1. Introduction

Metal powders play a crucial role in various industries, offering a wide range of applications and benefits. From additive manufacturing to surface coating, these finely divided particles have become essential for many processes. If you’re looking to explore the world of metal powders for sale and their uses, this article will guide you through the basics. We will discuss the applications of metal powders, different types available, production methods, factors to consider when choosing metal powders, safety precautions, where to find metal powders for sale, and cost considerations.

2. What are Metal Powders?

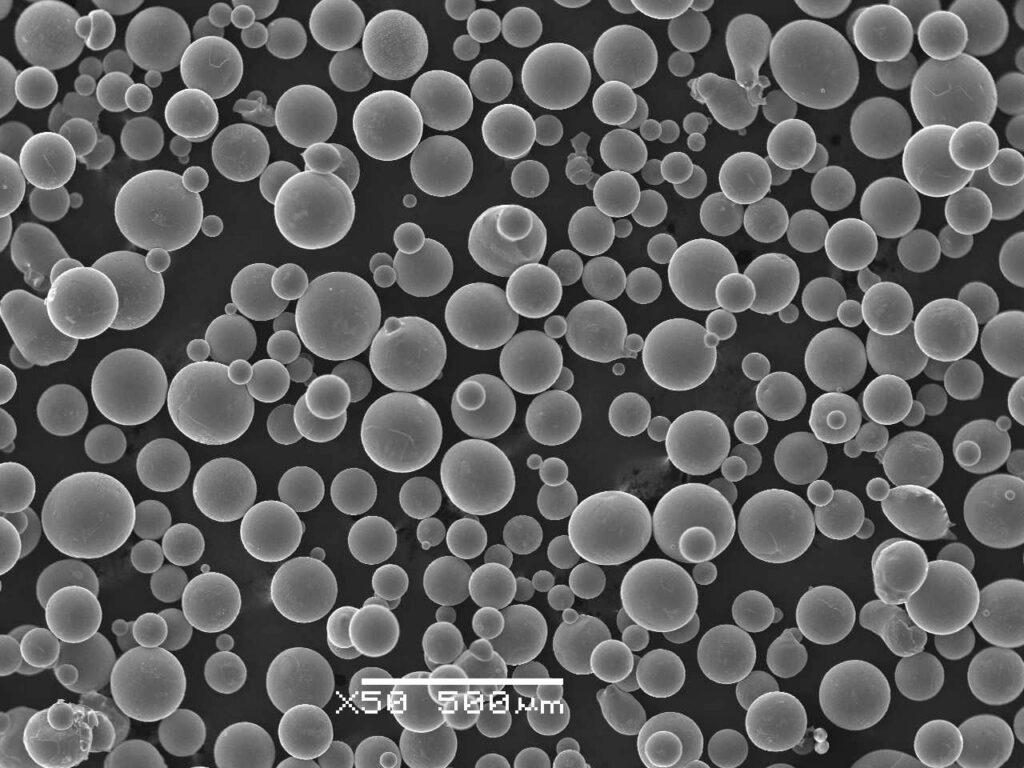

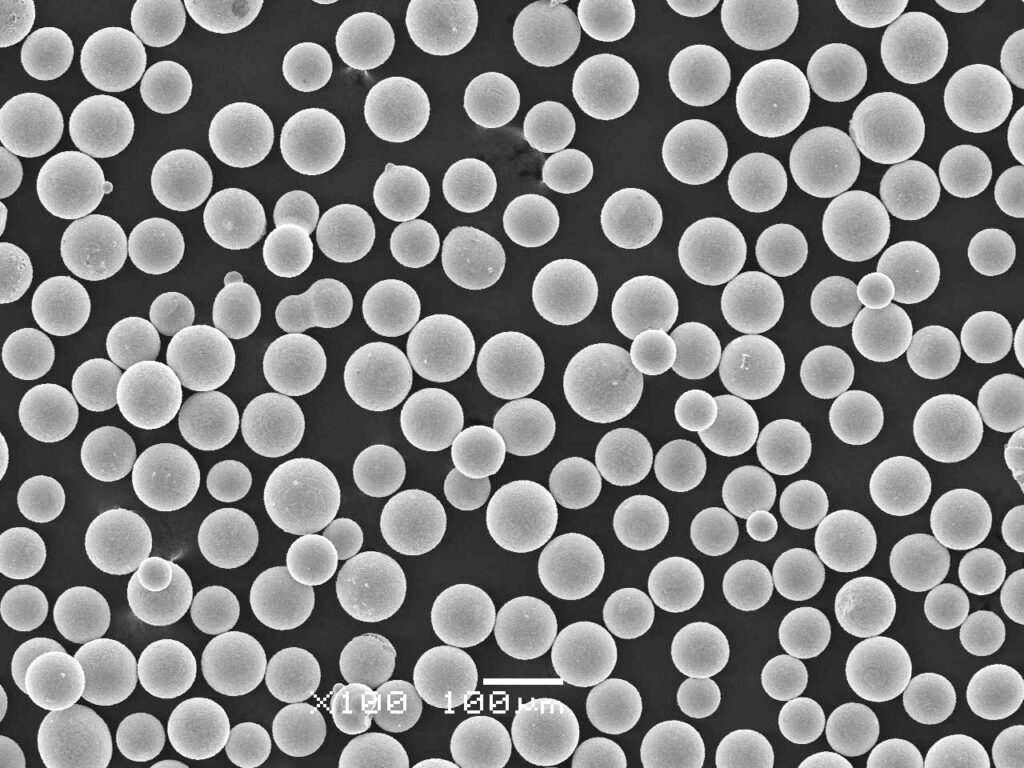

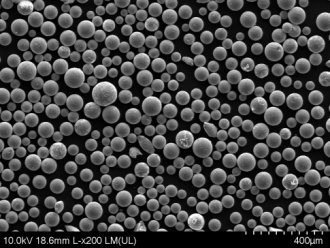

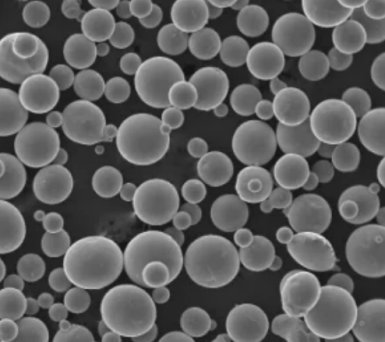

metal powders for sale are finely divided particles of metals, typically ranging in size from a few micrometers to a few hundred micrometers. They are produced through various techniques like atomization, chemical reduction, electrolysis, and mechanical processes. These powders exhibit unique properties due to their high surface area-to-volume ratio, which makes them suitable for a wide range of applications.

3. Applications of Metal Powders

metal powders for sale find applications across various industries due to their unique characteristics. Let’s explore some of the key applications:

3.1 Additive Manufacturing

Additive manufacturing, also known as 3D printing, has revolutionized the manufacturing industry. metal powders for sale are used as the raw material in metal 3D printers to create intricate and complex parts. Additive manufacturing allows for design freedom, rapid prototyping, and cost-effective production.

