Titanium-Based Alloy Powders have become the go-to material for a vast array of industries, prized for their exceptional strength-to-weight ratio, excellent corrosion resistance, and high biocompatibility. But how do these wonder alloys transform from raw materials into the fine, metallic powders used in additive manufacturing (AM) techniques like 3D printing? Buckle up, because we’re diving deep into the fascinating world of titanium-based alloy powder preparation methods!

A Glimpse into Metal Powder Marvels

Before we delve into the nitty-gritty of production methods, let’s meet some of the key players in the titanium-based alloy powder arena. Here’s a sneak peek at ten distinct metal powder models, each boasting unique properties and applications:

| Metal Powder Model | Description | Applications |

|---|---|---|

| Ti-6Al-4V ELI | The industry workhorse, renowned for its excellent balance of strength, ductility, and biocompatibility. | Aerospace components, biomedical implants, sporting goods |

| Ti-6Al-4V | A more economical alternative to ELI grade, offering slightly lower oxygen content. | Industrial components, chemical processing equipment |

| Gr-2 Titanium | Commercially pure titanium, known for its superior formability and weldability. | Chemical processing equipment, heat exchangers |

| Ti-5Al-5Mo-5V-3Fe | A high-strength alloy boasting exceptional creep resistance at elevated temperatures. | Aircraft engine components, medical implants |

| Beta Ti Alloy Powders | Offer superior formability compared to alpha-beta alloys, ideal for complex geometries. | Biomedical implants, aerospace components |

| Near Net Shape (NNS) Powders | Pre-alloyed and pre-shaped powders, minimizing post-processing needs. | Medical and dental implants, aerospace components |

| Titanium Carbide (TiC) | An extremely hard and wear-resistant ceramic powder. | Cutting tools, wear plates, molds |

| Titanium Aluminum (TiAl) | High-temperature alloys known for their exceptional strength and oxidation resistance. | Jet engine components, high-performance automotive parts |

| Nickel-Titanium (NiTi) | Shape memory alloys exhibiting unique superelastic properties. | Medical devices, orthodontic wires |

| Copper-Titanium (CuTi) | High-conductivity alloys ideal for electrical applications. | Heat sinks, electrical connectors |

Each of these metal powder models possesses a specific blend of properties, making them suitable for a diverse range of applications. As we explore the production methods, you’ll gain a deeper understanding of how these properties are influenced by the chosen technique.

Production Methods for Titanium-Based Alloy Powders

Now, let’s unveil the magic behind creating these versatile powders. Here, we’ll explore three prominent methods:

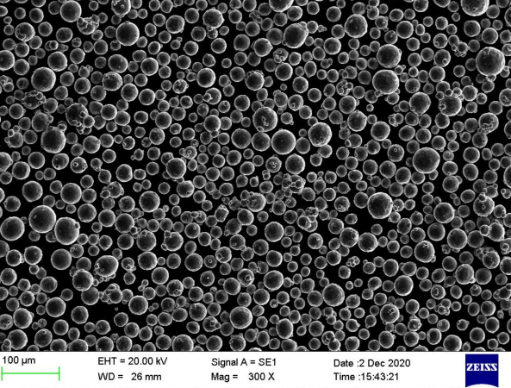

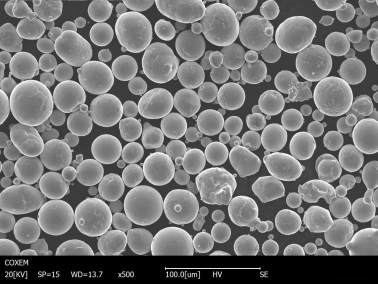

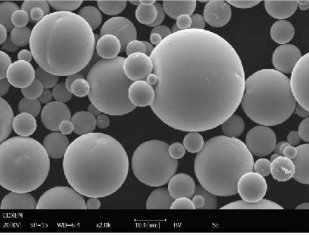

- Vacuum Atomization (VA): Imagine molten titanium alloy being poured through a high-velocity stream of inert gas (like argon or helium) within a vacuum chamber. This rapid cooling process shatters the molten metal into fine, spherical particles – our coveted titanium-based alloy powder! VA offers excellent control over powder size and morphology, making it ideal for demanding AM applications.

- Electrolysis: This method involves dissolving titanium and alloying elements in a molten salt bath. By applying an electric current, the dissolved metals are deposited on a cathode (negative electrode) as a spongy mass. This material is then crushed and milled into a fine powder. Electrolysis produces high-purity powders but may require additional processing steps to achieve optimal particle size and morphology.

