3D printer metal powders are specialty metallic powders used as raw materials in various metal 3D printing processes. These powders allow complex metal parts and components to be fabricated layer-by-layer using additive manufacturing techniques.

Overview of 3D Printer Metal Powders

3D printer metal powders exhibit specific characteristics that make them suitable for additive manufacturing compared to conventional metal powders:

- Finer particle size distribution

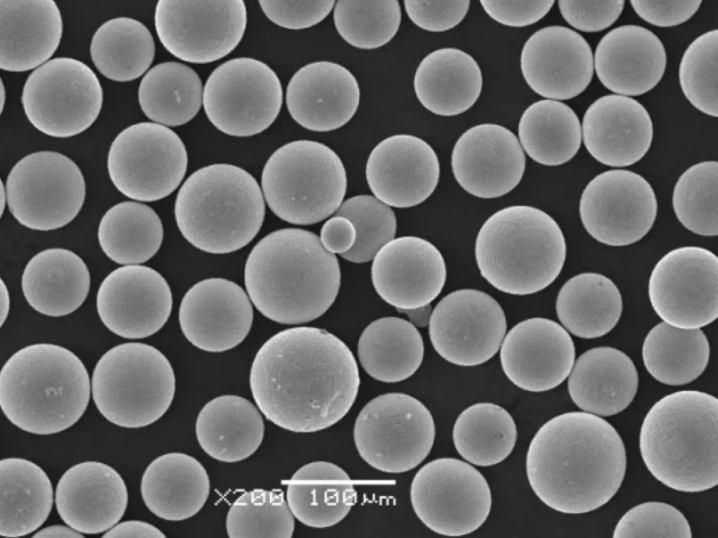

- Spherical morphology

- Controlled microstructure and crystallographic texture

- Consistent chemical composition

- Optimized flowability and packing density

These properties allow the powders to be precisely deposited and fused into accurate parts with reliable mechanical properties.

The most common metal powders used are:

- Stainless steel

- Aluminum

- Titanium alloys

- Cobalt-chrome

- Nickel superalloys

- Copper alloys

Various metal 3D printing technologies use powder bed fusion, directed energy deposition, or binder jetting processes. The type of powder is selected based on compatibility with the specific print process.

Table 1: Comparison of Metal 3D Printing Processes

| Process | Description | Metals Used |

|---|---|---|

| Powder Bed Fusion | Powder spread in thin layers and selectively melted by laser or electron beam | Stainless steel, aluminum, titanium, nickel and cobalt alloys |

| Directed Energy Deposition | Focused thermal energy source melts metal powder injected simultaneously | Stainless steel, titanium, aluminum, cobalt-chrome alloys |

| Binder Jetting | Liquid bonding agent selectively joins powder particles together | Stainless steel, tool steel, bronze, tungsten carbide |

Metal Powder Compositions

Here are some of the commonly used metal alloys and their compositions used in commercial 3D printing:

Table 2: Common Metal Powder Compositions

| Alloy | Main Elements | Example Grades |

|---|---|---|

| Stainless Steel | Fe, Cr, Ni, Mo | 316L, 17-4PH, 15-5PH, 420 |

| Aluminum | Al, Si, Mg, Cu | AlSi10Mg, AlSi7Mg0.6, AlSi12 |

| Titanium | Ti, Al, V | Ti6Al4V, Ti6Al4V ELI |

| Cobalt Chrome | Co, Cr, W, Ni, Fe, Si, Mn, C | CoCr, CoCrMo |

| Nickel Superalloy | Ni, Cr, Co, Mo, W, Al, Ti, Ta | Inconel 625, Inconel 718 |

| Copper Alloy | Cu, Zn | CuSn10, CuCr1Zr |

The ratios of the main alloying elements can be varied to obtain specific microstructures and tailored mechanical properties. Trace additives may also be included for enhanced performance.

