What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that enables a three-dimensional solid object of any shape to be rapidly realized through a digital model. The essence of 3D printing is to generate a digital model file by editing a series of digital slices of a specific processing style through computer-aided design software, and then to use specific additives as bonding materials in accordance with the dimensions of the model drawing, using specific molding equipment, i.e., 3D printers, to make solid metal powders or highly malleable substances in powder, liquid or filament form. Layered processing, stacking molding so that the raw material will melt and increase these thin layers layer by layer, so as to finally “print” a real and three-dimensional solid object.

The 3D Printing Materials

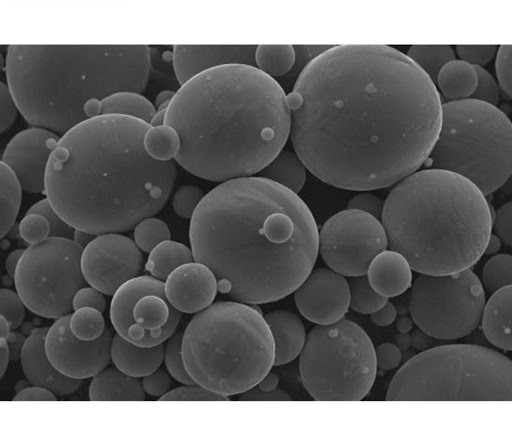

The world’s leading experts in the 3D printing industry define metal powder for 3D printing as a group of metal particles less than 1mm in size. This includes single metal powders, alloy powders, and certain refractory compound powder alloys with metallic properties, bronze alloys, industrial steels, stainless steels, titanium alloys, and nickel-aluminum alloys. However, in addition to good plasticity, metal powders for 3D printing must also meet the requirements of fine particle size, narrow particle size distribution, high sphericity, good flowability, and high apparent density.

The influence of metal powder particle shape, particle size and its distribution on the finished 3D printed product

In the process of metal powder preparation, the powder particles will take different shapes with different preparation methods, such as spherical, subspherical, polygonal, porous spongy, dendritic, etc. The particle shape of the powder directly affects the flowability and bulk density of the powder, which in turn has an impact on the properties of the prepared metal parts.

Spherical or nearly spherical powders have good fluidity, are less likely to clog the powder supply system during printing, and can be spread into thin layers, thereby improving the dimensional accuracy and surface quality of 3D printed parts, as well as the density and tissue uniformity of the parts, making them the preferred raw material shape type for 3D printing. However, it should be noted that spherical powders have low particle packing density and large voids, making the parts less dense, which also affects the forming quality.

The smaller the particle size of metal powder, the more conducive to the smooth sintering, because the smaller the particle size, the larger the specific surface area, the greater the driving force of sintering. In addition, the voids between the fine powder particles are small, and the connection between adjacent layered powder is tight, which is conducive to improving the sintering densification and sintering strength. Small particles of metal powder can also fill the voids of large particles, which can improve the stacking density of the powder, thus contributing to improving the surface quality and strength of the printed metal parts. However, not the finer the particles the better, if too many fine particles, in the sintering process is easy to appear “spheroidization” phenomenon, easy to cause the uneven thickness of the laying powder. The so-called “spheroidization” phenomenon, that is, in order to make the molten metal liquid surface and the surrounding media surface of the system with the minimum free energy, under the action of surface tension, the shape of the metal liquid surface to the spheroid surface transformation of a phenomenon. Spheroidization” usually prevents the metal powder from solidifying to form a continuous smooth pool after melting, thus forming a loose and porous part, resulting in molding failure.

Additional FAQs: The Influence of Metal Powder

1) How does particle shape affect powder bed density and final part porosity?

- Spherical powders flow and spread uniformly, reducing voids between layers and improving relative density. Angular/dendritic powders can increase mechanical interlocking but lower flowability, causing layer defects and porosity bands.

2) What particle size distribution (PSD) is ideal for LPBF/SLM?

- A narrow, near-unimodal PSD with D10 ≈ 15–20 µm, D50 ≈ 30–35 µm, D90 ≈ 45–55 µm is common. Slight bimodality can raise packing density by letting fines fill interstices, but excessive fines increase spatter, oxidation, and “balling” (spheroidization).

3) How do satellites and agglomerates influence build quality?

- Satellites increase effective roughness and reduce flow, causing uneven layer thickness and local energy overdosing. Agglomerates can trap gas, leading to lack‑of‑fusion or keyhole porosity. Image analysis per ISO 13322 helps quantify and control them.

4) Why does moisture content matter for powder spreading and fusion?

- Adsorbed moisture increases cohesion and reduces flowability; it also elevates hydrogen/oxygen pickup during melting, promoting porosity and hot cracking in sensitive alloys. Store under inert gas with desiccant; verify via Karl Fischer and O/N/H testing.

