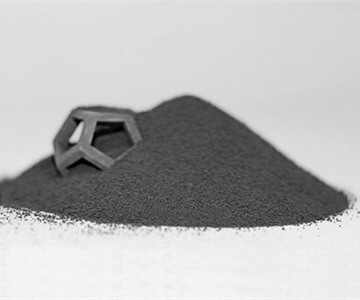

Alloy powder refers to metal powders made from an alloy rather than a single pure metal. Alloys are mixtures of two or more metallic elements designed to enhance specific properties such as strength, corrosion resistance, or machinability. Alloy powders provide unique advantages over pure metal powders for powder metallurgy applications.

Overview of Alloy Powder

Alloy powder offers properties that can be tailored by adjusting composition. This table provides an overview of alloy powder and its key characteristics:

| Parameter | Details |

|---|---|

| Definition | Metal powder composed of an alloy rather than pure metal |

| Composition | Mixture of two or more metallic elements |

| Key Properties | Strength, corrosion resistance, hardness, machinability, ductility, wear resistance, electrical conductivity, appearance |

| Adjustability | Properties can be tailored by changing ratios of alloying elements |

| Manufacturing Process | Atomization of molten alloy into fine powder |

| Particle Shape | Irregular, spherical, dendritic depending on process |

| Common Alloy Systems | Steel, stainless steel, aluminum, copper, nickel, cobalt, titanium |

| Applications | Powder metallurgy parts, thermal spraying, metal injection molding (MIM), additive manufacturing |

Alloy powder expands the capabilities of powder metallurgy by offering the ability to engineer materials with specific properties. Key characteristics of alloy powder include:

- Composition – Alloy powders contain at least two metallic elements in varying ratios to achieve desired attributes. Common systems include steel, aluminum, and copper alloys.

- Adjustable Properties – By changing the percentages of alloying elements, materials can be tailored for strength, corrosion resistance, hardness, ductility, electrical resistivity, and other properties.

- Manufacturing Process – Alloy powder is made by atomization of molten alloy to produce fine spherical powder particles with good flow and packing properties.

- Particle Characteristics – Powder morphology, size distribution, and purity depend on the atomization method. Powders can be irregular, spherical, or dendritic.

- Alloy Systems – Hundreds of standardized and custom alloy compositions are available. Steel, stainless steel, aluminum, copper, nickel, cobalt, and titanium alloys are common.

- Applications – Alloy powder is used to manufacture PM parts, thermal spray coatings, metal injection molded components, and 3D printed objects.

With such a wide range of tunable properties, alloy powder offers an important materials engineering tool for industrial applications. The next sections provide more details on alloy powder types, processing methods, and uses.

Alloy Powder Compositions and Properties

Many standardized and proprietary alloy powder formulations exist. This table summarizes some of the most common alloy systems and their general characteristics:

| Alloy System | Typical Composition | Key Properties | Applications |

|---|---|---|---|

| Stainless steel | Fe, Cr (10-20%), Ni | Corrosion resistance, strength, wear resistance | Valves, marine components, food processing equipment |

| Tool steel | Fe, Cr, V, W, Mo | High hardness, strength, wear resistance | Cutting tools, dies, machine parts |

| Low alloy steel | Fe + Mn, Si, Ni, Cr, Mo | Toughness, strength, hardenability | Gears, engine parts, fasteners |

| Aluminum | Al + Cu, Mg, Si, Zn | Lightweight, corrosion resistance, machinability | Aerospace components, automotive parts |

| Copper | Cu + Zn, Sn, Al | Electrical conductivity, corrosion resistance, machinability | Electrical contacts, welding tips, bearings |

| Nickel | Ni + Cr, Mo, Cu, Fe | Corrosion resistance, high temperature strength | Gas turbine blades, chemical equipment |

| Cobalt | Co + Cr, Mo, Ni, W, C | High temperature strength, biocompatibility | Dental implants, cutting tools, orthopedic implants |

| Titanium | Ti + Al, V, Cu, Ni | Lightweight, corrosion resistance, biocompatibility | Aerospace components, medical implants |

By selecting appropriate base metals and alloying elements, powder metallurgy alloys can be designed with:

- High strength for load bearing applications

- Hardness and wear resistance for cutting tools and abrasion resistance

- Corrosion resistance in chemicals and seawater

- High temperature capability and creep resistance

- Tailored electrical conductivity from insulation to high conduction

- Biocompatibility for medical implants and devices

- Combinations of these properties not attainable in pure metals

The flexibility of alloy compositions allows custom materials to be designed for specific applications and operating conditions.

