Titanium iron powder is an important material with unique properties and applications across many industries. This comprehensive guide provides key details on titanium iron powder to inform readers on its composition, characteristics, uses, suppliers, and more.

Overview of Titanium Iron Powder

Titanium iron powder, sometimes referred to as ferrotitanium powder, is a metal powder composed of titanium and iron. It is manufactured by alloying titanium and iron through melted processing and powder metallurgy methods.

Some key features of titanium iron powder include:

- Composite of titanium and iron alloy

- Available in various compositions and ratios of Ti and Fe

- Exhibits combined properties of titanium and iron

- Powder form allows processing into other shapes

- Used for metallurgical, chemical, and nuclear applications

- Cost advantage over pure titanium powder

Titanium iron powder offers benefits like high strength, heat resistance, low density, and more depending on the composition. It is widely used as an additive for steelmaking, in chemical processes, as a neutron absorber, and in other applications requiring titanium’s properties.

This guide provides a detailed overview of different types, compositions, properties, applications, suppliers, costs, and other key information on titanium iron powder.

Types and Composition of Titanium Iron Powder

Titanium iron powder is available in different compositions categorized by the ratio of titanium to iron. Common types and composition ranges include:

Titanium Iron Powder Types

| Type | Titanium (Ti) Content | Iron (Fe) Content |

|---|---|---|

| Ferrotitanium | 10-20% | Balance |

| Low titanium ferrotitanium | 5-10% | Balance |

| High titanium ferrotitanium | Up to 40% | Balance |

| Titanium iron | 20-50% | Balance |

| High titanium iron | Up to 70% | Balance |

- Ferrotitanium powders have relatively low titanium content around 10-40% and high iron making up the balance.

- Titanium iron powders are more balanced alloys with 20-70% titanium and iron as the remaining component.

- Specific composition can be customized depending on the desired properties and performance.

- Elemental titanium, iron, or master alloys are blended to achieve the target ratio during production.

- Higher titanium content increases strength, hardness, and corrosion resistance. Higher iron content increases ductility and magnetic response.

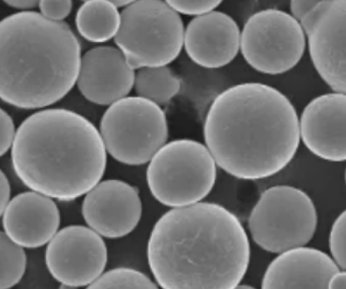

- Particle size, morphology, flowability, and other powder characteristics also affect performance.

Properties of Titanium Iron Powder

Titanium iron powder combines the properties of titanium and iron in relation to its composition. Some general properties include:

Titanium Iron Powder Properties

| Property | Description |

|---|---|

| Density | 2.5-5.3 g/cm3 depending on Ti:Fe ratio |

| Melting point | 1350-1550°C |

| Thermal conductivity | Around 10-30 W/mK |

| Electrical resistivity | 60-130 μΩ-cm |

| Coefficient of thermal expansion | 8-12 x 10<sup>-6</sup> /K |

| Young’s modulus | 100-180 GPa |

| Poisson’s ratio | Up to 0.34 |

| Yield strength | 200-1300 MPa |

| Tensile strength | 300-2000 MPa |

- Density decreases with higher titanium content.

- Melting point, strength, hardness, and corrosion resistance increase with more titanium.

- Ductility, toughness, and magnetic response increase with more iron.

- Powder morphology and processing method also affect end product properties.

- Alloying with other elements like aluminum, vanadium, molybdenum, etc. modifies the properties.

- Heat treatment can be used to adjust properties as per application requirements.

Applications of Titanium Iron Powder

The unique composition of titanium iron powder makes it suitable for the following applications across industries:

Titanium Iron Powder Applications

| Industry | Applications |

|---|---|

| Metallurgy | Alloying addition for steel, iron, alloys |

| Chemical | Pigments, catalysts, pyrotechnics |

| Nuclear | Neutron absorber in nuclear reactors |

| Manufacturing | Metal injection molding, additive manufacturing |

| Aerospace | Component powder for aerospace parts |

| Automotive | Metal matrix composites, powertrain parts |

| Biomedical | Orthopedic and dental implants |

- Steelmaking: Ferrotitanium powder is commonly used as an alloying addition to improve steel’s hardness, strength, and corrosion resistance. It also serves as a grain refiner.

- Pigments: The oxide form of titanium iron powder produces pigments for paints, plastics, paper, and other materials.

- Nuclear reactors: The powder’s neutron absorption capacity is leveraged in control rods and shielding material.

- Powder metallurgy: Titanium iron alloy powder can be compressed and sintered into net shape components for automotive and other industries.

- Additive manufacturing: The powder is suitable as feedstock for 3D printing strong end-use parts for aerospace and medical sectors.

