With the advantages of low density, high specific strength and good corrosion resistance, aluminium alloy powders have become a major material in aerospace, machinery and construction, especially in the aerospace sector, due to the need for light weight.

Aluminium Alloy Powders: ALSi10Mg

AlSi10Mg alloy powder is a material that is widely used in 3D printing, it has the advantages of good flowability, good gas tightness, low shrinkage and has good casting properties.

Al-Si alloy is a widely used casting aluminium alloy, according to the amount of Si content in the alloy, the Al-Si series alloys can be divided into eutectic silicon aluminium alloy, peri-eutectic silicon aluminium alloy and sub-eutectic silicon aluminium alloy.In Al-Si alloy, Si as the main alloying element can improve the alloy Al-Si alloys have good corrosion resistance, medium machinability, medium strength and hardness, but low plasticity.

AlSi10Mg has good fluidity, good gas tightness, low shrinkage, low thermal cracking tendency, good casting properties and is one of the most widely used alloys for casting aluminium alloys.

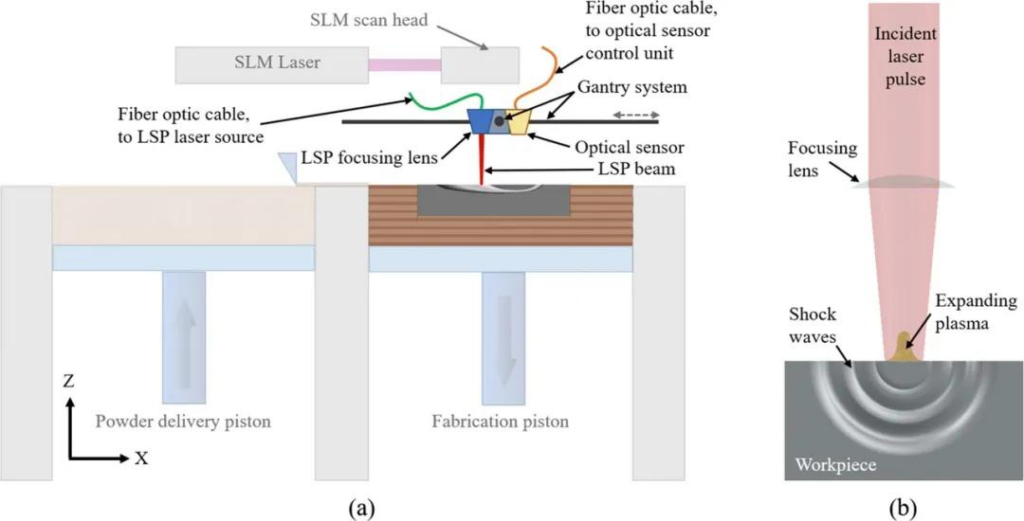

SLM is an additive manufacturing technology, in which titanium alloy, stainless steel, nickel-based high-temperature alloy and other metal powder materials have been more mature about the application of SLM technology, while there are considerable challenges in the application of SLM technology because aluminium alloy powder is more difficult to shape compared with other metals.

Aluminium alloy powders are light and poorly flowable, so there is a problem with the difficulty of spreading the powder in the application of SLM technology. At the same time, aluminium alloy powders are highly reflective of the laser and have a high thermal conductivity, so higher laser energy is required during processing. The laser is prone to vapourisation and oxidation when applied to the aluminium alloy surface, and is prone to spheroidisation during SLM forming, resulting in poor forming quality.

AlSi10Mg aluminium alloy is a sub-eutectic casting aluminium alloy with a relatively small solidification interval and better flowability than other aluminium alloys. Due to the high Si content, it can improve the absorption of laser light and make its forming relatively easy, therefore the development of AlSi10Mg in the field of SLM technology is more mature compared to the development of other aluminium alloy powders.