Methods for Manufacturing Alloy Powder

Alloy powder can be produced using several atomization techniques to generate small spherical particles necessary for powder metallurgy. Typical methods include:

| Method | Description | Particle Characteristics | Alloy Capability |

|---|---|---|---|

| Gas atomization | Molten metal stream atomized by high pressure inert gas jets | Fine spherical powder, good flowability | Most alloys |

| Water atomization | Molten stream broken up by high velocity water jets | Irregular particles with satellite formation | Limited to oxidation resistant alloys |

| Rotating electrode | Centrifugal force disperses molten metal into fine droplets | Relatively coarse powder size distribution | Only for electrically conductive alloys |

| Plasma atomization | Metal powder evaporated in a plasma and recondensed | Very fine spherical particles | High performance alloys |

Gas atomization is the most widely used process due to its versatility and fine spherical powder production. Water atomization is lower cost but restricted to alloys that resist oxidation like stainless steels. Plasma methods can produce nanoscale alloy powders but have higher capital costs.

The atomization process parameters such as gas flow rate, metal pour rate, and cooling rate can be optimized to obtain the desired particle size distribution, morphology, purity, and microstructure. The alloy powder manufacture process is tailored for the specific composition to produce high quality powder feedstock for PM parts fabrication.

Alloy Powder Characteristics

In addition to composition, the properties and performance of alloy powder are determined by characteristics such as:

| Parameter | Description |

|---|---|

| Particle size distribution | Range of particle diameters in the powder; controlled by atomization process |

| Particle shape | Spherical, irregular, or dendritic; affects powder flow and packing |

| Particle surface morphology | Presence of satellites, surface smoothness, internal porosity |

| Chemical composition | Ratio of alloying elements; may differ from nominal due to segregation |

| Phases present | Phases formed in powder due to rapid solidification; affects properties |

| Impurities | Contaminants such as oxygen, nitrogen, or carbon picked up during atomization |

| Apparent density | Powder packing density under specified compaction pressure |

| Flow rate | Ability of powder to flow, related to particle shape and size distribution |

These powder characteristics influence manufacturing behavior in processes like pressing, sintering, metal injection molding, and additive manufacturing. For example, irregular powder particles degrade die filling and green strength in powder pressing. Chemically reactive elements like titanium are sensitive to oxygen pickup during atomization.

Careful control and testing of both alloy chemistry and physical powder properties ensures high quality feedstock for subsequent powder metallurgy processing. Testing methods include optical and electron microscopy, laser diffraction particle size analysis, tap density measurement, powder rheology, and chemical analysis.

Applications of Alloy Powder

With their unique tunable properties, alloy powder compositions are used across a wide range of powder metallurgy applications:

Powder Press and Sinter Parts

- Structural automotive components – alloy steels for strength

- Stainless steel valves, fittings, filters – corrosion resistance

- Copper alloy contacts, connectors – electrical conductivity

- Ferrous and non-ferrous mechanical parts – strength, wear resistance

Metal Injection Molded Components

- Stainless steel orthopedic implants – biocompatibility, strength

- Cobalt superalloy turbine blades – high temperature strength

- Copper alloy electronics parts – thermal conductivity

- Aluminum alloy firearms parts – light weight

- Low alloy steel gears – toughness, fatigue strength

Thermal Sprayed Coatings

- Stainless steel coatings – corrosion, wear resistance

- Cobalt alloy coatings – high temperature hardness, wear resistance

- Nickel alloy coatings – corrosion resistance

- Carbide reinforced coatings – extreme wear resistance

Additive Manufacturing Powders

- Titanium alloys for aerospace parts – strength, light weight

- Cobalt chrome alloys for dental bridges – strength, biocompatibility

- Tool steel for mold tooling – high hardness, thermal stability

- Aluminum alloys for automotive – light weight, corrosion resistance

Other Applications

- Powder forged connecting rods, gears – alloy steel, aluminum

- Brazing alloys, solder pastes – copper, silver, nickel alloys

- Hardfacing alloys – iron, cobalt, carbide blends

Alloy powder compositions enable the engineering of materials for these specific applications and operating conditions.

