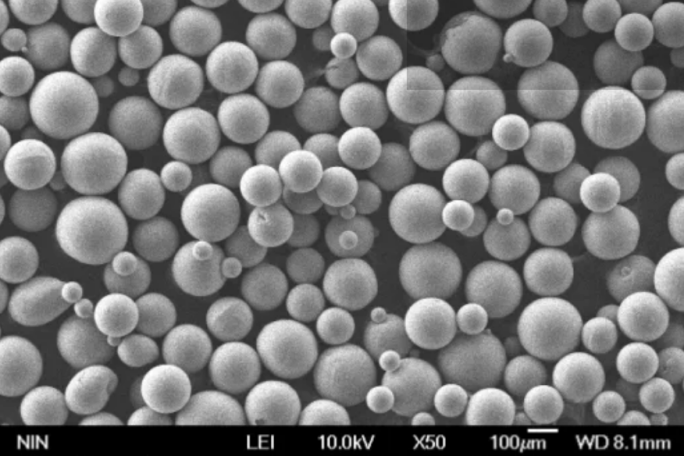

Importância dos pós esféricos

Os pós esféricos são materiais avançados caracterizados por partículas com formato esférico, oferecendo uma série de benefícios em comparação com os pós irregulares, especialmente no setor de fabricação.

Vantagens

- Fluxo e densidade aprimorados: Melhoram a fluidez e a densidade de empacotamento, levando a um processamento mais eficiente.

- Consistência: As partículas esféricas proporcionam uma distribuição uniforme do tamanho e um acabamento mais suave nos produtos finais.

- Versatilidade: Esses pós são adequados para várias aplicações, incluindo manufatura aditiva e metalurgia do pó1.

Técnicas de produção

- Atomização de gás: Utiliza um jato de gás de alta pressão para formar gotículas que se solidificam em pó.

- Atomização por plasma: Envolve a fusão de metal com uma tocha de plasma e, em seguida, sua atomização em esferas.

- Fusão por indução de eletrodos: Derrete uma barra de metal que é então formada em gotículas por meio de forças centrífugas.

- Métodos químicos: Produz partículas por meio de precipitação química de sais metálicos1.

Formulários

Os pós esféricos são essenciais em setores como:

- Manufatura aditiva para impressão 3D de metais

- Metalurgia do pó para a criação de peças sinterizadas

- Moldagem por injeção de metal para componentes complexos

- Pulverização térmica para revestimentos

- Eletrônica para pastas condutoras1.

Especificações

Parâmetros como tamanho da partícula, forma e tipo de material são fundamentais. A personalização geralmente está disponível para atender aos requisitos de aplicações específicas1.

Desafios

Apesar de suas vantagens, os pós esféricos enfrentam desafios, como custos de produção mais altos e a necessidade de manuseio avançado para manter a qualidade1.

Para obter informações detalhadas e explorar vários pós esféricos, visite Material Aditivo de Fabricação.

Fornecedores

Entre os principais fornecedores de pós esféricos estão:

| Empresa | Materiais em Pó |

|---|---|

| Sandvik Osprey | Ligas de titânio, níquel e cobalto |

| TLS Technik | Titânio, aços para ferramentas, cobre |

| Höganäs | Ferro, aços inoxidáveis |

| Praxair | Titânio, tungstênio, tântalo |

| Aditivo Carpenter | Cobalto-cromo, Inconel, Aços inoxidáveis |

| Tecnologia LPW | Titânio, alumínio, magnésio |

A tabela destaca a variedade de materiais oferecidos pelos principais fornecedores globais, refletindo a ampla aplicabilidade e a personalização disponíveis para pós esféricos.

Custo do pó esférico

O custo dos pós esféricos varia de acordo com o tipo de material, com a seguinte comparação com os pós irregulares:

Comparação de custos

| Tipo de pó | Custo por kg (USD) |

|---|---|

| Liga de níquel irregular | $30-60 |

| Liga esférica de níquel | $45-90 |

| Liga de titânio irregular | $80-150 |

| Liga esférica de titânio | $120-220 |

Observa-se que os pós esféricos têm um preço mais alto devido aos processos de fabricação especializados necessários. Entretanto, considera-se que suas propriedades superiores justificam o custo para aplicações em que o desempenho é fundamental1.

