Introduction

Laser-based Powder Bed Fusion (PBF) is an advanced additive manufacturing (AM) process that has revolutionized how we create complex metal parts. Whether you’re in aerospace, automotive, or even medical industries, the chances are you’ve encountered products made using this technology. This guide will explore the intricacies of laser-based PBF, diving into the types of metal powders used, the process’s technical details, and its applications. We’ll also compare it with other manufacturing methods, discuss its pros and cons, and provide valuable insights for anyone looking to implement or learn about this transformative technology.

Overview of Laser-Based Powder Bed Fusion

Laser-Based Powder Bed Fusion (PBF) is a form of additive manufacturing that uses a high-powered laser to fuse metallic powders into solid structures layer by layer. The technology is known for producing highly complex geometries that are difficult or impossible to achieve using traditional manufacturing methods. PBF is particularly valued in industries requiring high precision, such as aerospace, automotive, and medical device manufacturing.

- Technology: Laser-Based Additive Manufacturing

- Process: Powder Bed Fusion

- Materials Used: Metal powders

- Key Industries: Aerospace, Automotive, Medical, Tooling

- Advantages: High precision, complex geometries, material efficiency

- Limitations: High cost, slow production speeds

Types of Metal Powders Used in Laser-Based Powder Bed Fusion

Choosing the right metal powder is crucial for the success of a PBF project. Each type of powder offers unique properties that can significantly impact the final product’s strength, durability, and performance.

| Metal Powder | Composition | Properties | Applications |

|---|---|---|---|

| Titanium (Ti-6Al-4V) | 90% Titanium, 6% Aluminum, 4% Vanadium | High strength-to-weight ratio, corrosion resistance | Aerospace, medical implants |

| Stainless Steel (316L) | Iron, Chromium, Nickel, Molybdenum | Corrosion-resistant, good weldability | Medical, food processing |

| Inconel 718 | Nickel-Chromium alloy | High-temperature resistance, excellent creep resistance | Aerospace, gas turbines |

| Aluminum (AlSi10Mg) | Aluminum, Silicon, Magnesium | Lightweight, good thermal conductivity | Automotive, aerospace |

| Cobalt-Chromium (CoCr) | Cobalt, Chromium | High wear and corrosion resistance | Dental, orthopedic implants |

| Maraging Steel (1.2709) | Nickel, Molybdenum, Cobalt | High strength, toughness | Tooling, aerospace |

| Copper (CuCrZr) | Copper, Chromium, Zirconium | Excellent electrical and thermal conductivity | Electronics, heat exchangers |

| Hastelloy X | Nickel, Molybdenum, Chromium, Iron | High oxidation resistance, good weldability | Chemical processing, aerospace |

| Tool Steel (H13) | Chromium, Molybdenum, Vanadium | High toughness, wear resistance | Injection molds, die casting |

| Nickel Alloy (Hastelloy C-276) | Nickel, Molybdenum, Chromium | Exceptional corrosion resistance | Chemical processing, nuclear reactors |

Process of Laser-Based Powder Bed Fusion

Understanding the process of laser-based PBF is essential for appreciating its capabilities and limitations. The following sections will break down each step of the process, from powder preparation to post-processing.

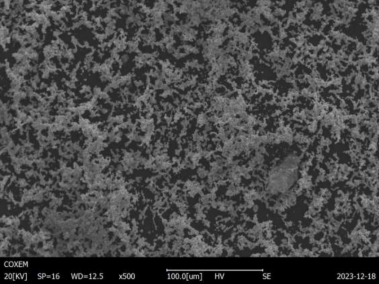

Powder Preparation

The first step in the PBF process is the preparation of metal powder. Powders must meet strict specifications regarding particle size, distribution, and purity. This ensures that the powder spreads evenly across the build platform and that the laser can fuse it effectively.

- Particle Size: Typically ranges from 15-45 microns

- Purity: Must be free of contaminants to prevent defects in the final part

- Moisture Content: Must be minimized to avoid clumping

Layer-by-Layer Fabrication

Once the powder is prepared, it is evenly spread across the build platform. The laser then selectively fuses the powder based on the design specifications provided by a CAD file.

