Inconel Powders

Shanghai Truer Technology Co,.LTD

Inconel Powders

Truer offers below Inconel alloy powders, including Inconel 718, Inconel 625, Inconel 939, Inconel 738, Inconel 713, Inconel 690, Inconel 600 and Inconel X-750 or other customized powders.

Inconel 718 alloy is a precipitation hardening nickel chromium alloy containing some Mo, Ta and Nb. It can be used at temperatures ranging from -253° to 705°C.

Inconel 625 is Ni-Cr-Mo-Nb solid solution superalloy also called as NiCr22Mo9Nb and 2.4856 in EN name and number, N06625 in UNS number. containing more Cr and Mo comparable to IN718.

Inconel 939 is a precipitation hardening superalloy which high hot fatigue resistance and oxidation resistance.

Inconel 738 also called as K438, is a precipitation hardenable Ni-base superalloy by gamma-prime with superior corrosion resistance and high temperature creep-rupture strength. It has high carbon type IN738C and low carbon type IN738LC.

Inconel 713, also called as, K418, UNS N07713, or 2.4856 in EN number, is a precipitation hardening superalloy, which has high cold and hot fatigue resistance and oxidation resistance.

Inconel 690 is a high-chromium nickel alloy having excellent resistance to many corrosive aqueous media and high temperature atmospheres.

Inconel 600, also called as UNS N06600, is Ni-Cr-Fe series superalloy.

Inconel X-750 (Haynes X-750) is a nickel-chromium-iron alloy with good corrosion resistance and oxidation resistance below 980℃, high strength below 800℃.

| CHEMICAL COMPOSITION (wt%) | ||||||||

| Item | Ni | Cr | Mo | Nb | W | Co | Ti | Other |

| Inconel 718 | Bal | 17.0-21.0 | 2.8-3.3 | 4.75-5.50 Nb+Ta | / | 1.0 max | 0.65-1.15 | / |

| Inconel 625 | Bal | 20.0-23.0 | 8.0-10.0 | 3.15-4.15 Nb+Ta | / | 5.0 max | / | / |

| Inconel 939 | Bal | 21.5-23.5 | 0.5-1.5 | 1.0-3.0 | 9.0-11.0 | 3.0-4.5 | Ta 1.0-1.8 | |

| Inconel 738LC | Bal | 15.7-16.3 | 1.5-2.0 | 0.6-1.1 | 2.4-2.8 | 9.0-11.0 | 3.0-3.5 | Ta 1.5-2.0 C 0.09-0.13 |

| Inconel 738C | Bal | 15.7-16.3 | 1.5-2.0 | 0.6-1.1 | 2.4-2.8 | 9.0-11.0 | 3.0-3.5 | Ta 1.5-2.0 C 0.15-0.20 |

| Inconel 713C | Bal | 11.5-13.5 | 3.8-4.8 | 1.8-2.5 | / | 9.0-11.0 | 0.5-1.0 | AI 5.5-6.4 |

| Inconel 690 | Bal | 28.5-31.0 | 9.0-11.0 | Fe 9.0-11.0 | ||||

| Inconel 600 | Bal | 14.0-17.0 | 9.0-11.0 | Fe 6.0-10.0 | ||||

| Inconel X-750 | Bal | 14.0-17.0 | 9.0-11.0 | 2.25-2.75 | Fe 5.0-9.0 | |||

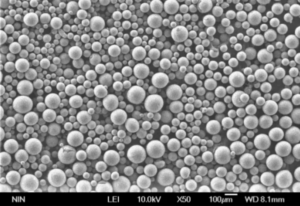

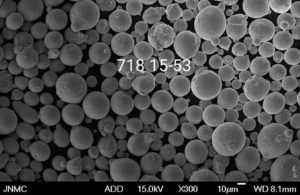

Particle Size Distribution (PSD): 0-25, 15-45, 15-53, 45-105, 45-150um or sieved as required.

Shape: Spherical

Process: Gas atomized (GA) or Plasma rotating electrode powder (PREP)

Packing: 5kg, 10kg, 25kg or as required; plastic bottle/can.

Application: additive manufacturing (3D printing, SLM/EBM/DLD) , HIP, MIM, PM, spraying.

GA Powder