Suppliers and Costs of Alloy Powder

Many major metal powder suppliers have extensive alloy powder inventories and custom alloy capabilities. Here are some leading global suppliers of gas atomized alloy powder:

| Company | Headquarters Location |

|---|---|

| Sandvik | Sweden |

| Hoganas | Sweden |

| Rio Tinto Metal Powders | Canada |

| Pometon | Italy |

| JFE Steel | Japan |

| BASF | Germany |

| CNPC Powder | China |

Costs of alloy powder depend on the specific composition, powder characteristics, lot size, and purchase quantity. Some example price ranges are:

| Alloy Powder | Approximate Cost (USD/kg) |

|---|---|

| Stainless steel | $12 – $60 |

| Tool steel | $9 – $30 |

| Aluminum alloy | $10 – $50 |

| Copper alloy | $20 – $60 |

| Cobalt alloy | $80 – $220 |

| Titanium alloy | $100 – $500 |

Prices vary widely based on alloy type, particle size distribution, production method (gas vs. water atomization), and order volume. Custom alloys cost more than standard compositions. Precious metals like cobalt and titanium alloys are more expensive.

How to Select an Alloy Powder Supplier

Choosing a reputable alloy powder supplier is critical to obtain high quality feedstock. Here are key factors in selecting a supplier:

- Experience with manufacturing the specific alloy composition needed

- Stringent quality assurance testing of each powder lot

- Documentation of chemical analysis and powder characteristics

- Inventory of standard compositions for quick delivery

- Ability to customize alloy composition as required

- Knowledgeable technical support staff

- Competitive pricing, especially for large order quantities

- Willingness to supply small trial quantities

- Responsiveness to inquiries and requests for quotes

- Established reputation of product consistency and reliability

The supplier should be able to provide a certificate of analysis detailing the chemical composition, particle size distribution, morphology, apparent density, flow rate, and other properties of the powder. Testing samples and validating actual powder performance is also recommended during initial qualification.

How to Store and Handle Alloy Powder

Proper storage and handling prevents alloy powder contamination or property changes. Recommended practices include:

- Store containers sealed in a cool, dry, clean environment away from sources of moisture, oils, or corrosive vapors

- Limit temperature fluctuations during storage to avoid condensation inside containers

- Rotate stock to use older inventory first

- Protect powder from exposure to air during handling to prevent oxidation

- Avoid mixing powders of different alloys or size distributions

- Handle containers carefully to prevent toppling and spillage

- Use clean, dry scoops and equipment for powder transfer

- Seal containers immediately after removing powder

- Measure and record the mass of powder removed to maintain a material balance

- Clean equipment thoroughly between processing batches to prevent cross-contamination

Care in handling, storage, and recordkeeping ensures the alloy powder retains its shape, composition, and properties for subsequent processing.

Alloy Powder Maintenance Considerations

Once alloy powder metallurgy components are put into service, occasional maintenance may be needed. This table lists some maintenance aspects specific to alloys:

| Consideration | Details |

|---|---|

| Galvanic corrosion | Dissimilar alloy combinations can increase corrosion if wetted. Avoid assembling dissimilar alloys in direct contact. |

| Stress corrosion | Susceptible alloys like austenitic stainless steel may crack if exposed to chlorides under stress. Avoid use under these conditions. |

| Elevated temperature properties | Strength and creep resistance can decrease in some alloys at higher temperatures. Verify design limits are not exceeded. |

| Contact resistance | Conductive coatings may be needed to prevent voltage drop at interfaces between copper alloys and steel. |

| Biofouling | Copper alloys naturally resist biofouling in marine environments. Other alloys may require protective coatings. |

| Joint strength | Brazing or welding alloys should match the base material composition to ensure joint integrity. |

Consider environmental factors and alloy compatibilities when maintaining equipment containing alloy powder metallurgy components. Periodic inspection, lubrication, cleaning, and tightening of joints may be required.

