Overview of 6061 Aluminium Alloy Powder

6061 aluminium alloy powder is one of the most widely used aluminium alloys for powder metallurgy applications. Some key features of 6061 aluminium alloy powder include:

- Excellent corrosion resistance and weldability

- Good mechanical properties and strength-to-weight ratio

- Versatile alloy that can be strengthened through heat treatment

- Widely available and cost-effective

6061 alloy powder can be used to manufacture high-performance components through powder metallurgy techniques such as metal injection molding (MIM), cold isostatic pressing (CIP), additive manufacturing, and conventional press and sinter methods. Parts made from 6061 powder exhibit properties comparable to or better than wrought 6061 alloy.

Types of 6061 Aluminium Alloy Powder

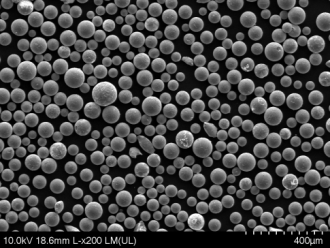

There are several types of 6061 aluminium alloy powder available depending on particle size, shape, and production method:

| Type | Description | Typical Particle Size | Shape | Production Method |

|---|---|---|---|---|

| Atomized | Irregular spheroidal particles produced by gas or water atomization | 10 – 150 μm | Rounded | Gas atomization or water atomization |

| Spherical | Highly spherical powder produced through plasma atomization | 5 – 45 μm | Highly spherical | Plasma atomization |

| Flattened | Flattened particle morphology with high flowability | 5 – 150 μm | Flattened, angular | Mechanical comminution |

| Blended | Mixture of particle sizes and shapes | 5 – 150 μm | Mixed | Blending of atomized and comminuted powders |

Atomized powders with spherical particles typically have better flow and packing properties. Spherical and flattened powders improve powder injection molding behavior. Blended powders provide a balance of properties and cost.

Characteristics and Properties of 6061 Aluminium Powder

6061 aluminium alloy powder offers a versatile mix of properties that make it suitable for a wide range of applications.

| Property | Description |

|---|---|

| Composition | Al-Mg-Si alloy with Cu and Cr additions |

| Density | 2.7 g/cm3 |

| Melting Point | 582°C |

| Strength | 190 – 310 MPa |

| Hardness | 55 – 100 HB |

| Corrosion Resistance | Excellent resistance in various environments |

| Thermal Conductivity | 167 W/m-K |

| Electrical Conductivity | 41% IACS |

| Fatigue Strength | 100 – 155 MPa |

| Elongation | 8 – 15% |

| Workability | Excellent formability in softened condition |

| Heat Treatability | Can be heat treated to high strength – T4 and T6 tempers |

| Weldability | Excellent weldability using most techniques |

| Machinability | Fair machinability but high speeds and feeds required |

The properties of sintered parts can be tailored by 6061 powder characteristics, process parameters, and heat treatment. Proper control ensures high strength, hardness, and corrosion resistance.

Applications and Uses of 6061 Aluminium Alloy Powder

The versatile properties of 6061 alloy powder make it suitable for manufacturing lightweight, high-performance components across many industries:

Transportation: Engine brackets, steering knuckles, suspension arms, wheels

Aerospace: Aircraft fittings, helicopter rotors and transmission parts

Military: Grenades, shell casings, gun components

Marine: Gears, shafts, fittings, fasteners, pumps

Electronics: Heat sinks, packaging, enclosures, shields

Industrial: Flanges, couplings, valves, tooling fixtures, gears

Consumer: Power tools, sporting goods, hardware, appliances

Medical: Orthopedic implants, dental implants, medical instruments

6061 is commonly used instead of 2014 and 7075 alloys when very high strength is not required. It offers the best balance of cost, corrosion resistance, and mechanical properties.

