Metal alloy powder refers to fine metallic powders made by combining two or more metal elements to enhance properties like strength, corrosion resistance, ductility, and conductivity. This guide provides an overview of metal alloy powder including types, production methods, applications, specifications, selection considerations, and frequently asked questions.

Overview of Metal Alloy Powder

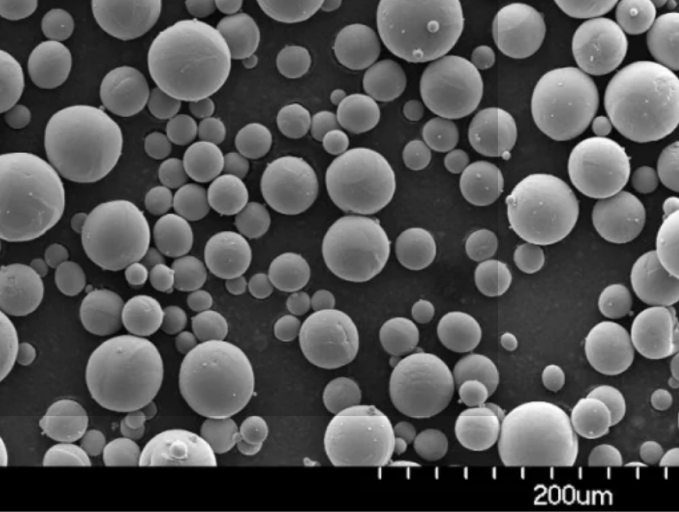

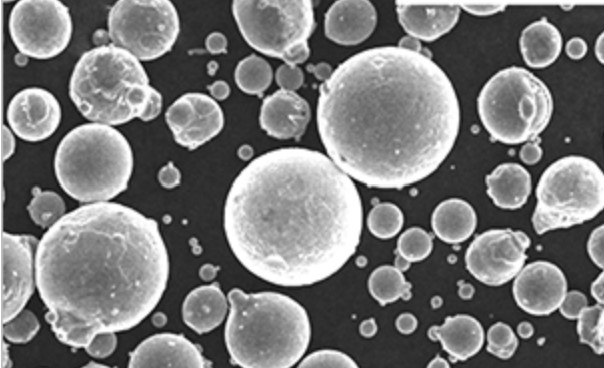

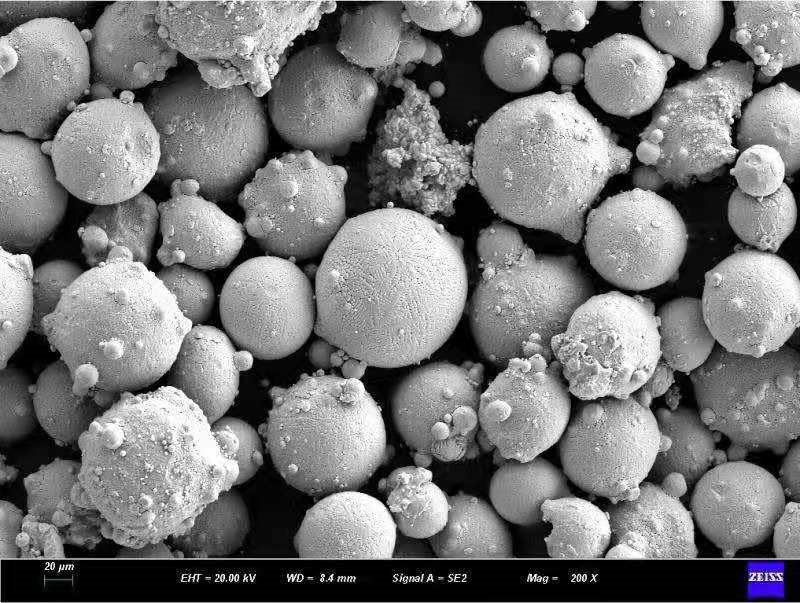

Metal alloy powders are particulate materials composed of two or more metals manufactured via atomization or chemical reduction into fine spherical powders ideal for industrial applications.

Key benefits of using metal alloy powders include:

- Tailored properties by combining metals

- More uniform structure than cast alloys

- Versatility for diverse manufacturing techniques

- Ability to produce complex component geometries

- Excellent repeatability and quality control

- Cost-effectiveness for high volume production

Common metal alloys in powder form include stainless steel, tool steel, superalloys, low alloy steel, nickel alloys, cobalt alloys, and more. Both ferrous and non-ferrous alloys are produced as powders.

