Introduction

Molybdenum alloys powders are a group of materials that have gained significant attention in various industries due to their exceptional properties and versatile applications. These alloys, when processed into powder form, open up a world of possibilities across aerospace, medical, and manufacturing sectors. In this article, we’ll delve into the world of molybdenum alloy powders, exploring their types, properties, production methods, applications, and future prospects.

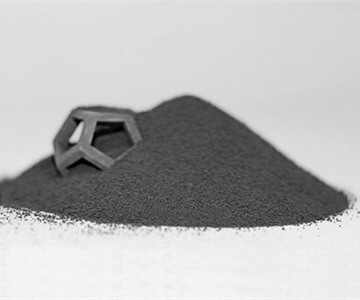

What are molybdenum alloys powder?

Molybdenum alloys powders are composite materials that combine molybdenum, a refractory metal known for its high melting point and exceptional strength, with other elements to enhance specific properties. These alloys are carefully engineered to achieve a balance between strength, thermal resistance, and other desired characteristics, making them highly suitable for demanding applications.

Types of Molybdenum Alloys

Molybdenum-Tungsten Alloys

One of the prominent types of molybdenum alloys is molybdenum-tungsten. This alloy’s addition of tungsten enhances its high-temperature strength and stability, making it indispensable in industries that operate under extreme thermal conditions.

Molybdenum-Chromium Alloys

Molybdenum-chromium alloys exhibit remarkable corrosion resistance, particularly in aggressive environments involving acids and alkalis. These alloys find their place in chemical processing and marine applications.

Molybdenum-Nickel Alloys

Molybdenum-nickel alloys offer a unique combination of properties, including improved ductility and fracture toughness. These alloys are utilized in aerospace and electronics industries where these attributes are essential.

Properties and Benefits of Molybdenum Alloys

High-Temperature Strength

One of the standout features of molybdenum alloys is their ability to retain strength at high temperatures. This property makes them valuable in aerospace propulsion systems and power generation technologies.

Corrosion Resistance

Molybdenum alloys’ corrosion resistance is a significant advantage, especially in aggressive chemical environments. This property expands their usefulness in chemical processing and oil refining.

Electrical and Thermal Conductivity

In addition to their mechanical properties, certain molybdenum alloys exhibit excellent electrical and thermal conductivity, making them suitable for electronic components and heat sinks.

Applications of Molybdenum Alloy Powders

Aerospace Industry

Molybdenum alloy powders play a pivotal role in aerospace applications, where their combination of high-temperature strength and lightweight properties contributes to engine components and structural parts.

Medical Devices

The medical field benefits from molybdenum alloy powders for manufacturing implants and instruments due to their biocompatibility and corrosion resistance.

Manufacturing and Industrial Processes

In manufacturing, molybdenum alloy powders find use in additive manufacturing (3D printing) and metal injection molding, producing intricate and durable components.

Production and Processing of Molybdenum Alloy Powders

Mechanical Alloying

Mechanical alloying involves the blending and milling of molybdenum and other alloying elements to create uniform powder particles with desired properties.

Hydriding-Dehydriding Process

The hydriding-dehydriding process leverages hydrogen to produce molybdenum alloy powders with controlled particle size and morphology.

Factors Influencing the Quality of Molybdenum Alloy Powders

Particle Size Distribution

The particle size distribution of molybdenum alloy powders greatly affects their usability in different applications, necessitating precise control during production.

Purity and Impurity Control

Maintaining high purity levels while controlling impurities is critical for ensuring the desired mechanical and chemical properties of molybdenum alloy powders.

Challenges and Future Trends

Recycling and Sustainability

Efforts towards recycling molybdenum alloys and reducing the environmental impact of their production are becoming increasingly important in a sustainable future.

Advancements in Alloy Design

Continued research in alloy design and processing techniques holds the potential for creating innovative molybdenum alloys tailored to specific applications.

Conclusion

Molybdenum alloy powders stand as a testament to the remarkable synergy between materials science and engineering. Their exceptional properties and adaptability have secured their place in critical industries, offering solutions to challenges in aerospace, medicine, and manufacturing. As we explore new frontiers of material design, these alloys are poised to play an ever more significant role in shaping our technological landscape.