Specifications for 6061 Aluminium Powder

6061 aluminium alloy powder must conform to certain specifications for chemistry, particle size distribution, flow rate, and other properties based on the intended application:

| Parameter | Specification | Test Method |

|---|---|---|

| Aluminium Content | Balance | ASTM E539 |

| Magnesium | 0.8-1.2 wt% | ASTM E539 |

| Silicon | 0.4-0.8 wt% | ASTM E539 |

| Iron | Max 0.7 wt% | ASTM E539 |

| Copper | 0.15-0.4 wt% | ASTM E539 |

| Manganese | Max 0.15 wt% | ASTM E539 |

| Chromium | 0.04-0.35 wt% | ASTM E539 |

| Zinc | Max 0.25 wt% | ASTM E539 |

| Titanium | Max 0.15 wt% | ASTM E539 |

| Particle Size | 10 – 150 μm | ASTM B822 |

| Flow Rate | Min 25 s/50 g | ASTM B213 |

| Apparent Density | Min 2.5 g/cm3 | ASTM B212 |

| Tap Density | Min 75% of alloy density | ASTM B527 |

The particle shape, size ranges, flow, and chemistry must be optimized to the specific component requirements and manufacturing process.

Design Considerations for 6061 Aluminium Powder Parts

Proper design is key to achieving optimal properties in sintered 6061 alloy parts:

- Wall thickness: Minimum 2-3 mm. Thinner walls risk lower strength.

- Fillets and corners: Add fillets to minimize stress concentrations. Avoid sharp corners.

- Draft angles: Incorporate draft angles ≥ 1-2° to ease part ejection.

- Surface finish: Finer powder and sizing can improve surface finish. Secondary operations may be required.

- Dimensional tolerances: ±0.5% is achievable but ±0.2% for high precision components.

- Density: Aim for ≥ 97% of theoretical density for highest mechanical properties.

- Heat treatment: T4 and T6 heat treatment significantly increases part strength.

- Secondary operations: Machining, drilling, milling or grinding may be needed for critical features.

Careful control of these aspects during design allows optimal performance of the final part.

Standards for 6061 Aluminium Alloy Powder

6061 aluminium alloy powder must meet the chemical composition limits in national and international standards:

| Standard | Region |

|---|---|

| ASTM B295 | USA |

| EN AC-AlSi0,7Mg0,6 | Europe |

| GB/T 3190-2008 | China |

| IS 733 | India |

| JIS H2080 | Japan |

These standards also specify requirements for powder production method, particle shape and size, sampling, testing, inspection, packaging, and labeling to ensure quality.

Compliance to standards is essential for applications in aerospace, defense, transportation, medical devices and other regulated industries. Customers usually request test reports showing conformance.

Suppliers of 6061 Aluminium Alloy Powder

Some leading global suppliers of 6061 aluminium alloy powder include:

| Supplier | Powder Types | Particle Size | Production Capacity |

|---|---|---|---|

| Hoeganaes Corporation | Atomized, AncorMax® spherical | 10-150 μm | High tonnage |

| Kymera International | Blended, spherical | 10-150 μm | High tonnage |

| Sandvik | Osprey® atomized | 5-150 μm | High tonnage |

| AMC Powders | Atomized, spherical | 10-60 μm | Medium tonnage |

| TLS Technik GmbH | Gas atomized | 10-100 μm | Low tonnage |

Key factors to consider when selecting a powder supplier are production capacity, powder quality, particle characteristics, lot-to-lot consistency, and pricing. Some additional customization such as sieving or blending may be required to achieve the desired powder properties.

Pricing for 6061 Aluminium Alloy Powder

The price of 6061 aluminium alloy powder can vary significantly depending on:

- Powder type: Spherical is more expensive than blended or irregular powder

- Particle size: Finer powders below 20 μm cost more

- Order quantity: Prices are highest for low volumes and reduce for bulk orders

- Production method: Plasma atomized powder costs more than gas atomized

- Quality: Aircraft or medical grade powder certified to tight tolerances is costlier

- Supplier: Premium powders from leading suppliers demand higher prices

Typical price ranges are:

| Powder Grade | Particle Size | Price Range |

|---|---|---|

| Irregular | -150 +10 μm | $15-25 per kg |

| Spherical | 15-45 μm | $25-60 per kg |

| Plasma Spherical | 15-45 μm | $45-120 per kg |

Reduced prices can be negotiated for bulk orders exceeding 1 ton. There may also be fluctuating surcharges for raw material, energy, and transportation costs.

