Nickel-based powders have become a cornerstone of various industries, renowned for their exceptional properties and versatility. These finely-ground materials, primarily composed of nickel and meticulously selected alloying elements, offer a compelling combination of strength, heat resistance, and corrosion defiance, making them ideal for demanding applications.

Physical and Chemical Properties of Nickel-Based Powders

| Property | Description |

|---|---|

| High Purity | Typically exceeding 99% nickel content, ensuring consistent performance. |

| Controlled Particle Size and Morphology | Tailored for specific applications, influencing flowability, packing density, and sintering behavior. |

| Excellent Thermal Conductivity | Facilitates efficient heat transfer, crucial for applications like heat exchangers and thermal management systems. |

| Good Electrical Conductivity | Enables diverse electrical applications, including battery electrodes and electronic components. |

| Superior Corrosion Resistance | Exhibits remarkable resistance to oxidation, acidic/alkaline environments, and pitting/crevice corrosion, extending product lifespan. |

| Outstanding High-Temperature Performance | Retains structural integrity and mechanical properties even under extreme heat, making them suitable for applications like gas turbines and aerospace engines. |

| Impressive Mechanical Strength | Offers exceptional resistance to deformation, cracking, and wear, ideal for components requiring high durability. |

Processing Performance of Nickel-Based Powders

Nickel-based powders are not just remarkable materials themselves, but they also possess a unique advantage: their exceptional processing performance. This translates to their ability to thrive in various manufacturing techniques, making them highly sought-after in numerous industries. Let’s delve deeper into two key areas where these powders truly shine:

1. Powder Metallurgy (PM): This technique involves compacting and sintering metal powders to create near-net-shape components. Nickel-based powders excel in PM due to their:

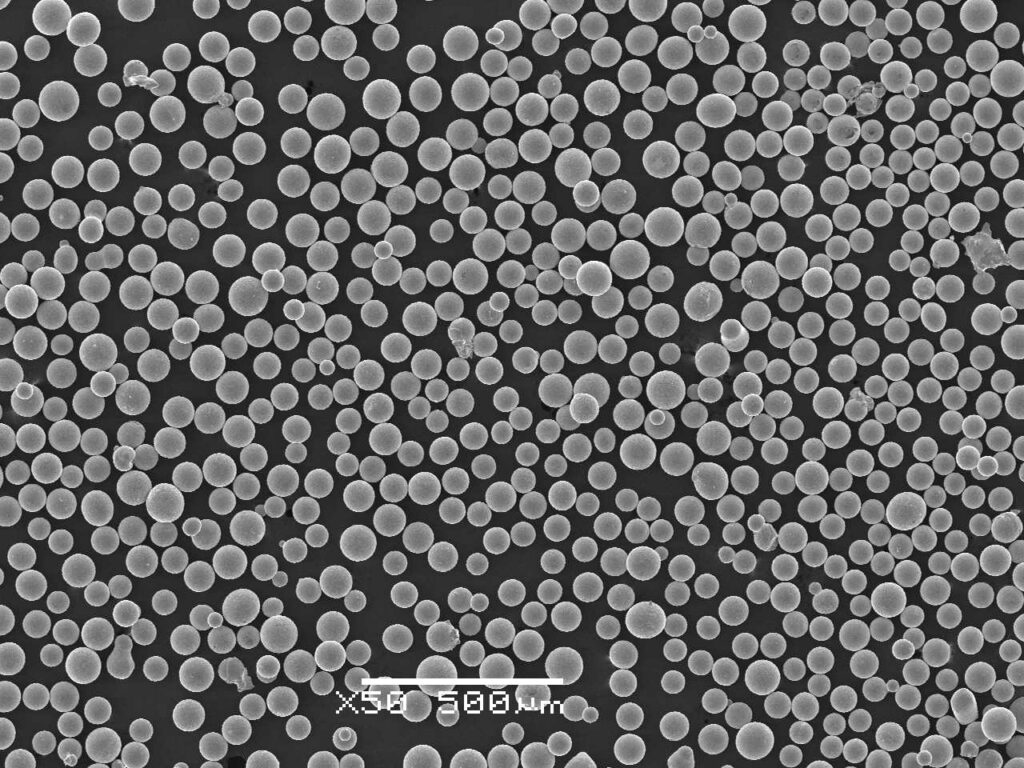

- Fine and uniform particle size: This allows for efficient packing during compaction, leading to denser and stronger final products.