Table 3: Elemental Composition Ranges of Common Alloys

| Alloy | Major Constituents (wt%) | Minor Constituents (wt%) |

|---|---|---|

| 316L stainless steel | Cr 16-18, Ni 10-14, Mo 2-3 | C, Si, P, S < 0.1 |

| AlSi10Mg aluminum | Al bal., Si 9-11, Mg 0.2–0.45 | Fe < 0.55, Mn < 0.45, Ti < 0.15 |

| Ti6Al4V titanium | Al 5.5-6.75, V 3.5-4.5 | Fe < 0.3, O < 0.2 |

| CoCrMo cobalt chrome | Co bal., Cr 26-30, Mo 5-7 | Si < 1, Mn < 1, C < 0.35, Fe < 0.75 |

| Inconel 718 nickel alloy | Ni 50-55, Cr 17-21, Nb+Ta 4.75-5.5 | Mo 2.8-3.3, Ti 0.65-1.15 |

Metal Powder Properties

The properties of metal powders determine print quality, part functionality and production economics:

Table 4: Key Properties of Metal Powders for Additive Manufacturing

| Property | Typical Range | Role |

|---|---|---|

| Particle size | 10-75 μm | Affects layer thickness, detail resolution, density |

| Morphology | Predominantly spherical | Influences packing, spreadability, flow |

| Apparent density | Up to 80% of solid | Determines quantity required to build parts |

| Tap density | Up to 90% of solid | Indicates packing efficiency during processing |

| Flow rate | Up to 50 s/50g | Ensure smooth powder spreading during printing |

| Chemical purity | Up to 99.9% target metal | Avoids reaction products or inclusions |

The specifications depend on the exact part quality and mechanical properties needed.

For most metals in laser-based processes, the ideal powder size is ~20-45 μm for optimized part density (>99%) and surface finish (Ra 5-15 μm).

Spherical powders flow and spread evenly. Irregular shapes negatively impact packing and cause defects. Powders for binder jetting can be 10-100 μm since there is no melting.

Higher apparent and tap densities lead to better utilization of expensive metal powders during printing. Lower densities cause excess wastage.

Reliable flow ensures uniform layers. Poor flow causes uneven melting and distorted builds. Moisture absorption severely reduces flowability.

Even minor impurities can degrade alloy properties or clog print nozzles. Use of high purity raw materials is critical.

Table 5: Supplier Specifications for Common Metal Powders

| Material | Size Range | Oxygen Content | Tap Density | Flow Rate |

|---|---|---|---|---|

| 316L stainless | 15-45 μm | < 0.1 wt% | Up to 4.2 g/cc | < 40 s |

| AlSi10Mg | 25-55 μm | < 0.45 wt% | Up to 2.7 g/cc | < 32 s |

| Ti6Al4V | 10-75 μm | < 0.13 wt% | Up to 2.7 g/cc | < 50 s |

| CoCr | 20-63 μm | < 0.1 wt% | Up to 4.4 g/cc | < 60 s |

| Inconel 718 | 10-45 μm | < 0.04 wt% | Up to 4.5 g/cc | < 45 s |

Operating within the recommended range ensures high product quality. Excess variation risks defects.

Metal Powder Applications

Here are some examples of end-use applications taking advantage of 3D printed metal parts, along with the typical alloys used:

Table 6: End-use Applications and Alloys for Metal AM Parts

| Industry | Application | Metals Used | Benefits |

|---|---|---|---|

| Aerospace | Turbine blades, frames, antennas | Ti alloys, Ni superalloys, Al alloys | Weight savings, complex cooling channels |

| Automotive | Brake levers, pistons, manifolds | Al alloys, stainless steel | Performance gains, consolidated assemblies |

| Medical | Orthopedic implants, surgical tools | Ti, CoCr, stainless steel | Patient-specific shapes, bio-compatibility |

| Oil & gas | Valve bodies, pump impellers | Stainless steel, Inconel | Withstand extreme environments |

| Consumer | Jewelry, decorative art | Gold alloys, silver | Intricate geometries, custom designs |

Metal additive enables lighter, stronger products optimal for each function at lower costs compared to traditional fabrication processes in small batch production scenarios.

Table 7: Highlights of Metal 3D Printing vs Traditional Methods

| Metric | Metal AM | Subtractive Machining | Casting |

|---|---|---|---|

| Part complexity | No restrictions | Limited by tool access | Restricted by molds |

| Customization | Easily change designs | New programs required | Redesign patterns |

| Operating costs | Low up to 10,000 parts | High setup costs | High tooling costs |

| Mechanical properties | Similar or exceed | Depends on method | Varies, heat treatment |

FAQ:

Q: What is the difference between pre-alloyed and blended elemental metal powders?