Pros and Cons of Alloy Powder

Alloy powder has many benefits but also some inherent drawbacks relative to pure metal powder:

Advantages of Alloy Powder

- Tailored properties like strength, wear resistance, conductivity

- More corrosion resistant than pure iron or steel powders

- Less prone to galling or seizing than pure metals

- Can be made stronger for load bearing applications

- Options for high hardness, toughness, or biocompatibility

- Consistent composition from recycled production scrap

Disadvantages of Alloy Powder

- Higher cost than pure iron, copper or aluminum powders

- Limited number of standardized compositions available

- Custom alloy development is expensive and time consuming

- Segregation can lead to deviations from nominal chemistry

- Reactive elements like chromium can be oxidized during atomization

- Powder reuse is limited since alloy compositions cannot be intermixed

- Alloying elements may create processing challenges in P/M

For many applications, the advantages of tailored alloy properties outweigh the increased cost and processing complexity relative to pure metal powders. But feasibility evaluation is needed when substituting alloys in an existing P/M part design.

Alloy Powder versus Pre-alloyed Steel Powder

Alloy powder differs from pre-alloyed steel powder in composition and production:

| Parameter | Alloy Powder | Pre-alloyed Steel Powder |

|---|---|---|

| Base composition | Various metal systems, e.g. stainless steel, tool steel, nickel alloys | Iron or iron + carbon (steel) |

| Alloying elements | One or more metals added to tailor properties | Carbon + trace alloying elements like Mn, Ni, Mo |

| Production method | Atomization of molten alloy | Pre-blending iron and graphite powders |

| Alloy distribution | Uniform throughout powder particle | Alloying elements only on powder surface |

| Sintered structure | Homogeneous, phases formed during solidification | Heterogeneous, phases formed during sintering |

| Cost | Higher due to alloying additions | Lower since carbon is inexpensive |

Pre-alloyed steel powders have lower production cost but are limited in alloy content. Alloy powder has greater composition flexibility but higher raw material expenses. The composition choice depends on balancing performance needs with cost targets for the application.

How Alloying Elements Affect Properties

Different alloying elements influence powder metallurgy properties in various ways:

| Alloying Element | Key Effects |

|---|---|

| Carbon | Increases strength and hardness but reduces ductility and corrosion resistance |

| Chromium | Improves corrosion resistance and hardenability in steels |

| Nickel | Enhances toughness, tensile strength and elevated temperature properties |

| Molybdenum | Increases high temperature strength, creep resistance and hardenability |

| Manganese | Raises hardenability and tensile strength while lowering cost versus nickel |

| Silicon | Improves fluidity during sintering but decreases ductility and surface finish |

| Copper | Strengthens low alloy steels and bronzes; also aids corrosion resistance |

| Aluminum | Lightweight alloying element that boosts strength and corrosion resistance in steels |

| Vanadium | Fine carbide former to significantly increase wear resistance and hardness |

| Tungsten | Forms very hard tungsten carbides for abrasion resistance in tool steels |

By understanding the effects of each addition, material engineers can model and optimize compositions to achieve the target properties with alloy powder. Small variations in alloy content can significantly impact the performance.

Design Considerations with Alloy Powder

Several factors should be considered when designing powder metallurgy parts using alloy powder:

- Cost – Alloying additions increase raw material cost versus pure iron or steel powder. Balance performance against budget constraints.

- Post-sintering processing – Alloys must be compatible with any secondary operations like heat treatment, machining, welding or surface finishing.

- Corrosion resistance – Alloy composition can be adjusted to withstand operating environment. Use stainless steel in water for example.

- Mechanical properties – Required strength, hardness, wear resistance, etc. will dictate the alloy system and amounts of carbides or reinforcing phases.

- Dimensional control – Higher alloy content can increase sintering shrinkage. Account for this in tooling dimensions.

- Technical capability – Ensure the P/M manufacturer has experience with the particular alloy composition being considered.

- Part integration – Alloy mismatch between assemblies can lead to galvanic corrosion. Standardize on families of alloys where possible.