- Sphericity: Spherical particles flow better, enabling uniform distribution within the mold and reducing the risk of defects during compaction.

- High purity: This ensures consistent material properties and minimizes the formation of unwanted phases during sintering.

As a result, PM with nickel-based powders allows for the creation of intricate components with:

- Enhanced mechanical properties: These include high strength, good ductility, and excellent wear resistance.

- Complex geometries: The ability to create near-net-shape components significantly reduces the need for post-processing, minimizing material waste and production costs.

2. Additive Manufacturing (AM): Also known as 3D printing, AM utilizes computer-aided design (CAD) data to build objects layer-by-layer. Nickel-based powders are ideal for AM due to their:

- Sphericity: This ensures smooth flowability through the printing nozzle, enabling precise deposition and intricate design features.

- High melting point: This allows for the creation of structures with excellent thermal stability, ideal for high-temperature applications.

- Tailorable properties: By manipulating the composition and processing parameters, the properties of the final product can be customized to meet specific requirements.

Therefore, AM with nickel-based powders enables the production of:

Highly complex structures: This unlocks the possibility of creating intricate designs that are impossible with traditional manufacturing methods.

Lightweight components: The efficient use of material in AM combined with the inherent properties of nickel-based powders, such as high strength-to-weight ratio, results in lightweight yet robust structures.

Applications of Nickel-Based Powders

Nickel-based powders find extensive use across various industries due to their unique properties:

| Industry | Application Examples |

|---|---|

| Aerospace: | Turbine blades, rocket engine components, heat exchangers, and landing gear. |

| Automotive: | Engine components, exhaust manifolds, and catalytic converters. |

| Energy: | Gas turbine components, heat exchangers, and chemical processing equipment. |

| Chemical Processing: | Reactors, pumps, and valves for harsh environments. |

| Electronics: | Battery electrodes, electrical contacts, and heat sinks. |

| Medical: | Prosthetic implants, surgical instruments, and dental applications. |

Specific Metal Powder Models and Their Descriptions

While an exhaustive list exceeds the scope of this article, here are 10 commonly used nickel-based powder models with their defining characteristics:

IN625: This widely used alloy possesses excellent high-temperature strength, oxidation resistance, and fabricability, making it ideal for turbine blades, discs, and combustors in aerospace applications.

Inconel 625: Offers superior creep resistance and strength compared to IN625, making it suitable for hotter sections of gas turbines and combustors.

Inconel 718: Renowned for its exceptional strength, high-temperature performance, and good corrosion resistance, making it a popular choice for aerospace components, discs, and fasteners.

Rene 41: Delivers exceptional creep resistance and strength at very high temperatures, ideal for turbine blades and other hot-section components in jet engines.

AM350: A gas-atomized nickel-based superalloy powder specifically designed for additive manufacturing, offering a balance of strength, ductility, and high-temperature performance.

AWS A5.16 ERNi-1: A nickel welding powder known for its excellent weldability, corrosion resistance, and high-temperature strength, used for joining similar and dissimilar metals.

Nickel 200: A commercially pure nickel powder featuring high ductility, excellent electrical conductivity, and good corrosion resistance, used in electronics, electrodes, and chemical processing equipment.

Nickel 270: Offers better high-temperature strength compared to Nickel 200, making it suitable for applications requiring moderate strength at elevated temperatures.

Nickel 601: A nickel-chromium alloy powder known for its good oxidation resistance and high-temperature strength, used in electrical heating elements, furnace components, and heat exchangers.

Nickel-Copper: Combining nickel’s corrosion resistance with copper’s superior electrical conductivity, this powder finds application in brazing alloys, electrical contacts, and heat sinks.

Advantages and Limitations of Nickel-Based Powders

Pros:

- Exceptional mechanical properties: Nickel-based powders offer outstanding strength, wear resistance, and high-temperature performance, making them ideal for demanding applications.

