Overview

Aluminum powder refers to fine aluminum metal particles used as feedstock for manufacturing techniques like additive manufacturing, thermal spraying, powder metallurgy pressing and welding rods. Controlling aluminum powder characteristics like particle size distribution, morphology, oxide levels and microstructure is critical to properties of finished aluminum components.

There are various methods used for producing aluminum powders including:

- Gas atomization

- Air atomization

- Explosive wire fragmentation

- Milling and grinding

- Electrolytic process

- Chemical methods

Each aluminum powder production technique results in powders with different properties suited to specific applications.

Aluminum Powder Production Methods

| Method | Key Characteristics | Main Applications |

|---|---|---|

| Gas Atomization | Spherical powders, moderate oxygen levels | Metal AM, thermal spray coatings |

| Air Atomization | Irregular powder shapes, controlled oxide levels | Automotive parts, powder extrusion |

| Explosive Wire | Very fine spherical powders | Additive manufacturing, rocket fuel |

| Ball Milling | Composite aluminum powders | Energetic materials, pyrotechnics |

| Electrolytic | Flake, angular and dendritic powders | Explosives, thermite reactions |

| Chemical | Ultrafine to nanoscale particles | Pyrotechnic compositions |

Aluminum Powder Production Methods

There are a variety of commercial methods used for producing aluminum powders depending on required material characteristics and end-use applications:

Gas Atomization

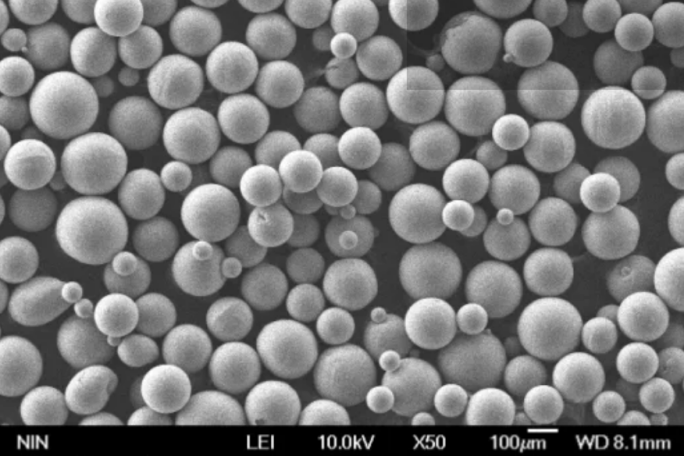

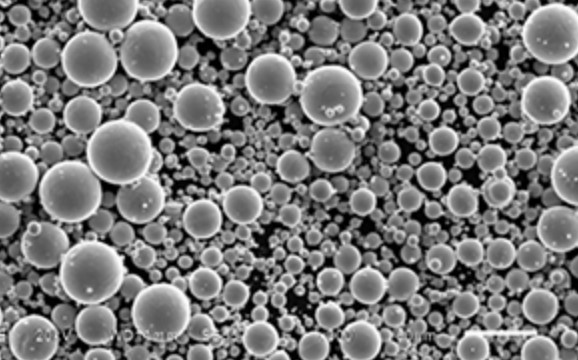

In gas atomization process, molten aluminum is disintegrated by high pressure inert gas jets into fine droplets which solidify into powder particles. Gas atomized aluminum powders have a spherical shape with sizes ranging from 10 microns to 350 microns based on processing parameters. This is the predominant technique for reactive aluminum powder production with lower oxygen pickup than liquid metal atomization.

| Parameter | Description |

|---|---|

| Particle shape | Spherical morphology |

| Particle size | 10 – 350 μm typical |

| Oxide content | <3% by weight |

| Production scale | Hundreds of tons per year |

| Cost | Higher |

Air Atomization

In air atomization, molten aluminum stream is disrupted by compressed air jets, leading to formation of fine irregular aluminum particles containing higher surface oxide levels from oxygen in air. Air atomization facilitates economic, high volume aluminum powder production for structural P/M parts and aluminothermic reactions.