Thorough alloy selection is essential early in design to produce a robust, cost competitive powder metallurgy component.

Example Alloy Powder Applications

Here are some illustrative applications of alloy powder in various industries:

Automotive

- Camshafts – Made from sintered low alloy steel powder for high strength and wear resistance. The alloy composition is optimized for hardness and fracture toughness needed in engine valve actuation.

- Connecting rods – Forged or sintered from alloy steel powder to obtain the enhanced tensile strength required while minimizing weight. Alloying with nickel, molybdenum, and other elements provides suitable mechanical properties.

- Gears – Alloy steel powder with additions of chromium, nickel, and molybdenum allows sintered powertrain gears to achieve the necessary fatigue strength and fracture toughness under cyclic automotive loads. The tailored alloy composition reduces wear.

- Turbocharger wheels – High performance superalloys like Inconel 718 are used in powder form for additive manufacturing of turbocharger compressor wheels able to withstand extreme centrifugal stresses and temperatures. The nickel-based alloy provides strength and creep resistance.

- Engine valves – Stainless steel alloy powder containing chromium and nickel enables manufacture of corrosion resistant exhaust valves that withstand attack from hot exhaust gases over long operating lifetimes. The alloy remains strong and stable even at high temperatures.

- Brake discs – Copper alloy powder is sometimes incorporated in brake disc formulations to improve thermal conductivity, damping, and wear resistance without excessive weight addition. The higher heat dissipation reduces fade during repeated braking.

Alloy powder compositions enable optimization of automotive powertrain component properties like strength, hardness, corrosion resistance, fatigue life, and high temperature stability using powder metallurgy techniques.

know more 3D printing processes

Additional FAQs on Alloy Powder

1) How do pre-alloyed powders differ from blended elemental powders in performance?

Pre-alloyed powders solidify with uniform chemistry inside each particle, giving consistent sintering behavior and mechanical properties. Blended elemental mixes can segregate and rely on diffusion during sintering, which may cause local chemistry variation.

2) What particle size distributions work best for different PM processes?

- Press-and-sinter: ~20–150 μm (often multimodal to boost packing).

- MIM/binder jetting: D50 ~5–20 μm for high sinter activity.

- Laser PBF: D10–D90 ≈ 15–45 μm spherical for stable recoating.

- EBM: 45–105 μm spherical, tolerant of coarser cuts.

3) Which alloy powder systems are preferred for corrosion-critical applications?

Austenitic stainless steels (e.g., 316L), duplex SS in some cases, Ni-based alloys (e.g., 625, 718), and Ti alloys for chloride and biomedical environments, provided low O/N/C and appropriate surface finish.

4) How do interstitials (O, N, C, H) impact alloy powder parts?

They can embrittle (raise DBTT), alter phase balance, reduce ductility/fatigue, and change sinter kinetics. Control via inert atomization, vacuum/H2 heat treatments, and dry, inert storage/handling.

5) What data should be on a certificate of analysis (CoA) for alloy powder?

Full chemistry (including interstitials), PSD, morphology notes, apparent/tap density, flow (Hall/Carney), moisture, and lot traceability. For AM, also satellite content, internal porosity, and recommended sieving limits.

2025 Industry Trends in Alloy Powder

- Qualification at scale: Material passports link alloy powder lots to part serials; in-situ PBF monitoring reduces destructive testing for common alloys.

- Copper and aluminum AM uptake: Wavelength-optimized lasers enable higher conductivity Al/Cu builds; new Al–Sc and Cu–Cr–Zr variants mature.

- Sustainability: Broader recycled content (particularly Fe-, Ni-, Cu-based powders), argon recirculation, and Environmental Product Declarations (EPDs).

- Cost-down via process hybrids: AM preforms + forging/HIP for Ni and Ti alloys to achieve wrought-like properties with reduced buy-to-fly.