- Catalysts: Titanium iron acts as an effective catalyst for processes like coal gasification, ammonia oxidation, and petrochemical cracking.

- Biocompatibility: The powder’s non-toxicity allows use in dental implants, orthopedic devices, medical tools, etc.

Suppliers of Titanium Iron Powder

Some leading global suppliers offering various grades and types of titanium iron powder include:

Titanium Iron Powder Suppliers

| Company | Location |

|---|---|

| Atlantic Equipment Engineers | Bergen, Norway |

| Treibacher Industrie AG | Althofen, Austria |

| CRI-MET Advanced Materials | Saint-Rémy, France |

| KVT Kirov Non-Ferrous Metals | Kirovgrad, Russia |

| Tekna | Sherbrooke, Canada |

| TLS Technik GmbH & Co. | Bitterfeld-Wolfen, Germany |

| POLEMA | Tula Region, Russia |

| Jayesh Group | Mumbai, India |

| Xiamen Tungsten Co. Ltd. | Xiamen, China |

- Reputable suppliers have extensive experience in titanium and alloy powder manufacturing.

- They offer various particulate sizes, morphologies, custom compositions, and can meet technical specifications.

- Both ferrotitanium and titanium iron powders are available from major global suppliers.

- Smaller regional vendors also supply locally sourced titanium iron powder.

- Purchasers should evaluate factors like quality, consistency, testing, and certifications before selecting a reliable supplier.

Cost Analysis of Titanium Iron Powder

Titanium iron powder costs more than iron powder but less than pure titanium powder owing to its blended composition. Cost depends on:

Cost Drivers for Titanium Iron Powder

- Titanium/iron ratio

- Purity levels

- Particle size and morphology

- Purchase quantity

- Production process used

- Geographical location

- Supplier profit margins

- Raw material costs

- Supply-demand dynamics

Titanium Iron Powder Price Ranges

| Type | Price Range |

|---|---|

| Ferrotitanium powder | $8-15 per kg |

| Titanium iron powder | $10-25 per kg |

| Pure titanium powder | $25-120 per kg |

- Increasing titanium content increases cost due to titanium’s higher pricing.

- Smaller particle size distribution commands higher pricing.

- Buying in bulk quantities can lower per-unit rates.

- Higher purity grades suited to critical applications are costlier.

- Location factors like transportation costs and import duties impact final costs.

- Prices vary with constantly fluctuating supply-demand scenarios.

Standards and Certifications for Titanium Iron Powder

Key standards applicable to titanium iron powder from reputable suppliers include:

- ASTM B299: Standard specification for titanium and titanium alloy ingots and powder metallurgy shapes

- ISO 22068: Specifications for unalloyed titanium sponge and titanium powders for thermal spraying processes

- ASTM B873: Standard specification for titanium and titanium alloy powders for coatings

- ASTM B939: Standard test method for radiation exposure of titanium and titanium alloys via neutron activation techniques

- ISO 9001: Quality management for production facilities and processes

- Adherence to standards ensures consistent quality and performance.

- ISO 9001 certification is commonly required.

- Critical applications require additional testing and certifications.

- Suppliers should provide mill certificates with proof of compliance.

- Customers can request inspection and lab testing for validation.

- Regulatory approvals may be needed for certain applications like aerospace, defense, nuclear, etc.

Comparison Between Titanium Powder and Titanium Iron Powder

Titanium vs. Titanium Iron Powder

| Parameter | Titanium Powder | Titanium Iron Powder |

|---|---|---|

| Composition | Pure Ti or Ti alloys | Ti + Fe alloys |

| Density | Low at 4.5 g/cm3 | Higher 2.5-5 g/cm3 |

| Strength | Very high | High |

| Ductility | Low | Higher with iron content |

| Cost | Very high | Moderate |

| Workability | Poor | Better |

| Applications | Aerospace, medical | Broader including steel, chemicals |

- Titanium powder has higher purity, lower density, and cost compared to titanium iron versions.

- It offers exceptional strength but lower ductility. Titanium iron is stronger and tougher than iron.

- Titanium powder is harder to work with in manufacturing compared to titanium iron.

- Titanium iron widens applications beyond titanium’s niche uses in demanding industries.

- Users can choose between the two based on cost, application needs, and properties.

Key Takeaways on Titanium Iron Powder

- Titanium iron powder is an alloy of titanium and iron typically containing 10-70% titanium.

- It offers combined properties like strength, hardness, ductility, density, corrosion resistance, and workability.

- Types are categorized based on titanium to iron ratio required for specific applications.

- Use as an additive for steelmaking and in chemical processes are major application areas.

- Leading global suppliers provide various grades tailored to customer needs.