- Laser Type: Typically a fiber laser with a wavelength of 1.064 microns

- Laser Power: Ranges from 200W to 1000W depending on the material and part requirements

- Scanning Speed: Up to 7 m/s

- Layer Thickness: Typically 20-60 microns

Post-Processing

After the part is fully built, it undergoes several post-processing steps to achieve the desired properties. This may include heat treatment, surface finishing, and removal of any residual powder.

- Heat Treatment: Used to relieve stresses and improve mechanical properties

- Surface Finishing: Methods like CNC machining, polishing, or coating are used to achieve the desired surface finish

- Powder Removal: Unfused powder is removed and can be recycled for future builds

Quality Control

Quality control is an integral part of the PBF process, ensuring that the final parts meet the required specifications.

- Dimensional Accuracy: Typically within ±0.1 mm

- Surface Roughness: Typically ranges from Ra 6 to 12 µm, depending on material and layer thickness

- Mechanical Testing: Tensile, fatigue, and hardness tests are often performed to verify part integrity

Characteristics of Laser-Based Powder Bed Fusion

The characteristics of PBF make it an ideal choice for certain applications but also limit its use in others. Below, we’ll explore these characteristics in more detail.

| Characteristic | Description |

|---|---|

| Precision | Capable of producing parts with high dimensional accuracy and fine detail. Ideal for complex geometries and tight tolerances. |

| Material Efficiency | Powder can be recycled, minimizing waste. However, efficiency depends on the ability to remove and reuse unfused powder. |

| Surface Finish | Generally rougher than traditionally manufactured parts. Post-processing is often required to meet surface finish requirements. |

| Speed | Relatively slow compared to other manufacturing methods, making it less suitable for high-volume production. |

| Cost | High initial costs for equipment and materials, but can be cost-effective for small batches or custom parts. |

| Complexity | Excellent for producing intricate designs that are difficult or impossible with conventional methods. |

| Material Properties | Properties of the final part can be tailored through material selection and post-processing techniques. |

| Support Structures | Often required to prevent warping and ensure part stability during the build. These must be carefully designed and removed after fabrication. |

Applications of Laser-Based Powder Bed Fusion

The versatility of PBF makes it suitable for a wide range of applications across various industries. The following table highlights some of the most common uses.

| Industry | Application | Example Components |

|---|---|---|

| Aerospace | Lightweight, complex parts | Turbine blades, brackets, fuel nozzles |

| Automotive | High-performance components | Engine parts, transmission components |

| Medical | Custom implants and prosthetics | Hip implants, dental crowns, surgical instruments |

| Tooling | High-strength tools and molds | Injection molds, cutting tools, dies |

| Electronics | Thermal management components | Heat exchangers, connectors, housings |

| Energy | High-temperature components | Gas turbine parts, fuel cells, heat exchangers |

| Defense | Specialized components | Weapon systems, armor, communication devices |

| Architecture | Complex, aesthetic designs | Custom fixtures, artistic installations |

| Jewelry | Intricate, customized designs | Rings, necklaces, bracelets |

Advantages and Limitations of Laser-Based Powder Bed Fusion

Like any manufacturing method, PBF has its pros and cons. Understanding these can help you decide if this technology is the right fit for your project.

| Advantages | Limitations |

|---|---|

| High Precision | High Cost |

| Capable of producing intricate and complex parts with excellent dimensional accuracy. | Initial investment in equipment and materials is significant, making it less cost-effective for high-volume production. |

| Material Efficiency | Slow Production Speed |

| Ability to recycle unused powder reduces waste and material costs. | The layer-by-layer process is time-consuming, especially for large parts. |

| Customizability | Surface Roughness |

| Ideal for producing custom, one-of-a-kind parts, such as medical implants. | Parts often require post-processing to achieve the desired surface finish. |

| Complex Geometries | Support Structure Requirements |

| Enables the creation of designs that are impossible with traditional methods. | Support structures are often needed, which can complicate the design and increase post-processing time. |

| Wide Material Selection | Material Limitations |

| Compatible with a wide range of metals and alloys. | Not all materials can be effectively processed using PBF, limiting the choice of materials for certain applications. |

Comparing Laser-Based Powder Bed Fusion with Other Manufacturing Methods

How does laser-based PBF stack up against other manufacturing technologies? Let’s break it down by comparing it to conventional machining, casting, and other additive manufacturing methods.

