3D printing metal powders

Metal powders are the most important raw material for 3D printing of metal parts, and powder properties are one of the most important factors affecting the quality of metal 3D printing products. Powder materials with a diameter of less than 1 mm are generally considered suitable for 3D printing, but high-quality 3D printed metal products have higher requirements for the shape, particle size and purity of the powder. The main types of 3D printing equipment are powder spreading, coaxial powder feeding and lateral powder feeding, depending on the powder replenishment method. The lateral powder feeding 3D printing final part

The shape and dimensional accuracy of the final part is low, the laser energy cannot be fully utilised and the powder utilisation rate is low. Therefore, high-quality metal 3D printing equipment is mainly The two main methods of powder replenishment are powder spreading or coaxial powder feeding.

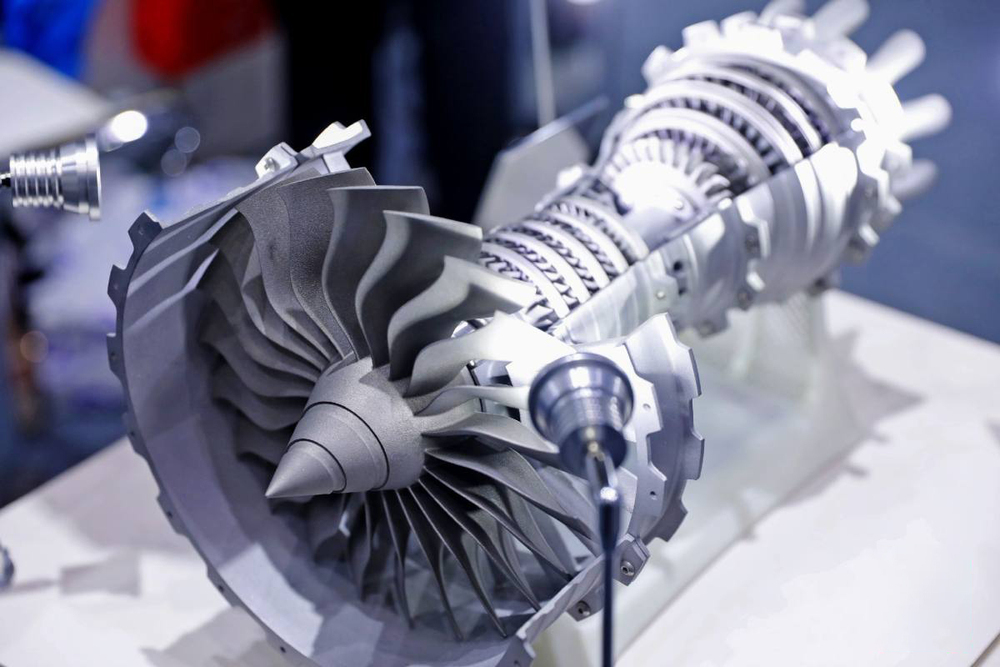

Unlike traditional metal material manufacturing technology with its huge equipment, long process, high energy consumption, pollution and low material utilisation, metal 3D printing has the following advantages: (1) high overall material utilisation; (2) no need to open moulds, few manufacturing processes and short cycle time; (3) can manufacture parts with complex structures; (4) free design according to mechanical property requirements, without considering manufacturing processes. In recent years, metal 3D printing has developed rapidly, with GKN Aerospace supplying France’s Airbus and Safran with 2.5 m diameter Ariane 6 rocket nozzles (SWAN), processing key structural components through laser welding and laser energy deposition processes, reducing the number of nozzle components from

approximately 1,000 to approximately 100 parts, reducing costs by 40% and delivery times by 30%. Metal 3D printing is mainly used to provide rapid production of models for industrial design and the machining of complex moulds, as well as the production of small batches, complex structures, high performance and large metal components. Metal 3D printing uses metal powder as an additive material and uses rapid forming methods such as selective laser melting (SLM), electron beam selective melting (EBSM) or laser near net forming (LENS) to rapidly transform directly from a computerised digital model into a solid part. High quality 3D printed metal parts for aerospace, defence, medical, automotive and electronics applications need to have high strength, dimensional accuracy, water tightness and light weight. Quality control means for metal 3D printing processes In addition to the printing equipment, the properties of the metal powder, including powder sphericity and cleanliness, particle size distribution

sphericity and cleanliness of the powder, particle size distribution, oxygen content, flowability and loose packing density The quality of the metal powder, including powder sphericity and cleanliness, particle size distribution, oxygen content, fluidity and bulk density, also have a significant impact.