5) Can reused powder maintain properties across multiple cycles?

- Yes, if sieved and monitored. Track PSD shift, satellite growth, oxide thickness, and O/N/H. Establish reuse limits tied to CT porosity metrics and mechanical property acceptance, refreshing with virgin powder as needed.

2025 Industry Trends: Powder Shape, Size, and Distribution Effects

- Inline rheology and vision: Printers increasingly integrate spreadability metrics and bed imaging to flag shape/PSD anomalies in real time.

- Digital powder passports: Genealogy linking PSD, sphericity, and O/N/H across reuse cycles adopted in aerospace/medical.

- Atomization advances: EIGA/UPC and plasma spheroidization reduce satellites and narrow PSDs, improving layer consistency.

- AI-driven parameter tuning: Melt pool signatures tied to PSD/shape statistics optimize energy density to minimize balling and porosity.

- Sustainability: Closed-loop reclamation sorts fines/oversize to maintain target PSD while maximizing reuse.

2025 Snapshot: Shape/PSD Quality Metrics vs. Build Outcomes (Indicative)

| Powder metric (typical LPBF targets) | 2023 fleet median | 2025 fleet median | Impact on build KPIs |

|---|---|---|---|

| Circularity/sphericity (image analysis) | 0.90 | 0.93 | Higher flow, fewer streaks |

| Satellite content (% by count) | 4–6% | 2–3% | Lower recoater alarms |

| PSD D10/D50/D90 (µm) | 18/33/52 | 20/34/50 | Tighter layer thickness |

| Moisture at fill (ppm H2O) | 350–500 | 150–250 | Reduced gas porosity |

| First‑pass density (relative, %) | 99.3–99.5 | 99.5–99.7 | Less HIP reliance |

| First‑article pass rate (%) | ~68 | ~75 | Fewer rebuilds |

Sources:

- ISO/ASTM 52907 (feedstock requirements), ISO 13322 (image analysis): https://www.iso.org

- ASTM B212/B213/B214/B527 (powder characterization), ASTM E2651/E1019 (O/N/H): https://www.astm.org

- NIST AM‑Bench and powder‑bed monitoring research: https://www.nist.gov/ambench

- MPIF standards and guides: https://www.mpif.org

Latest Research Cases

Case Study 1: Reducing Balling via PSD Tuning in 316L (2025)

Background: A service bureau observed surface ripples and occasional balling on thin walls despite stable parameters.

Solution: Narrowed fines tail (raised D10 from 16→20 µm), reduced satellites via secondary plasma spheroidization; implemented humidity-controlled hopper purge and 0.5% contour energy reduction.

Results: Surface Ra improved 14%; lack‑of‑fusion defects down 40% (CT); first‑pass yield +9% across six builds.

Case Study 2: Image‑Based Shape Control for Ti‑6Al‑4V Reuse (2024)

Background: An aerospace supplier needed to extend powder reuse without compromising fatigue properties.

Solution: Introduced per‑lot image analysis for circularity and satellite count; dynamic sieving thresholds; periodic oxygen checks; adjusted stripe overlap when circularity dropped below 0.91.

Results: Reuse cycles extended from 6–7 to 9–10; oxygen remained ≤0.12 wt%; high‑cycle fatigue scatter narrowed by 12%.

Expert Opinions

- Dr. Brandon A. Lane, Additive Manufacturing Metrologist, NIST

- “Bed imaging and spreadability metrics tied to PSD and shape are now strong predictors of porosity—and are increasingly used for in‑process acceptance.”

- Prof. Amy J. Clarke, Professor of Metallurgy, Colorado School of Mines

- “Controlling interstitials and particle morphology together narrows property scatter; fines management is especially critical for titanium alloys.”

- Dr. Martin Wegener, Head of Materials & Processes, EOS GmbH

- “Digital powder passports with PSD and sphericity trends across reuse are becoming standard for serial production qualifications.”

Practical Tools and Resources

- ISO/ASTM 52907 (metal powder feedstock) and 52904 (LPBF of metals): https://www.iso.org

- ASTM B212/B213/B214/B527 (density/flow/size), ASTM E2651/E1019 (O/N/H analysis): https://www.astm.org

- ISO 13322‑1/2 for particle image analysis: https://www.iso.org

- NIST AM‑Bench datasets and powder‑bed monitoring: https://www.nist.gov/ambench

- MPIF Standard 01/35 for powder characterization and design: https://www.mpif.org

- Senvol Database for machine–material mappings and qualifications: https://senvol.com

Last updated: 2025-08-25

Changelog: Added 5 targeted FAQs; created a 2025 snapshot table linking shape/PSD metrics to build outcomes with sources; included two recent case studies; provided expert viewpoints; listed practical standards and resources

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM/MPIF standards update, OEMs mandate new powder passport fields, or in‑situ monitoring practices change acceptance criteria by >10%