| Method | Advantages Compared to PBF | Disadvantages Compared to PBF |

|---|---|---|

| Machining | Faster for high-volume production, better surface finish without post-processing | Limited to simpler geometries, more material waste, less material efficiency |

| Casting | Suitable for large, complex parts, lower material costs | Requires molds, can lead to defects, less precision compared to PBF |

| Injection Molding | Extremely fast for high-volume production, very low cost per part | Limited to simpler designs, high initial tooling cost, not as customizable |

| Electron Beam Melting (EBM) | Faster build times for large parts, no support structures needed | Limited material choices, lower resolution compared to PBF |

| Stereolithography (SLA) | Excellent surface finish for polymer parts, fast build times | Not suitable for metals, limited material properties compared to PBF |

Key Specifications for Laser-Based Powder Bed Fusion

When considering laser-based PBF, understanding the key specifications and standards involved is crucial. Here’s a summary of the most important parameters.

| Specification | Description |

|---|---|

| Layer Thickness | Typically ranges from 20 to 60 microns, affecting build time and detail. |

| Build Volume | Varies by machine; common sizes are 250x250x300 mm or 500x500x500 mm. |

| Laser Power | Ranges from 200W to 1000W, influencing the speed and quality of the build. |

| Scanning Speed | Up to 7 m/s, affecting how quickly the part is built. |

| Build Speed | Generally slower compared to other methods, dependent on part size and complexity. |

| Material Types | Includes titanium, stainless steel, aluminum, cobalt-chrome, and others. |

| Post-Processing | Includes heat treatment, surface finishing, and powder removal. |

Suppliers and Pricing for Laser-Based Powder Bed Fusion Systems

Knowing where to source equipment and materials can make a big difference in your project’s success. Here’s a snapshot of some prominent suppliers and their pricing information.

| Supplier | Equipment | Price Range | Notes |

|---|---|---|---|

| EOS | EOS M 290, EOS P 396 | $500,000 – $1,000,000 | Known for high precision and reliability. |

| SLM Solutions | SLM 280, SLM 500 | $450,000 – $1,200,000 | Offers large build volumes and high speed. |

| Renishaw | RenAM 500Q, RenAM 500M | $400,000 – $1,000,000 | Emphasizes flexibility and high resolution. |

| 3D Systems | ProX DMP 320, ProX DMP 200 | $400,000 – $900,000 | Features advanced material handling and precision. |

| GE Additive | Concept Laser M2, Arcam A2X | $600,000 – $1,500,000 | Known for high performance and extensive material options. |

| Trumpf | TruPrint 1000, TruPrint 3000 | $350,000 – $1,000,000 | Offers compact and scalable solutions. |

| Additive Industries | MetalFAB1 | $500,000 – $1,200,000 | Provides modular and scalable systems. |

| ExOne | ExOne X1-Lab, ExOne X1 160Pro | $300,000 – $800,000 | Focuses on binder jetting as well as PBF. |

| DMLS | DMLS M2, DMLS M1 | $500,000 – $1,000,000 | Known for precision and high-quality parts. |

| Sinterit | Lisa X, Lisa PRO | $100,000 – $300,000 | Offers lower-cost solutions for smaller-scale production. |

FAQ

Let’s tackle some frequently asked questions about laser-based Powder Bed Fusion to help clear up any lingering uncertainties.

| Question | Answer |

|---|---|

| What is the primary advantage of laser-based PBF over traditional manufacturing methods? | Laser-based PBF allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional methods. It also reduces material waste by recycling unused powder. |

| How does the cost of laser-based PBF compare to other manufacturing technologies? | While laser-based PBF has high initial costs for equipment and materials, it can be cost-effective for small batches and custom parts due to its material efficiency and reduced need for tooling. |

| What are the common applications for laser-based Powder Bed Fusion? | Common applications include aerospace components, medical implants, automotive parts, and tooling. The technology is valued for its precision and ability to produce complex parts. |

| How long does it take to build a part using laser-based PBF? | Build times vary depending on part size and complexity. Smaller and less complex parts may take several hours, while larger and more intricate components can take days. |

| What types of materials can be used in laser-based PBF? | A wide range of metals can be used, including titanium, stainless steel, aluminum, cobalt-chrome, and various alloys. Each material offers different properties and advantages. |

| What are the main challenges associated with laser-based PBF? | Challenges include high equipment costs, relatively slow production speeds, and the need for post-processing to achieve desired surface finishes. Additionally, managing and recycling powder efficiently can be complex. |