316L powder-stainless steel

Shanghai Truer Industrial Development Co., Ltd

Table of Contents

What is 316L powder

316L has a wide range of applications in the chemical industry due to its excellent corrosion resistance. 316L is also a derivative steel grade belonging to the 18-8 type austenitic stainless steel, with 2 to 3% Mo added. On the basis of 316L, many steel grades have also been derived, such as 316Ti with a small amount of Ti, 316N with a small amount of N, and 317L with increased Ni and Mo content.

Properties of 316L Powder

316L powder refers to a type of metal powder composed primarily of stainless steel grade 316L. It is commonly used in various additive manufacturing processes, such as powder bed fusion (e.g., selective laser melting) and binder jetting, to create complex metal parts. Here are some key properties of 316L powder:

Chemical Composition: 316L powder is typically composed of iron (Fe), chromium (Cr), nickel (Ni), molybdenum (Mo), and small amounts of other elements. The specific composition of 316L powder adheres to the requirements of the ASTM A276/A276M standard.

Corrosion Resistance: 316L stainless steel is known for its excellent corrosion resistance properties. It is highly resistant to corrosion in various environments, including marine and chemical environments, making it suitable for applications where exposure to corrosive substances is expected.

High Temperature Resistance: 316L powder exhibits good resistance to high temperatures. It retains its mechanical properties and corrosion resistance even at elevated temperatures, making it suitable for applications involving heat and thermal cycling.

Mechanical Properties: The mechanical properties of parts manufactured from 316L powder depend on the specific manufacturing process and parameters used. However, in general, 316L stainless steel offers good strength, toughness, and ductility, making it suitable for structural and load-bearing applications.

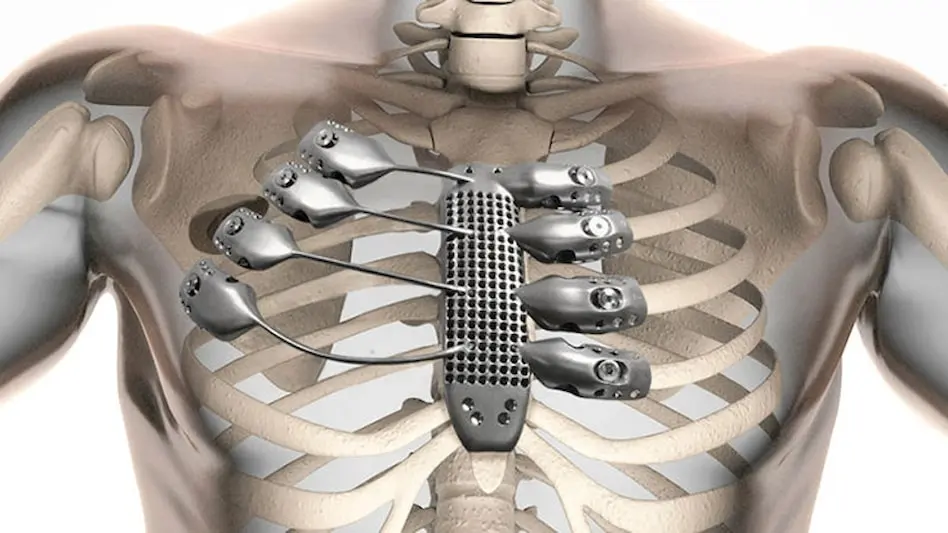

Biocompatibility: 316L stainless steel is often used in medical and dental applications due to its biocompatible nature. It is non-toxic and has low allergenic potential, making it suitable for implants, surgical instruments, and biomedical devices.

Surface Finish: Parts manufactured using 316L powder may exhibit a slightly rough surface finish compared to conventionally machined parts. However, the surface finish can be improved through post-processing techniques such as polishing or machining if a smoother finish is desired.

Powder Handling and Storage: 316L powder should be handled with care to prevent contamination. It is advisable to store the powder in a controlled environment, away from moisture and other reactive substances, to maintain its quality and prevent oxidation.

