Introduction to Aluminum Additive Manufacturing

Remember the last time you marveled at a sleek new aircraft or admired the design of a lightweight car? There’s a good chance aluminum additive manufacturing played a role! This technology has risen in popularity due to its capability to produce intricate parts with a strong, yet lightweight material: aluminum.

The Process of Aluminum Additive Manufacturing

Additive manufacturing, or as many of us fondly call it, 3D printing, is no longer limited to plastic toys or prototypes. It’s evolved to utilize metals, and aluminum has taken a front seat.

2.1. Layer-by-layer Production

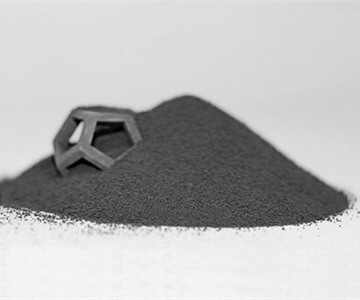

Just like a cake is made one layer at a time (remember those mouthwatering multi-layered cakes?), additive manufacturing builds objects layer by layer. Each thin sheet of aluminum powder is fused together using high-powered lasers until our desired object takes shape. It’s like magic, right?

2.2. Material Selection and Preparation

Choosing the right grade of aluminum is crucial. The powder is pre-alloyed, meaning the required alloying elements are blended before processing. Got a vision of sifting flour before baking? This is the metal equivalent!

2.3. Post-processing Steps

After the object is printed, it’s time for finishing touches, such as heat treatment, to enhance the material properties. Think of it as polishing a diamond to make it shine!

Benefits of Aluminum in Additive Manufacturing

Now, why aluminum? Let’s dive into its perks.

3.1. Strength and Durability

Aluminum offers a great balance between strength and weight. Imagine a gymnast: strong, yet incredibly agile. That’s our aluminum in the manufacturing world!

3.2. Lightweight Properties

In industries like aviation or automotive, every gram matters. Aluminum, with its feather-like weight, is the unsung hero behind many efficient and eco-friendly designs.

3.3. Cost-effectiveness

Who doesn’t love good quality at a pocket-friendly price? The cost savings in transportation and material efficiency make aluminum a popular choice.

Applications of Aluminum Additive Manufacturing

Where is aluminum additive manufacturing making waves?

4.1. Aerospace and Aviation

Aircraft require materials that are strong yet lightweight. And who better than aluminum to fit the bill?

4.2. Automotive Industry

From engine components to chassis parts, aluminum additive manufacturing is revving up the automotive world.

4.3. Medical Equipment

Surprised? Aluminum’s biocompatible nature makes it suitable for creating certain medical tools and implants.

4.4. Consumer Electronics

The sleek laptop or smartphone you admire? Thank aluminum for that chic, lightweight design.

Challenges and Solutions

As with any technology, there are hurdles to overcome.

5.1. Surface Roughness

Finishing is essential as aluminum parts can have a rough surface post-production. But ever heard of the saying, “rough around the edges but a gem at heart”?

5.2. Managing Thermal Stresses

Too much heat can warp the parts. The solution? Optimized support structures and controlled build environments.

5.3. Ensuring Product Consistency

Quality assurance is paramount. With the right checks and balances, it’s possible to maintain consistency in production.

The Future of Aluminum Additive Manufacturing

As we gaze into the horizon, the potential for this technology seems boundless. From sustainable production to innovative designs, the sky’s the limit!

Conclusion

Aluminum additive manufacturing is reshaping industries with its strength, lightweight properties, and cost-effectiveness. As technology advances, its applications and influence are set to expand even further. Ready for the aluminum revolution?

FAQs

- What is aluminum additive manufacturing?

- It’s a 3D printing process that uses aluminum powder to create objects layer by layer.

- Why is aluminum preferred in additive manufacturing?

- Due to its strength, lightweight nature, and cost-effectiveness.

- Which industries benefit the most from aluminum additive manufacturing?

- Aerospace, automotive, medical, and consumer electronics are prime beneficiaries.

- Are there challenges in using aluminum in additive manufacturing?

- Yes, challenges include surface roughness, thermal stresses, and product consistency, but solutions exist.

- Is aluminum additive manufacturing eco-friendly?

- It can be, given its potential for material efficiency and sustainable production.

know more 3D printing processes

Frequently Asked Questions (FAQ)

1) Which aluminum alloys are most common in Aluminum Additive Manufacturing and why?

- AlSi10Mg and AlSi7Mg lead due to good weldability, low cracking tendency, and predictable heat-treat response. High‑strength Sc/Zr‑modified Al‑Mg alloys and F357 (AlSi7Mg0.6) are growing for better fatigue and higher temperature stability.

2) What powder characteristics most affect build quality in LPBF?

- Particle size distribution 15–45 μm (sometimes 20–63 μm), high sphericity (>0.93), low satellites, low moisture, and low oxygen. Consistent apparent/tap density and stable Hall/Carney flow per ISO/ASTM 52907 and ASTM B213 are key.

3) How do heat treatments differ for AlSi10Mg vs F357 after printing?

- AlSi10Mg: T5/T6‑like regimes (e.g., stress relief 2–3 h at ~300–320°C) to adjust Si morphology and relieve stress. F357/F357‑AM: full T6 (solution ~540–550°C + quench + age ~155–170°C) to maximize strength and fatigue.

4) Can Aluminum Additive Manufacturing match wrought properties?