- Superior corrosion resistance: They exhibit remarkable resistance to various corrosive environments, ensuring long-lasting performance and reduced maintenance costs.

- Versatility: These powders can be processed using various techniques like powder metallurgy and additive manufacturing, enabling the creation of complex and diverse components.

- Tailorable properties: By adjusting the composition, particle size, and processing methods, the properties of nickel-based powders can be fine-tuned for specific applications.

Cons:

- High cost: Compared to other materials, nickel-based powders can be more expensive due to the high cost of raw materials and complex processing involved.

- Brittleness: Certain types of nickel-based powders can be brittle, requiring careful handling and processing techniques to avoid cracking.

- Limited ductility: Compared to some materials like steel, nickel-based powders may exhibit lower ductility, limiting their suitability for applications requiring significant deformation.

Choosing the Right Powder

Selecting the most suitable nickel-based powder for your application requires considering several crucial factors:

- Intended application: The specific function and operating conditions of the component will significantly influence the required properties of the powder.

- Processing method: Whether you plan to use powder metallurgy, additive manufacturing, or other techniques will impact the powder’s desired characteristics.

- Mechanical properties needed: Consider the required strength, wear resistance, and high-temperature performance for your application.

- Corrosion resistance requirements: Evaluate the specific corrosive environment the component will encounter and choose a powder with adequate resistance.

- Cost considerations: While nickel-based powders offer exceptional properties, their cost might be a factor depending on your budget constraints.

Expert Opinions and Industry Trends

Industry experts acknowledge the growing demand for nickel-based powders driven by their unique combination of properties and the increasing adoption of additive manufacturing technologies. Advancements in powder production methods are expected to lead to more cost-effective and efficient production processes, further expanding their applications across various industries.

Conclusion

Nickel-based powders have established themselves as a valuable material in diverse industrial sectors due to their exceptional properties, versatility, and potential for advanced manufacturing techniques. By understanding their characteristics, advantages, limitations, and selection criteria, you can unlock their potential for creating high-performance and durable components in various demanding applications.

FAQs

Q: What are the typical particle sizes of nickel-based powders?

A: The particle size of nickel-based powders can vary depending on the application. They typically range from 10 to 150 microns, with finer particles offering better surface area and packing density, while coarser particles might improve flowability and reduce processing costs.

Q: Are nickel-based powders safe to handle?

A: Nickel dust can be harmful if inhaled. Proper safety precautions, including wearing appropriate personal protective equipment (PPE) such as masks and gloves, are crucial when handling and processing nickel-based powders.

Q: What are some emerging applications of nickel-based powders?

A: The increasing adoption of additive manufacturing is opening new possibilities for nickel-based powders in creating lightweight and intricate components for aerospace, medical implants, and other demanding applications. Research is also ongoing to explore their potential in energy storage solutions and catalysts.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) Which nickel-based powders are most common for additive manufacturing and why?

- IN718 and IN625 lead due to balanced weldability, strength, and corrosion/oxidation resistance with robust, published process windows. Emerging high-temperature grades include IN738LC and IN939, which need tighter oxygen control and post-processing.

2) What powder characteristics most affect AM build quality?

- Particle size distribution (typically 15–45 μm for LPBF), high sphericity (>0.93), low satellites, controlled O/N/H (e.g., O ≲0.03–0.06 wt% for Ni superalloys), stable flow (Hall/Carney), and consistent apparent/tap density per ISO/ASTM 52907.

3) Can nickel-based powders be reused without degrading properties?

- Yes, with inert handling, sieving, and blending rules. Track PSD shift, oxygen/nitrogen pickup (ASTM E1019), flow, and density. Many shops achieve 5–10 reuse cycles before blending with virgin powder.

4) How do gas-atomized and water-atomized nickel powders differ?

- Gas atomized powders are more spherical with superior flow—preferred for LPBF and thermal spray. Water atomized powders are irregular, lower cost, and common in press-and-sinter powder metallurgy where flow aids and compaction compensate.

5) What post-processing is typical for AM nickel superalloy parts?