3.2 Chemical Reactions

metal powders for sale can participate in chemical reactions to produce a variety of compounds. For example, iron powders can be used in the production of iron oxide or other metal salts. These reactions are employed in industries such as pharmaceuticals, pigments, and catalysts.

3.3 Surface Coating

metal powders for sale are used in surface coating applications to provide improved wear resistance, corrosion protection, and aesthetic appeal. They can be applied through methods like thermal spraying or electrodeposition to enhance the surface properties of substrates.

3.4 Sintering and Powder Metallurgy

Sintering is a process that involves heating metal powders for sale below their melting point to fuse them together and form a solid object. This technique is widely used in powder metallurgy to produce high-strength components such as gears, bearings, and automotive parts.

4. Types of Metal Powders

metal powders for sale are available in various compositions, each offering unique properties and applications. Let’s explore some common types of Metal Powders.

4.1 Iron Powders

Iron powders are widely used in industries such as automotive, construction, and electronics. They are known for their high strength, magnetic properties, and excellent conductivity. Iron powders find applications in powder metallurgy, magnetic alloys, and as a raw material for chemical reactions.

4.2 Aluminum Powders

Aluminum powders are lightweight and known for their high strength-to-weight ratio. They are extensively used in aerospace, automotive, and packaging industries. Aluminum powders find applications in additive manufacturing, explosives, pigments, and thermite reactions.

