare and medicine.

EBM Technology in Healthcare and Medicine (contd.)

Customized Implants and Prosthetics

One of the most significant contributions of EBM technology to healthcare is the production of customized implants and prosthetics. EBM allows for the creation of patient-specific designs, ensuring a perfect fit and reducing the risk of complications after implantation.

Dental Applications

EBM has found applications in the dental industry, where it is used to fabricate dental crowns, bridges, and orthodontic devices. The precise nature of EBM ensures that dental prosthetics match the patient’s unique dental anatomy accurately.

Medical Instrumentation

EBM technology enables the production of specialized medical instruments, such as surgical tools and guides. These instruments can be designed to be lightweight, ergonomic, and tailored to specific medical procedures.

Tissue Engineering

Researchers are exploring the use of EBM to print living tissues and scaffolds for tissue engineering applications. This breakthrough could revolutionize regenerative medicine and organ transplantation.

EBM in Aerospace and Automotive Industries

Lightweight Components for Aerospace

Aerospace engineers leverage EBM to fabricate lightweight and complex components for aircraft and spacecraft. This not only reduces the overall weight of the vehicles but also contributes to fuel efficiency and improved performance.

Engine Components for Automotive

In the automotive industry, EBM is utilized to manufacture critical engine components with intricate internal structures, leading to better engine performance and reduced fuel consumption.

Spare Parts Production

EBM has the potential to revolutionize spare parts production for both aerospace and automotive industries. By printing spare parts on-demand, manufacturers can significantly reduce inventory costs and ensure rapid maintenance and repairs.

EBM and Sustainability

Resource Efficiency

EBM’s material efficiency translates into reduced material waste, making it an environmentally friendly manufacturing process compared to traditional methods.

Energy Savings

The additive nature of EBM consumes less energy than traditional subtractive manufacturing techniques, contributing to overall energy savings.

Sustainable Design

EBM enables the creation of sustainable designs with optimized geometries, leading to lighter products that require less energy to operate.

EBM vs. Traditional Manufacturing Methods

Additive vs. Subtractive Manufacturing

Comparing EBM to traditional subtractive manufacturing methods, we explore the key differences and advantages offered by the additive approach.

Complexity and Design Freedom

EBM allows for the production of highly complex geometries that would be challenging or impossible to achieve with subtractive methods.

Material Waste and Efficiency

Traditional manufacturing often generates significant material waste, while EBM minimizes waste by using only the necessary amount of material.

Cost and Time Savings

EBM can lead to cost and time savings in production, particularly for customized and low-volume manufacturing.

Innovations and Research in EBM

Material Innovation

Researchers are continually exploring new materials and alloys to expand the material options available for EBM technology.

EBM at the Nanoscale

Advancements in EBM are pushing the boundaries of resolution, allowing for nanoscale 3D printing, opening new possibilities in microelectronics and biomedicine.

In-Process Monitoring

Researchers are developing in-process monitoring techniques to ensure the quality and reliability of EBM-produced parts.

Conclusion

EBM technology has emerged as a revolutionary force in modern manufacturing. Its ability to create complex, lightweight, and customized objects has transformed industries like aerospace, healthcare, and automotive. While EBM faces challenges and limitations, ongoing research and innovations are expected to address these issues, propelling EBM towards a more sustainable and interconnected future.

FAQs

Is EBM technology limited to specific materials?EBM currently works best with certain metals, such as titanium, stainless steel, and nickel-based alloys. However, ongoing research aims to expand the range of compatible materials.

How does EBM benefit the aerospace industry?EBM allows aerospace manufacturers to create lightweight and intricate components, leading to increased fuel efficiency and improved performance of aircraft and spacecraft.

Can EBM be used for mass production?While EBM is excellent for low-volume and customized production, it is currently not as suitable for mass production due to its slower printing speed.

What is the potential impact of EBM on the medical field?EBM has the potential to revolutionize healthcare by enabling the production of patient-specific implants and prosthetics, as well as facilitating advances in tissue engineering and regenerative medicine.

How does EBM contribute to sustainability?EBM’s material efficiency, reduced energy consumption, and ability to create lightweight designs contribute to a more sustainable and eco-friendly manufacturing process compared to traditional methods.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) What metals perform best in EBM Technology and why?

- Ti-6Al-4V, pure titanium, CoCr, and some nickel-based superalloys print reliably due to good electron-beam absorptivity, vacuum compatibility, and powder stability at high temperatures.

2) How does EBM differ from laser PBF for medical and aerospace parts?

- EBM operates in high vacuum with elevated bed temperatures, reducing residual stress and enabling crack-resistant builds (e.g., Ti‑6Al‑4V lattice implants). Laser PBF offers finer surface finish but can carry higher residual stresses without preheating.

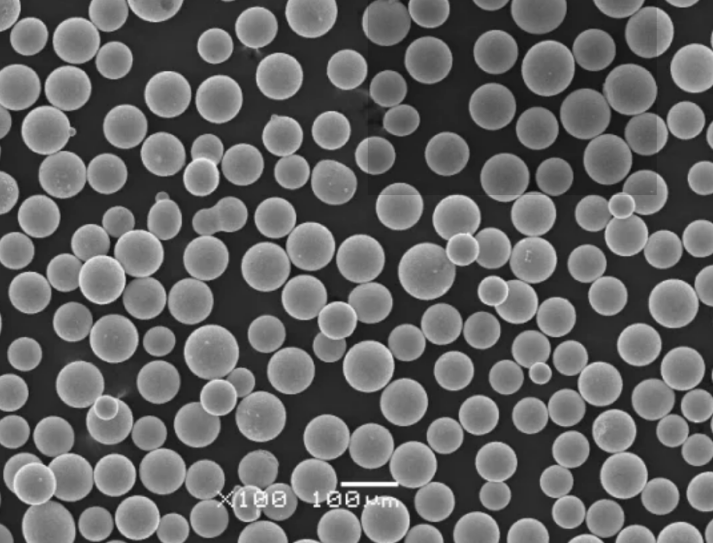

3) What powder specifications are critical for consistent EBM builds?

