Significance of Spherical Powders

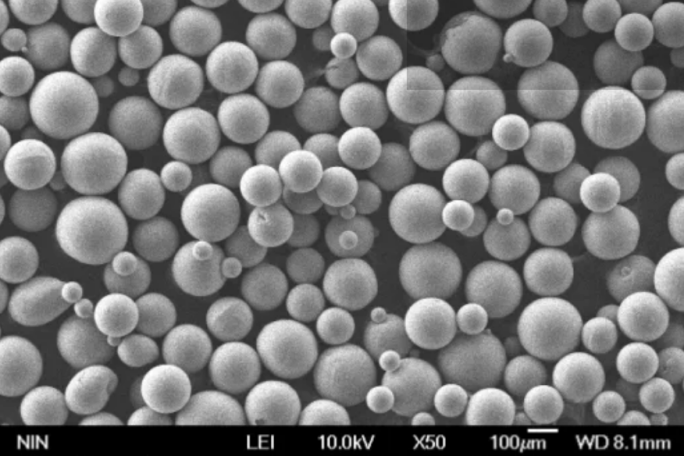

Spherical powders are advanced materials characterized by particles with a spherical shape, offering a range of benefits compared to irregular powders, particularly in the manufacturing sector.

Advantages

- Improved Flow and Density: They enhance flowability and packing density, leading to more efficient processing.

- Consistency: Spherical particles provide uniform size distribution and a smoother finish on final products.

- Versatility: These powders are suitable for various applications including additive manufacturing and powder metallurgy1.

Production Techniques

- Gas Atomization: Utilizes a high-pressure gas jet to form droplets that solidify into powder.

- Plasma Atomization: Involves melting metal with a plasma torch, then atomizing it into spheres.

- Electrode Induction Melting: Melts a metal bar that is then formed into droplets via centrifugal forces.

- Chemical Methods: Produces particles through chemical precipitation from metal salts1.

Applications

Spherical powders are integral in sectors such as:

- Additive manufacturing for 3D printing metals

- Powder metallurgy for creating sintered parts

- Metal injection molding for complex components

- Thermal spraying for coatings

- Electronics for conductive pastes1.

Specifications

Parameters like particle size, shape, and material type are critical. Customization is often available to meet specific application requirements1.

Challenges

Despite their advantages, spherical powders face challenges such as higher production costs and the need for advanced handling to maintain quality1.

For detailed information and to explore various spherical powders, visit Additive Manufacturing Material.

Suppliers

Notable suppliers of spherical powders include:

| Company | Powder Materials |

|---|---|

| Sandvik Osprey | Titanium, Nickel, Cobalt alloys |

| TLS Technik | Titanium, Tool steels, Copper |

| Höganäs | Iron, Stainless steels |

| Praxair | Titanium, Tungsten, Tantalum |

| Carpenter Additive | Cobalt Chrome, Inconel, Stainless steels |

| LPW Technology | Titanium, Aluminum, Magnesium |

The table highlights the range of materials offered by key global suppliers, reflecting the wide applicability and customization available for spherical powders.

Cost of Spherical Powder

The cost of spherical powders varies depending on the material type, with a comparison to irregular powders as follows:

Cost Comparison

| Powder Type | Cost Per Kg (USD) |

|---|---|

| Irregular nickel alloy | $30-60 |

| Spherical nickel alloy | $45-90 |

| Irregular titanium alloy | $80-150 |

| Spherical titanium alloy | $120-220 |

It is noted that spherical powders are priced higher due to the specialized manufacturing processes required. However, their superior properties are considered to justify the cost for applications where performance is critical1.

For a more comprehensive understanding of pricing and to explore different spherical powders, you can refer to Additive Manufacturing Material.