4.3 Copper Powders

Copper powders are valued for their excellent electrical conductivity, thermal conductivity, and corrosion resistance. They are used in electrical and electronic applications, as well as in the production of conductive pastes, brazing alloys, and decorative coatings.

4.4 Titanium Powders

Titanium powders possess high strength, low density, and excellent corrosion resistance. They are widely used in aerospace, medical, and automotive industries. Titanium powders find applications in additive manufacturing, biomedical implants, and advanced composites.

5. Production of Metal Powders

metal powders for sale are produced through various methods, each suited for different applications and desired particle characteristics. Let’s explore some common production techniques:

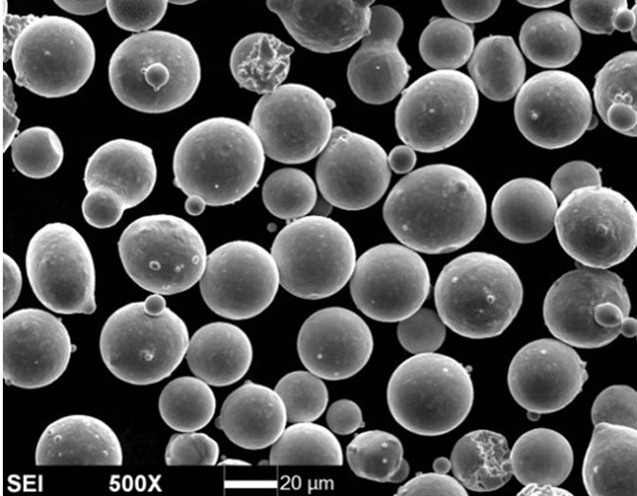

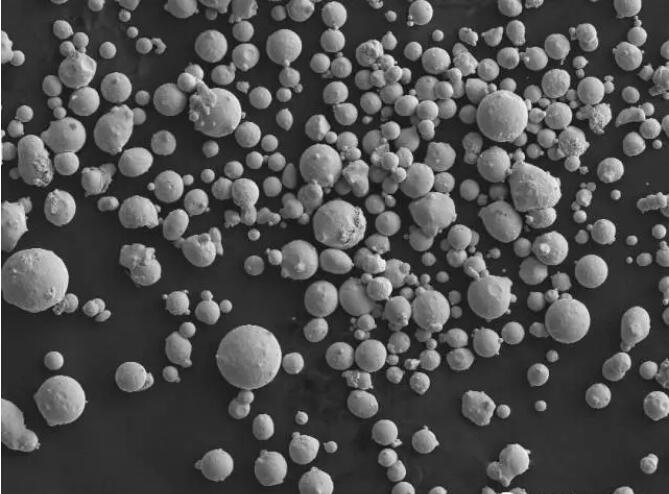

5.1 Atomization

Atomization is a widely used technique for producing metal powders for sale. It involves the conversion of molten metal into droplets, which solidify rapidly to form fine particles. Atomization can be achieved through gas atomization, water atomization, or centrifugal atomization.

5.2 Chemical Reduction

Chemical reduction involves the reduction of metal compounds using chemical reactions to obtain metal powders. This method is commonly used for the production of iron, copper, and nickel powders.

5.3 Electrolysis

Electrolysis is a process in which metal ions are reduced at the cathode to form metal powders. It is commonly used for the production of powders like copper, zinc, and aluminum.

5.4 Mechanical Processes

Mechanical processes involve the mechanical fragmentation of bulk metals to obtain metal powders. Techniques such as milling, grinding, and crushing are employed to break down the metal into desired particle sizes.

6. Factors to Consider when Choosing Metal Powders

When selecting metal powders for specific applications, several factors need to be taken into account. Let’s discuss some important considerations:

6.1 Particle Size

The particle size of metal powders plays a significant role in determining their behavior and suitability for specific applications. Different particle size distributions can affect properties such as flowability, compaction, and sintering behavior.

6.2 Purity

The purity of metal powders for sale is crucial, especially in applications where contaminants can negatively impact the final product’s performance. High-purity metal powders are often required for industries such as electronics and aerospace.

6.3 Flowability

Flowability refers to the ability of metal powders for sale to flow freely and uniformly during processing. It is an important characteristic for applications such as powder metallurgy and additive manufacturing.