- Health and safety focus: Wider adoption of NFPA 484-aligned powder rooms, closed-loop sieving, and O2/moisture monitoring.

| 2025 Metric (Alloy Powder/PM-AM) | Typical Range/Value | Why it matters | Source |

|---|---|---|---|

| LPBF relative density (316L, 718, Ti-64; with HIP) | 99.5–99.9% | Production-grade properties | Peer-reviewed AM studies; OEM notes |

| Binder jetted density after sinter/HIP (17-4PH, 420) | 95–99% | Large parts at lower cost | Vendor case data |

| Typical LPBF PSD | D10–D90 ≈ 15–45 μm | Recoating stability | ISO/ASTM 52907 |

| Oxygen spec (implant-grade Ti-64 ELI) | ≤0.13 wt% | Ductility/biocompatibility | ASTM F136/F3001 |

| Recycled content in Fe/Ni powders | 25–45% | Sustainability and cost | USGS/industry reports |

| Indicative prices (gas-atomized) | SS: $12–$60/kg; Ni: $40–$150/kg; Ti: $180–$450/kg | Budgeting and sourcing | Supplier quotes/market trackers |

Authoritative references and further reading:

- ISO/ASTM 52907 (feedstock), 52910 (DFAM), 52931 (LPBF metals): https://www.astm.org and https://www.iso.org

- ASM Handbook (Powder Metallurgy; Stainless, Nickel, Titanium): https://www.asminternational.org

- USGS Mineral Commodity Summaries: https://pubs.usgs.gov/periodicals/mcs

- NFPA 484 (combustible metals safety): https://www.nfpa.org

- NIST AM Bench and datasets: https://www.nist.gov

Latest Research Cases

Case Study 1: Gas‑Atomized Duplex Stainless Alloy Powder for Corrosion‑Fatigue Parts (2025)

Background: A marine pump OEM needed improved chloride SCC resistance and fatigue strength over 316L.

Solution: Qualified a duplex SS alloy powder (balanced austenite/ferrite) with tight O/N control; LPBF with platform preheat, followed by HIP and solution treatment.

Results: 2.1× improvement in corrosion‑fatigue life (3.5% NaCl, R=0.1) vs. LPBF 316L; density 99.8% after HIP; 12% cost increase offset by 30% longer service interval.

Case Study 2: Binder‑Jetted Low‑Alloy Steel with Cu‑Ni Additions for Gears (2024)

Background: An automotive supplier sought near‑net gears with reduced machining and comparable fatigue to wrought 8620.

Solution: Fine PSD water‑atomized pre‑alloyed Fe‑Cu‑Ni powder; debind + sinter + optional carburize/HIP; controlled porosity distribution.

Results: 97–98.5% density (99% with HIP), bending fatigue met target; machining time reduced 35%, part cost down 18% on pilot lot.

Expert Opinions

- Prof. Randall M. German, Powder Metallurgy authority and author

Key viewpoint: “Sphericity and clean surfaces are the strongest predictors of sinter densification and AM part integrity across alloy systems.” - Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

Key viewpoint: “For Ni and Ti alloy powders, interstitial control and HIP remain decisive for fatigue; in‑situ monitoring is now integral to qualification strategies.” - Richard Preston, Technical Director, International Molybdenum Association (IMOA)

Key viewpoint: “Alloy design leveraging Mo and Cr continues to drive corrosion and high‑temperature performance in pre‑alloyed powders used for harsh environments.”

Citations for expert profiles:

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

- IMOA: https://www.imoa.info

Practical Tools and Resources

- Standards and safety

- ISO/ASTM 52907, 52910, 52931; NFPA 484 combustible metals

- Powder and process data

- ASM Handbooks; NIST AM Bench datasets; USGS commodity stats

- Characterization and QC

- LECO O/N/H analyzers: https://www.leco.com

- Laser diffraction/SEM services (e.g., Malvern, university labs)

- CT scanning per ASTM E1441 for internal defects

- Design and simulation

- Ansys Additive/Mechanical; COMSOL; nTopology (lattices, heat flows)

- Market and sourcing

- Senvol Database for machines/materials: https://senvol.com/database

Last updated: 2025-08-21

Changelog: Added 5 targeted FAQs, 2025 trend table with metrics and sources, two recent alloy powder case studies, expert viewpoints with citations, and a practical tools/resources list.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards update, major OEMs publish new qualification datasets, or alloy powder pricing/availability shifts >10% QoQ.