Titanium alloy powders refer to fine granular materials made from various combinations of titanium mixed with other metals like aluminum, vanadium, molybdenum, zirconium, etc. They exhibit high strength-to-weight ratio, corrosion resistance, and biocompatibility making them suitable for diverse applications from aerospace components to medical implants.

This guide covers different types of titanium alloy powders, their composition and properties, manufacturing methods, applications, specifications and grades, pricing details, pros and cons, and supplier landscape. It also answers common questions on using titanium alloy powders for industrial fabrication of lightweight, durable parts via additive manufacturing.

Types of titanium alloy powder

There are many varieties of titanium alloy powder categorized by their metallic composition:

| Alloy Type | Chemical Composition | Characteristics |

|---|---|---|

| Ti-6Al-4V (Grade 5) | 90% titanium, 6% aluminum, 4% vanadium | The most common and cost-effective titanium alloy, offers best combination of strength, low weight and corrosion resistance. |

| Ti 6Al-7Nb | 6% aluminum, 7% niobium | Contains no vanadium. Higher biocompatibility for medical uses, slightly lower strength. |

| Ti-555 | 5% aluminum, 5% molybdenum, 5% vanadium | Higher strength than Ti-64, used for aerospace parts operating at moderate temperatures up to 300°C. |

| Ti-1023 | 10% vanadium, 2% iron, 3% aluminum | Excellent cold formability and weldability. Used for critical rotating components. |

There are many other possible combinations based on optimizing for strength, hardness, heat resistance or other parameters depending on application requirements.

Production Methods for Titanium Alloy Powder

Common industrial techniques to produce titanium alloy powder include:

| Method | Description | Typical Output |

|---|---|---|

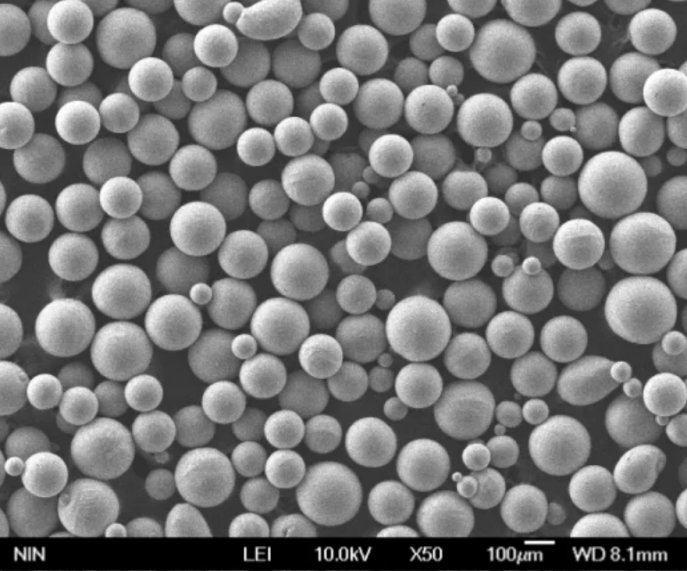

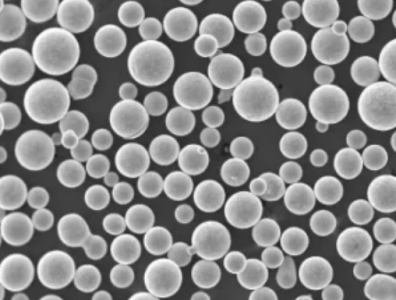

| Gas Atomization | Molten titanium alloy stream disintegrated by high pressure inert gas jets into fine droplets that solidify into powder. | Spherical powders ideal for additive manufacturing, high purity. |

| Plasma Atomization | Similar to gas atomization, but plasma energy used instead of gas to create higher melt temperatures and finer powders. | Very spherical, smaller size distribution powders compared to gas atomization. |

| Hydriding/Dehydriding | Hydrogenation and decomposition process reduces titanium ingots to brittle titanium hydride which is then crushed and sieved into powder form. | Irregular shaped powder particles with higher oxygen content. Lower cost process. |

| Milling/Mechanical Alloying | Ball mills grind titanium ingots/scrap with other alloying agents into fine composite particles. | Angular powder shape, higher impurity levels, wider particle distribution. |

Gas atomized and plasma atomized methods allow precise control over powder size, shape and distribution resulting in higher quality raw materials preferred for critical additive manufacturing uses in aerospace and medical implants.