Metal alloy powders enable manufacturing techniques like metal injection molding, additive manufacturing, and powder metallurgy as well as surface coatings.

Types of Metal Alloy Powder

Various metal alloys are converted into powder form depending on required properties and applications:

| Alloy Type | Composition | Properties |

|---|---|---|

| Stainless Steel | Fe, Cr, Ni | Corrosion resistance |

| Tool Steel | Fe, Cr, C | Wear resistance |

| Low Alloy Steel | Fe, Mn, C | Strength |

| Superalloys | Ni, Cr, Co | Heat resistance |

| Cobalt Alloys | Co, Cr, W, Ni | Wear resistance |

| Copper Alloys | Cu, Zn | Electrical conductivity |

| Nickel Alloys | Ni, Cr | Corrosion resistance |

By combining powder properties, performance can be optimized for hardness, strength, ductility, conductivity, magnetism, corrosion resistance, wear resistance, high temperature resistance, and other attributes.

Metal Alloy Powder Production

Metal alloy powders are commercially produced via:

- Atomization – Melted alloy streamed into water or gas jet to form droplets.

- Electrolysis – Aqueous electrolytic process reduces metal ions into powders.

- Carbonyl – Metal reacts with carbon monoxide to form volatile powders.

- Mechanical Alloying – Repeated welding and fracturing creates nanostructured powder.

Atomization is the most common method allowing rapid large scale production of consistent spherical alloy powders ideal for manufacturing processes.

Applications of Metal Alloy Powder

Thanks to their tailored properties and ability to form complex geometries, metal alloy powders enable diverse applications across industries:

Additive Manufacturing

- Aerospace components with superalloys

- Medical implants with cobalt chrome and titanium

- Automotive prototypes with tool steel

Metal Injection Molding

- Small complex metal parts like gears and nozzles

- High volume production possible

Surface Coatings

- Wear-resistant coatings with tool steel

- Corrosion resistant coatings with stainless steel

Powder Metallurgy

- High performance auto parts

- Permanent magnets

- Friction materials like brakes and clutches

Sintered Components

- Structural parts with controlled porosity

- Filters, bushings, bearings

Brazing Pastes

- Joining similar and dissimilar metals

Chemical Industries

- Metal catalysts

Electronics

- Conductive films and thermal management

Metal Alloy Powder Specifications

Metal alloy powders are characterized by composition, particle size distribution, morphology, flowability, and other specifications:

Metal Alloy Powder Properties

| Specification | Typical Values |

|---|---|

| Alloy Composition | Steel, Ni, Co, Cu alloys |

| Particle Size | 5 – 150 microns |

| Particle Shape | Spherical, irregular |

| Size Distribution | D10, D50, D90 |

| Flowability | Angle of repose, flow rate |

| Apparent Density | 2 – 8 g/cm3 |

| Tap Density | Up to 80% of solid density |

| Oxide Content | less than 2% |

| Moisture Content | less than 0.2% |

| Purity | 98% min |

The powder characteristics dictate manufacturing process suitability, quality, mechanical properties, and performance.

Metal Alloy Powder Size Types

A key specification is particle size distribution. Powders are classified into different size ranges:

Metal Alloy Powder Size Classification

| Type | Particle Size Range |

|---|---|

| Coarse Powder | 75 to 150 μm |

| Medium Powder | 25 to 75 μm |

| Fine Powder | 15 to 45 μm |

| Extra Fine Powder | 5 to 25 μm |

| Nano Powder | Under 100 nm |

- Larger particles improve flow and permeability

- Smaller particles provide higher resolution and densities

- Most powders are under 45 μm for manufacturing processes

- Nano powders offer unique properties

particle size and shape are controlled during production and classified by screening. Custom particle distributions are possible.

Factors in Selecting Metal Alloy Powders

Key considerations when selecting an appropriate metal alloy powder include:

- Application – Required material properties and capabilities

- Manufacturing process – Compatibility with equipment and methods

- Cost – Raw material cost and production efficiencies

- Lead time – Availability from stock or custom production

- Quality – Consistent composition, morphology, size distribution

- Technical support – Expertise from powder manufacturer

- Health and safety – Flammability, reactivity, toxicity factors

- Environmental impact – Recyclability, emissions, waste disposal

Work with knowledgeable powder producers early in the design process to select optimized alloys and powder characteristics for the application.