- Mechanical Grinding Method: This technique involves ball milling – think of a high-energy shaking machine filled with metal balls and titanium alloy chunks. The intense collision and friction between the balls and chunks break down the material into a fine powder. While cost-effective, this method often results in irregular-shaped particles and may introduce contamination from the grinding media.

Key Considerations for Each Method:

Each production method has its own set of advantages and limitations. Here’s a quick comparison to help you navigate the options:

| Feature | Vacuum Atomization (VA) | Electrolysis | Mechanical Grinding Method |

|---|---|---|---|

| Powder Purity | High | Highest | Moderate |

| Particle Shape | Spherical | Irregular | Irregular |

| Particle Size Control | Excellent | Good | Moderate |

| Production Cost | High | Moderate | Low |

| Applications | Demanding AM applications | High-purity components | Cost-sensitive applications |

Choosing the right production method depends heavily on the desired final product characteristics and budget constraints. For instance, if you require high-purity, spherical powder for mission-critical aerospace components, vacuum atomization might be the preferred choice. However, for less demanding applications where cost is a major concern, mechanically ground powders could be a viable option.

Exploring Additional Techniques

The world of titanium-based alloy powder preparation extends beyond the three main methods discussed earlier. Here are some additional techniques that cater to specific needs:

- Hydride-Dehydride (HDH) Process: This method involves converting titanium sponge into a titanium hydride powder, followed by dehydriding to remove the hydrogen and obtain a fine titanium powder. HDH powders offer excellent flowability, making them ideal for processes like metal injection molding (MIM).

- Plasma Rotating Electrode Technique (PEROT): This advanced technique utilizes a rotating electrode melted by a plasma torch within a vacuum chamber. The molten metal droplets are then ejected by centrifugal force, rapidly solidifying into fine, spherical powders. PEROT is known for producing high-quality powders with excellent size and morphology control.

- Electron Beam Melting (EBM) Additive Manufacturing (AM) Powder: EBM is an AM technique itself, but the leftover powder from the process can be recycled and reused for subsequent AM builds. This recycled powder offers a cost-effective solution for certain applications.

Choosing the Right Tool for the Job

Once you’ve selected a production method, it’s crucial to consider the specific specifications and standards for your chosen titanium-based alloy powder. Here’s a breakdown of key factors to keep in mind:

- Particle Size Distribution (PSD): The size and distribution of powder particles significantly impact flowability, packing density, and the final properties of the additively manufactured part. Different AM techniques may have specific PSD requirements.

- Powder Chemistry: The exact composition of the alloy powder, including trace elements like oxygen, nitrogen, and hydrogen, plays a vital role in the mechanical properties and performance of the final part. Strict adherence to industry standards like ASTM International (ASTM) specifications is essential.

- Powder Flowability: Powders with good flowability are easier to handle and process in AM equipment, leading to consistent build quality. Standardized tests measure flowability to ensure the powder meets the requirements of the chosen AM technique.

- Surface Area: The surface area of the powder particles influences factors like reactivity and sintering behavior. Understanding the surface area characteristics is crucial for optimizing the AM process.

By carefully considering these specifications and adhering to relevant standards, you can ensure you’re using the optimal titanium-based alloy powder for your specific application.

Suppliers and Pricing

The hunt for the perfect titanium-based alloy powder doesn’t end at the production method or specifications. Partnering with a reputable supplier who offers high-quality powders at competitive prices is equally important. Here are some factors to consider when choosing a supplier:

- Powder Variety: Does the supplier offer a wide range of titanium-based alloy powders to meet your specific needs?

- Quality Control: Does the supplier have a robust quality control system to ensure consistent powder quality?

- Technical Support: Can the supplier provide technical expertise and guidance to help you select the right powder for your application?

- Pricing and Lead Times: Are the prices competitive, and do they fit your budget? What are the typical lead times for powder orders?

By conducting thorough research and considering these factors, you can find a reliable supplier who can provide the high-quality titanium-based alloy powders you need for your project.

the Pros and Cons of Titanium-Based Alloy Powders

While titanium-based alloy powders offer a plethora of advantages for AM applications, it’s essential to acknowledge the limitations. Here’s a balanced perspective to help you make informed decisions:

Advantages:

- Excellent Material Properties: Titanium-based alloys possess outstanding strength-to-weight ratio, corrosion resistance, and biocompatibility, making them ideal for demanding applications.

- Design Freedom: AM techniques enable the creation of complex geometries with titanium-based alloy powders, pushing the boundaries of traditional manufacturing.

- Lightweighting: The ability to create lightweight, high-strength components using titanium-based alloy powders is a major advantage in industries like aerospace and automotive.

- Reduced Waste: AM with titanium-based alloy powders minimizes material waste compared to traditional subtractive manufacturing techniques.