Properties of Titanium Alloy Powder

Key properties that make titanium alloy powder so uniquely suited to fabricating lightweight, durable finished parts:

| Property | Characteristics | Significance |

|---|---|---|

| High strength-to-weight ratio | Up to 4 times stronger than aluminum alloys while remaining light weight | Enables design of lighter, smaller components without sacrificing durability |

| Corrosion resistance | Naturally forms protective oxide coating preventing degradation across wide pH range | Outperforms stainless steel parts in harsh environments from acids to sea water with minimal maintenance |

| Biocompatibility | Non-toxic and not rejected by human body tissues over long term implanted uses | Preferred over other metals for pins, screws, hip joints, skull plates and other internal prosthetics with lifetimes from 10-20+ years |

| Workability and ductility | Withstand repeated stress cycles without fracturing and formable across variety of machining and fabrication methods | Reliable lasting performance in dynamic mechanically loaded applications like aircraft landing gear and turbine engine blades |

| Heat resistance | Retains high tensile strength at elevated temperatures up to 600°C for some alloys | Allows lightweight design for hot section components like jet engines, auto exhaust systems, chemical reactors and other heat transfer equipment |

Combined with modern additive manufacturing techniques, these superb physical and chemical capabilities make titanium alloys suitable to replace heavier, corrosive-prone or bio-incompatible traditional materials across transportation, chemical processing, biomedical and consumer product industries.

Applications of Titanium Alloy Powder

Common end uses of additively manufactured titanium alloy components from metal powders:

| Industry | Applications | Benefits |

|---|---|---|

| Aerospace | Aircraft structural frames, engine blades, landing gear parts | Lightweight with heat/fatigue resistance to cut fuel costs |

| Medical | Hip, knee, dental implants. Surgical tools | Biocompatible, strong devices to improve patient outcomes |

| Automotive | Connecting rods, valves, turbochargers | High strength at elevated under-hood temperatures |

| Chemical plants | Corrosion-resistant vessels, pipes, pumps | Withstand contact with wide range of aggressive substances |

| Consumer goods | Eyeglass frames, watches, bicycles | Lightweight luxury products |

| Defense | Ballistic armor plates, combat vehicle panels | Effective protection from bullets/blasts with lower tactical weight burden |

Both prototyping one-off custom components like artificial joints tailored to a patient’s scan data to 3D printing at commercial batch scales for aircraft components demonstrates the versatility of titanium alloys across small and massive finished parts.

Specifications and Grades

International material standards classify titanium alloy grades for consistent powder feedstock identification:

| Specification | Common Grades | Details |

|---|---|---|

| ASTM F2924 | Ti-6Al-4V Ti 6Al-7Nb Ti 6-4 ELI | Defines 20+ titanium grades compositions and mechanical properties for additive manufacturing uses |

| ASTM F3049 | Ti 6Al-4V Ti 5Al-5V-5Mo-3Cr | Grades tailored for biocompatible medical device applications like implants and instruments |

| ASTM F3001 | Ti-6Al-4V Ti 6-4 ELI Ti 6Al-7Nb | Focused on heat resistance capabilities at 300°C+ environments common in aerospace engines and airframe hotspots |

The ELI designation refers to “extra low interstitial” with stricter limits on contaminants. Aerospace and medical sectors have the most stringent specifications given liability risks. Talk to manufacturers to understand which grade suitability best aligns with application design requirements and operating conditions.

