SLM technology

SLM, also known as Selective Laser Melting, is similar in principle to SLS in that a laser is used to melt and solidify metal powder in a specified area, which is then molded in a layer-by-layer stack.

SLM technology

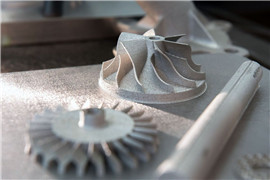

SLM technology is currently mainly used in industry and has outstanding technical advantages in areas such as complex moulds, personalised medical parts and automobiles.

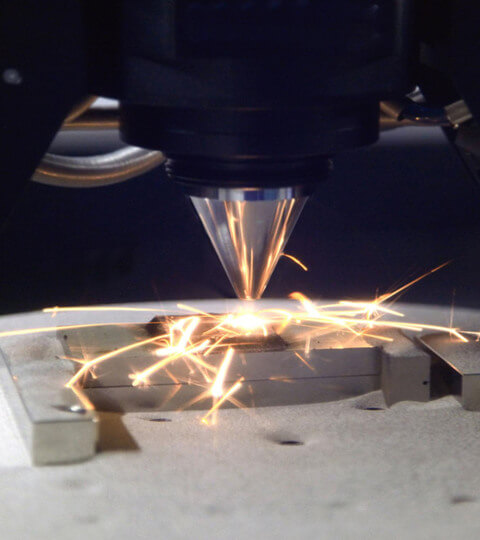

Process principle

SLM, also known as Selective Laser Melting, is similar in principle to SLS in that a laser is used to melt and solidify metal powder in a specified area, which is then moulded in a layer-by-layer stack.

The model is first support loaded in the software, and when the support loading is complete a slice export is performed to import the data into the printer.

Process of 3D Printing

The laser emits a beam of laser light which will be directed to a designated area under computer control. The metal powder in the irradiated area will melt and the molten metal will quickly cool and solidify.

After printing one layer, the forming substrate is lowered by one layer and the squeegee lays down a new layer of powder, and so on until the part is formed.

After printing the basal plate is raised, the excess powder is swept away from the basal plate and the basal plate is then removed from the studio.

After the workpiece has been printed and the support removed from the model, the workpiece is ground and polished with a grinder and the workpiece is completed.

truer industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

- Professional Specialist

- Fair prices

- Top sales and quality

- Support customization

What We Offer

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Relying on the innovation platform of top labs, the company has established a joint innovation center for metal 3D printing, and is working with high-level research institutions and well-known experts to carry out 3D printing innovation.

Shanghai Truer’s professional team continues to provide customers with personalized additive manufacturing solutions to promote industry technology development and expand the application areas of 3D printing. From testing to finished products, from professional customization to scale manufacturing, we continue to create value to industry through technological innovation.

Applications

3D Printing

HIP technology is now widely used in cemented carbide sintering, densification of refractory metals and alloys such as tungsten, aluminium and titanium, defect repair of products (e.g. 3D printed metal parts)

precision instruments

MIM products can be complex in shape, precise in size, high in strength and produced automatically in large quantities, and can significantly reduce the complexity and cost of traditional metalworking

Complex moulds

SLM, also known as Selective Laser Melting, is similar in principle to SLS in that a laser is used to melt and solidify metal powder in a specified area, which is then moulded in a layer-by-layer stack.

We Provide the Best Service in AM Industry

We offer free expert consultation opportunities