Evaluating and Choosing a Metal Powder Supplier

Not all metal powder producers offer the same range of alloys, quality, lot sizes, and capabilities. Key factors in choosing a supplier include:

How to Select a Metal Powder Supplier

| Factor | Criteria |

|---|---|

| Capabilities | Range of alloys, size distributions, production volumes, sampling, testing |

| Quality | Powder morphology, consistency, purity, certification standards |

| Technical Expertise | Alloy knowledge, manufacturing process experience, R&D capabilities |

| Customer Service | Responsiveness, order fulfillment reliability, communication |

| Facilities | Quality control and testing equipment, health and safety systems |

| Logistics | On-time delivery, inventory, lead times |

| Business Standing | Industry reputation, financials, growth |

| Pricing | Quoted powder pricing, minimums, shipping |

| Terms | Payment options, warranties |

Visiting a shortlist of suppliers to audit their operations firsthand provides the best assurance of capabilities and professionalism.

Cost Analysis of Metal Alloy Powders

Metal alloy powder pricing depends on:

- Composition – More expensive alloys mean higher powder cost

- Purity – Tighter chemistry controls increase price

- Particle size – Finer powders are more costly to produce

- Production method – Atomization is lower cost than specialty methods

- Order quantity – Bulk ordering >1000 kg lowers per-kilogram pricing

- Testing – Additional characterization adds cost

- Packaging – Specialized options like sealed bags add cost

Typical Metal Alloy Powder Cost Ranges

| Alloy Type | Cost per kg |

|---|---|

| Iron and Low Alloy Steel | $5 – $15 |

| Stainless Steel | $15 – $30 |

| Tool Steel | $20 – $50 |

| Copper Alloys | $50 – $100 |

| Cobalt Alloys | $50 – $200 |

| Superalloys | $100 – $500 |

Request quotes from shortlisted suppliers to compare pricing for the required alloy, particle size, purity, testing, and delivery.

Handling and Storage Recommendations

Special care must be taken when handling reactive fine metal powders:

- Use grounded, conductive containers and scoops

- Avoid sparks, flames, and ignition sources

- Disperse dust accumulation with good housekeeping

- Use PPE like masks, gloves, and protective clothing

- Provide proper ventilation and dust collection

- Store sealed containers in a cool, dry area

Follow all safety guidelines from the powder manufacturer’s SDS document. Explosive dust hazards must be managed appropriately.

Metal Alloy Powder Trends and Innovations

Recent trends in metal alloy powder technology include:

- More customizable alloys for additive manufacturing

- Nanopowder manufacturing methods

- Automated powder handling and quality control

- Simulation software for powder production

- Increased use of metal powders for 3D printing

- New functional alloys with multiple elements

- Powder recycling systems

Continued alloy and process developments will expand the possibilities for high performance powder metallurgy components.

FAQ

Q: What are the most common metal alloy powders used?

A: Stainless steel, tool steel, and nickel alloys are among the most widely used metal alloy powders.

Q: What industries use metal alloy powders the most?

A: Aerospace, automotive, medical, and industrial/consumer products utilize metal alloy powders extensively.

Q: What production method makes the highest quality powders?

A: Inert gas atomization produces the most spherical and consistent alloy powder suitable for AM and MIM processes.

Q: How are metal powders handled safely?

A: Use conductive containers, grounding, bonding, inert gas blanketing, ventilation, and explosion prevention systems for safe powder handling.

Q: Are metal alloy powders expensive?

A: Prices range widely from $5/kg for common steel powders to over $500/kg for specialty superalloys. Quotes from suppliers establish current pricing.

Q: What is the typical size range of powders for manufacturing?

A: Most manufacturing applications use powder sizes from 10 – 45 microns. Finer nano powders below 100 nm also have niche uses.

Q: What is the shelf life of sealed metal powders?

A: If kept dry in sealed containers, metal powders can be stable for 1-5 years depending on alloy composition and storage conditions.

Q: Are metal powders environmentally friendly?