| Parameter | Description |

|---|---|

| Particle shape | Irregular particle shape |

| Particle size | 20 – 180 μm |

| Oxide content | 3-8% by weight |

| Production scale | Thousands of tons per year |

| Cost | Very economical |

Rotating Electrode Process (REP)

In REP technique, molten aluminum metal in the form of wire or rod electrodes is rotated at high speeds, melting it using electrical arcing. Centrifugal forces eject the molten droplets producing very fine spherical aluminum particles ideal for specialized applications.

| Parameter | Description |

|---|---|

| Particle shape | Highly spherical |

| Particle size | 5 – 60 μm |

| Oxide content | <1% by weight |

| Production scale | Lower volumes |

| Cost | Higher pricing |

Ball Milling

High energy ball milling of aluminum metal flakes, particles and chemical powders is done to form composite aluminum powders by embedding reinforcing particulates providing specialized mechanical, chemical or explosive reactivity.

| Parameter | Description |

|---|---|

| Particle shape | Flattened and composite particles |

| Particle size | 1 – 100 μm |

| Oxide content | Coated particles |

| Production scale | Small batches |

| Cost | Moderate |

Electrolytic Process

In molten salt electrolysis process, aluminum ions are electro-deposited onto cathodes producing dendritic or irregular shaped particles with porous surface morphology ideally suited for pyrotechnic thermites.

| Parameter | Description |

|---|---|

| Particle shape | Dendrites and irregular |

| Particle size | 1 – 75 μm |

| Oxide content | High from morphology |

| Production scale | Lower volume |

| Cost | Economical for niche applications |

Aluminum Powder Compositions

Most aluminum powders constitute high purity aluminum with over 98% Al content. The main considerations in composition are:

1. Alloying Elements

Small quantities of silicon, magnesium, zinc or other elements are added to impart specific properties.

| Alloy Additions | Wt % Range | Effect |

|---|---|---|

| Silicon | 0.5 – 12% | Increase hardness and wear resistance |

| Magnesium | 1 – 5% | Improves strength |

| Zinc | 1 – 8% | Higher elevated temperature strength |

2. Oxide Content

Processing methods determine if thin protective oxide layers or heavier non-adherent oxides are present on particle surfaces.

| Oxide Level | Suitability |

|---|---|

| <3% | High performance alloys, AM components |

| 3-8% | P/M structural parts |

| >10% | Thermites, pyrotechnics |

3. Hydrogen Content

Moisture pickup during handling and storage of very reactive aluminum powder surface needs monitoring to prevent fire or detonation hazards. Manufacturing atmospheres with minimal humidity is beneficial.

Properties of Aluminum Powders

Key attributes considered in qualifying aluminum powders include:

Powder Particle Size Distribution

Laser diffraction particle analyzers or sieve analyses provide full range granulometry from submicron to 500 microns size fractions. Typical size parameters reported are:

| Parameter | Description |

|---|---|

| D10, D50, D90 | Particle diameter below which 10%, 50% and 90% particles by volume fall |

| Mean, modal size | Measure of central tendency |

| Span = (D90-D10)/D50 | Width of distribution – lower span indicates narrower distribution |

Matching particle sizes to production method capabilities allows maximizing density and properties in finished components.

Particle Morphology

Scanning electron microscopy reveals fine details of particle shape which dictates powder behavior. Smooth rounded particles improve flow and packing density. Irregular shapes provide mechanical interlocking.

Apparent and Tap Density

These indicate powder consolidation and handling behavior using standardized test procedures. Higher densities ease densification during compaction.

| Parameter | Typical Range |

|---|---|

| Apparent density | 0.2 – 0.6 g/cc |

| Tap density | 0.7 – 1.3 g/cc |

Flow Characteristics

Time for 50 g powder to flow through a Hall flowmeter funnel correlates well with spreading performance during layer filling in binder jet 3DP and filling die cavities in powder metallurgy compaction. Smooth spherical particles show improved flow rates.