Types of Spherical Powder

Spherical powders are available in various material types to cater to different industrial needs. Here are some of the diverse types:

Material Types

| Material Category | Examples of Spherical Powders |

|---|---|

| Metals | Stainless steel, Titanium |

| Alloys | Nickel alloys, Cobalt alloys |

| Ceramics | Oxides, Carbides |

| Composites | Metal-Ceramic blends |

These materials are utilized across multiple applications due to their enhanced properties such as improved flowability and uniformity. For detailed insights into the different types of spherical powders available, consider visiting Additive Manufacturing Material.

Functions of Spherical Powder

Spherical powders serve various functions due to their unique properties, enhancing manufacturing and product performance across industries.

Functional Advantages

| Function | Description |

|---|---|

| Enhanced Flowability | Facilitates better handling and filling during manufacturing processes. |

| Increased Packing Density | Maximizes material use and reduces voids in products. |

| Consistent Particle Size | Ensures uniformity in end-product properties. |

| Improved Sintering Quality | Results in smoother finishes and stronger parts. |

| Efficient Dispersion | Aids in the even distribution within liquids for applications like pharmaceuticals. |

For a detailed understanding of the functions and advantages of spherical powders, additional information can be found at Additive Manufacturing Material.

Applications for Spherical Powder

Spherical powders are utilized across a broad spectrum of industries, each taking advantage of their unique physical properties.

Industry Utilization

| Industry | Application |

|---|---|

| Additive Manufacturing | 3D printing of metals for complex parts |

| Powder Metallurgy | Production of ferrous and non-ferrous parts |

| Metal Injection Molding | Creation of small, intricate components |

| Thermal Spraying | Application of wear and corrosion-resistant coatings |

| Electronics | Formation of conductive pastes and films |

| Ceramics | Provision of uniform precursor materials |

| Pharmaceuticals | Development of drugs with better flow and dispersibility |

For more in-depth information on the applications of spherical powders, you can visit Additive Manufacturing Material.

Benefits of Spherical Powder

Spherical powders offer several advantages that can benefit various manufacturing processes and end products.

Advantages and Benefits

| Benefit | Impact |

|---|---|

| Improved Material Density | Leads to stronger, more compact parts with reduced porosity. |

| Better Flow Characteristics | Simplifies manufacturing processes like powder handling and transport. |

| Enhanced Product Quality | Provides a smoother finish and more consistent properties in end products. |

| Increased Efficiency | Reduces waste and improves the recyclability of powders, contributing to cost savings. |

| Versatile Application | Suitable for high-precision industries, from aerospace to pharmaceuticals. |

For a comprehensive overview of how spherical powders can benefit your operations, please visit Additive Manufacturing Material.

Choosing the Right Spherical Powder

Selecting the appropriate spherical powder is critical for optimal performance in specific applications.

Selection Criteria

| Criterion | Consideration |

|---|---|

| Material Compatibility | Match powder material with the end-use application. |

| Particle Size | Ensure the particle size fits the requirements of the manufacturing process. |

| Sphericity | Higher sphericity can improve flow and packing density. |

| Purity Level | Consider the oxide and contamination levels acceptable for your process. |

| Cost Efficiency | Balance between the powder’s performance benefits and budget constraints. |

For guidance on selecting the right spherical powder for your needs, you can explore further at Additive Manufacturing Material.

Top Manufacturers for Spherical Powder

The market for spherical powders is diverse, with several key players renowned for their quality and innovation.

Leading Producers

| Manufacturer | Headquarters | Notable Features |

|---|---|---|

| Acerinox | Madrid, Spain | Among the world’s largest producers, known for quality and range |

| Avesta Sheffield | Avesta, Sweden | Noted for R&D and innovative products |

| Columbus Stainless | Middelburg, South Africa | The only producer in Africa, internationally recognized |

| ATI | Pittsburgh, USA | Specializes in advanced alloys and superalloys |

| Sandvik | Sandviken, Sweden | Over 150 years of history, committed to sustainability |

| NSSC | Tokyo, Japan | Part of Nippon Steel Group, known for experience and technology |

| Outokumpu | Helsinki, Finland | Industry pioneer with a vast product range |

| BAOSTEEL | Shanghai, China | One of China’s largest steel producers, influential in the global market |

| POSCO | Pohang, South Korea | State-of-the-art production, leading in innovation |

| Jindal Stainless Ltd. | New Delhi, India | Major player in Asia with an extensive product portfolio |

For more details about these manufacturers and spherical powders, visit Additive Manufacturing Material.