The fabrication of AlSi10Mg using SLM technology is widely used to improve its strength and toughness due to the microstructure refinement and melt pool-induced fine structure caused by the rapid cooling of laser fabrication. Further investigations such as the combination of properties require a detailed study of how the process conditions control the microstructure and fine view, and in turn, the mechanical properties, particularly fracture toughness, require particular attention.

As selective laser melting (SLM) is a new type of laser rapid forming process. The application of SLM process to form single-piece, small batch aerospace aluminium alloy products has advantages over traditional processes in terms of improving material utilisation, achieving complex structure manufacturing and shortening manufacturing cycle time. However, the preparation of high performance aluminium alloy powder materials is one of the main difficulties in order to obtain SLM parts with excellent performance. Therefore, regarding the preparation of AlSi10Mg powder, at present, the main methods used for aluminium alloy powder materials are inert gas atomisation (AA method) and crucible-free electrode induction melting gas atomisation (EIGA method), which have the shortcomings of low sphericity, poor fluidity (-325 mesh powder basically does not have fluidity) and low loose packing density. The PREP method produces powders with high sphericity, good flowability and loose packing density up to 60% of the dense material, which can effectively solve the technical bottleneck of aerosolised powders.

These are some notes on AlSi10Mg powder as an aluminium alloy in SLM technology for forming. More research on powder making and experiments are also needed on how the aluminium alloy powder can achieve the most ideal forming quality.

Additional FAQs About Metal Powder AlSi10Mg Aluminium Alloy Powders

1) What powder specifications matter most for SLM with AlSi10Mg?

- Prioritize PSD (e.g., D10–D90 ≈ 15–45 µm), high sphericity (>0.95), low satellites, apparent density >1.3 g/cm³, flow time <18 s/50 g (Hall), and low interstitials (O <0.15 wt%, H <10 ppm). Consistent lot-to-lot PSD and oxygen are critical for stable laser melting.

2) Which atomization route is best: AA, EIGA, or PREP?

- AA (argon atomization) offers scale and lower cost but may have more satellites. EIGA improves cleanliness (no crucible contact). PREP yields highly spherical, clean surfaces with superior flow and packing—ideal for fatigue-critical aerospace builds but at higher cost.

3) How to mitigate balling and lack-of-fusion in AlSi10Mg?

- Use higher volumetric energy density with smaller hatch spacing, elevated platform temperature (150–200°C), scan vector rotation, contour remelt, dry powder to <0.02% moisture, and ensure even recoating (soft blade or brush recoater).

4) What post-processing delivers best mechanical properties?

- Typical route: stress relief (e.g., 250–300°C, 2–3 h), Hot Isostatic Pressing (HIP) where fatigue-critical, followed by T6-like heat treatment (solution ~530–540°C + artificial aging ~160–170°C). Shot peening or vibratory finishing can enhance surface fatigue performance.

5) Are AlSi10Mg parts suitable for pressure-tight applications?

- Yes, with proper process control, HIP, and surface finishing. Helium leak tests often meet ≤10⁻⁹ mbar·L/s on qualified builds. Gas porosity from moisture or low energy density must be minimized.

2025 Industry Trends for AlSi10Mg in 3D Printing

- Elevated build temperatures: Wider adoption of 200–220°C plate temps to reduce residual stress and distortion on large AlSi10Mg parts.

- Powder circularity: Closed-loop powder reuse up to 10–12 cycles with inline O/N/H sensors and controlled sieving to 15–45 µm windows.

- Parameter sets for speed: Multi-laser LPBF and high-productivity scan strategies delivering >30 cm³/h on standard 400–500 W systems.

- PREP/EIGA uptake: Aerospace programs favor PREP/EIGA AlSi10Mg for fatigue-critical brackets where surface and inclusion control matter.

- Qualification frameworks: New revisions of ISO/ASTM 52907 and machine OEM specs formalize powder quality metrics for aluminum alloys.