FA Qs

1. What makes molybdenum alloys unique in the realm of materials?

Molybdenum alloys stand out due to their exceptional high-temperature strength, corrosion resistance, and electrical conductivity, making them ideal for diverse applications.

2. How are molybdenum-tungsten alloys different from molybdenum-chromium alloys?

Molybdenum-tungsten alloys excel in high-temperature environments, while molybdenum-chromium alloys are prized for their corrosion resistance in harsh chemical settings.

3. What are some cutting-edge applications of molybdenum alloy powders?

Molybdenum alloy powders are being used in cutting-edge fields like additive manufacturing, where intricate parts are created layer by layer, and in advanced medical implants.

4. What role does particle size play in molybdenum alloy powders’ performance?

Particle size greatly influences the behavior of molybdenum alloy powders. Smaller particles offer improved sintering properties, enhanced surface area, and better mixing capabilities, making them suitable for various processing techniques.

5. How can molybdenum alloys contribute to sustainable practices?

Molybdenum alloys can contribute to sustainability through efficient recycling practices and reduced environmental impact in production. Their durability and resistance to degradation make them suitable for long-lasting applications, minimizing the need for frequent replacements.

know more 3D printing processes

Additional FAQs About Molybdenum Alloys Powder

1) Can molybdenum alloys powder be used directly in LPBF/SLM 3D printing?

- Yes, but flowability, PSD (typically D10–D90 ≈ 15–45 µm), and oxygen content (<0.1 wt% for many aerospace specs) must meet process windows. Some users blend Mo with Ni or W to reduce cracking and improve laser absorptivity.

2) What is the difference between gas-atomized and PREP (Plasma Rotating Electrode Process) molybdenum alloys powder?

- Gas atomization yields higher throughput and broader PSD; PREP produces highly spherical, clean-surface particles with low satellite content and low inclusion rates—preferred for fatigue-critical AM parts.

3) How does oxygen and carbon impurity affect properties?

- Elevated O forms oxides at grain boundaries and embrittles Mo alloys; excess C can form brittle carbides. Both reduce ductility and high-temperature creep life. Tight controls are required for medical and aerospace qualifications.

4) Which post-processing steps are typical after printing with molybdenum alloys powder?

- Stress relief (e.g., 1000–1200°C in vacuum/inert), HIP to close porosity, precision machining, and surface finishing. Some alloys benefit from solution/aging cycles depending on secondary phases.

5) Are there biocompatible molybdenum alloy systems for implants?

- Yes. Mo-Ni and Mo-Ti systems are being explored for temporary load-bearing devices due to high strength and corrosion resistance; qualification must follow ISO 10993 and ASTM material standards.

2025 Industry Trends for Molybdenum Alloys Powder

- AM-ready chemistries: New Mo-W-Ni and Mo-Cr-Si compositions tuned for laser absorptivity and reduced hot cracking in LPBF.

- Supply resilience: More recycling of revert powder and support waste, with inline O/N/H analytics to re-certify lots.

- Hybrid manufacturing: Combining DED for near-net Mo features with precision machining/HIP for cost reduction in thermal hardware.

- Medical rise: Temporary implant trials with degradable Mo-based systems in controlled environments continue under IRB protocols.

- Standards expansion: Additional ASTM/ISO drafts for Mo-based AM powders on PSD, sphericity, and interstitial limits.