A: Pre-alloyed powders have the target alloy composition pre-made by the manufacturer, ensuring chemical homogeneity. Blended elemental powders consist of pure metal powders that are mixed together in the target ratios before printing, combining during melting.

Q: How are these powder properties measured and analyzed?

A: Particle size distribution is quantified by laser diffraction analysis. Morphology and microstructure are studied under scanning electron and optical microscopy. Densities are measured by Hall flowmeter and tapped density tester instruments per ASTM standards. Chemical analysis is done using atomic absorption or emission spectroscopy and inert gas fusion for oxygen and nitrogen content.

know more 3D printing processes

Frequently Asked Questions (Supplemental)

1) Which particle size distributions are best for different AM processes using 3D Printer Metal Powders?

- LPBF/SLM: 15–45 μm (tight PSD for spreadability and density)

- EBM: 45–105 μm (hot build reduces residual stress)

- DED: 45–150 μm (stable powder feeding)

- Binder Jetting/MIM: ≤22–30 μm (high green density and sinterability)

2) How many reuse cycles are acceptable for LPBF powders?

- It depends on alloy and controls. With sieving, blend-back, and monitoring O/N/H, PSD, and flow, many plants qualify 5–10 cycles before a full refresh. Define limits by mechanical property drift and defect analytics.

3) What are the key acceptance tests for incoming 3D printer metal powders?

- Chemistry (ICP/OES; O/N/H by inert gas fusion), PSD (laser diffraction per ASTM B822), morphology/cleanliness (SEM), flow and apparent density (ASTM B213/B212), tap density, Hall/Carney flow, and powder moisture. Request a lot-level Certificate of Analysis/powder passport.

4) Do green/blue lasers change powder requirements?

- Yes. For reflective alloys (Al, Cu), green/blue lasers improve absorptivity and broaden the process window, often enabling slightly coarser PSDs and higher build rates while holding density. Still specify spherical morphology and low oxide films.

5) How do post‑processing choices impact performance across alloys?

- HIP closes pores and boosts fatigue (notably Ti and Ni). Heat treatments per alloy (e.g., 17‑4PH H900, IN718 AMS 5662/5664) set strength/ductility. Surface finishing (shot peen, chemical/electropolish) reduces Ra and initiation sites; passivation (ASTM A967) benefits stainless parts in chlorides.

2025 Industry Trends and Data

- Powder traceability: Digital “powder passports” with chemistry, PSD, O/N/H, reuse count, and build linkage are becoming standard in aerospace and medical RFQs.

- Throughput: Multi‑laser LPBF, improved gas flow, and adaptive scanning yield 10–30% faster builds while maintaining density.

- Copper and aluminum renaissance: Green/blue lasers expand adoption of high‑conductivity Cu and reflective Al alloys for heat exchangers and RF parts.

- Sustainability: Argon recirculation, higher recycled content feedstocks, and extended reuse policies cut material OPEX and CO2e.

- QA automation: In‑situ melt‑pool/layer imaging with AI anomaly detection reduces CT burden and shortens qualification.

| KPI (3D Printer Metal Powders & AM), 2025 | 2023 Baseline | 2025 Typical/Target | Why it matters | Sources/Notes |

|---|---|---|---|---|

| LPBF relative density post‑HIP (Ti, Ni, SS) | 99.6–99.8% | 99.8–99.95% | Fatigue, leak‑tightness | OEM/peer‑reviewed data |

| Chamber O2 during LPBF (ppm) | ≤1000 | 100–300 | Oxide, defects | Machine vendor guidance |

| Qualified powder reuse cycles (LPBF steels) | 4–6 | 6–10 | Cost, sustainability | Plant case studies |

| Build rate improvement (multi‑laser) | — | +10–30% | Productivity | AMUG/Formnext 2024–2025 |

| Binder‑jet sintered density (316L) | 95–97% | 96–98% (≥99% w/HIP) | Mechanical reliability | OEM notes |

| Green/blue laser adoption (Cu/Al installs) | Pilot | Common on new lines | Conductive alloys | OEM releases |

| Recycled content in feedstock | 5–20% | 20–40% | ESG, cost | EPD/LCA disclosures |