Installation, Operation, and Maintenance of 6061 Powder Systems

Proper practices for storage, handling, and processing must be followed when working with 6061 powder:

| Activity | Instructions |

|---|---|

| Storage | Store sealed powder containers in a cool, dry area away from moisture First in, first out inventory management Avoid temperature extremes and humidity |

| Handling | Use PPE – respirators, gloves, eye protection Carefully pour powder to avoid spills and dust Ground all equipment to dissipate static charge |

| Processing | Do not overmix powder or use excess lubricant Ensure uniform powder feed into press or printer Follow recommended thermal debinding and sintering cycles |

| Maintenance | Check powder handling and processing equipment regularly for issues Clean dies, tooling, and accessories after production runs Calibrate critical dimensional checks and scales |

Proper PPE, equipment checks, and process control minimize powder contamination and sustain consistent output quality over long production runs.

How to Select a 6061 Aluminium Powder Supplier

Choosing the right aluminium powder supplier is crucial for manufacturing high quality components economically. Here are key considerations when selecting a supplier:

- Powder types: Supplier should offer a range of powder types – spherical, blended, atomized etc.

- Production capacity: Ensure supplier can provide consistent volumes of powder as per production schedule.

- Quality systems: Supplier must have quality certifications such as ISO 9001 and tightly control processes.

- Technical expertise: Seek suppliers with metallurgy and powder production know-how to collaborate on optimizing powder characteristics.

- Customer service: Responsiveness to inquiries, technical support, and packaging/logistics services are vital.

- Prices: Compare pricing between different suppliers and Powder grades based on quantity. Seek competitive quotes.

- Testing capabilities: Supplier should be able to provide detailed test reports for each powder lot.

- Inventory: Ask about stock levels and lead times for orders. Just-in-time inventory capability is preferred.

- Location: Geographic proximity helps reduce shipping costs and delays especially for frequent small orders.

Selecting a supplier who comprehensively meets these criteria will deliver the most consistent, cost-effective 6061 powder for production.

Pros and Cons of 6061 Aluminium Alloy Powder

6061 aluminium alloy powder offers several benefits but also has some limitations to consider:

Advantages

- Excellent corrosion resistance in various environments

- Higher strength than pure aluminium and many other alloys

- Good weldability using most welding methods

- Versatile alloy that can be heat treated to tune properties

- Better ductility than 2xxx and 7xxx alloys when hardened

- Lower cost than specialty alloys used in aerospace applications

- Readily available from a wide range of powder suppliers

Disadvantages

- Lower strength than 2xxx and 7xxx aluminium alloy powders

- Not recommended for very high temperature applications

- Susceptible to stress corrosion cracking in certain environments

- Powder metallurgy process can be more expensive than wrought processing

- Achieving tensile properties equivalent to wrought 6061 can be challenging

- Surface finish and dimensional precision may be inferior to CNC machined parts

- Powder production requires handling of explosive fine aluminium particles

For many commercial applications where moderate strength, good corrosion resistance, and reasonable cost are required, 6061 alloy powder offers the best trade-offs. Aerospace and defense applications demanding very high strength would need specialty powder alloy grades.

Comparison Between 6061, 6063, 7075 Aluminium Alloy Powders

6061 aluminium alloy powder offers a middle ground between 6063 and 7075 alloys:

| Alloy | Composition | Strength | Corrosion Resistance | Weldability | Cost |

|---|---|---|---|---|---|

| 6061 | Al-Mg-Si | Medium | Excellent | Excellent | Medium |

| 6063 | Al-Mg-Si | Low | Excellent | Excellent | Low |

| 7075 | Al-Zn-Mg | High | Good | Fair | High |

- 6063 has the lowest strength but best corrosion resistance and weldability. It is commonly used for architectural applications.

- 6061 provides the best combination of medium strength, excellent corrosion resistance, and good weldability. It is widely used in structural applications across industries.

- 7075 offers very high strength but poorer corrosion resistance and weldability. It is predominantly used in high-strength aerospace applications.

For most commercial powder metallurgy applications, 6061 offers the optimal balance of properties and cost-effectiveness.

FAQ

Q: What are the main alloying elements in 6061 aluminium powder?

A: The main alloying elements are magnesium, silicon, copper, and chromium. Magnesium and silicon additions control the precipitation hardening behavior. Copper improves machining characteristics. Chromium contributes to strength and corrosion resistance.

Q: What is the difference between 6061-T4 and T6 tempers?

A: In the T4 condition, 6061 is solution heat treated and naturally aged to a stable condition. T6 is artificially aged after solution heat treatment to achieve peak strength. T6 offers the highest strength in the 6000 series.