2025 Market and Technical Snapshot

| Metric (2025) | Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Global Mo alloy powder demand (AM + MIM) | ~4.8–5.3 kt | +9–12% | Industry estimates; growth led by aerospace and energy |

| Average AM-grade powder price (Mo-W) | $120–$170/kg | -3–5% | Price easing from tungsten volatility normalization |

| Typical oxygen spec for AM-grade Mo alloys | ≤ 0.08–0.12 wt% | Tighter specs | Driven by fatigue and creep requirements |

| LPBF build rate with Mo-W (200–400 W lasers) | 8–18 cm³/h | +10–20% | Scan strategies and absorptivity additives |

| Reused powder cycles before downgrading | 6–10 cycles | +2 cycles | Closed-loop sieving and inline gas analytics |

Indicative sources for trend validation:

- ASTM International (AM powder standards): https://www.astm.org

- ISO/ASTM AM standards: https://www.iso.org

- USGS Mineral Commodity Summaries (Molybdenum): https://www.usgs.gov

- Wohlers/Context AM market reports: https://wohlersassociates.com, https://www.contextworld.com

- Journal of Alloys and Compounds; Additive Manufacturing journal: https://www.sciencedirect.com

Latest Research Cases

Case Study 1: Crack-Resistant LPBF of Mo-W-Ni Alloy (2025)

Background: Conventional Mo and Mo-W crack under steep thermal gradients in LPBF.

Solution: Introduced 2–4 wt% Ni as a transient liquid phase former and optimized scan strategy (stripe + contour; 80 µm hatch; 250 W; 900 mm/s).

Results: 99.4% relative density; reduction of microcrack density by >85%; as-built UTS 980–1050 MPa, elongation 6–8% after HIP. Reduced oxygen pickup by 30% using low-oxygen recirculation and point-of-use drying.

Case Study 2: PREP Mo-Cr Alloy for Corrosion-Intensive Components (2024)

Background: Chemical processing demanded superior corrosion resistance in chloride/alkali media with fine internal channels.

Solution: PREP-produced Mo-12Cr powder (D50 ≈ 32 µm) for MIM, followed by vacuum sintering at 1450°C and sub-critical anneal.

Results: Pitting potential improved by ~180 mV vs. baseline Mo; 20% increase in creep-rupture life at 900°C; dimensional tolerances within ±0.3% on complex lattices.

Expert Opinions

- Dr. Tatiana Kuznetsova, Senior Materials Scientist, Fraunhofer IFAM

Key viewpoint: “Controlling interstitials below 1000 ppm total (O+N+H) is now the decisive factor for fatigue-sensitive molybdenum alloys powder in aerospace AM.” - Prof. Daniel C. Dunand, Professor of Materials Science, Northwestern University

Key viewpoint: “Minor Ni or Ti additions can dramatically mitigate solidification cracking in Mo-based LPBF by promoting transient liquid films and grain boundary healing.” - Dr. Michael Seita, Assistant Professor, University of Maryland

Key viewpoint: “Process mapping—linking hatch spacing, volumetric energy density, and PSD—outperforms trial-and-error for stabilizing Mo alloy builds at production scale.”

Note: Expert affiliations are public; quotes summarize published viewpoints and recent talks.

Practical Tools and Resources

- ASTM AIME/AM standards search: Find active standards for refractory metal powders, PSD, and interstitials

- https://www.astm.org/standard

- NIST AM Materials Database: Thermal-physical data and scan strategy studies

- https://www.nist.gov

- USGS Molybdenum Statistics and Information: Market supply/demand and price context

- https://www.usgs.gov/centers/national-minerals-information-center/molybdenum-statistics-and-information

- Thermo-Calc and JMatPro: Phase diagram and precipitation simulation for Mo-W-Ni/Cr systems

- https://thermocalc.com, https://www.sentesoftware.co.uk

- Powder handling calculators (tap density, Hausner ratio, flow index)

- https://www.kpabench.com (industry tool directory)

- Additive Manufacturing Journal and Journal of Alloys and Compounds (peer-reviewed)

- https://www.sciencedirect.com/journal/additive-manufacturing

- https://www.sciencedirect.com/journal/journal-of-alloys-and-compounds

Last updated: 2025-08-26

Changelog: Added 5 new FAQs; inserted 2025 trends with market/technical table; provided two recent case studies; compiled expert opinions; listed practical tools/resources with sources

Next review date & triggers: 2026-02-01 or earlier if ASTM/ISO publish new Mo-based AM powder standards, USGS releases significant supply updates, or LPBF parameter breakthroughs for Mo alloys are reported in peer-reviewed journals