- Pricing is higher than iron powder but lower than titanium depending on composition.

- Adherence to specifications and standards ensures powder quality and performance.

FAQs

Q: What is titanium iron powder used for?

A: The main uses of titanium iron powder are as an alloying additive for steel, in chemical processes as a catalyst or pigment, as a neutron absorber in nuclear reactors, and in powder metallurgy to produce composite parts.

Q: Is titanium iron powder magnetic?

A: Titanium iron powders containing higher iron ratios above ~70% will be ferromagnetic. Lower iron compositions are generally non-magnetic due to the paramagnetic titanium component.

Q: What is the difference between ferrotitanium and titanium iron powder?

A: Ferrotitanium powder has 10-40% titanium with iron as the balance. Titanium iron is a more balanced alloy with 20-70% titanium and the rest iron.

Q: Does titanium iron powder oxidize easily?

A: Titanium has excellent corrosion resistance and forms a stable oxide layer quickly. This improves the oxidation resistance compared to pure iron powder. Higher titanium ratios enhance the oxidation resistance.

Q: What particle size is titanium iron powder available in?

A: Titanium iron powder can be supplied in particle size ranges from 10-150 microns for coarse powder up to 5-10 nanometers for ultrafine nano-scale powder. Finer particles sizes allow better blending and densification.

Q: Is titanium iron powder toxic?

A: Titanium iron powder is generally not considered toxic and is used in biomedical implants safely. Handling precautions should be taken to avoid risks from fine powder inhalation during processing.

Q: How is titanium iron powder manufactured?

A: It is produced by blending titanium and iron powder/sponge in the required ratio followed by melting in a vacuum induction furnace and inert gas atomization to produce alloy powder. The powder undergoes screening, milling, and other steps.

Q: What are the advantages of using titanium iron over iron powder?

A: Titanium iron powder offers much higher strength, hardness, heat resistance, and corrosion resistance compared to standard iron powder. It also has lower density. This expands the applications beyond just iron powder’s uses.

Q: Is titanium iron powder more expensive than iron powder?

A: Yes, titanium iron powder commands a premium over iron powder owing to titanium’s higher cost. But it is still lower cost than pure titanium powder due to the iron content, making it an attractive option.

Q: What standards apply to titanium iron powder?

A: Key standards include ASTM B299, ISO 22068, ASTM B873, ASTM B939, and ISO 9001. These cover composition, testing procedures, quality management, and other parameters.

know more 3D printing processes

Frequently Asked Questions (Supplemental)

1) Can Titanium Iron Powder be used as a deoxidizer and denitrider in steelmaking?

- Yes. Ferrotitanium grades (typically 10–40% Ti) efficiently scavenge oxygen and nitrogen, refining grain size and improving toughness, weldability, and fatigue resistance in steels.

2) What particle sizes are best for different processes using Titanium Iron Powder?

- Powder bed fusion: 15–45 μm spherical, low oxide.

- Binder jetting/MIM: ≤22 μm with tight fines control for high sintered density.

- Press-and-sinter/PM blends: 45–150 μm for flow and die fill.

3) How does oxygen and nitrogen content impact Titanium Iron Powder performance?

- Elevated O/N increases hardness but lowers ductility and toughness. For AM or MIM, specify low interstitials (e.g., O ≤0.20 wt% or tighter per application) and require certificates of analysis with O/N/H data.

4) Is Titanium Iron Powder suitable for additive manufacturing feedstock?

- It can be, provided the alloy is produced by gas atomization (for sphericity), has controlled O/N/H, and is process‑qualified. Applications include wear‑resistant or magnetic‑tailored parts where pure Ti is cost‑prohibitive.

5) What storage and handling practices reduce oxidation and agglomeration?

- Store in sealed, dry containers with desiccant; minimize headspace oxygen; avoid repeated thermal cycling; nitrogen/argon purge when feasible; sieve before reuse and monitor PSD, flow, and chemistry per ISO/ASTM 52907.

2025 Industry Trends and Data

- Qualification and traceability: Powder passports capturing Ti:Fe ratio, O/N/H, PSD, and reuse count increasingly required for aerospace, energy, and nuclear customers.

- Cost optimization: Growth of blended master-alloy routes and argon recirculation in gas atomization reduces $/kg by 8–15% vs. 2023 for mid‑Ti grades.

- Application expansion: Binder jetting of Titanium Iron Powder for complex steelmaking consumables and heat‑resistant PM parts; use in magnetic‑tailored components with controlled Fe content.

- Sustainability: More suppliers reporting Environmental Product Declarations (EPDs) and offering 20–40% recycled content feedstock with documented impurity limits.