It’s important to note that the specific properties of 316L powder can vary based on the manufacturer, powder particle size distribution, and processing conditions. Therefore, it is recommended to consult the supplier or refer to the material data sheet for precise information regarding a particular batch or source of 316L powder.

316L powder Application

Additive Manufacturing: 316L powder is extensively used in additive manufacturing processes, such as selective laser melting (SLM) and binder jetting, to produce complex metal parts. These parts can be found in industries like aerospace, automotive, and medical, where high precision, corrosion resistance, and strength are required.

Aerospace Industry: 316L powder is utilized in aerospace applications due to its high strength, corrosion resistance, and heat resistance. It is used to manufacture components like turbine blades, engine parts, brackets, and structural components.

Medical and Dental Field: The biocompatibility of 316L powder makes it suitable for medical and dental applications. It is used in the production of surgical instruments, orthopedic implants (such as bone plates and screws), dental implants, and medical devices.

Chemical Processing: 316L powder is employed in the chemical industry due to its corrosion resistance properties. It is used for manufacturing reactors, heat exchangers, piping systems, and other equipment that come into contact with corrosive substances.

Food and Beverage Industry: Stainless steel, including 316L powder, is commonly used in the food and beverage industry due to its hygienic and corrosion-resistant properties. It is used to fabricate equipment like storage tanks, processing machinery, and food-grade piping systems.

Marine Applications: 316L powder’s resistance to corrosion in marine environments makes it suitable for marine applications. It is used in the construction of marine hardware, boat fittings, propellers, and other components exposed to saltwater and harsh conditions.

Oil and Gas Industry: The oil and gas sector utilizes 316L powder for various applications. It is employed in the production of offshore platforms, pipelines, valves, and other equipment that require resistance to corrosive environments and high temperatures.

Architectural and Design Applications: Stainless steel, including 316L powder, is often used in architectural projects and design applications. It can be found in decorative elements, structural components, handrails, and other design features due to its aesthetic appeal and durability.

316L powder Characteristics

- Low pick-up of oxygen and other impurities

- Perfectly spherical and essentially satellite-free

- Narrow particle size distribution.

- high flowability and high packing density

- Low internal porosity

316L powder price

316L stainless steel powder is considered a premium material, and therefore it tends to be more expensive compared to other standard metal powders. On average, the price of 316L powder can range from $50 to $100 per kilogram (kg). However, prices may fluctuate over time, and it’s advisable to check with suppliers or distributors to obtain up-to-date pricing information.

Additionally, bulk purchasing or larger orders may offer economies of scale, resulting in lower prices per kilogram. Some suppliers may also offer discounts or negotiate pricing based on factors such as long-term contracts, repeat orders, or specific requirements.

316L powder Chemical Components

Element C Si Mn S P Cr Ni Mo

Contain(min) 16.0 10.0 2.0

(max) 0.03 1.00 2.00 0.03 0.045 18.0 14.0 3.0

Related Post

TiC Powder:Composition, Properties, Applications, and More

TiC powder, or Titanium Carbide powder, is an essential material in various industries due to its exceptional hardness, wear resistance, and high-temperature stability. Whether you’re in the aerospace, automotive, or cutting tools industry, TiC powder plays a crucial role in improving performance and durability. This comprehensive guide will dive deep into all aspects of TiC

FeCoNiCr Powder

FeCoNiCr powder, a high-entropy alloy (HEA), is gaining prominence in advanced manufacturing, materials science, and industrial applications due to its exceptional properties. Known for its versatility and robust performance, this metal alloy powder comprises iron (Fe), cobalt (Co), nickel (Ni), and chromium (Cr). Whether you’re an engineer, researcher, or manufacturer, understanding FeCoNiCr powder can transform

CuAlFe Powder

Overview of CuAlFe Powder Copper-Aluminum-Iron (CuAlFe) powder is a high-performance metallic powder renowned for its strength, durability, and versatility in industrial applications. This alloy combines copper (Cu), aluminum (Al), and iron (Fe) to create a material suitable for a range of cutting-edge applications, from additive manufacturing to thermal spraying. Its unique composition makes it an