Key Performance Indicators of 3D Printing Metal Powders

(1) Purity. Ceramic inclusions can significantly reduce the performance of the final part, and these inclusions generally have a high melting point and are difficult to sinter into shape, so the powder needs to be free of ceramic inclusions. In addition, the oxygen and nitrogen content needs to be strictly controlled. The current powder preparation technology for metal 3D printing is mainly based on atomisation (including techniques such as aerosolisation and rotary electrode atomisation), where the powder has a large specific surface area and is easily oxidised. In aerospace and other special applications, the customer requirements for this indicator is more stringent, such as high temperature alloy powder oxygen content of 0.006% ~ 0.018%, titanium alloy powder oxygen content of 0.007% ~ 0.013%, stainless steel powder oxygen content of 0.010% ~ 0.025% (all mass fraction). For titanium alloy powder, nitrogen, hydrogen and titanium at high temperatures will form TiN and TiH2, reducing the plasticity and toughness of titanium alloy. Therefore, the powder preparation process should be strictly controlled for the atmosphere.

(2) Powder particle size distribution. As mentioned above, different 3D printing equipment and forming processes require different powder particle size distributions. At present, the commonly used powder particle size range for metal 3D printing is 15-53 μm (fine powder), 53-105 μm (coarse powder), which can be relaxed to 105-150 μm (coarse powder) in some occasions [11]. 3D printing with metal powder particle size selection is mainly based on the different energy sources of metal printers, with laser as the energy source of the printer, because of its fine focus spot, easier to melt Fine powder, suitable for use 15 ~ 53 μm powder as consumables, powder replenishment method for layer by layer laying powder; to electron beam as the energy source of laying powder type printer, focusing spot slightly coarse, more suitable for melting coarse powder, suitable for use 53 ~ 105 μm coarse powder as the main; for coaxial powder feed type printer can use the particle size of 105 ~ 150 μm powder as consumables.

(3) Powder morphology. Powder morphology and powder preparation method is closely related, generally from the metal gas or molten liquid into powder, powder particle shape tends to spherical; from the solid state into powder, powder particles are more irregular shape; and by the aqueous solution electrolysis method of preparing the powder most dendritic. Generally speaking, the higher the sphericity, the better the fluidity of the powder particles.

3D printing metal powders require a sphericity of 98% or more, which makes it easier to spread and feed the powder during printing. Aerosolisation and rotating electrode methods are the main methods for the preparation of high quality 3D printing metal powders.

- Powder fluidity and loose packing density. Powder fluidity directly affects the uniformity of powder spreading and the stability of the powder feeding process in the printing process. (4) Powder fluidity and bulk density. The fluidity is related to the powder morphology, particle size distribution and bulk density. The larger the powder particles, the larger the particle size distribution and the density of the powder. The larger the powder particles, the more regular the particle shape and the smaller the proportion of very fine powder in the particle size composition The larger the powder particles, the more regular the particle shape and the smaller the proportion of very fine powder in the particle size composition, the better the mobility. Particle The density remains the same, the relative density increases and the powder mobility increases. Particles The adsorption of water, gases etc. on the surface will reduce the fluidity of the powder. Loose packing density is a unit volume of powder when the powder specimen naturally fills the specified container. The mass of the powder. In general, the coarser the powder size, the higher the bulk density. The coarser the powder, the higher the bulk density. Loose The effect of bulk density on the density of the final metal printing product is not conclusive. There is no conclusive evidence on the effect of bulk density on the density of the final metal print product, but an increase in bulk density improves the flow of the powder.

3D printing is an emerging material manufacturing technology that has developed rapidly in recent years, as it is suitable for a wide range of materials and has a wide range of applications and high materialisation rates.

