Introduction

CuAl10 Powder is a high-performance metal powder made from an alloy of copper (Cu) and aluminum (Al), typically containing about 10% aluminum by weight. Known for its excellent mechanical properties and corrosion resistance, CuAl10 Powder is widely used in various industries, from aerospace to electronics and additive manufacturing. If you’re wondering what makes CuAl10 so special, keep reading—we’ll dive into its unique composition, properties, and applications.

Composition of CuAl10 Powder

Understanding the composition of CuAl10 Powder is key to recognizing why it’s such a versatile material. This alloy combines copper’s conductivity and aluminum’s lightweight properties, making it ideal for applications that require strength and corrosion resistance without too much added weight.

| Element | Percentage by Weight | Properties Contributed |

|---|---|---|

| Copper (Cu) | 90% | Provides conductivity, ductility |

| Aluminum (Al) | 10% | Adds strength, lightweight property |

| Trace Elements | <1% | Stabilizes and fine-tunes performance |

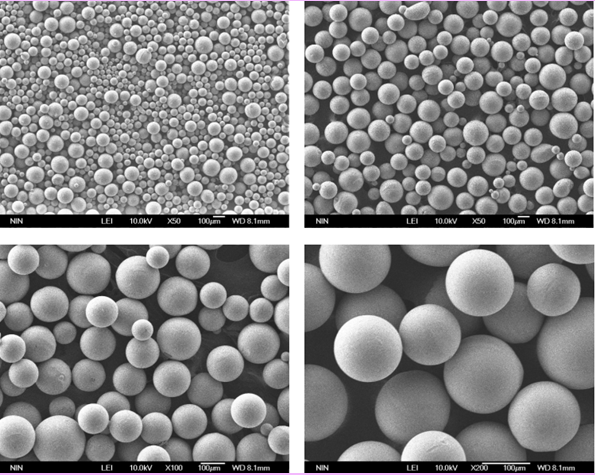

Manufacturing Process of CuAl10 Powder

There are several ways to manufacture CuAl10 Powder, each affecting the final characteristics of the material. Let’s look at the main manufacturing methods and how they influence properties like particle size, density, and purity.

| Manufacturing Method | Process Description | Resulting Characteristics |

|---|---|---|

| Gas Atomization | Molten CuAl10 alloy sprayed with inert gas | Fine, spherical particles; high purity |

| Water Atomization | Alloy sprayed with high-pressure water | Irregular shape; cost-effective; dense |

| Plasma Atomization | Alloy exposed to plasma arc for high precision | Ultra-fine particles; highly controlled size |

Choosing the right manufacturing method largely depends on the intended application. For example, gas-atomized powder is preferred for 3D printing due to its spherical particle shape and consistent flow.

Characteristics of CuAl10 Powder

The unique combination of copper and aluminum in CuAl10 Powder gives it a balance of mechanical strength, corrosion resistance, and thermal conductivity. Below are some key characteristics that define this alloy’s performance.

| Property | Value | Importance |

|---|---|---|

| Density | ~7.3 g/cm³ | Light enough for aerospace applications |

| Melting Point | 1,030°C | Suitable for high-temperature environments |

| Tensile Strength | Up to 280 MPa | Provides durability for structural uses |

| Thermal Conductivity | ~125 W/mK | Excellent heat dissipation, useful in electronics |

These properties make CuAl10 Powder ideal for applications where a balance of strength and weight is crucial, and where heat dissipation plays a vital role.

Types and Models of CuAl10 Powder

CuAl10 Powder is available in various models, each tailored to specific applications by adjusting parameters like particle size and purity. Below is a breakdown of some commonly used models of CuAl10 Powder.

| Model | Particle Size Range | Purity Level | Common Use |

|---|---|---|---|

| CuAl10-40S | 40-60 microns | 99% | Sintering processes |

| CuAl10-25F | 25-45 microns | 99.5% | Metal Injection Molding (MIM) |

| CuAl10-80M | 80-100 microns | 98% | Thermal spray coatings |

| CuAl10-15P | 10-20 microns | 99.9% | 3D printing, high precision |

| CuAl10-Nano | <1 micron | 99.8% | Conductive inks, electronics |

| CuAl10-MAX300 | 250-300 microns | 98.5% | Structural applications |

| CuAl10-HF45 | 45-75 microns | 99.7% | High-frequency inductive heating |

| CuAl10-XP40 | 40-60 microns | 99% | Additive manufacturing |

| CuAl10-LowO2 | 40-60 microns | Low-Oxidation | Oxidation-sensitive applications |

| CuAl10-HP20 | 20-30 microns | 99.5% | High-performance welding filler |

Each model offers distinct advantages depending on the application, so selecting the right variant ensures optimal performance and efficiency.