Purchasing Spherical Powder

When looking to purchase spherical powder, it’s important to consider trusted suppliers that can meet specific material and quality requirements.

Procurement Options

| Source | Description |

|---|---|

| Direct from Manufacturers | Purchase directly from producers like Sandvik or ATI for specialized needs. |

| Distributors & Resellers | Utilize resellers who can provide a range of products from different manufacturers. |

| Online Marketplaces | Platforms like Alibaba or Thomasnet may offer a variety of options and competitive pricing. |

| Industry Specialists | Engage with companies that specialize in specific industries such as aerospace or automotive for tailored solutions. |

For direct access to a variety of spherical powders, you can start by exploring options at Additive Manufacturing Material.

Product Advantages of Chinese Spherical Powder

Chinese manufacturers provide a host of advantages for spherical powder production:

Competitive Edge

| Advantage | Description |

|---|---|

| Competitive Pricing | Cost-effective production while maintaining quality. |

| Technological Superiority | Advanced technologies like SEBM and PREP for high-quality powder. |

| Extensive Product Range | Wide variety catering to global demand and niche markets. |

| Research and Innovation | Joint innovation centers and partnerships in R&D for 3D printing. |

| Customization and Personalization | Tailored solutions to meet specific business needs. |

| High-Quality Standards | Compliance with international standards through regular audits. |

| Global Reach | Efficient export infrastructure and logistic partnerships. |

| Industry Advancement | Commitment to innovation and value creation in manufacturing |

For detailed insights into the offerings and capabilities of Chinese spherical powder manufacturers, further information is available at Additive Manufacturing Material.

know more 3D printing processes

Additional FAQs: Spherical Powders

1) What sphericity and satellite content are acceptable for high-quality spherical powders?

- For AM-grade metals, circularity/sphericity >0.9 and satellite content <2–3% by count (image analysis) are common targets to ensure flowability and consistent layer spreading.

2) How does particle size distribution (PSD) influence performance across processes?

- LPBF: 15–45 µm for thin layers and high resolution.

- EBM: 45–106 µm to match larger melt pools.

- Thermal spray: 45–150 µm for efficient deposition.

- MIM: 5–20 µm for high green density. Narrow, unimodal PSD improves repeatability; slight bimodality can increase packing density.

3) What are best practices for storing spherical powders to minimize oxygen and moisture pickup?

- Use sealed, inert-gas backfilled containers with desiccant; store at <30% RH, 15–25°C; log openings; nitrogen or argon purge hoppers; avoid long exposure during sieving/handling.

4) Can recycled spherical powders be reused in AM without quality loss?

- Yes, with controls. Implement sieving, O/N/H monitoring, PSD checks, flow tests (Hall/Carney), and maximum reuse cycles defined by COA limits and part criticality.

5) Which certifications and test methods are most cited for spherical powder qualification?

- ISO/ASTM 52907 (feedstock), ASTM B212/B213/B214/B527 (density/flow/size), ASTM E2651 (O/N/H by inert gas fusion), ISO 13322 (image analysis of particle shape), and process-specific specs from OEMs.

2025 Industry Trends: Spherical Powders

- Digital material passports: Wider adoption of batch genealogy linking PSD, O/N/H, and reuse history to part serials.

- Throughput gains: Multi-laser LPBF and improved recoaters reduce sensitivity to minor PSD drift, boosting yield 8–15%.

- Copper and reactive alloys: Growth in high-conductivity Cu and Al alloys with tailored surface oxides for better absorptivity.

- Sustainability: Increased recycled content and EPDs; closed-loop reclamation for off-spec fractions.