Q: Is 6061 aluminium powder weldable?

A: Yes, 6061 powder maintains the excellent weldability of wrought 6061 alloy. Most fusion and solid-state welding processes can be readily used on 6061 components produced from powder. Proper preheating practices should be followed to avoid cracking.

Q: What are common applications of 6061 powder in aerospace?

A: 6061 is used for a variety of non-critical aircraft components like fittings, brackets, landing gear parts, helicopter rotor components, transmission casings, hydraulic manifolds, and other assemblies where medium to high strength and light weight are required.

Q: How does 6061 aluminium powder compare to stainless steel powder?

A: 6061 has lower strength than stainless steel but offers higher strength-to-weight ratio. It provides better corrosion resistance than carbon steel but lower than stainless steel in some environments. 6061 powder can produce components at lower cost than stainless steel in most cases.

Q: What precautions are necessary when handling 6061 aluminium alloy powder?

A: Fine aluminium powder is highly reactive and flammable. Precautions include grounding equipment, avoiding all ignition sources, wearing appropriate PPE, keeping the environment moisture-free, and having fire suppression systems in place. Careful powder handling procedures must be implemented.

know more 3D printing processes

Frequently Asked Questions (Supplemental)

1) What particle size distribution (PSD) works best for LPBF with 6061 Aluminium Alloy Powder?

- Typically D10/50/90 ≈ 15/30/45 μm with high sphericity and low satellite count. This improves spreadability, packing, and melt-pool stability for higher density.

2) How should oxygen and hydrogen be controlled in 6061 powder for AM/MIM?

- For LPBF/EBM: target O ≤0.10 wt% (many OEMs prefer ≤0.05–0.08 wt%) and H ≤0.010 wt% to reduce porosity and hot cracking. For MIM: slightly higher O can aid sintering, but keep O ≤0.25 wt%. Verify via inert gas fusion per ASTM E1019.

3) What heat‑treatment path is recommended for AM parts made with 6061?

- Common sequence: stress‑relief (e.g., 300–350°C for 2–4 h), full solution heat treatment (~530–550°C, water quench), then artificial aging to T6 (e.g., 160–180°C for 6–12 h). Validate per part thickness and properties.

4) Can recycled 6061 Aluminium Alloy Powder be re‑used across builds?

- Yes, with sieve maintenance (e.g., 45–53 μm), removal of spatter/oxides, and blend‑back (10–30%) into virgin powder. Track PSD, flow, apparent/tap density, and O/H via a powder passport; re‑qualify mechanicals after several cycles.

5) What common printability challenges occur with 6061 and how to mitigate?

- Hot cracking and porosity: use optimized scan strategies (island/chessboard), preheat build plate (100–200°C), maintain chamber O2 < 300 ppm, and consider grain refiners in alloy variants when available.

2025 Industry Trends and Data

- Low‑oxygen atomization: VIM + inert gas atomization with argon recirculation reduces O to ≤0.06 wt% for 6061 AM grades.

- AM‑tuned 6xxx variants: Emerging 6061‑like powders with trace grain refiners (e.g., Zr/Sc micro‑additions) to curb cracking and raise as‑built strength.

- ESG and cost: Disclosed recycled Al content (15–35%) and closed‑loop powder recovery standard in RFQs.

- Post‑processing playbooks: More published T6/T7 thermal routes tailored to LPBF 6061 for improved fatigue and corrosion.

- In‑situ monitoring: Melt‑pool imaging and acoustic signatures increasingly tied to powder lot passports for faster qualification.

| KPI (6061 Aluminium Alloy Powder & AM), 2025 | 2023 Baseline | 2025 Typical/Target | Why it matters | Sources/Notes |

|---|---|---|---|---|

| LPBF PSD (μm, D10/D50/D90) | 20/35/55 | 15/30/45 | Spreadability, density | ISO/ASTM 52907; supplier QC |

| Oxygen in AM‑grade 6061 (wt%) | 0.08–0.12 | 0.04–0.08 | Porosity/cracking | ASTM E1019 |

| As‑built density (LPBF) | 99.2–99.6% | 99.6–99.9% | Mechanical properties | OEM/peer‑reviewed data |

| Chamber O2 during build (ppm) | ≤1000 | 100–300 | Oxidation control | Machine vendor guidance |

| Qualified reuse cycles (LPBF) | 3–5 | 5–8 | Cost, consistency | Plant case studies |

| Disclosed recycled Al content (%) | Limited | 15–35 | ESG, cost | EPD/LCA reports |