6.4 Composition

The composition of metal powders determines their chemical and physical properties. Different compositions can exhibit varying mechanical, electrical, or thermal properties, making it important to choose the right composition for specific applications.

7. Safety Precautions when Handling Metal Powders

Handling metal powders requires adherence to proper safety precautions to prevent accidents and health risks. Here are some safety measures to consider:

- Wear appropriate personal protective equipment (PPE), including gloves, goggles, and respiratory protection.

- Ensure proper ventilation in the working area to minimize exposure to airborne particles.

- Store metal powders in appropriate containers away from sources of ignition or heat.

- Follow proper handling and disposal procedures to prevent environmental contamination.

- Train personnel on safe handling practices and emergency procedures.

- Regularly inspect and maintain equipment to prevent accidents.

8. Where to Find Metal Powders for Sale?

If you’re looking to purchase metal powders for your specific applications, there are several sources you can explore. Here are two common options:

8.1 Online Marketplaces

Online marketplaces provide a convenient platform to browse and purchase metal powders. Websites like Amazon, Alibaba, and specialized metal powders for sale suppliers offer a wide range of options. Ensure to check the credibility of the seller and verify product quality before making a purchase.

8.2 Specialty Suppliers

Specialty suppliers and distributors focus specifically on metal powders and related materials. They often have a comprehensive range of options and can provide expert guidance on selecting the right powders for your requirements. Research reputable suppliers in your region and inquire about their product offerings.

Cost Considerations

The cost of metal powders for sale can vary depending on factors such as material type, purity, particle size, and quantity. It’s essential to consider both the upfront cost of purchasing the powders and their overall impact on the final product or process. In some cases, investing in higher-quality powders may yield better results and cost savings in the long run.

Conclusion

metal powders for sale offer diverse applications across industries, ranging from additive manufacturing to chemical reactions and surface coating. Understanding the types of metal powders, production methods, and factors to consider when selecting powders is crucial for achieving optimal results. Remember to prioritize safety when handling metal powders and explore reputable sources for purchasing them. By choosing the right metal powders and employing them effectively, you can unlock new possibilities and enhance the performance of your products and processes.

FAQs

1. Are metal powders hazardous to health? Metal powders can pose health risks if proper safety measures are not followed during handling. It is important to use personal protective equipment (PPE) and ensure adequate ventilation when working with metal powders.

2. Can metal powders be recycled? Yes, metal powders can often be recycled and reused. Recycling metal powders can help reduce waste and conserve resources.

3. Can I mix different types of metal powders together? Yes, it is possible to mix different types of metal powders to achieve desired properties or create alloys. However, careful consideration of compatibility and composition is necessary for successful blending.

4. Can metal powders be used in food applications? Metal powders are generally not intended for direct use in food applications due to potential health risks. They are primarily used in industrial and manufacturing processes.

5. How can I ensure the quality of metal powders I purchase? To ensure the quality of metal powders, it is recommended to purchase from reputable suppliers who provide detailed specifications and certifications for their products. Additionally, conducting thorough research and reading customer reviews can provide insights into product quality and reliability.

Frequently Asked Questions (FAQ)

1) What powder characteristics matter most across Metal Powders for AM and PM?

- Particle size distribution (PSD), morphology (sphericity/aspect ratio), flow (Hall/Carney), apparent/tap density, and oxygen/nitrogen/hydrogen levels. These govern spreadability, packing, sintering/melting, and defect rates.

2) How do gas‑atomized vs water‑atomized metal powders differ?

- Gas atomized: more spherical, better flow, typically used for additive manufacturing and thermal spray. Water atomized: more irregular, higher surface oxides, cost‑effective for press‑and‑sinter powder metallurgy.

3) What is a practical approach to powder reuse in metal 3D printing?

- Closed‑loop inert handling, sieving to remove spatter/oversize, blending with virgin powder, and routine QA on PSD, O/N/H (ASTM E1019), flow, and density. Define reuse limits (e.g., 5–10 cycles) based on data.

4) Which Metal Powders are best for thermal/electrical conductivity?

- Copper and silver for top conductivity; aluminum for lightweight conductivity; copper alloys (CuCrZr) balance conductivity with strength for AM heat exchangers and tooling inserts.

5) How should Metal Powders be stored to preserve quality?

- Keep sealed under dry inert gas or desiccation, minimize headspace O2, avoid humidity and vibration, and use conductive, grounded containers. Label lots and track shelf life with periodic QA.