References and standards:

- ISO/ASTM 52907 (powder characterization), 52904 (LPBF practice): https://www.iso.org

- ASTM F3302 (AM process control), ASTM B822/B214 (PSD), B212/B213 (density/flow): https://www.astm.org

- NIST AM Bench datasets: https://www.nist.gov/ambench

- ASM Handbook: Additive Manufacturing and Materials: https://dl.asminternational.org

Latest Research Cases

Case Study 1: Green‑Laser LPBF of CuCr1Zr Heat Exchangers with Enhanced Density (2025)

- Background: An e‑mobility OEM needed compact copper heat exchangers with high thermal conductivity and leak‑tight channels.

- Solution: Switched to 515 nm green laser LPBF; spherical CuCr1Zr powder (15–45 μm), O ≤0.08 wt%; optimized gas flow and contour strategies; HIP + aging to peak conductivity.

- Results: As‑built density 99.3%, post‑HIP 99.9%; thermal conductivity 360–380 W/m·K; helium leak rate <1×10⁻⁹ mbar·L/s; build time −18% vs. IR laser baseline.

Case Study 2: Binder‑Jetted 316L Manifolds Achieving Near‑Wrought Properties via Sinter‑HIP (2024)

- Background: A robotics firm targeted cost and weight reductions for complex manifolds.

- Solution: Used 316L powder D50 ≈ 20 μm; controlled debind/sinter; HIP; implemented powder passports and SPC on shrinkage/porosity.

- Results: Final density 99.5%; UTS 550–570 MPa, elongation ~40%; unit cost −15% vs. machined assembly; CT reject rate −40%.

Expert Opinions

- Dr. Todd Palmer, Professor of Materials Science, Penn State CIMP‑3D

- Viewpoint: “Powder quality—especially interstitial control and PSD consistency—remains the strongest predictor of fatigue performance in metal AM.”

- Prof. Ian Gibson, Additive Manufacturing Scholar, University of Texas at Arlington

- Viewpoint: “Process choice should be driven by downstream finishing and qualification: LPBF for fine features, binder jetting for throughput, DED for large repairs.”

- Dr. Martina Zimmermann, Head of Additive Materials, Fraunhofer IWM

- Viewpoint: “AI‑assisted in‑situ monitoring tied to digital powder passports is rapidly becoming mandatory for regulated aerospace and medical builds.”

Affiliation links:

- Penn State CIMP‑3D: https://www.cimp-3d.psu.edu

- University of Texas at Arlington: https://www.uta.edu

- Fraunhofer IWM: https://www.iwm.fraunhofer.de

Practical Tools/Resources

- Standards: ISO/ASTM 52907, 52904; ASTM F3302; ASTM B212/B213/B822

- Databases: NIST AM Bench; Senvol Database (https://senvol.com/database); MatWeb (https://www.matweb.com)

- QA/Monitoring: Melt‑pool and layerwise imaging (EOS, SLM Solutions, Renishaw); CT scanning for porosity; LECO O/N/H (https://www.leco.com)

- Design/Simulation: nTopology (lattices, heat exchangers), Ansys Additive and Simufact Additive (distortion/scan strategy), Autodesk Netfabb

- Post‑processing: HIP service providers; electropolish/passivation (ASTM A967) for stainless; age/solution treatments per alloy specs (e.g., IN718 AMS 5662/5664)

Last updated: 2025-08-22

Changelog: Added 5 supplemental FAQs; included 2025 trends with KPI table and standards; provided two case studies (CuCr1Zr green‑laser LPBF and binder‑jet 316L manifolds); added expert viewpoints with affiliations; compiled practical standards, QA, simulation, and database resources for 3D Printer Metal Powders.

Next review date & triggers: 2026-02-01 or earlier if ISO/ASTM standards update, major OEMs publish new oxygen/reuse specs, or new datasets on green/blue laser processing of Cu/Al powders are released.