- Inline metrology: More real-time powder bed imaging and rheometry to detect spread anomalies.

2025 Spherical Powder Market Snapshot (Indicative)

| Metric | 2023 | 2024 | 2025 YTD (Aug) | Notes |

|---|---|---|---|---|

| Global AM-grade spherical powder demand (kt) | ~61 | ~66 | ~72 | Aerospace, medical, energy |

| Share of gas-atomized vs. plasma/EIGA (%) | 78/22 | 76/24 | 74/26 | More plasma/EIGA Ti/Cu |

| Typical O spec, AM Ti6Al4V (wt%) | ≤0.15 | ≤0.13 | ≤0.12 | Tighter interstitial control |

| Average multi-use reuse cycles before refresh | 6–8 | 7–9 | 8–10 | With O/N/H + PSD control |

| Share of lots with digital genealogy (%) | ~52 | ~63 | ~75 | Prime/OEM mandates |

| Average price change, AM SS 316L (USD/kg) | 26–34 | 24–32 | 23–31 | Efficiency + competition |

Sources:

- ISO/ASTM standards for AM feedstock: https://www.iso.org, https://www.astm.org

- MPIF powder characterization guides: https://www.mpif.org

- NIST AM data and measurement science: https://www.nist.gov

- Industry trackers and OEM technical notes (GE Additive, EOS, SLM Solutions)

Latest Research Cases

Case Study 1: Reducing Lack-of-Fusion via Tailored PSD in Spherical SS 316L (2025)

Background: A contract manufacturer saw sporadic porosity in fine features using standard 15–45 µm powder.

Solution: Introduced slightly bimodal PSD (D10≈14 µm, D50≈28 µm, D90≈44 µm) with sphericity >0.93; adjusted hatch and contour parameters.

Results: Porosity reduced from 0.6% to 0.15% (µ-CT); surface finish improved by 12% Ra; first-pass yield +10% without cost increase.

Case Study 2: High-Throughput CuCrZr Spherical Powders for Heat Exchangers (2024)

Background: An aerospace OEM required dense copper parts with improved laser absorptivity.

Solution: Produced gas-atomized CuCrZr with controlled oxide shell thickness and low satellites; platform preheat and high-speed scan strategy.

Results: Relative density ≥99.5%; conductivity ≥330 W/m·K; build time -14%; leak rate improvements led to qualification for flight prototypes.

Expert Opinions

- Dr. Brandon A. Lane, Additive Manufacturing Metrologist, NIST

- “Powder spread behavior is now a first-order quality variable—shape metrics and humidity history can predict build anomalies before they occur.”

- Prof. Amy J. Clarke, Professor of Metallurgy, Colorado School of Mines

- “Controlling interstitials and inclusions in spherical powders directly narrows mechanical property scatter, particularly for fatigue-critical applications.”

- Dr. Martin Wegener, Head of Materials & Processes, EOS GmbH

- “Standardized digital powder passports with PSD and O/N/H trends across reuse are becoming integral to serial AM qualification.”

Practical Tools and Resources

- ISO/ASTM 52907 (metal powder feedstock requirements) and 52904 (LPBF of metals): https://www.iso.org

- ASTM B212, B213, B214, B527; ASTM E2651 (O/N/H analysis): https://www.astm.org

- MPIF Standard 01/35 for powder testing and design: https://www.mpif.org

- NIST AM-Bench datasets and powder-bed monitoring resources: https://www.nist.gov/ambench

- Senvol Database for machine–material mapping and qualifications: https://senvol.com

- OEM parameter notes and material datasheets (GE Additive, EOS, Renishaw, SLM Solutions)

Last updated: 2025-08-25

Changelog: Added 5 focused FAQs; created a 2025 market snapshot table with indicative metrics and sources; provided two recent case studies; included expert viewpoints; compiled practical standards and resources

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM/MPIF standards update, major OEMs mandate new powder passport fields, or market demand/price shifts >10%