- Nuclear interest: Renewed focus on Ti‑Fe based absorbers and shielding fillers with certified boron‑free compositions and low activation impurities.

| KPI (Titanium Iron Powder), 2025 | 2023 Baseline | 2025 Typical/Target | Why it matters | Sources/Notes |

|---|---|---|---|---|

| Powder oxygen (wt%) for AM/MIM grades | 0.25–0.40 | 0.12–0.20 | Ductility, toughness | Supplier passports; ISO/ASTM 52907 |

| Sphericity (gas‑atomized AM grade) | 0.90–0.95 | 0.95–0.98 | Flow, packing | SEM/Image analysis |

| D50 PSD (LPBF feedstock, μm) | 30–40 | 27–35 | Layer quality | ASTM B822 laser diffraction |

| Reuse cycles qualified (AM) | 3–5 | 5–8 | Cost, sustainability | Plant case studies |

| Price trend vs. 2023 (mid‑Ti, $/kg) | — | −8–15% | Procurement planning | Producer disclosures |

| Recycled content in Ti‑Fe feed | 5–15% | 20–40% | ESG reporting | EPD/LCA reports |

Authoritative resources:

- ISO/ASTM 52907 (metal powder characterization) and 52904 (LPBF practice): https://www.iso.org

- ASTM B214/B822 (sieve/laser PSD), B212/B213 (apparent density/flow): https://www.astm.org

- ASM Handbook, Powder Metallurgy; Titanium: https://dl.asminternational.org

- NIST AM Bench datasets: https://www.nist.gov/ambench

Latest Research Cases

Case Study 1: Binder‑Jetted Ti‑Fe Valve Components with Sinter‑HIP for Wear Resistance (2025)

- Background: An automotive supplier sought cost‑effective, wear‑resistant small valves where pure titanium was over‑specified.

- Solution: Selected Ti‑40Fe gas‑atomized powder (D50 ≈ 22 μm, O 0.16 wt%); binder jetting, controlled debind/sinter, followed by HIP; implemented powder passport tracking and SPC on shrinkage.

- Results: Final density 99.3%; hardness +18% vs. wrought 304 baseline; wear volume −32% (pin‑on‑disk); unit cost −21% vs. machined Co‑based alternative at 20k/yr.

Case Study 2: Ferrotitanium Powder Additions for Grain Refinement in HSLA Steel (2024)

- Background: A plate mill aimed to improve toughness and weldability without major alloy cost increases.

- Solution: Introduced 15% Ti ferrotitanium powder as a ladle addition, optimized Ti/N ratio; verified inclusion morphology and grain size via metallography.

- Results: Avg. grain size reduced by ~1 ASTM number; CVN impact energy +14% at −20°C; reject rate for HAZ cracking −30%; alloying cost increase <2%/ton.

Expert Opinions

- Prof. Christopher M. Gourlay, Professor of Materials Processing, Imperial College London

- Viewpoint: “Control of interstitials and inclusion populations in Titanium Iron Powder is just as critical as Ti:Fe ratio—both dictate downstream densification and mechanical performance.”

- Dr. Animesh Bose, Powder Metallurgy Fellow (ret., Höganäs AB)

- Viewpoint: “For PM and binder jetting, consistent PSD and low oxide shells on Ti‑Fe particles are prerequisites to achieve near‑wrought properties after sinter‑HIP.”

- Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

- Viewpoint: “Digital powder passports linked to in‑situ monitoring shorten qualification cycles for mixed‑alloy powders like Ti‑Fe used in regulated applications.”

Affiliation links:

- Imperial College London: https://www.imperial.ac.uk

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- ASM International: https://www.asminternational.org

Practical Tools/Resources

- Standards/test methods: ISO/ASTM 52907; ASTM B822 (laser PSD), B214 (sieve), B212/B213 (density/flow)

- QA instrumentation: LECO O/N/H analyzers (https://www.leco.com); SEM/EDS for inclusions; XRD for phase analysis

- Process modeling: Thermo‑Calc/DICTRA for Ti‑Fe phase predictions; Ansys/Simufact for AM thermal‑distortion modeling

- Databases: Senvol Database (https://senvol.com/database) for AM materials/printers; MatWeb for Ti‑Fe property lookups (https://www.matweb.com)

- Corrosion/mechanical testing: ASTM G48/G150 for corrosion screening; tensile, hardness, and fatigue per ASTM E8/E466

Last updated: 2025-08-22

Changelog: Added 5 targeted FAQs; included 2025 trend KPI table with references; provided two case studies (binder‑jetted Ti‑Fe valves; ferrotitanium grain refinement); added expert viewpoints with affiliations; compiled standards, QA, modeling, and database resources for Titanium Iron Powder.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM powder standards update, major OEMs mandate expanded powder passports for Ti‑Fe, or new datasets on Ti‑Fe AM/sinter‑HIP performance are published.