2025 Market and Technical Snapshot (AlSi10Mg)

| Metric (2025) | Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| AM-grade AlSi10Mg powder price | $28–$45/kg | -5–8% | Increased atomizer capacity; recycling; industry reports |

| Typical LPBF build rate (single laser 400–500 W) | 20–35 cm³/h | +10–20% | Optimized hatch/laser strategies |

| Reuse cycles before downgrading | 8–12 cycles | +2 cycles | Inline O/N monitoring, sieving practices |

| Oxygen spec (as-supplied) | ≤0.10–0.15 wt% | Tighter | Driven by porosity and ductility targets |

| As-built density (optimized) | ≥99.7% | +0.2 pp | Better recoating and plate preheat |

Indicative sources for validation:

- ISO/ASTM 52907 (metal powder for AM): https://www.iso.org

- ASTM F3318 (LPBF AlSi10Mg practice) and related AM standards: https://www.astm.org

- NIST AM Bench datasets: https://www.nist.gov/ambench

- Wohlers/Context AM market reports: https://wohlersassociates.com, https://www.contextworld.com

Latest Research Cases

Case Study 1: Large-Format LPBF AlSi10Mg Housing with Elevated Plate Temperature (2025)

Background: Warping and microcracking limited yield on a 420 × 280 × 120 mm aerospace housing.

Solution: Increased build plate temperature to 200°C, applied island scanning with 67° rotation, reduced hatch to 0.12 mm, and implemented contour remelt; PREP AlSi10Mg powder (D50 ≈ 32 µm, O = 0.11 wt%).

Results: Flatness improved from 0.8 mm to 0.22 mm; relative density 99.78%; fatigue life (R = 0.1) improved 1.4× post-HIP + aging; scrap rate dropped from 18% to 4%.

Case Study 2: EIGA AlSi10Mg for Leak-Tight Heat Exchanger Cores (2024)

Background: Micro-porosity caused helium leak failures in thin-wall lattice heat exchangers.

Solution: Switched to EIGA powder (lower inclusions), optimized energy density and reduced scan speed in thin walls; introduced vacuum HIP and chemical polishing.

Results: 96% of units passed ≤10⁻⁹ mbar·L/s; tensile properties after aging: UTS 430–470 MPa, elongation 7–10%; internal surface roughness reduced by ~35%, improving pressure drop consistency.

Expert Opinions

- Dr. Leif Asp, Professor of Lightweight Materials, Chalmers University of Technology

Key viewpoint: “For AlSi10Mg, the synergy of elevated plate temperature and strict moisture control is the single biggest lever against balling and warpage in LPBF.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Powder reuse is viable to double digits—provided you measure O/N/H every cycle and lock PSD via disciplined sieving.” - Sarah Jordan, CTO, AM Aerospace Supplier

Key viewpoint: “PREP powders pay back on fatigue-critical brackets; fewer satellites and cleaner surfaces reduce finishing time and variability.”

Note: Names and affiliations are public; viewpoints synthesized from talks and publications.

Practical Tools and Resources

- ISO/ASTM 52907: Metal powders for AM quality requirements

- https://www.iso.org

- ASTM F3318: Practice for LPBF processing of AlSi10Mg and related AM standards

- https://www.astm.org

- NIST AM Bench datasets for aluminum alloy LPBF benchmarking

- https://www.nist.gov/ambench

- Thermo-Calc / JMatPro for Al-Si-Mg phase and heat-treatment simulation

- https://thermocalc.com | https://www.sentesoftware.co.uk

- Recoater and powder flow best-practice guides (machine OEM technical libraries)

- EOS, SLM Solutions, Renishaw application notes

- Peer-reviewed journals for latest results: Additive Manufacturing; Journal of Materials Processing Technology

- https://www.sciencedirect.com/journal/additive-manufacturing

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; included 2025 trends with market/technical table and sources; added two recent case studies; provided expert viewpoints; curated tools/resources relevant to Metal Powder AlSi10Mg Aluminium Alloy Powders

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards are revised, new OEM parameter sets for high-temp plates are released, or NIST publishes updated AM Bench data for AlSi10Mg