Para uma compreensão mais abrangente dos preços e para explorar diferentes pós esféricos, você pode consultar Material Aditivo de Fabricação.

Tipos de pó esférico

Os pós esféricos estão disponíveis em vários tipos de materiais para atender a diferentes necessidades industriais. Aqui estão alguns dos diversos tipos:

Tipos de materiais

| Categoria de material | Exemplos de pós esféricos |

|---|---|

| Metais | Aço inoxidável, titânio |

| Ligas metálicas | Ligas de níquel, ligas de cobalto |

| Cerâmica | Óxidos, carbonetos |

| Compostos | Misturas de metal e cerâmica |

Esses materiais são utilizados em várias aplicações devido às suas propriedades aprimoradas, como melhor fluidez e uniformidade. Para obter informações detalhadas sobre os diferentes tipos de pós esféricos disponíveis, considere visitar Material Aditivo de Fabricação.

Funções do pó esférico

Os pós esféricos têm várias funções devido às suas propriedades exclusivas, aprimorando a fabricação e o desempenho dos produtos em todos os setores.

Vantagens funcionais

| Função | Descrição |

|---|---|

| Fluidez aprimorada | Facilita um melhor manuseio e enchimento durante os processos de fabricação. |

| Aumento da densidade da embalagem | Maximiza o uso do material e reduz os espaços vazios nos produtos. |

| Tamanho de partícula consistente | Garante a uniformidade das propriedades do produto final. |

| Melhoria na qualidade da sinterização | Resulta em acabamentos mais suaves e peças mais resistentes. |

| Dispersão eficiente | Auxilia na distribuição uniforme dentro de líquidos para aplicações como produtos farmacêuticos. |

Para uma compreensão detalhada das funções e vantagens dos pós esféricos, informações adicionais podem ser encontradas em Material Aditivo de Fabricação.

Aplicações para pó esférico

Os pós esféricos são utilizados em um amplo espectro de setores, cada um aproveitando suas propriedades físicas exclusivas.

Utilização do setor

| Setor | Aplicativo |

|---|---|

| Manufatura Aditiva | Impressão 3D de metais para peças complexas |

| Metalurgia do pó | Produção de peças ferrosas e não ferrosas |

| Moldagem por injeção de metal | Criação de componentes pequenos e complexos |

| Pulverização térmica | Aplicação de revestimentos resistentes ao desgaste e à corrosão |

| Eletrônicos | Formação de pastas e filmes condutores |

| Cerâmica | Fornecimento de materiais precursores uniformes |

| Produtos farmacêuticos | Desenvolvimento de medicamentos com melhor fluxo e dispersibilidade |

Para obter informações mais detalhadas sobre as aplicações de pós esféricos, visite Material Aditivo de Fabricação.

Benefícios do pó esférico

Os pós esféricos oferecem diversas vantagens que podem beneficiar vários processos de fabricação e produtos finais.

Vantagens e benefícios

| Benefício | Impacto |

|---|---|

| Densidade aprimorada do material | Produz peças mais resistentes e compactas com porosidade reduzida. |

| Melhores características de fluxo | Simplifica os processos de fabricação, como manuseio e transporte de pó. |

| Qualidade aprimorada do produto | Proporciona um acabamento mais suave e propriedades mais consistentes nos produtos finais. |

| Aumento da eficiência | Reduz o desperdício e melhora a capacidade de reciclagem dos pós, contribuindo para a economia de custos. |

| Aplicação versátil | Adequado para setores de alta precisão, do aeroespacial ao farmacêutico. |

Para obter uma visão geral abrangente de como os pós esféricos podem beneficiar suas operações, visite Material Aditivo de Fabricação.

Escolhendo o pó esférico certo

A seleção do pó esférico adequado é fundamental para o desempenho ideal em aplicações específicas.