Limitations:

- High Cost: Titanium-based alloy powders are generally more expensive than other metal powders, which can impact the overall project cost.

- Safety Considerations: Titanium powder is flammable and requires careful handling to prevent fires and explosions.

- Limited Availability: Compared to some other metal powders, titanium-based alloy powders may have lower production volumes and potentially longer lead times.

- Process Challenges: AM techniques with titanium-based alloy powders can be more complex and require specialized equipment and expertise compared to some other materials.

FAQ

Here are some of the most commonly asked questions regarding titanium-based alloy powders, presented in a clear and concise FAQ format:

| Question | Answer |

|---|---|

| What are the different types of titanium-based alloy powders available? | There’s a wide variety, including Ti-6Al-4V (various grades), Gr-2 Titanium, high-temperature alloys, and even ceramic and shape memory alloy variants. Each offers unique properties for specific applications. |

| What factors influence the choice of production method for titanium-based alloy powders? | Cost, desired powder purity, particle size and morphology, and application requirements all play a crucial role. |

| What are some key specifications to consider when selecting a titanium-based alloy powder? | Particle size distribution, powder chemistry adhering to standards like ASTM, flowability, and surface area are all important factors. |

| Besides production method and specifications, what else should I consider when choosing a titanium-based alloy powder supplier? | Look for a supplier offering a variety of powders, with robust quality control, technical support, competitive pricing, and reasonable lead times. |

| What are the biggest advantages of using titanium-based alloy powders in additive manufacturing? | Exceptional material properties, design freedom for complex geometries, lightweighting capabilities, and reduced waste compared to traditional methods. |

| Are there any limitations to consider when using titanium-based alloy powders? | Yes, factors like higher cost, safety concerns due to flammability, limited availability, and potential process challenges require careful consideration. |

By delving into the fascinating world of titanium-based alloy powder preparation methods, specifications, suppliers, and the associated pros and cons, you’re well on your way to making informed decisions for your next AM project. Remember, the right powder, chosen with careful consideration, can unlock the true potential of additive manufacturing and pave the way for innovative advancements across various industries.

know more 3D printing processes

Additional FAQs: Preparation method of Titanium-Based Alloy Powders

1) Which preparation method yields the most spherical Titanium-Based Alloy Powders for AM?

- Vacuum/gas atomization and Plasma Rotating Electrode Process (PREP/PEROT) produce the highest sphericity and lowest satellite content, ideal for LPBF/EBM. Mechanical grinding and HDH produce more irregular particles suited to MIM or press-and-sinter.

2) When should I choose Hydride–Dehydride (HDH) over atomization?

- Choose HDH for cost-sensitive applications, larger PSD cuts, or when targeting MIM/press–sinter routes. It provides good flow after conditioning but typically higher oxygen and irregular shape than atomized Ti-6Al-4V powders.

3) How do interstitials (O/N/H) differ by preparation method?

- PREP and high-quality gas atomization with inert pack-out achieve lower O/N/H; HDH and mechanical milling tend to increase oxygen due to larger specific surface and processing exposure. For ELI grades, target O ≤ 0.12–0.13 wt% per ASTM F3001.

4) Can recycled EBM/LPBF powder be blended back into virgin Titanium-Based Alloy Powders?

- Yes, under a controlled reuse plan: sieve, test O/N/H and PSD tails, cap blend ratios (e.g., 20–50% recycled depending on specs), and maintain digital lot genealogy. Follow ISO/ASTM 52907 guidance.

5) What particle size distributions are typical by method?

- LPBF: 15–45 µm (atomized/PREP). EBM: 45–105 µm (atomized/PREP). MIM: sub‑22 µm preferred (HDH or fine atomized). Mechanical grinding often needs classification to meet tight PSD windows.

2025 Industry Trends: Titanium-Based Alloy Powders

- Interstitial tightening: Aerospace/medical RFQs increasingly specify O ≤ 0.13 wt% for Ti‑6Al‑4V ELI powders with documented inert handling.

- Vertical/transfer‑arc PREP: More suppliers adopt vertical bars and transfer‑arc torches to boost yield of 15–45 µm cuts and cut satellites.

- Sustainability and passports: Powder Environmental Product Declarations (EPDs) and digital passports tying PSD, O/N/H, and atomizer telemetry to build data are mainstream.

- Beta‑Ti expansion: Beta-rich powders (e.g., Ti‑5Al‑5Mo‑5V‑3Cr‑like families) gain adoption for higher toughness and formability in space/aero brackets.

- Cost control: Helium‑lean gas mixes and argon recirculation lower per‑kg costs without compromising morphology.