Surface Area

Measured BET gas absorption surface area is used to calculate thicknesses of surface oxide layers present which impact initiation behavior in aluminothermic reactions or pyrotechnic combustion performances.

Applications of Aluminum Powders

Unique properties of reactive aluminum powders make them critical for various industries:

Metal Additive Manufacturing

Spherical aluminum powders are used as feedstock for selective laser melting, electron beam melting and binder jetting additive manufacturing after classifying powder particle size distribution to meet machine requirements.

Thermal Spray Coatings

Specialized low oxide aluminum powders plasma or wire sprayed create protective aluminum coatings offering high reflectivity combined with corrosion resistance.

Powder Metallurgy

Compacting and sintering aluminum powders produce high volume precision components like automotive parts with excellent dimensional control and performance unachievable by other techniques.

Energetic Materials

Fine aluminum powders thermite reactions with metal oxides or pyrotechnic combustions provide intense exothermic outputs for military, aerospace, or civil applications ranging from explosives and propellants to illumination, gas generation or heating.

Al-Mg Alloy Strips

Compacted aluminum powder preforms are hot extruded into Al-Mg alloy strips and coiled sheets ideal for armor plate fabrication. Powder metallurgy enables microstructural refinements and uniformity unfeasible in conventionally cast alloys.

Specifications and Standards

Aluminum powder producers must carefully control production atmospheres, processing techniques and handling procedures to meet certified standards for critical markets including:

AMS Metal Powder Specifications

- AMS 4200 steel shot and grit

- AMS 4205 aluminum powders for thermal spray

ASTM Standards

- B215 for gas atomized powders

- B951 for pressed and sintered aluminum powder extrusions

- B937 for gas atomized additively-manufactured aerospace parts

ISO Standards

- ISO 14361 thermal spray coatings

- ISO 22068 design of aluminium alloy die castings

CEN Standards

- EN 10204 3.1 material quality certification

SAE Aerospace Material Specifications (AMS)

- AMS 4200 shot/grit

- AMS 4205 gas atomized aluminum powder

Maintaining rigorous quality control to satisfy mandated chemistry limits on impurities like iron, silicon and zinc coupled with verifying powder characteristics fulfills application needs and safety in sensitive domains.

Aluminum Powder Market Analysis

Global demand for aluminum powders is estimated to reach 1.6 million metric tons by 2027 driven by:

1. Growth in Metal Additive Manufacturing

- Lightweighting benefits for aerospace components

- Healthcare implants and instruments from biocompatible Al alloys

2. Momentum in Automotive Lightweighting

- P/M aluminum parts replacing cast iron and steel

3. Innovation in Reactive Aluminum Energetic Formulations

- Defense, space, civil industries

Leading international aluminum powder producers are:

| Supplier | Headquarters | Production Capabilities |

|---|---|---|

| Toyo Aluminium K.K. | Japan | Gas, air, vacuum atomization |

| UC Rusal | Russia | Air atomization |

| Alcoa Corporation | USA | Air atomization |

| Luxfer Magtech | USA | Gas, air and centrifugal atomization |

| Hoganas AB | Sweden | Air atomization |

Pricing varies based on:

- Production volume

- Purity levels

- Additional screening or milling

| Grade | Price Estimate |

|---|---|

| Air atomized Al powders | $3 – $5 per kg |

| Gas atomized spherical Al powder | $15 – $30 per kg |

| Specialty Al alloy grades | Up to $50 per kg |

Benefits and Challenges

Advantages

- Lightweighting compared to steel or titanium

- Economical compared to other structural metals

- Reactive formulations providing intense exothermic outputs

- Recyclable and reusable

Challenges

- Highly exothermic oxidation requiring controlled inert handling and storage

- Hydrogen embrittlement decreasing mechanical properties

- Limited use temperatures up to 200°C for most formulations

Comparing aluminum powders to alternatives:

| Parameter | Aluminum Powder | Stainless Steel | Titanium |

|---|---|---|---|

| Density | Low | Higher | Higher |

| Cost | Low | Moderate | High |

| Reactivity | High | Low | Moderate |

| Environmental stability | Fair | Excellent | Very Good |

| Food contact approvals | ✅ Yes | ✅ Yes | Some grades |

FAQs

Q: What particle size distribution is typically used with aluminum alloy powders for additive manufacturing?