Suppliers and Pricing

| Supplier | Grades Offered | Pricing Estimate |

|---|---|---|

| LPW Technology | Ti-6Al-4V, Ti 6Al-7Nb, Custom Alloys | $150-$500 per kg |

| AP&C | Ti 6Al-4V, Ti 6Al-7Nb, Ti 6-4 ELI | $200-$600 per kg |

| Pyrogenesis | TiAlCrY, Ti6Al4V, Ti Alloys | $250-$800 per kg |

| Oerlikon AM | Ti6Al4V, TiAl6V4, Ti6242 | $100-$650 per kg |

Costs can range widely for titanium alloy powders from as low as $100 per kg for more common grades from basic manufacturing methods up to $800 per kg for highly customized alloys leveraging proprietary plasma atomization processes. Typically expect $200 – $400 per kg for workhorse grades like Ti-6Al-4V ELI meeting aerospace or medical specifications.

Remember – total costs must be calculated based on buy-to-fly ratio from powder material to final dense part weight, not just initial raw powder quantity. Work with suppliers to optimize this yield efficiency in printing process.

Pros and Cons of Titanium Alloy Powder

| Pros | Cons |

|---|---|

| Lightweight parts reduce component weight by 50% or more | Material costs higher than metals like aluminum or steels |

| Withstand extreme environments from sea water to high heat | Limited choice of alloys and powder suppliers compared to other metals |

| Create novel geometries impossible via subtractive machining | Post-processing like hot isostatic pressing often needed to meet mechanical properties |

| Eliminate subassemblies via integrated printed parts | Still lacks comprehensive codes and standards for defect tolerance |

| Customize designs tailored to patient anatomy or application loads | Requires inert gas handling expertise for powder and printing safety |

While titanium itself costs more than other common metals and needs secondary finishing steps post-printing, the long term part performance in reliability-critical applications and flexible opportunities to reinvent lighter, integrated component designs ultimately provide excellent value over theOperational lifetime – particularly for sectors like aerospace and medical.

Limitations and Considerations

Be aware of these restrictions when working with titanium alloy powders:

- Reactivity with oxygen – powder and printed parts must be handled in inert argon environments to prevent fires

- Lower laser absorption compared to other metals – may require hotter laser powers, resulting in slower build speeds

- Due to high chemical affinity, contamination from build plate adhesion during printing remains risk

- Lack of comprehensive codes and standards for quality control allowances – CAAM, MMPDS and historical data aid but still an evolving field

- Secondary processing like Hot Isostatic Pressing (HIP) adds costs but needed to achieve material properties similar to wrought equivalents

Engineers considering titanium applications must partner closely with specialized metal printing service bureaus to develop robust process parameters and validate mechanical performance meet design specifications across small batches before committing to mass production.

FAQ

| Question | Answer |

|---|---|

| What particle sizes are typical for titanium alloy printing powders? | 10-45 microns is common, as optimized for most laser powder bed fusion machines. Some technologies support sub-10 micron particles. |

| What is an example chemical composition for grade 5 titanium alloy? | 89.7% titanium, 6% aluminum, 4% vanadium, 0.25% iron, 0.2% oxygen. Other trace elements. |

| What temperature does Ti-6Al-4V melt at? | 1,605 °C, but starts becoming super plastic at over 800 °C which aids dense laser sintering behavior. |

| Does titanium alloy powder expire or go bad over time? | If stored sealed with desiccant bags to prevent moisture exposure, powder lasts many years. Re-test critical properties after 3-5 years. |

| Is titanium alloy powder flammable? | Yes, fine titanium powder is highly flammable especially when aerosolized. Follow strict precautions using inert gases only. |

| Are these alloys compatible with metal injection molding? | Yes, they can also feed MIM processes, not just additive printing. Adjust mesh sizes per the injection mold equipment capabilities. |

| What post-processing method is best? | Hot isostatic pressing gives the best microstructure, densification and material properties. |

| How much does a hip implant device made from titanium alloy powder cost? | Approximately $8,000 with half the cost being the titanium powder raw material. |

With sound handling procedures and quality processes, titanium alloys deliver tremendous advances in metal printed lightweight part innovation.