Authoritative resources:

- ISO/ASTM 52907 (metal powder characterization), 52904 (PBF practice): https://www.iso.org

- ASTM B822/B214 (PSD), B212/B213 (density/flow), E1019 (O/N/H), F3122 (AM property reporting): https://www.astm.org

- ASM Handbook: Powder Metallurgy; Aluminum and Aluminum Alloys: https://dl.asminternational.org

- NFPA 484 (combustible metals safety): https://www.nfpa.org

- NIST AM Bench datasets: https://www.nist.gov/ambench

Latest Research Cases

Case Study 1: LPBF 6061 with Low‑Oxygen Powder and Preheat for Automotive Housings (2025)

- Background: An automotive supplier needed leak‑tight, lightweight housings with consistent mechanicals.

- Solution: VIM + inert gas atomized 6061 Aluminium Alloy Powder (PSD 15/30/45 μm; O = 0.055 wt%); build‑plate preheat 160°C; island hatch; contour passes; stress‑relief + solution + T6 aging; CT‑based acceptance.

- Results: As‑built density 99.85%; helium leak rate <1×10⁻⁹ mbar·L/s; YS/UTS +8–10% vs. 2023 baseline; scrap −21%; validated 6 reuse cycles with 20% blend‑back.

Case Study 2: Sinter‑Based AM (Binder Jet) 6061 Heat Sinks with Sinter‑HIP (2024)

- Background: An electronics OEM required high‑surface‑area heat sinks with lower unit cost.

- Solution: Fine spherical 6061 powder (D50 ≈ 18 μm); binder jetting; debind in N₂; sinter in H₂‑N₂ followed by HIP; aging to T6; dye penetrant and thermal conductivity tests.

- Results: Final density 99.1–99.4%; thermal conductivity 150–160 W/m·K post‑T6; unit cost −12% vs. CNC + brazed fins; lead time −30%.

Expert Opinions

- Prof. John Campbell, Metallurgy (retired), University of Birmingham; casting and aluminum alloys expert

- Viewpoint: “Powder cleanliness—minimizing bifilm/oxide populations—remains decisive for fatigue and leak‑tightness in AM‑processed 6061.”

- Dr. Brandon Lane, Research Engineer, NIST

- Viewpoint: “Linking melt‑pool imaging to powder passports can flag off‑spec 6061 lots earlier than downstream tensile tests.”

- Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

- Viewpoint: “AM‑tuned 6xxx chemistries with micro‑additions show promise to tame hot cracking while preserving corrosion resistance.”

Affiliation links:

- University of Birmingham: https://www.birmingham.ac.uk

- NIST (Additive Manufacturing): https://www.nist.gov

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

Practical Tools/Resources

- Standards/QC: ISO/ASTM 52907; ASTM B212/B213/B214/B822; ASTM E1019; ASTM F3122

- Metrology: LECO O/H analyzers (https://www.leco.com); laser diffraction PSD; SEM for morphology/satellites; CT for internal porosity; helium leak testing

- Process/simulation: Ansys Additive or Simufact Additive for scan/preheat optimization; Thermo‑Calc/DICTRA for Al‑Mg‑Si precipitation modeling; nTopology for lattice heat‑sink optimization

- Databases: Senvol Database (https://senvol.com/database); MatWeb (https://www.matweb.com)

- Safety: NFPA 484 guidance; ISO 80079 for explosive atmospheres; supplier SDS and handling SOPs

Last updated: 2025-08-22

Changelog: Added 5 supplemental FAQs focused on PSD, interstitials, reuse, and heat treatment; introduced a 2025 KPI table and trend insights for AM/MIM use of 6061 Aluminium Alloy Powder; provided two recent case studies (LPBF automotive housings; binder‑jet heat sinks); included expert viewpoints with affiliations; compiled standards, simulation, and safety resources.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards update, OEMs publish new O/H limits or preheat guidance for 6061 AM grades, or new datasets on AM‑tuned 6xxx chemistries and in‑situ monitoring correlations are released.