Critérios de seleção

| Critério | Considerações |

|---|---|

| Compatibilidade de materiais | Combine o material em pó com a aplicação de uso final. |

| Tamanho da partícula | Certifique-se de que o tamanho da partícula atenda aos requisitos do processo de fabricação. |

| Esfericidade | Uma maior esfericidade pode melhorar o fluxo e a densidade de empacotamento. |

| Nível de pureza | Considere os níveis de óxido e contaminação aceitáveis para seu processo. |

| Eficiência de custo | Equilíbrio entre os benefícios de desempenho do pó e as restrições orçamentárias. |

Para obter orientação sobre como selecionar o pó esférico certo para suas necessidades, você pode explorar mais em Material Aditivo de Fabricação.

Principais fabricantes de pó esférico

O mercado de pós esféricos é diversificado, com vários participantes importantes reconhecidos por sua qualidade e inovação.

Produtores líderes

| Fabricante | Sede social | Recursos notáveis |

|---|---|---|

| Acerinox | Madri, Espanha | Entre os maiores produtores do mundo, conhecidos por sua qualidade e variedade |

| Avesta Sheffield | Avesta, Suécia | Reconhecida por seus produtos inovadores e de P&D |

| Columbus Stainless | Middelburg, África do Sul | O único produtor na África, reconhecido internacionalmente |

| ATI | Pittsburgh, Estados Unidos | Especializada em ligas e superligas avançadas |

| Sandvik | Sandviken, Suécia | Mais de 150 anos de história, comprometidos com a sustentabilidade |

| NSSC | Tóquio, Japão | Parte do Nippon Steel Group, conhecido por sua experiência e tecnologia |

| Outokumpu | Helsinki, Finlândia | Pioneira no setor com uma vasta gama de produtos |

| BAOSTEEL | Xangai, China | Um dos maiores produtores de aço da China, influente no mercado global |

| POSCO | Pohang, Coreia do Sul | Produção de última geração, líder em inovação |

| Jindal Stainless Ltd. | Nova Délhi, Índia | Grande participante na Ásia com um amplo portfólio de produtos |

Para obter mais detalhes sobre esses fabricantes e os pós esféricos, acesse Material Aditivo de Fabricação.

Compra de pó esférico

Ao procurar comprar pó esférico, é importante considerar fornecedores confiáveis que possam atender a requisitos específicos de material e qualidade.

Opções de aquisição

| Fonte | Descrição |

|---|---|

| Direto dos fabricantes | Compre diretamente de produtores como a Sandvik ou a ATI para necessidades especializadas. |

| Distribuidores e revendedores | Utilize revendedores que possam fornecer uma variedade de produtos de diferentes fabricantes. |

| Mercados on-line | Plataformas como Alibaba ou Thomasnet podem oferecer uma variedade de opções e preços competitivos. |

| Especialistas do setor | Envolva-se com empresas especializadas em setores específicos, como o aeroespacial ou o automotivo, para obter soluções personalizadas. |

Para ter acesso direto a uma variedade de pós esféricos, você pode começar explorando as opções em Material Aditivo de Fabricação.

Vantagens do produto Pó esférico chinês

Os fabricantes chineses oferecem uma série de vantagens para a produção de pós esféricos:

Vantagem competitiva

| Vantagens | Descrição |

|---|---|

| Preços competitivos | Produção econômica, mantendo a qualidade. |

| Superioridade tecnológica | Tecnologias avançadas como SEBM e PREP para pó de alta qualidade. |

| Ampla gama de produtos | Ampla variedade que atende à demanda global e a nichos de mercado. |

| Pesquisa e inovação | Centros de inovação conjuntos e parcerias em P&D para impressão 3D. |

| Personalização e customização | Soluções sob medida para atender a necessidades comerciais específicas. |

| Padrões de alta qualidade | Conformidade com os padrões internacionais por meio de auditorias regulares. |

| Alcance global | Infraestrutura de exportação eficiente e parcerias logísticas. |

| Avanço do setor | Compromisso com a inovação e a criação de valor na fabricação |

Para obter insights detalhados sobre as ofertas e os recursos dos fabricantes chineses de pó esférico, mais informações estão disponíveis em Material Aditivo de Fabricação.