Metal powders are an important consumable for metal 3D printing, of which AA and PREP methods have been successfully applied in the aerospace industry. The AA and PREP methods have been successfully applied in the aerospace industry. However, metal powders for 3D printing need to be The powder size must be small, with a narrow particle size distribution, high sphericity, low oxygen content The use of metal powders for 3D printing is clearly a major challenge. It is clear that the PREP method is better than the traditional AA method (VIGA) for the application of metal powders in 3D printing. The PREP method is clearly more advantageous than the traditional AA method (VIGA method) for the preparation of high-quality 3D printed metal components, and is now widely used in coaxially fed 3D printing machines. The PREP method has been widely used in coaxially fed 3D printing machines. The PREP method has been widely used in coaxially fed 3D printing machines due to its ability to produce ultra-fine spherical powders (particle size up to 50 μm). (particle size up to 50 μm) and the relatively low production The use of PREP in powder spreading 3D printing equipment is relatively low due to its low yield and relatively low productivity. Therefore, there is an urgent need to optimize the process and develop a new generation of plasma rotary electrode atomised powder technology and equipment to further improve the yield of ultra-fine spherical metal The development of a new generation of plasma rotary electrode atomisation technology and equipment is therefore urgently needed to further improve the yield of ultra-fine spherical metal powders and to achieve The technology and equipment will further improve the yield of ultra-fine spherical metal powders and achieve the continuous production of high quality ultra-fine spherical metal powders such as nickel-based, cobalt-based alloys and titanium alloys in large quantities, thereby

The PREP method can be used to improve the cost performance of metal powders and adapt them to various This will improve the cost effectiveness of the PREP method and enable it to be adapted to various types of 3D printing equipment, making it more widely used in 3D printing.

Frequently Asked Questions (FAQ)

1) What powder specs matter most for aerospace-grade Metal Powder Additive Manufacturing?

- Tight particle-size distribution (LPBF: typically 15–45 μm), high sphericity (>98% where possible), low satellites, low O/N/H (per alloy-specific limits), and consistent flowability and apparent/tap density per ISO/ASTM 52907.

2) How do PREP and gas atomization compare for aerospace parts?

- PREP (plasma rotating electrode) yields ultra-clean, highly spherical powders with low inclusions—ideal for critical LPBF/DED builds but with lower yield and higher cost. Gas atomization (VIGA/EIGA) provides scale and cost efficiency with excellent sphericity; EIGA reduces contamination via crucible-free melting.

3) What storage and handling practices minimize oxygen pickup and variability?

- Use sealed inert containers, maintain RH <10% and O2 <0.1% during handling, inert-glovebox or closed-loop powder stations, track reuse cycles, and test O/N/H, PSD, and Hall/Carney flow each cycle.

4) How many reuse cycles are acceptable in aerospace production?

- With closed-loop inert handling and sieving, 6–10 cycles are common before blending with 20–50% virgin powder. Qualification plans should define limits tied to oxygen increase and PSD shifts.

5) Which AM process should I choose for large aerospace structures vs intricate features?

- LPBF for fine, high-accuracy lattice and thin-wall features; EBM for larger, coarser titanium builds with lower residual stress; DED/LENS for large near-net structures and repairs; Binder Jetting for high-throughput small/medium components followed by sintering and HIP.

2025 Industry Trends in 3D Printing Metal Powders for Aerospace

- Multi-laser LPBF at scale: 8–12 laser platforms with synchronized stitching deliver 20–35% throughput gains while maintaining >99.7% relative density.

- AI in-situ control: Coaxial melt pool sensing with real-time parameter modulation reduces lack-of-fusion and improves fatigue scatter bands.

- Powder circularity: Closed-loop inert reconditioning extends reuse to 8–12 cycles with minimal chemistry drift; digital material passports improve traceability.

- Titanium and Ni-superalloy focus: Expanded PREP/EIGA capacity for Ti-6Al-4V, Ti-6242, Inconel 718/625 to meet flight-rate demand.

- Standardization: Faster qualification using ISO/ASTM 52907 + ASTM process routes; more OEM-shared parameter sets for cross-machine transfer.