- Spherical morphology, tight PSD (commonly 45–105 μm), low oxygen/nitrogen, controlled flow/tap density, and minimal satellites. Powder recyclability and oxidation control are essential due to repeated high-temperature exposure.

4) Can EBM produce lattice structures and internal channels reliably?

- Yes. The high preheat and vacuum conditions support robust fusion of struts and nodes, making EBM well-suited for porous implants, heat exchangers, and lightweight aerospace brackets.

5) What are typical post-processing steps after EBM?

- Powder removal, hot isostatic pressing (HIP) to close porosity, heat treatment, machining of critical interfaces, surface finishing (blasting, machining, or electropolishing), and inspection (CT scanning, metallography, mechanical testing).

2025 Industry Trends: EBM Technology

- Higher throughput platforms: Multi-beam scanning strategies and smarter raster planning improve build rates for Ti‑6Al‑4V orthopedic and aero brackets.

- Qualification acceleration: Digital build records with powder passports (PSD, O/N/H, reuse count) shorten aerospace and medical qualifications.

- Enhanced surface strategies: Parameter sets that reduce surface roughness 10–20% on as-built features, decreasing machining burden.

- Cost control: Argon-free vacuum operation remains an advantage; improved powder reuse protocols cut material costs per build.

- Regulatory alignment: Expanded use of ASTM F3301-style data packages linking process parameters to CT density and mechanical outcomes.

2025 KPI Snapshot for EBM (indicative ranges)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| Build rate (Ti‑6Al‑4V, cm³/h) | 55–80 | 70–110 | Multi-beam and path optimization |

| As-built porosity (%) | 0.3–0.8 | 0.15–0.5 | Improved parameter windows |

| Surface roughness Ra (μm, vertical) | 25–35 | 20–28 | Scan and contour tuning |

| Powder reuse cycles (Ti‑6Al‑4V) | 8–12 | 10–16 | Controlled O pickup and sieving |

| Post-HIP UTS (Ti‑6Al‑4V, MPa) | 900–980 | 930–1000 | Heat treatment optimization |

| Qualification lead-time reduction | — | 20–35% | Digital traceability and CT linkage |

Sources: ASTM/ISO standards (e.g., ISO/ASTM 52900, ASTM F2924 for Ti‑6Al‑4V), OEM application notes, peer-reviewed AM studies, NIST AM‑Bench resources

Latest Research Cases

Case Study 1: EBM Ti‑6Al‑4V Porous Acetabular Cups with Reduced Post-Machining (2025)

Background: An orthopedic OEM needed to lower finishing time while maintaining osseointegration pore structures.

Solution: Adopted updated EBM contour strategies and elevated preheat to stabilize overhangs; implemented powder passport tracking (PSD 45–90 μm, O ≤ 0.15 wt%) and CT-based acceptance criteria.

Results: As-built Ra reduced 18% on rim features; HIP yield +6%; machining time −22% per cup; zero nonconformances on pore size distribution across three lots.

Case Study 2: Nickel Superalloy Brackets for Hypersonic UAV Using EBM (2024)

Background: An aerospace supplier required high-temperature brackets with internal cooling passages and low residual stress.

Solution: EBM-printed Ni-based alloy with staged preheat and beam offset tuning; post-build HIP and age hardening; pressure-tested channels and CT inspection.

Results: Dimensional deviation halved vs prior L-PBF route without stress relief; creep life at 800°C improved 12%; leak-tightness 100% pass at 5 bar; overall lead time −28%.

Expert Opinions

- Dr. Brent Stucker, AM Industry Executive and Researcher

Key viewpoint: “Vacuum, high preheat, and multi-beam controls in EBM are enabling serial production of stress-sensitive aerospace and orthopedic parts that would require extensive stress mitigation in laser PBF.” - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “With improved scan strategies and powder management, EBM Technology is closing the gap on surface quality while keeping its lead in low-stress builds.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Process data tied to standardized COAs and CT inspections is accelerating pathway-to-approval for EBM medical implants.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52900: AM terminology and categories

https://www.iso.org/ - ASTM F2924: Standard specification for additively manufactured Ti‑6Al‑4V by PBF

https://www.astm.org/ - ISO/ASTM 52907: Metal powder feedstock characterization (PSD, O/N/H)

https://www.iso.org/standard/78974.html - NIST AM‑Bench: Datasets linking AM process parameters to part performance

https://www.nist.gov/ambench - FDA Guidance on Additive Manufactured Medical Devices (for U.S. submissions)

https://www.fda.gov/ - OEM technical notes (e.g., GE Additive/Arcam) on EBM parameter development, powder handling, and qualification

Last updated: 2025-08-27

Changelog: Added five focused FAQs, a 2025 KPI table for EBM Technology, two recent case studies (orthopedic cups; hypersonic UAV brackets), expert viewpoints, and vetted tools/resources.

Next review date & triggers: 2026-03-31 or earlier if ASTM/ISO standards update, major EBM platforms release multi-beam upgrades, or new medical/aerospace qualification data is published.