- With optimized scan strategies, proper heat treatment, and surface finishing/HIP where needed, tensile strength can meet or exceed cast equivalents and approach wrought in some cases. Surface‑initiated fatigue remains a focus; machining or shot peen improves results.

5) What are common challenges when printing aluminum and how to mitigate them?

- Keyholing and porosity: tune laser power/hatch/scan speed and maintain low humidity.

- Warping: preheat plate, optimize supports, balanced scan vectors.

- Spatter/soot buildup: high‑flow inert gas management and regular optics cleaning.

- Hydrogen porosity: dry powder and maintain low dew point in the chamber.

2025 Industry Trends: Aluminum Additive Manufacturing

- High‑strength AM alloys: Commercialization of Sc‑ and Zr‑modified Al‑Mg systems with improved crack resistance, enabling thicker sections and better fatigue.

- Multi‑laser productivity: 4–12 laser platforms with coordinated overlap reduce build times 25–60% for AlSi10Mg and F357.

- Digital material passports: Lot‑level PSD, O/H, flow, and reuse counts standardize cross‑site validation and regulatory submissions.

- Sustainability: Argon recirculation and powder circularity programs extend reuse cycles (5–12 blends) and cut gas consumption 20–40%.

- Hybrid manufacturing: AM near‑net shapes + 5‑axis machining deliver cast‑like surface finishes with reduced lead time for complex housings and heat exchangers.

2025 KPI Snapshot (indicative ranges for LPBF aluminum)

| Metric | 2023 Typical | 2025 Typical | Notes/Sources |

|---|---|---|---|

| LPBF build rate (cm³/h per laser, AlSi10Mg) | 40–70 | 60–110 | Multi‑laser + scan optimization |

| As‑built density (relative) | 99.3–99.7% | 99.5–99.9% | Optimized parameter sets |

| Surface roughness Ra (μm, vertical) | 12–25 | 8–18 | Process tuning + finishing |

| Oxygen in AM powder (wt%) | 0.06–0.12 | 0.04–0.08 | Improved handling/drying |

| Reuse cycles before blend | 3–6 | 5–12 | Digital tracking + sieving |

| Heat exchanger weight reduction vs cast | 20–35% | 25–45% | Lattice/conformal designs |

References: ISO/ASTM 52907; ASTM B213/B212; ASTM F3318 (LPBF AlSi10Mg); OEM application notes (EOS, SLM Solutions, Renishaw, 3D Systems); NIST AM‑Bench; industry sustainability reports

Latest Research Cases

Case Study 1: Conformal Aluminum Heat Exchanger via LPBF (2025)

Background: An EV OEM needed higher thermal performance and shorter lead time than investment casting could deliver.

Solution: Printed AlSi10Mg exchanger with conformal channels; applied stress relief and targeted machining on sealing faces; implemented digital powder passports and argon recirculation.

Results: Build time −41%; mass −33%; pressure drop −18% at equal duty; CT‑verified density 99.7%; cycle time from design to test article cut from 10 weeks to 4 weeks.

Case Study 2: Sc‑Modified Al‑Mg Brackets for Aerospace Interiors (2024)

Background: A tier‑1 supplier sought higher specific stiffness and fatigue life than AlSi10Mg brackets.

Solution: Qualified Sc/Zr‑modified Al‑Mg powder (15–45 μm), optimized scan to avoid hot cracking; full T6‑like heat treatment; shot peen to improve surface fatigue.

Results: High‑cycle fatigue life +28% vs AlSi10Mg baseline; part count reduced 5→2 via consolidation; lead time −35%; no cracking observed in coupon metallography.

Expert Opinions

- Prof. Ian Gibson, Professor of Additive Manufacturing, University of Twente

Key viewpoint: “Coordinated multi‑laser strategies and parameter portability are moving Aluminum Additive Manufacturing from prototypes to repeatable serial production.” - Dr. John Slotwinski, Materials Research Engineer, NIST

Key viewpoint: “Powder quality—PSD, oxygen, and moisture—verified by standardized methods remains the strongest predictor of porosity and fatigue in LPBF aluminum.” https://www.nist.gov/ - Dr. Anushree Chatterjee, Director, ASTM International AM Center of Excellence

Key viewpoint: “Expect broader alignment of COAs with ISO/ASTM 52907 and faster qualification under ASTM F3318 for AlSi10Mg and emerging high‑strength Al alloys.” https://amcoe.astm.org/

Practical Tools/Resources

- ISO/ASTM 52907: Metal powder feedstock characterization

https://www.iso.org/standard/78974.html - ASTM F3318: Standard for AlSi10Mg processed by LPBF

https://www.astm.org/ - ASTM B213/B212: Flow and apparent density tests for metal powders

https://www.astm.org/ - NIST AM‑Bench: Benchmark datasets for AM validation

https://www.nist.gov/ambench - Senvol Database: Machine/material data for Aluminum Additive Manufacturing

https://senvol.com/database - OEM parameter libraries and guides (EOS, SLM Solutions, Renishaw, 3D Systems) for AlSi10Mg/F357

Last updated: 2025-08-27

Changelog: Added 5 focused FAQs, 2025 KPI/trend table, two recent case studies, expert viewpoints, and curated standards/resources specific to Aluminum Additive Manufacturing.

Next review date & triggers: 2026-03-31 or earlier if ISO/ASTM standards update, OEMs release new Al AM parameter sets, or major data on powder reuse/gas recovery is published.