2025 Snapshot: Preparation Route Benchmarks for Titanium-Based Alloy Powders (Indicative)

| Attribute | Gas/Vacuum Atomization | PREP/PEROT | HDH | Mechanical Grinding |

|---|---|---|---|---|

| Typical PSD for LPBF (µm) | 15–45 | 15–45 | Needs classification; often finer for MIM | Broad; requires classification |

| Sphericity (mean) | 0.92–0.95 | 0.94–0.96 | 0.80–0.88 | 0.70–0.85 |

| Satellites (count %) | 1–3 | 0.8–2 | N/A (irregular) | N/A (irregular) |

| Oxygen in Ti‑6Al‑4V (wt%) | 0.13–0.16 (ELI 0.12–0.13) | 0.12–0.14 (ELI 0.12) | 0.16–0.22 | 0.18–0.25 |

| AM‑grade yield (15–45 µm, %) | 30–38 | 32–40 | Low without fine classification | Low without intensive classification |

| Cost (relative) | High | High–Premium | Medium | Low |

| Primary use cases | LPBF/EBM AM | LPBF/EBM AM (critical) | MIM, PM | PM, R&D, cost‑sensitive |

Sources:

- ISO/ASTM 52907 (metal powder feedstock), 52904 (LPBF of metals), 52920/52930 (quality/qualification): https://www.iso.org

- ASTM F2924 (Ti‑6Al‑4V), ASTM F3001 (Ti‑6Al‑4V ELI), F3301/F3302 (AM practice), E1019/E1409/E1447 (O/N/H): https://www.astm.org

- NIST AM‑Bench metrology resources: https://www.nist.gov/ambench

- SAE/AMS specs for AM titanium (e.g., AMS7015/7011): https://www.sae.org

Latest Research Cases

Case Study 1: Transfer‑Arc PREP to Meet ELI Oxygen Targets (2025)

Background: A hip implant producer struggled to meet O ≤ 0.13 wt% with conventional atomized Ti‑6Al‑4V ELI.

Solution: Adopted vertical, transfer‑arc PREP; added inert closed transfer and inline O2 sensors; tuned RPM/stand‑off for 15–45 µm LPBF cut; implemented digital powder passports.

Results: Oxygen 0.135→0.120 wt%; satellites reduced by 45%; first‑pass build yield +10%; fatigue life of coupons +18% after HIP and polish.

Case Study 2: HDH‑to‑MIM Route for Cost Reduction in Surgical Tools (2024)

Background: A medical tools OEM needed cost relief vs. fine atomized powders.

Solution: Qualified HDH Ti‑6Al‑4V powder with narrow sub‑22 µm classification; optimized binder and sinter cycle; applied post‑HIP for density.

Results: Powder cost −28% vs. fine GA; final density ≥99.2%; tensile strength matched spec; cosmetic surface improved after shot peen + electropolish.

Expert Opinions

- Prof. Amy J. Clarke, Professor of Metallurgy, Colorado School of Mines

- “For Titanium-Based Alloy Powders, interstitial control and morphology from the preparation route directly translate to fatigue scatter—particularly in ELI grades.”

- Dr. Brandon A. Lane, Additive Manufacturing Metrologist, NIST

- “Tying powder passports to in‑process monitoring is shortening qualification cycles; PSD tails and hollows from the preparation method are now traceable to porosity hot spots.”

- Dr. Laura G. Jensen, Director of Medical AM, Stryker (from public talks)

- “Graded porosity implants benefit most from low‑oxygen, high‑sphericity powders; consistent ELI feedstock is the foundation of reproducible osseointegration outcomes.”

Practical Tools/Resources

- ISO/ASTM standards for AM feedstock and processes: https://www.iso.org

- ASTM F2924/F3001, F3301/F3302, E1019/E1409/E1447 for titanium AM and O/N/H testing: https://www.astm.org

- NIST AM‑Bench datasets on powder morphology and porosity correlations: https://www.nist.gov/ambench

- Senvol Database for machine–material mappings and supplier discovery: https://senvol.com

- NFPA 484 combustible metal powder safety guidance

- OEM technical libraries (EOS, GE Additive, SLM Solutions, Velo3D) for titanium process parameters and PSD guidance

Last updated: 2025-08-25

Changelog: Added 5 focused FAQs on preparation routes; introduced a 2025 benchmark table comparing routes; included two recent case studies (PREP ELI and HDH–MIM); added expert viewpoints; compiled practical standards/resources

Next review date & triggers: 2026-02-01 or earlier if ASTM/ISO tighten O/N/H limits, major PREP/GA technology updates affect PSD/sphericity, or EPD/passport requirements change buyer specifications