Introduction

In the realm of advanced materials, niobium alloys powder stands out as a remarkable innovation that has revolutionized various industries. This article delves into the characteristics, benefits, manufacturing process, applications, and future prospects of niobium alloys powder, shedding light on its profound impact on technology and manufacturing.

What is Niobium Alloys Powder?

Niobium alloys powder is a finely divided form of niobium-based alloys, renowned for their exceptional combination of properties. These alloys typically consist of niobium as the primary element, often alloyed with other metals such as titanium, tantalum, or zirconium. The resulting powder exhibits remarkable mechanical, thermal, and chemical attributes that make it an invaluable material for numerous applications.

Advantages of Niobium Alloys Powder

Enhanced Strength and Durability

Niobium alloys powder offers unparalleled strength and durability, making it a favored choice in demanding industries. The unique crystalline structure of niobium-based alloys contributes to their high tensile strength and resistance to deformation, ensuring structural integrity even under extreme conditions.

Improved Corrosion Resistance

Corrosion resistance is a crucial factor in materials used for various applications. Niobium alloys powder boasts remarkable corrosion resistance, making it suitable for environments where exposure to harsh chemicals or corrosive agents is a concern. This attribute extends the lifespan of components and reduces maintenance requirements.

High-Temperature Stability

Industries operating under high-temperature conditions require materials that can withstand thermal stress. Niobium alloys powder exhibits exceptional stability at elevated temperatures, making it a preferred material for aerospace components, gas turbines, and nuclear reactors.

Applications of Niobium Alloys Powder

Aerospace Industry

The aerospace sector benefits greatly from niobium alloys powder due to its lightweight yet robust characteristics. It finds application in aircraft components, rocket engines, and structural elements, where the combination of strength, heat resistance, and reduced weight is paramount.

Medical Implants

Niobium alloys powder plays a vital role in the medical field, particularly in the production of biocompatible implants. Its non-toxic nature, corrosion resistance, and compatibility with living tissues make it an excellent choice for implants such as bone screws, joint replacements, and dental implants.

Electronics and Semiconductors

In the electronics industry, niobium alloys powder finds use in manufacturing high-performance capacitors and superconducting materials. Its ability to maintain stability under extreme electrical and thermal conditions enhances the efficiency and reliability of electronic devices.

Automotive Sector

The automotive industry utilizes niobium alloys powder to create lightweight yet strong components, contributing to fuel efficiency and safety. Applications include exhaust systems, engine parts, and suspension components.

Manufacturing Process of Niobium Alloys Powder

Atomization

Atomization is a widely employed technique for producing niobium alloys powder. In this method, molten alloy is subjected to high-pressure gas, resulting in the formation of fine droplets that solidify into powder upon cooling.

Mechanical Alloying

Mechanical alloying involves blending elemental powders of niobium and other metals, followed by high-energy milling. This process leads to the formation of homogenous alloys on a microscopic scale.

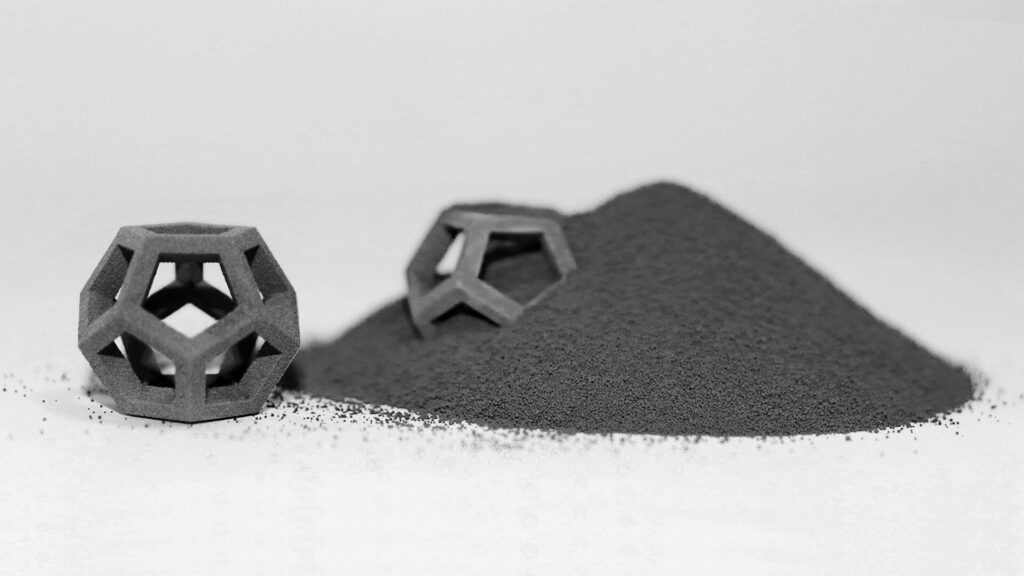

Additive Manufacturing

Additive manufacturing, or 3D printing, is gaining traction for producing intricate parts using niobium alloys powder. This technique allows for the creation of complex geometries and customized components.

Factors Influencing the Quality of Niobium Alloys Powder

Purity of Raw Materials

The quality of niobium alloys powder heavily depends on the purity of the raw materials used. Even minor impurities can impact the material’s properties and performance.

Particle Size Distribution

The particle size distribution of the powder significantly influences its behavior during processing and application. Controlling particle size is crucial for achieving desired material characteristics.

Alloy Composition

Fine-tuning the composition of niobium alloys powder allows manufacturers to tailor the material’s properties to specific applications. Different alloying elements impart unique attributes, enhancing versatility.

Future Trends and Innovations

Nanostructured Niobium Alloys

The development of nanostructured niobium alloys holds promise for even higher performance in various applications. Nanostructuring enhances mechanical properties and enables novel applications.

Sustainable Production Methods

As sustainability gains importance, research focuses on environmentally friendly production methods for niobium alloys powder. Reduced energy consumption and minimized waste are key goals.

Environmental and Health Considerations

While niobium alloys powder offers numerous benefits, it’s essential to consider potential environmental and health impacts. Proper handling, disposal, and recycling methods are vital to mitigate any adverse effects.

Conclusion

Niobium alloys powder represents a technological breakthrough with its exceptional attributes and versatile applications across industries. Its role in enhancing product performance, reducing weight, and improving efficiency underscores its significance in modern manufacturing. As research continues, we can anticipate even more exciting developments and novel applications of this remarkable material.

FAQs

- Is niobium alloys powder expensive to produce? Production costs of niobium alloys powder can vary depending on factors like raw material prices and manufacturing processes. However, advancements in production methods are contributing to cost optimization.

- Can niobium alloys powder be recycled? Yes, niobium alloys powder can be recycled through various processes, reducing waste and conserving valuable resources.

- What are some upcoming uses of niobium alloys powder? Researchers are exploring its potential in energy storage systems, such as advanced batteries, due to its high electrical conductivity.

- Are there any health risks associated with niobium alloys powder? When handled and processed properly, niobium alloys powder poses minimal health risks. Following safety guidelines is essential to ensure safe usage.

- How does niobium alloys powder contribute to sustainability? Niobium alloys powder’s lightweight properties contribute to fuel efficiency in transportation and its recyclability aligns with sustainable material practices.