A: In powder bed fusion AM, the aluminum particle size range is generally between 15 – 63 microns. Finer powders can improve resolution but make handling more difficult. Matching distributions to machine parameters is vital.

Q: What affects the shelf life of aluminum powders for energetic formulations?

A: Reactivity increases over time as storage humidity causes formation of aluminum hydroxides and hydrates on particle surfaces, releasing hydrogen and potential buildup flammable conditions. Inert sealed packaging and regulated humidity storage (<30%) is essential.

Q: What are common standards specified for aluminum powders used in thermal spray coatings?

A: Stringent chemistry limits on heavy metals regulated by FDA and USDA ensure finish coatings with no leachable impurities. Key standards include AMS 4205and ASTM B215 controlling Fe, Si, Cu trace elements. Thermal spray wire feedstock also follows ISO 14361.

Q: What aluminum alloy is preferred for additive manufacturing biomedical implants?

A: Aluminum alloy AlSi10Mg meets stringent chemistry requirements and offers excellent biocompatibility, strength and corrosion resistance combined with lower density than titanium or stainless steel alloys. Spherical powders enable complex printed geometries.

Q: How is risk of pyrophoric ignition handled when machining aluminum P/M components?

A: Low temperature annealing heat treatments are applied prior to any second machining operations to transform residual magnesium and aluminum particles present from explosive reactive states back into more stable intermetallic phases to safely enable conventional machining.

know more 3D printing processes

Additional FAQs About Aluminum Powders

1) What PSD and morphology are optimal for aluminum powders in LPBF vs. Binder Jetting?

- LPBF: spherical, 15–45 µm or 20–63 µm (machine dependent), sphericity ≥0.93, satellites <5%, low oxide. Binder Jetting: 20–80 µm with good flow and tap density; slightly wider PSD can aid packing.

2) How do oxide and hydrogen contents affect AM part quality?

- Thick oxide films and elevated H increase lack-of-fusion and porosity, degrading fatigue. Target O typically ≤0.10–0.25 wt% for AlSi10Mg AM-grade; control humidity to keep hydrogen pickup minimal.

3) Can aluminum powders be safely reused in AM?

- Yes, with sieving and QC. Many users validate 5–8 cycles for AlSi10Mg, monitoring PSD, flow (Hall/Carney), O/H content, and part density/mechanicals. Refresh with virgin powder when trends drift.

4) Which alloys are most common for Aluminum Powders in 3D printing?

- AlSi10Mg and A357/AlSi7Mg for general use; Sc- or Zr-modified Al alloys for higher strength; 2xxx/7xxx remain challenging but progress continues with tailored scan strategies.

5) What storage/handling reduces safety risk for reactive aluminum powders?

- Use inert, dry packaging (≤30% RH), conductive containers, bonding/grounding, Class II Division 1 appropriate equipment where required, and follow NFPA 484 housekeeping and ignition control practices.

2025 Industry Trends for Aluminum Powders

- Cleaner feedstocks: Wider use of EIGA and optimized gas atomization lowers oxide and satellite fractions, improving LPBF spreadability.

- Heated build platforms: 150–250°C plate heating increasingly applied for AlSi10Mg to reduce distortion and improve density.

- Qualification rigor: COAs now include image-based sphericity, satellite %, and O/H trends; powder genealogy and reuse SPC common in aerospace/medical.

- Sustainability: Argon recirculation, higher revert content, and local atomization plants shorten lead times and cut footprint.

- Alloy innovation: More validated parameter sets for Sc/Zr‑modified Al, and binder jet + sinter routes for larger Al components.