- Stress relief, hot isostatic pressing (HIP) for porosity, solution and age heat treatments (e.g., for IN718), machining/EDM, and surface finishing. Qualification often follows aerospace/medical standards and OEM specs.

2025 Industry Trends: Nickel-Based Powders

- Productivity gains: Multi-laser LPBF and scan optimization boost build rates 20–60% for IN718/IN625.

- Powder circularity: Digital material passports document PSD, O/N/H, reuse counts, and COA data; reuse windows extended with tighter QA.

- Advanced atomization: Close‑coupled gas atomization and selective He‑assist reduce satellites and narrow PSD; argon recovery cuts gas use 20–40%.

- Qualification acceleration: Wider use of standardized artifacts and data packages shortens aerospace and energy part approvals.

- Sustainability disclosures: More suppliers report recycled content (5–20%) and energy intensity per kg of powder.

2025 KPI Snapshot for Nickel-Based Powders (indicative ranges)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| LPBF build rate (cm³/h per laser, IN718) | 25–40 | 35–60 | Multi-laser + path tuning |

| As-built relative density (optimized) | 99.5–99.8% | 99.6–99.9% | CT verification on coupons |

| Oxygen content (wt%, AM grade) | 0.04–0.08 | 0.03–0.06 | Improved inert handling |

| Sphericity (gas-atomized) | 0.92–0.95 | 0.94–0.97 | Enhanced nozzle design |

| Reuse cycles before blend | 3–6 | 5–10 | Digital passports + sieving |

| Argon consumption (Nm³/kg powder) | 2.0–4.0 | 1.5–3.0 | Recovery systems adoption |

References: ISO/ASTM 52907; ASTM E1019; ASTM B212/B213/B703; NIST AM‑Bench; OEM application notes (EOS, SLM Solutions, GE Additive); industry sustainability reports

Latest Research Cases

Case Study 1: Multi‑Laser Overlap Calibration for IN718 Brackets (2025)

Background: An aerospace supplier observed stitch-line defects and roughness where laser fields overlapped.

Solution: Implemented automated multi‑laser alignment, synchronized hatch rotations, and in‑situ photodiode monitoring; standard HIP + age for IN718.

Results: Lack‑of‑fusion in overlap zones −48%; surface Ra improved from 19 μm to 12 μm; fatigue life at 650°C (R=0.1) +17%; scrap rate −23%.

Case Study 2: Argon Recovery Retrofit in Gas Atomization of IN625 (2024)

Background: A powder producer aimed to cut operating costs and stabilize oxygen levels.

Solution: Installed cryogenic argon recovery and O2 ppm real‑time monitoring; optimized gas‑to‑melt ratio to curb satellites.

Results: Argon use −34%; median O reduced from 0.061 to 0.045 wt%; satellite count −29%; customer Hall flow improved by 1.7 s/50 g.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Standardized powder metrics—PSD, O/N/H, flow, and density—combined with digital traceability are foundational to reproducible Nickel‑Based Powders performance in AM.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “In 2025, parameter portability and multi‑laser calibration push nickel superalloys from pilot runs to dependable serial production.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Alignment of supplier COAs with ISO/ASTM test methods and material passports is shortening qualification cycles across regulated sectors.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Feedstock characterization for metal AM powders

https://www.iso.org/standard/78974.html - ASTM standards for Ni powders: E1019 (O/N/H), B212/B213/B703 (density/flow), F3301/F3571 (LPBF practices)

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for additive manufacturing

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Nickel‑Based Powders applications

https://senvol.com/database - HSE ATEX/DSEAR guidance for combustible metal powders handling

https://www.hse.gov.uk/fireandexplosion/atex.htm - OEM parameter libraries and data sheets (GE Additive, EOS, SLM Solutions, 3D Systems, Renishaw)

Last updated: 2025-08-27

Changelog: Added 5 targeted FAQs, 2025 KPI table, two recent case studies, expert viewpoints, and authoritative tools/resources focused on Nickel‑Based Powders in AM and PM.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, major OEMs release new Ni alloy parameter sets, or new data on powder circularity and argon recovery adoption becomes available.