Applications and Uses of CuAl10 Powder

CuAl10 Powder finds applications across diverse industries due to its versatile properties. From complex aerospace components to thermal management in electronics, let’s see how CuAl10 Powder is applied in various fields.

| Application Area | Role of CuAl10 Powder | Notable Models |

|---|---|---|

| Additive Manufacturing | Enables precise, lightweight, durable 3D-printed parts | CuAl10-P15, CuAl10-40S |

| Aerospace | Used in components needing high strength, low weight | CuAl10-MAX300, CuAl10-25F |

| Electronics | Excellent for heat sinks, conductive inks | CuAl10-Nano, CuAl10-LowO2 |

| Thermal Spray Coatings | Provides corrosion-resistant, thermal protective layers | CuAl10-80M, CuAl10-40S |

| Metal Injection Molding | Suitable for creating small, complex shapes | CuAl10-25F, CuAl10-15P |

Whether in cutting-edge additive manufacturing or thermal spray coatings, CuAl10 Powder stands out due to its strength and conductivity.

Technical Specifications, Sizes, and Standards for CuAl10 Powder

Meeting industry standards is critical for metal powders like CuAl10. Compliance with ASTM and ISO specifications ensures quality and compatibility with other materials.

| Specification | Standard (ISO/ASTM) | Particle Size (microns) | Purity |

|---|---|---|---|

| Additive Manufacturing | ISO/ASTM 52900 | 10-100 | 99.5% |

| Sintering | ASTM B212 | 20-60 | 99% |

| Metal Injection Molding | ASTM B243 | 25-45 | 99.5% |

| Thermal Spray Coatings | ISO 14919 | 50-100 | 98% |

Suppliers, Pricing, and Availability

CuAl10 Powder is offered by several suppliers worldwide, each catering to various industries and requirements.

| Supplier | Location | Pricing (USD/kg) | Lead Time | Specialization |

|---|---|---|---|---|

| PowderMet Inc. | USA | $40-$60 | 2-4 weeks | High-purity powders |

| Global Alloys Co. | Germany | $50-$70 | 3-6 weeks | Industrial-grade, bulk orders |

| Nippon Alloys Ltd. | Japan | $45-$65 | 2-3 weeks | Nano and high-precision powders |

| EuroPowders GmbH | Germany | $55-$75 | 4-6 weeks | Thermal and structural applications |

Pricing depends on factors like model, purity, and bulk purchase quantities. Major suppliers often provide discounts for bulk orders and special sizes.

Advantages and Limitations of CuAl10 Powder

CuAl10 Powder offers numerous advantages, but it’s not without its challenges. Understanding both can help make informed purchasing and application decisions.

| Advantages | Limitations |

|---|---|

| Strong and corrosion-resistant | More expensive compared to basic alloys |

| Lightweight yet durable | Not ideal for high-temperature oxidation |

| Excellent conductivity | Limited suppliers for nano-grade powders |

| Available in various particle sizes | Some models have a longer lead time |

Comparing CuAl10 Powder to Similar Alloys

Curious how CuAl10 compares to similar alloys like CuAl8 or CuAl15? Here’s a quick comparison:

| Alloy | Cu Content | Al Content | Use Case Suitability | Cost |

|---|---|---|---|---|

| CuAl10 | 90% | 10% | Balanced applications | Moderate |

| CuAl8 | 92% | 8% | High ductility, moderate strength | Lower |

| CuAl15 | 85% | 15% | High corrosion resistance | Slightly higher |

FAQ

| Question | Answer |

| What is CuAl10 Powder used for? | CuAl10 Powder is used in 3D printing, electronics, and aerospace for its strength, conductivity, and corrosion resistance. |

| How is CuAl10 Powder made? | It’s primarily made through gas, water, or plasma atomization, each method producing different particle characteristics. |

| Is CuAl10 Powder expensive? | Prices vary, but it is generally more expensive than simpler alloys due to its specialized properties. |

| Can CuAl10 Powder be used in welding? | Yes, certain models like CuAl10-HP20 are suitable for welding filler materials. |

| How does CuAl10 compare to pure copper? | CuAl10 is lighter and stronger due to its aluminum content but offers slightly less conductivity compared to pure copper. |

Conclusion

CuAl10 Powder remains a highly sought-after material due to its durability, corrosion resistance, and adaptability across multiple industries. From 3D printing to aerospace and electronics, CuAl10 Powder is essential in applications where strength, conductivity, and corrosion resistance are critical. As manufacturing techniques evolve, the range of models and applications for CuAl10 Powder continues to grow, solidifying its place as a versatile, high-performance alloy in modern engineering.