A: Metal powders enable very efficient raw material usage. Contained dust and proper waste disposal minimizes environmental impact.

Q: What standards apply to metal powder production?

A: International standards like ISO 10149, ASTM B835, and MPIF Standard 35 govern various physical powder properties and testing procedures.

Q: Can metal alloy powders be recycled?

A: Yes, unused powder can be recycled and reprocessed. Some additive manufacturing uses recycled powder as feedstock.

Key Takeaways on Metal Alloy Powder

- Metal alloy powders combine multiple metals to achieve enhanced properties

- Atomization is the primary industrial production method

- Particle size distribution must match manufacturing process needs

- Metal powders enable additive manufacturing, MIM, coatings, and PM parts

- Alloy selection considers cost along with mechanical and physical properties

- Powder characteristics like flow and apparent density are important

- Work with expert suppliers who understand applications and processes

- Safe handling precautions are critical when working with reactive powders

With continued growth in powder metallurgy applications, metal alloy powders offer an expanding range of capabilities not possible with conventional metal processing alone.

know more 3D printing processes

Frequently Asked Questions (Supplemental)

1) What powder characteristics matter most for AM vs MIM?

- AM (LPBF/EBM/BJ): Highly spherical morphology, narrow PSD (typically D10/50/90 ≈ 15/30/45 μm for LPBF), low satellites, very low O/N/H, and consistent apparent/tap density. MIM: slightly finer PSD (D50 ≈ 10–18 μm), flow stability (Hausner ≤1.20), and controlled oxygen to aid sintering without embrittlement.

2) How does oxygen content impact Metal Alloy Powder performance?

- Elevated oxygen increases oxide films and viscosity (MIM) and causes lack‑of‑fusion or spatter (AM). Typical limits: 316L O ≤0.30 wt% (MIM) and ≤0.05–0.10 wt% (AM); Ni‑base superalloys often target O ≤0.03–0.05 wt% for AM. Verify via inert gas fusion (ASTM E1019).

3) Can recycled Metal Alloy Powder be blended without compromising quality?

- Yes, with powder passport controls: sieve to spec, remove spatter/inclusions, monitor PSD, flow, apparent/tap density, and interstitials. Many sites use 10–30% blend‑back ratios validated by tensile/fatigue and CT porosity checks.

4) What’s the best atomization route for highly reactive alloys?

- Inert gas atomization using vacuum induction melting (VIM) plus argon/nitrogen with O2/H2O scrubbing. Plasma atomization or PREP yield ultra‑spherical powders for Ti and superalloys but at higher cost.

5) How should Metal Alloy Powder be stored for long shelf life?

- Keep in sealed moisture‑barrier packaging with desiccant, purge headspace with dry inert gas, store at 15–25°C, RH <40%, and minimize handling cycles. Re‑test O/N/H and flow after any prolonged storage or reuse.

2025 Industry Trends and Data

- Digital traceability: Powder passports with chemistry (including O/N/H/C), PSD, inclusion ratings, reuse counts, and recycled content are standard in RFQs for aerospace/medical.

- ESG and cost: Argon recirculation, energy‑efficient atomization, and disclosed recycled content (metals and packaging) are increasingly demanded.

- Micro‑scale and large‑format divergence: Ultra‑fine PSDs for micro‑MIM and micro‑LPBF; coarser, high‑flow powders for DED/wire‑powder hybrid systems.

- Qualification acceleration: In‑situ monitoring (melt‑pool, acoustic) paired with standardized test artifacts shortens allowables development.

- Safer handling: Wider adoption of ISO 80079 and NFPA 484 guidance, conductive packaging, and dust‑exposure monitoring.

| KPI (Metal Alloy Powder Quality & Use), 2025 | 2023 Baseline | 2025 Typical/Target | Why it matters | Sources/Notes |

|---|---|---|---|---|

| LPBF PSD (μm, D10/D50/D90) | 20/35/55 | 15/30/45 | Packing, melt stability | ISO/ASTM 52907; supplier QC |

| Oxygen limit 316L (AM) wt% | 0.07–0.12 | 0.04–0.08 | Density, corrosion | ASTM E1019 |

| Satellite count (≥5 μm per 100 particles) | 4–6 | 2–3 | Spreadability/defects | SEM image analysis |

| Binder‑jet + HIP final density (%) | 98–99 | 99.0–99.5 | Reliability | OEM/peer‑reviewed data |

| Qualified reuse cycles (LPBF) | 3–6 | 6–10 | Cost, consistency | Plant case studies |

| Disclosed recycled content (%) | Limited | 15–35 | ESG, cost | EPD/LCA reports |

| Powder lot acceptance with passports | Emerging | Common | Faster qualification | RFQ requirements |

Authoritative resources:

- ISO/ASTM 52907 (metal powder characterization), 52904 (PBF practice), 52910 (design for AM): https://www.iso.org

- ASTM B822/B214 (PSD), B212/B213 (apparent density/flow), B923 (true density), E1019 (O/N/H), F3122 (property reporting): https://www.astm.org

- ASM Handbook: Powder Metallurgy; Additive Manufacturing: https://dl.asminternational.org

- NIST AM Bench datasets and monitoring research: https://www.nist.gov/ambench

- NFPA 484 (combustible metals): https://www.nfpa.org

Latest Research Cases

Case Study 1: Low‑Oxygen 316L Metal Alloy Powder for Corrosion‑Critical LPBF Parts (2025)

- Background: A medical device OEM needed improved pitting resistance for LPBF 316L fluidic manifolds.

- Solution: VIM + inert gas atomized powder (15/30/45 μm PSD; O = 0.045 wt%); optimized gas‑flow baffles; contour + chessboard hatch; stress‑relief + electropolish; passivation per ASTM A967.

- Results: As‑built density 99.92%; pitting potential +120 mV vs. 2023 baseline; CT porosity <0.05%; scrap −17%; validated 8 reuse cycles with blend‑back 20%.

Case Study 2: Binder‑Jetted Ni‑Cu Metal Alloy Powder Cores with Sinter‑HIP (2024)

- Background: A chemical processing customer sought corrosion‑resistant, thin‑fin heat‑exchange cores at lower cost.

- Solution: Fine spherical Ni‑Cu powder (D50 ≈ 20 μm); hydrogen‑rich sinter followed by HIP; SPC on linear shrinkage; helium leak testing; selective Ni‑P plating.

- Results: Final density 99.2–99.4%; leak rate <1×10⁻⁹ mbar·L/s; unit cost −14% at 2k units/year vs. brazed assembly; lead time −25%.

Expert Opinions

- Prof. Randall M. German, Powder Metallurgy Scholar and Author

- Viewpoint: “Packing density—from PSD engineering and morphology—controls shrinkage predictability across MIM and sinter‑based AM more than marginal thermal tweaks.”

- Dr. Brandon Lane, Research Engineer, NIST

- Viewpoint: “Linking powder passports to in‑situ monitoring accelerates process qualification and provides early warning of off‑spec lots in powder bed fusion.”

- Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

- Viewpoint: “Disclosed recycled content with tight O/N/H control is now feasible for many Metal Alloy Powder families without sacrificing performance.”

Affiliation links:

- NIST: https://www.nist.gov

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- ASM International: https://www.asminternational.org

Practical Tools/Resources

- QC and standards: ISO/ASTM 52907; ASTM B212/B213/B214/B822; ASTM B923; ASTM E1019; ASTM F3122

- Metrology: LECO inert‑gas fusion for O/N/H (https://www.leco.com); laser diffraction PSD; SEM for morphology/satellites; helium pycnometry for true density; CT for porosity

- Design/simulation: Thermo‑Calc/DICTRA for alloy behavior; Ansys/Simufact Additive for scan/distortion; nTopology/Materialise Magics for build prep and lattices

- Databases: Senvol Database (https://senvol.com/database); MatWeb (https://www.matweb.com); MPIF resources (https://www.mpif.org)

- Safety: NFPA 484 guidance; ISO 80079 for explosive atmospheres; supplier SDS libraries and handling SOPs

Last updated: 2025-08-22

Changelog: Added 5 supplemental FAQs, a 2025 KPI table and trend insights, two recent case studies (LPBF 316L manifolds; BJ Ni‑Cu cores), expert viewpoints with affiliations, and a curated tools/resources list focused on Metal Alloy Powder selection and qualification.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards update, major suppliers change O/N/H or PSD specs, or new datasets on powder reuse and in‑situ monitoring correlations are published.