CoCrMoW Powder

CoCrMoW powder—Cobalt-Chromium-Molybdenum-Tungsten alloy powder—has become a highly sought-after material for industries like aerospace, medical implants, and high-performance mechanical systems. This versatile metal powder, with its outstanding mechanical properties and resistance to wear, corrosion, and heat, makes it a crucial element in a range of advanced manufacturing processes like additive manufacturing, metal injection molding, and thermal

about us

Truer Industry

Shanghai Truer Industrial Development Co., Ltd. was established in 2009 and created the additive manufacturing business in 2019, which is dedicated to building integrating 3D printing powder making equipment and services, high quality 3D printing powders to help engineering applications of additive manufacturing.

The company not only provides professional selective electron beam melting (SEBM) technology and equipment, but also plasma rotating electrode process powder making (PREP) technology and equipment. We also have various grades of spherical metal powders, including TiNi, TiTa, TiAl, TiNbZr, CoCrMo and so on.

Our services

Various metal powders

More than 40 grades of high quality spherical metal powders.

Mature application system

More than 1000 customized orthopedic implant materials to more than 20 hospitals.

No risk of stock outage

Perfect supply chain layout and inventory control make no risk of product stock-out.

3D Printing Equipment

SEBM & PREP technology and equipment.

Support customization

We accept OEM/ODM

Fair prices

High quality products at reasonable prices

FAQ

Most frequent questions and answers

If you have questions or at any point or can’t find the answer you were looking for, call or email us directly at [email protected]. For issues about your orders or our refunds, please refer to our Team. Helping you answer all your questions and solving any problems you may have is our number one priority.

We are the 100% manufacturer specialized in Additive Manufacturing.

Sure. We accept custom orders and OEM/ODM.

You can get a quote by visiting the Request a Quote page, requesting a quote on a product page, phone, email, or from our live chat. Based on a large variance of requirements from project to project, most quotations need to be prepared by a packaging estimator. RFQs can be emailed directly to [email protected].

You will typically receive your quotation within 1-2 business days for most requests. RFQs and complex projects may require more time.

High quantity orders generally net a lower cost-per-unit on all of our orders. For greater savings for your project, you can consult one of our Product Specialists for a customized strategy based on your business requirements and project goals.

We make products easy for our customers. While the steps can differ from project to project, our typical process consists of the following stages:

1. Specification & Project Consultation

2. Quotation

3. Sampling and Prototyping

4. Production

5. Shipping and Fulfillment

We offer a wide range of Additive Manufacturing such as SEBM, PREP and more than 40 different compositions of high-quality spherical metal powders, such as TiNi, TiTa, TiAl, TiNbZr and CoCrMo with fully customizable options.

Most products need to be shipped by sea, but samples used only for testing may be shipped by courier and air to ensure timeliness. All of our products are carefully packaged with care to withstand the potentially harsh elements of travel. You can expect your products to arrive in the same condition they left our facilities.

Production time can range from 5 to 25 business days depending on products type, requirements many other factors. Greater customization with more additional processes generally yields slightly longer production times. For your best estimate in the timeline, consult with your Product Specialist.

While our products technically have no minimum order quantities, recommended MOQs are in place (which will differ based on products type, printing, or processes) to prevent individual unit prices from becoming too costly to recommend.

The minimum order quantity we can usually provide is 1-20kg for samples(based on the detailed products) and 100-200kg for official orders. But it may vary by product, so, please check with your Product Specialist to learn the recommended MOQ of any of our products.

Send Us A Message

Contact us

sales

Cassiel Ding

+86 – 13611869448

[email protected]

Sales Manager

Lucy Wen

+86 – 15250232891

[email protected]

Quality Control

Mike Wu

+86 – 13862291355

[email protected]

sales

Joan Zhou

+86 – 17316565943

[email protected]

Customer Service

Luke Zhang

+86 – 15250014048

[email protected]