2025 Performance and Supply Snapshot

| KPI (Aerospace AM Powders) | 2023 Baseline | 2025 Status | Notes/Source |

|---|---|---|---|

| LPBF throughput gain | — | +20–35% | Multi-laser sync; higher scan speeds. OEM app notes |

| Relative density (LPBF Ti/Ni) | 99.5–99.8% | 99.6–99.9% | AI-assisted control; HIP optional. Peer-reviewed studies |

| Oxygen content AM-grade (wt%) | 0.03–0.08 | 0.02–0.06 | Closed-loop handling; ISO/ASTM 52907 |

| Typical reuse cycles (pre-blend) | 3–6 | 6–10 | Inert reconditioning; ASTM AM CoE |

| Powder price trend (Ti/Ni, USD/kg) | rising | stable to slight down | Added atomizer capacity. Wohlers 2025 |

| Argon use per kg powder (GA) | — | −25–40% | Argon reclamation systems. Plant reports |

| CT-detected lack-of-fusion in QA | medium | lower | In-situ feedback + parameter libraries. NIST/AM-Bench |

Key references:

- ISO/ASTM 52907:2023 (powder characterization) https://www.iso.org/standard/78974.html

- ASTM AM CoE process qualification resources https://amcoe.astm.org/

- NIST AM-Bench datasets and validation studies https://www.nist.gov/ambench

- Wohlers Report 2025 market insights https://wohlersassociates.com/

Latest Research Cases

Case Study 1: Multi‑Laser LPBF of Ti‑6Al‑4V Brackets with AI In‑Situ Control (2025)

Background: An aerospace supplier scaling Ti‑6Al‑4V LPBF on a 12‑laser system observed stitch-line porosity and variable fatigue life.

Solution: Implemented coaxial melt pool sensing with AI-driven power/speed modulation and adaptive contour remelting; tightened powder QA (PSD 20–40 μm, O ≤ 0.12 wt% for Ti) and controlled reuse with 30% virgin blending.

Results: Porosity dropped from 0.42% to 0.11%; HCF life (R=0.1) median +28%; first‑pass yield +19%; stable properties through 8 reuse cycles confirmed by CT and O/N/H testing per ISO/ASTM 52907.

Case Study 2: EIGA 718 vs GA 718 Powders for Turbine Vane LPBF + HIP (2024)

Background: An engine OEM compared EIGA and GA Inconel 718 powders for vanes requiring excellent crack tolerance.

Solution: Parallel builds with identical scan strategies; HIP and solution aging; inclusion analysis by SEM/EDS; LCF/HCF testing.

Results: Both exceeded 99.8% density post‑HIP; EIGA batches showed ~12% fewer inclusions and slightly improved LCF; GA offered ~10% lower powder cost and better availability. Decision: EIGA for life‑limited hot‑section parts; GA for non‑critical hardware.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Viewpoint: “For aerospace LPBF, rigorous powder characterization—oxygen, flow, PSD per ISO/ASTM 52907—has greater impact on part reliability than marginal increases in laser power.” Source: NIST AM workshops https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Viewpoint: “Synchronization of multi‑laser strategies is essential to avoid stitch defects and preserve isotropy and fatigue strength in flight hardware.” Source: AM conference proceedings https://www.utwente.nl/ - Dr. Anushree Chatterjee, Director, ASTM International Additive Manufacturing Center of Excellence

Viewpoint: “2025 round‑robin datasets are compressing powder and process qualification timelines, enabling faster cross‑platform parameter adoption for aerospace alloys.” Source: ASTM AM CoE https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Powder characterization for AM (requirements and test methods)

https://www.iso.org/standard/78974.html - ASTM AM CoE: Standards, qualification guides, round‑robin data

https://amcoe.astm.org/ - NIST AM‑Bench: Public datasets for validating LPBF/EBM models

https://www.nist.gov/ambench - Senvol Database: Machines, materials (3D printing metal powders), and specs

https://senvol.com/database - HSE ATEX/DSEAR safety guidance for metal powder handling

https://www.hse.gov.uk/fireandexplosion/atex.htm - Open-source tools: pySLM (scan strategy optimization), AdditiveFOAM (thermal/porosity simulation), Thermo‑Calc (CALPHAD for alloy design), pyAM utilities

Last updated: 2025-08-27

Changelog: Added FAQs tailored to aerospace powder requirements, 2025 trends with KPI table and sources, two recent aerospace-focused case studies, expert opinions, and practical tools/resources.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major OEM multi‑laser parameter releases, or supply/cost shifts for Ti/Ni aerospace powders.