The microstructure and mechanicalproperty anisotropy of Invar36 alloy by LPBF

Invar 36 is widely used in aerospace and precision instruments. Truer RD team prepared the samples of Invar36 alloy through a laser powder bed fusion (LPBF) process to do some investigation for its microstructure& mechanical properties. The results showed its microstructure and mechannical properties of the three orientations have anisotropy characteristic.

Table 1 is the chemical composition of the powders of the LPBF samples produced by Truer.The nominal composition of the Invar 36 alloy consists of 36% Ni and 64% Fe, with other elements present as unavoidable trace impurities during the powder preparation process. Therefore, some residual stress caused by trace impurities is negligible.

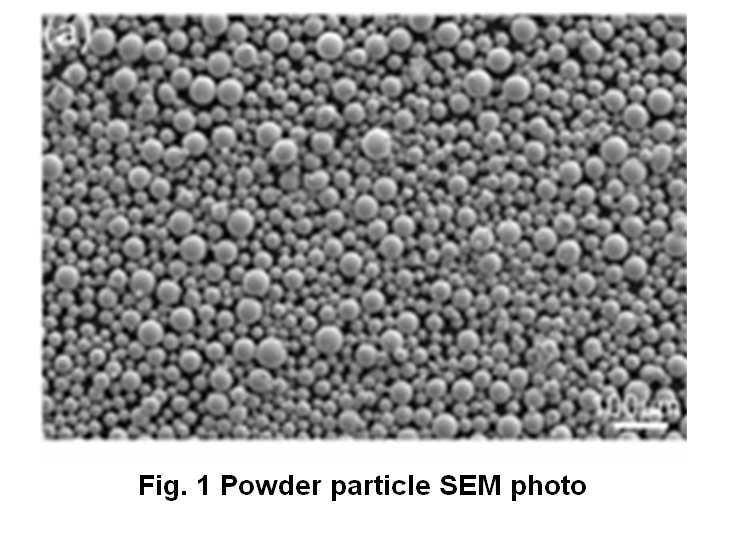

Fig.1 showed powder particle SEM photo which be tested with D10: 19.1μm, D50: 37.3μm and D90: 63.7μm.

| Table 1 Chemical compositionof Invar 36 powder studied | |||||||

| Elements | Fe | Ni | Cr | Mn | Co | P | C |

| wt% | Bal | 36.02 | 0.005 | 0.029 | 0.030 | 0.001 | 0.0011 |

Microstructure characterization of Invar 36 alloys prepared by LPBF with Invar 36 powder produced by Truer exhibits a clear single gamma phase with face-centered cubic lattice and strong orientations. This indicates that there is a possibility of optimal grain orientation in the samples.

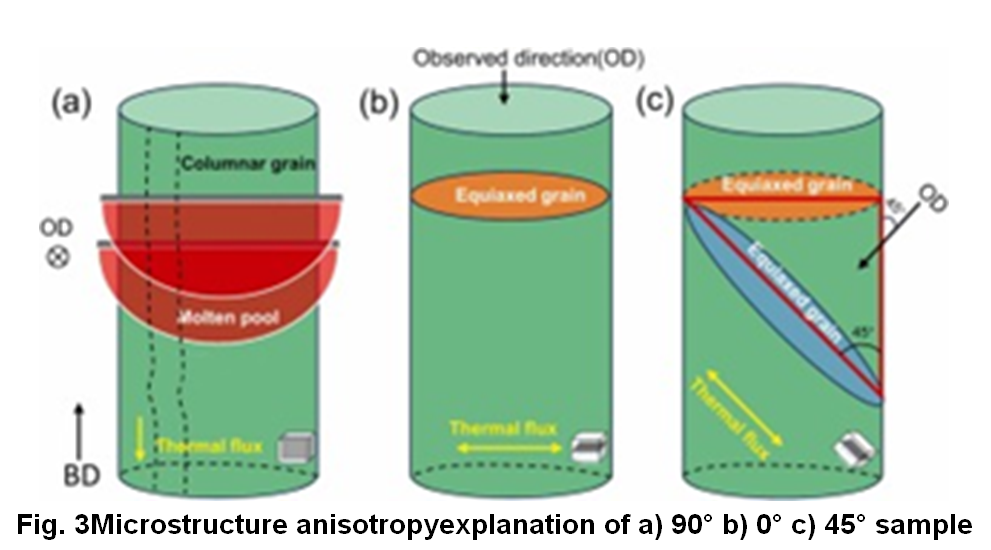

In order to study the microstructure anisotropy of Invar36 alloys with different orientations prepared by LPBF, the grain morphology and sizewere analyzed. The microstructure anisotropy of Invar 36 alloys (Fig. 2) prepared by LPBF at 0°, 45° and 90° orientations are similar to that observed in Inconel 718 and AlSi10Mg alloys prepared by LPBF.

At 0°, 45° and 90°, the microstructure of Invar 36 alloy prepared by LPBF is also similar to that of Ti15Mo alloy prepared by LPBF.Both 0° and 45° samples are equiaxial, the grain size of 90° is significantly different in grain size and shape compared with the other two samples.

According to the rule, grain intensity is the square root of the grain index indicating grain orientation. So after some calculation, