Overview of nickel molybdenum powder

Nickel molybdenum powder is a metal alloy powder composed of nickel and molybdenum. It offers a unique combination of properties including high strength, corrosion resistance, wear resistance, and ability to withstand high temperatures.

Some key details about nickel molybdenum powder:

- Composition – Typically contains 60-70% nickel and 30-40% molybdenum by weight. Specific ratios can be customized.

- Production Method – Usually manufactured by prealloying and atomizing nickel and molybdenum to create a fine homogeneous powder.

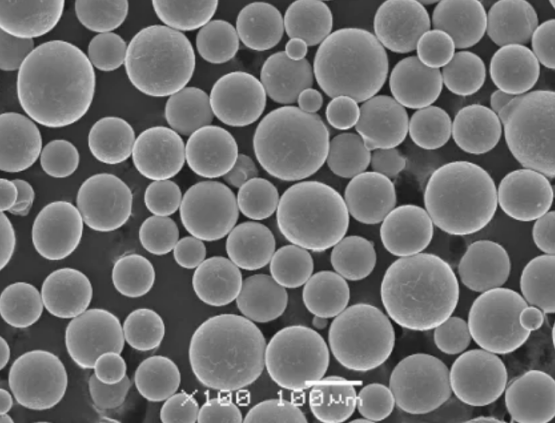

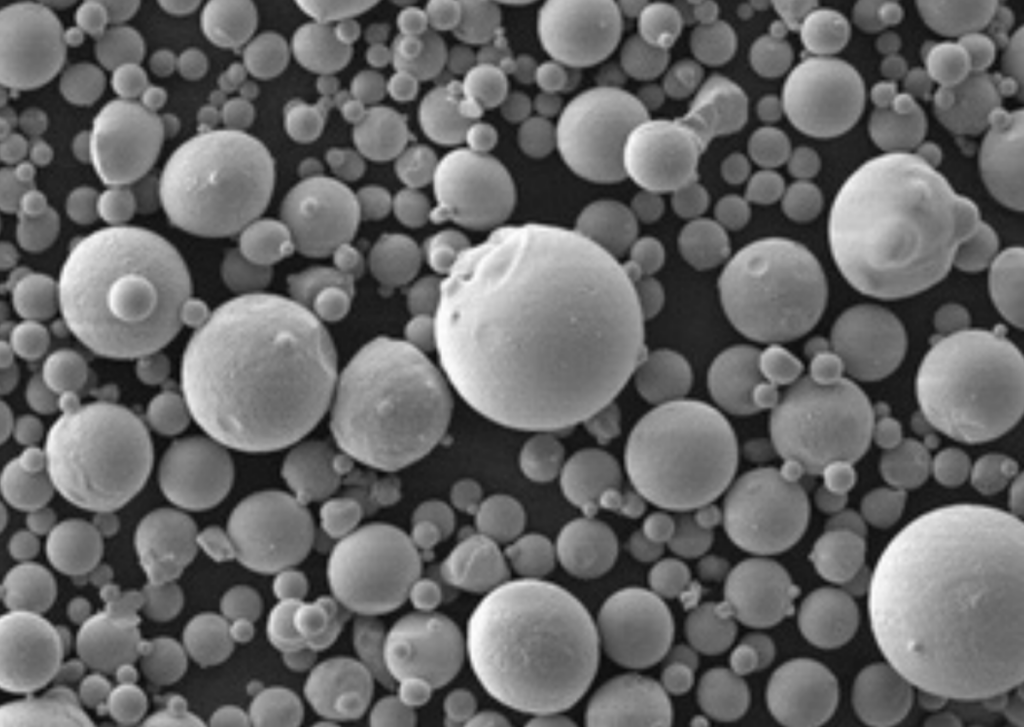

- Particle Size – Ranges from 10-150 microns depending on application. Finer powders provide more uniform properties.

- Shape – Spherical powder particles enable higher packing density and smooth flow. Irregular shapes are also available.

- Common Trade Names – Nickel moly powder, NiMo powder, 60NiMo, 65NiMo

Nickel Molybdenum Powder Types

| Type | Composition | Characteristics |

|---|---|---|

| Nickel molybdenum prealloy powder | 60-70% Ni, 30-40% Mo | Uniform composition, consistent properties, good performance |

| Custom nickel molybdenum ratios | 50/50 Ni/Mo to 90/10 Ni/Mo | Tailored to specific application needs |

| Nanocrystalline nickel molybdenum powder | 60-70% Ni, 30-40% Mo, <100 nm grain size | Very high strength,homogeneous microstructure |

Nickel Molybdenum Powder Properties

| Property | Characteristic |

|---|---|

| Composition | 60-70% Ni, 30-40% Mo |

| Density | 8.0-9.5 g/cc |

| Melting Point | 1315-1400°C (2400-2550°F) |

| Strength | High, 700-1300 MPa |

| Ductility | Moderate, 5-15% elongation |

| Hardness | 250-450 HV |

| Oxidation Resistance | Good up to 1000°C in air |

| Corrosion Resistance | Excellent, resistant to acids |

| Electrical Resistivity | ~138 μΩ.cm |

| Thermal Conductivity | 10-12.5 W/m.K |

| Coefficient of Thermal Expansion | 12-14 x 10ˉ6/°C |

Nickel Molybdenum Powder Applications

| Industry | Application | Benefits |

|---|---|---|

| Aerospace | Turbine blades, engine components | High strength at temperature, oxidation resistance |

| Oil & Gas | Downhole tools, valves, pumps | Strength, wear and corrosion resistance |

| Automotive | Gears, drive shafts | Fatigue and wear resistance |

| 3D Printing | Printed metal parts | High performance materials |

| Electronics | Conductive thick films | Electrical properties, stability |

Nickel Molybdenum Powder Specifications

| Parameter | Range |

|---|---|

| Nickel Content | 60-70 wt% |

| Molybdenum Content | 30-40 wt% |

| Particle Size | 10-150 μm |

| Apparent Density | 2.5-4.5 g/cc |

| Tap Density | 4-6 g/cc |

| Flow Rate | 25-35 s/50g |

| Oxygen Content | <0.5 wt% |

| Carbon Content | <0.1 wt% |

Compare the advantages and limitations of nickel molybdenum powder:

| Advantages | Limitations |

|---|---|

| High strength at elevated temperatures | More expensive than nickel powder |

| Excellent corrosion resistance | Lower ductility than nickel |

| High hardness and wear resistance | Heavier than titanium alloys |

| Oxidation resistant up to 1000°C | Not as conductive as pure nickel |

| Customizable alloy ratios | Refractory metal powders have higher melting points |

Where to Buy Nickel Molybdenum Powder

| Supplier | Description | Pricing |

|---|---|---|

| American Elements | Pure prealloy powder, custom particle sizes | $50-200/lb |

| Stanford Materials Corp | Prefab and blended NiMo powder | $75-250/kg |

| American Metal & Alloys | Broad selection of NiMo ratios | $100-350/kg |

| The Metal Powder Company | Spherical & irregular NiMo powders | £60-180/kg |

FAQs

What is nickel molybdenum powder used for?

Nickel molybdenum powder has high strength at elevated temperatures up to 1000°C. It resists corrosion and oxidation. Key uses include aerospace components like turbine blades, automotive gears and shafts, oil & gas downhole tools, and 3D printing metal parts across industries.

Is nickel molybdenum powder conductive?

Yes, nickel molybdenum powder has good electrical conductivity thanks to its high nickel content, around 138 μΩ.cm. This makes it useful for conductive thick film applications.

What is the composition of nickel molybdenum?

Typical composition is 60-70% nickel and 30-40% molybdenum by weight. Exact ratios can be customized according to application requirements.

What is the difference between nickel molybdenum and inconel?

Inconel is a family of nickel-chromium-based superalloys. Nickel molybdenum alloys rely on molybdenum instead of chromium to achieve high strength, hardness, and corrosion resistance.

What alloy is stronger than nickel molybdenum?

Refractory metal alloys like tungsten or rhenium have higher melting points than nickel molybdenum. Tungsten carbide cobalt powders offer extreme hardness and wear resistance. However, nickel molybdenum provides the best combination of elevated temperature strength, ductility, and oxidation resistance.