Conclusion

As additive manufacturing ushers in a new era of design freedom in engineering across industries from aerospace rockets to custom knee implants, titanium alloy powders will play a crucial role thanks unique qualities from high biocompatibility to heat resistance retaining good workability. With expanded alloy compositions beyond ever-popular Ti-6Al-4V now becoming available, engineers have an expanded materials palette to experiment with to push the performance limits of topologically-optimized printed metal components scarcely imaginable through traditional subtractive fabrication means. By partnering closely with specialized powder metallurgy manufacturing partners to properly characterize novel alloy grades for rigorous quality standards and leverage secondary enhancement processes like Hot Isostatic Pressing to maximize mechanical properties, businesses can take full advantage of titanium’s lightweight, high-strength benefits to deliver next generation vehicles, implants and industrial equipment. While costs exceed more common metals, the value over full life cycle more than compensates in many applications. Expect titanium alloys to continue growing as a critical technology material to push innovation across sectors.

know more 3D printing processes

Additional FAQs on Titanium Alloy Powder

1) What oxygen and nitrogen limits should I specify for aerospace or medical titanium alloy powder?

For Ti-6Al-4V ELI used in implants, O ≤0.13 wt% and N ≤0.03 wt% are typical; aerospace often targets O ≤0.20 wt% and N ≤0.05 wt% for standard Ti-6Al-4V. Always reference the applicable ASTM F3001/F2924/F136 limits.

2) How does powder reuse impact mechanical properties and defects?

Multiple reuse cycles can increase oxygen, alter PSD/sphericity, and raise lack-of-fusion and hot-cracking risk. Implement batch genealogy, blend-back limits (e.g., ≤30–50% recycled with virgin), and periodic O/N/H and flowability checks.

3) Which titanium alloy powders are best for high-temperature service?

Near-β and α+β alloys like Ti-6242, Ti-5553, and Ti-6246 outperform Ti-6Al-4V above ~300°C, offering better creep/fatigue resistance for compressors, airframes, and auto turbo components.

4) Can titanium alloy powder be used in binder jetting or MIM, not just LPBF/EBM?

Yes. Binder jetting and MIM use finer PSDs (often D50 ~5–20 μm) and require debind/sinter/HIP cycles. Mechanical properties can approach wrought with proper densification and interstitial control.

5) What surface finishes are achievable on AM titanium parts?

As-built LPBF Ra is typically 6–20 μm depending on orientation. Post-processes like shot peen, abrasive flow, chemical milling, electropolishing, and machining can reach Ra <0.8 μm; implants often use dual-texture (macro porous + micro-rough) for osseointegration.

2025 Industry Trends for Titanium Alloy Powder

- AM at production scale: Multi-laser LPBF (8–12 lasers) and faster recoaters lower cost-per-part for Ti-64 and near-β alloys.

- Bio-focused grades: Wider adoption of vanadium-free Ti-6Al-7Nb and β-type alloys (e.g., Ti-13Nb-13Zr) to tune elastic modulus for implants.

- Sustainability: Closed-loop powder recovery, higher recycled Ti content, and material passports for aerospace traceability.

- Fatigue-critical qualification: In-situ monitoring + HIP + surface conditioning become standard for rotating hardware and orthopedic stems.

- Hybrid builds: AM preforms + forging or HIP consolidation to achieve wrought-like microstructures in thick sections.

| 2025 Metric (Titanium Alloy Powder/AM) | Typical Range/Value | Relevance/Notes | Source |

|---|---|---|---|

| LPBF relative density (Ti-6Al-4V) | 99.5–99.9% (with HIP) | Production-grade parts | OEM app notes; peer-reviewed AM studies |

| High-cycle fatigue (Ti-64 AM, HIP, machined) | 300–600 MPa at 10⁷ cycles | Orientation and surface finish dependent | Journal reports; ASTM E466 tests |

| Oxygen spec (ELI implant powder) | ≤0.13 wt% | Biocompatibility/ductility | ASTM F136/F3001 |

| Typical PSD for LPBF | D10–D90 ≈ 15–45 μm | Flow and recoating stability | ISO/ASTM 52907 |

| Indicative powder price (Ti-64 ELI, spherical) | $180–$450/kg | Certs, PSD, and atomization route drive spread | Supplier quotes/market trackers |

| Powder reuse cycles before refresh | 5–15 cycles typical | Govern with O/N/H and flow tests | MES/QA best practices |

