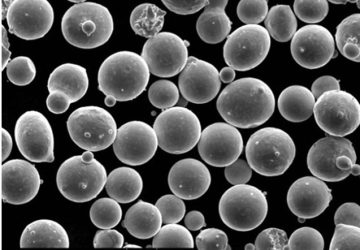

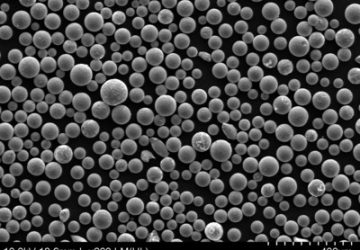

inconel powder

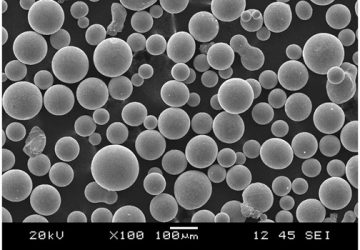

nickel powder

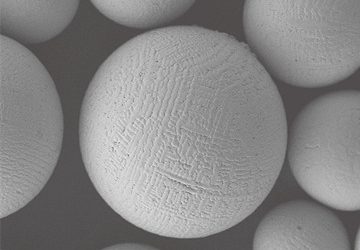

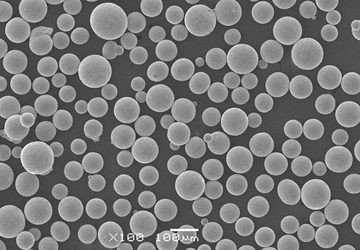

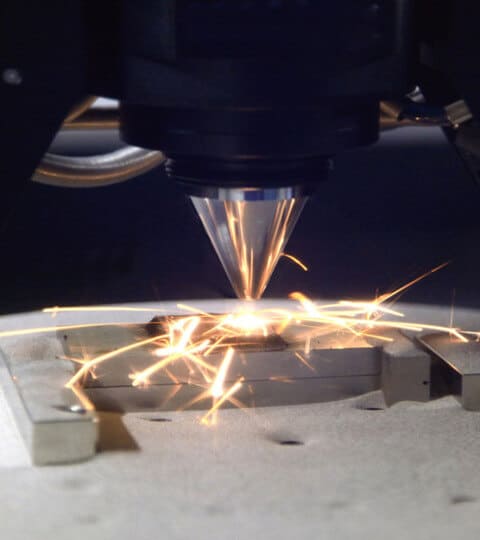

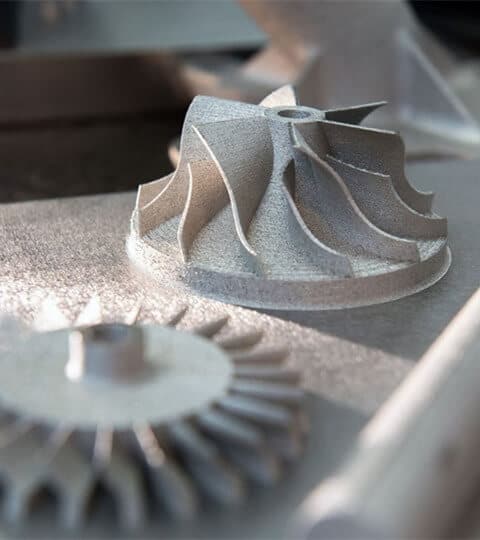

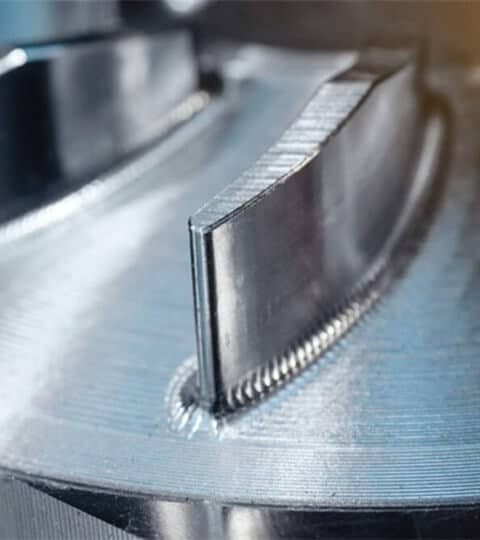

inconel powder additive manufacturing

High-temperature alloys are iron, nickel, and cobalt-based metal materials that can work for a long time at temperatures above 600°C and under certain stresses, and have excellent high-temperature strength, good resistance to oxidation and thermal corrosion, good fatigue properties, fracture toughness, and other comprehensive properties, also known as “superalloy“.

Our Inconel powder is mainly used in SLM, EBM, HIP, MIM, LDM. The particle size of the powders is 15-53μm, 45-106μm, 45-150μm, etc.

| Inconel Powders Produced by Gas Atomizing | |||||

| Superalloy Powders | |||||

| Alloy grades | Chemistry | Particle Size | ASTM | AMS | |

| Hastelloy X (GH3536) | Ni Bal. | Co 0.5 – 2.5 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B572 | 5754 |

| Cr 20.5 – 23.0 | Al 0.5max | ||||

| Fe 17.0 – 20.0 | W 0.2 – 1.0 | ||||

| C 0.05 – 0.15 | B 0.01max | ||||

| Mn 1.0max | P 0.04max | ||||

| Si 1.0max | S 0.03max | ||||

| Mo 8.0 – 10.0 | Ti 0.15max | ||||

| Cu 0.5max | |||||

| Inconel 625 (GH3625) | Ni Bal. | Nb+Ta: 3.15-4.15 | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B446 | 5666 |

| C 0.10max | Co 1.0max | ||||

| Mn 0.50max | Mo 8.0-10.0 | ||||

| Si 0.50max | Fe 5.0 max | ||||

| P 0.015 max | Al 0.40max | ||||

| S 0.015 max | Ti 0.40max | ||||

| Cr 20.0-23.0 | |||||

| Inconel 718 (GH4169) | Ni 50.0-55.0 | Co 1.0max | 0-45μm 0-53μm 15-45μm 15-53μm 45-106μm 53-150μm | B637 | 5664 |

| C 0.08max | Mo 2.80-3.30 | ||||

| Mn 0.35max | Nb+Ta: 4.75-5.50 | ||||

| Si 0.35max | Ti 0.65-1.15 | ||||

| P 0.015 max | Al 0.20-0.80 | ||||

| S 0.015 max | B 0.006max | ||||

| Cu 0.30max | Fe Bal. | ||||

| Cr 17.0-21.0 | |||||

| Haynes alloy 188 (GH5188) | C 0.05-0.15 | Cr 20.0-24.0 | 15-53μm 15-45μm 53-150μm | – | 5772 |

| Mn 1.25max | W 13.0-16.0 | ||||

| Si 0.20-0.50 | La 0.02-0.12 | ||||

| P 0.020max | B 0.015max | ||||

| S 0.015 max | Fe 3.0max | ||||

| Ni 20.0-24.0 | Co Bal. | ||||

application

Our products can be used in 3D Printing /small mechanical parts with complex shapes, high precision, and high-performance materials such as 3C electronics, hand tools, remote control cars. etc.

about us

Truer Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]