2025 Market and Technical Snapshot (Aluminum Powders)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| AM-grade AlSi10Mg powder price | $18–$35/kg | -3–7% | Supplier/distributor indices |

| Recommended PSD (LPBF / BJ / DED) | 15–45 or 20–63 µm / 20–80 µm / 53–150 µm | Stable | OEM guidance |

| Sphericity (image analysis) | ≥0.93–0.97 | Slightly up | Supplier CoAs |

| Satellite fraction (image) | ≤3–6% | Down | Process tuning |

| Typical oxygen (AM-grade Al) | 0.10–0.25 wt% | Down | Improved atomization control |

| Validated reuse cycles (with QC) | 5–8 | Stable | O/H + sieving programs |

| LPBF density after process tuning (AlSi10Mg) | 99.5–99.9% | +0.1–0.2 pp | OEM/academic datasets |

Indicative sources:

- ISO/ASTM 52907 (Metal powders), 52908 (Process qualification), 52910 (Design for AM): https://www.iso.org | https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM Handbooks (Additive Manufacturing; Aluminum and Aluminum Alloys): https://www.asminternational.org

- NFPA 484 (Combustible metal powders): https://www.nfpa.org

Latest Research Cases

Case Study 1: Heated-Plate LPBF for AlSi10Mg Brackets (2025)

Background: An aerospace tier-1 aimed to reduce distortion and improve fatigue consistency on thin-wall brackets.

Solution: Gas-atomized AlSi10Mg (PSD 20–63 µm, sphericity 0.95), build plate at 200°C, contour-first scans; in-situ thermography; T6-like heat treatment.

Results: Distortion reduced 35%; relative density 99.8%; HCF life improved 1.8× at R=0.1; machining time down 12% due to better flatness.

Case Study 2: Binder Jet + Sinter A356 Housings (2024)

Background: An EV supplier sought larger Al housings without PBF size constraints.

Solution: Binder jet with 25–80 µm powder blend for high green density; debind + vacuum sinter with Mg vapor control; hot isostatic pressing for critical lots.

Results: Final density 98.5–99.2%; leak rate within spec; cycle-time reduction 28% vs. machining from billet; cost per part −18%.

Expert Opinions

- Prof. Diran Apelian, Distinguished Professor (emeritus), Metal Processing

Key viewpoint: “Atomization control and melt cleanliness set the ceiling for aluminum powder performance—lower oxide and tight PSD translate to higher density and fatigue reliability.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “For Aluminum Powders in AM, consistent O/H and satellite fraction on the CoA accelerate qualification more than incremental scan tweaks.” - Prof. Todd Palmer, Materials Science, Penn State (AM/Al alloys)

Key viewpoint: “Moderate preheat and scan strategies that stabilize melt pools are essential for minimizing lack-of-fusion in AlSi10Mg while preserving fine microstructures.”

Note: Viewpoints synthesized from public talks and publications; affiliations are publicly known.

Practical Tools and Resources

- Standards and guidance

- ISO/ASTM 52907, 52908, 52910; ASTM B215/B951 for aluminum powders and PM: https://www.iso.org | https://www.astm.org

- Metrology and safety

- NIST powder characterization; LECO O/H analyzers; CT for hollows/satellites: https://www.nist.gov

- NFPA 484 guidance for aluminum powder handling: https://www.nfpa.org

- Technical databases and handbooks

- ASM Digital Library (AM; Aluminum alloys): https://www.asminternational.org

- QC workflow examples

- PSD/shape: laser diffraction + image analysis/SEM

- Flow: Hall/Carney funnels, FT4 rheometer

- Process validation: density (Archimedes/CT), tensile/fatigue per ASTM E8/E466

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; introduced 2025 market/technical snapshot table with indicative sources; included two aluminum powder case studies; compiled expert viewpoints; listed practical tools/resources for Aluminum Powders

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM update aluminum powder/AM standards, OEMs release new AlSi10Mg allowables, or NIST/ASM publish updated datasets on oxide/satellite–defect correlations