Authoritative references and further reading:

- ASTM F2924, F3001, F136: https://www.astm.org

- ISO/ASTM 52907 (feedstock), 52910 (DFAM): https://www.astm.org and https://www.iso.org

- NIST AM benchmarks and fatigue data: https://www.nist.gov

- ASM Handbook (Titanium and Titanium Alloys): https://www.asminternational.org

Latest Research Cases

Case Study 1: Multi-Laser LPBF Ti-5553 Brackets for Regional Jet (2025)

Background: An airframe OEM sought weight reduction with stable fatigue for secondary structural brackets.

Solution: Produced Ti-5553 on a 12-laser LPBF system using tight PSD spherical powder; stress relief, HIP, and contour machining; in-situ melt pool monitoring linked to acceptance criteria.

Results: 19% mass reduction versus machined Ti-64, 1.6× fatigue life at 10⁶ cycles after HIP + surface finishing, and 14% part-cost reduction at series rate.

Case Study 2: Binder-Jetted Ti-6Al-7Nb Porous Cups for Cementless Hips (2024)

Background: A medical device firm needed consistent open-porosity acetabular cups with vanadium-free chemistry.

Solution: Binder jetting fine-cut Ti-6Al-7Nb; debind, vacuum sinter, and selective HIP to keep surface porosity (500–800 μm) while densifying the bulk; validated per ISO 10993.

Results: 98% dense cores with 55–65% porous surfaces; pull-out strength +25% versus plasma-sprayed coatings; sterile-pack lead time reduced by 30%.

Expert Opinions

- Prof. Michael J. Bermingham, Professor of Advanced Manufacturing, The University of Queensland

Key viewpoint: “Powder specification and handling—especially interstitials and PSD stability—remain the dominant levers for repeatable fatigue in AM titanium.” - Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

Key viewpoint: “HIP plus targeted surface treatment closes the performance gap to wrought for many Ti-64 applications; process signatures from in-situ monitoring are increasingly part of certification dossiers.” - Dr. Laura Fox, Director of Materials Engineering, Stryker (personal viewpoint)

Key viewpoint: “Vanadium-free and β-type titanium alloy powders enable modulus matching and improved osseointegration, accelerating adoption in next-gen implants.”

Citations for expert profiles:

- The University of Queensland: https://www.uq.edu.au

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- Stryker: https://www.stryker.com

Practical Tools and Resources

- Standards and qualification

- ASTM F2924/F3001/F136 for Ti alloys; ISO 10993 biocompatibility: https://www.astm.org and https://www.iso.org

- Design and simulation

- Ansys Additive and Ansys Mechanical (distortion, fatigue): https://www.ansys.com

- nTopology for lattices/porous implants: https://ntop.com

- COMSOL Multiphysics (heat transfer, structural): https://www.comsol.com

- Powder QC and process control

- ISO/ASTM 52907 feedstock testing guidance

- LECO O/N/H analyzers: https://www.leco.com

- Senvol Database (machines/materials): https://senvol.com/database

- MES/QA suites with genealogy (e.g., material passports)

- Regulatory and testing

- FDA device database (AM implants): https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfpmn/pmn.cfm

- ASTM F3122 (AM process control), F3303 (metal PBF safety)

Last updated: 2025-08-21

Changelog: Added 5 focused FAQs, 2025 trend table with metrics and sources, two recent titanium alloy powder case studies, expert viewpoints with credible affiliations, and a curated tools/resources list.

Next review date & triggers: 2026-02-01 or earlier if ASTM/ISO standards change, major OEMs publish new multi-laser Ti AM parameters/fatigue datasets, or powder pricing/availability shifts >10% QoQ.