2025 Industry Trends: Metal Powders

- Productivity leap in AM: Multi‑laser LPBF and improved scan strategies increase build rates 20–50%, expanding demand for 15–45 μm spherical powders.

- Circularity and disclosures: Material passports track PSD, O/N/H, reuse counts, and recycled content; more suppliers publish LCA and recycled fraction.

- Process intensification: Close‑coupled gas atomization with argon recovery trims gas usage 20–40% and reduces satellites; continuous precipitation for reactive metals tightens PSD.

- Safety by design: ATEX/DSEAR‑aligned facilities, real‑time dust and O2 monitoring, and improved housekeeping SOPs become standard, especially for Al/Ti powders.

- Application expansion: Copper, Al, and Ni superalloy Metal Powders lead growth in heat exchangers, tooling conformal cooling, and high‑temp components.

2025 KPI Snapshot for Metal Powders (indicative ranges)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| LPBF build rate (cm³/h per laser, 316L) | 20–35 | 30–55 | Multi‑laser and path optimization |

| Powder reuse cycles (with blending) | 3–6 | 6–10 | Digital passport + QA control |

| Argon consumption in atomization (Nm³/kg) | 2.0–4.0 | 1.5–3.0 | Recovery systems adoption |

| Sphericity (gas‑atomized AM grades) | 0.92–0.95 | 0.94–0.97 | Improved nozzle design/GMR |

| Reported recycled content (select alloys) | Rare | 5–20% | Supplier sustainability reports |

References: ISO/ASTM 52907; ASTM B212/B213/B703; ASTM E1019; NIST AM‑Bench; OEM atomizer/application notes; industry market briefs

Latest Research Cases

Case Study 1: Argon Recovery and Satellite Reduction in Gas Atomized Stainless Powder (2025)

Background: A powder producer faced high inert gas costs and variable flow due to satellites.

Solution: Installed cryogenic argon recovery, optimized close‑coupled nozzle geometry and gas‑to‑melt ratio; implemented inline optical monitoring.

Results: Argon use −31%; satellite count −28%; Hall flow improved by 1.5 s/50 g; LPBF customers reported as‑built density gains (+0.1–0.2%).

Case Study 2: Copper Alloy Powder for AM Heat Exchangers with Enhanced Conductivity (2024)

Background: An electronics OEM needed compact heat exchangers with high thermal performance.

Solution: Qualified gas‑atomized CuCrZr (PSD 15–45 μm), optimized LPBF parameters and solution aging; introduced HIP and internal roughness polishing.

Results: Thermal conductivity 320–340 W/m·K; pressure drop variance ±3%; build time −12% vs baseline; field reliability improved over 2,000 h testing.

Expert Opinions

- Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Consistent powder properties—PSD, O/N/H, flow, and density—paired with documented reuse histories are essential for portable AM parameters and predictable outcomes.” https://www.nist.gov/ - Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “In 2025, multi‑laser LPBF and better powder control push metal AM from prototyping into dependable serial production across aerospace and energy.” - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Material passports tied to ASTM/ISO test methods are accelerating qualification and closing the loop on powder circularity.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Guidance for metal powder feedstock characterization

https://www.iso.org/standard/78974.html - ASTM standards: E1019 (O/N/H), B212/B213/B703 (density/flow), F3301/F3571 (LPBF practices)

https://www.astm.org/ - NIST AM‑Bench: Public datasets for AM validation

https://www.nist.gov/ambench - Senvol Database: Compare machines/materials for Metal Powders in AM

https://senvol.com/database - HSE ATEX guidance for combustible dusts and metal powder handling

https://www.hse.gov.uk/fireandexplosion/atex.htm - Materials Project/PubChem: Composition and structure data for metals/alloys

https://materialsproject.org/ and https://pubchem.ncbi.nlm.nih.gov/

Last updated: 2025-08-27

Changelog: Added 5 targeted FAQs, 2025 KPI/market snapshot table, two recent case studies, expert viewpoints, and authoritative tools/resources aligned to ISO/ASTM and NIST guidance for Metal Powders.

Next review date & triggers: 2026-03-31 or earlier if major powder standards change, atomization gas recovery becomes industry baseline, or new safety regulations affect metal powder handling.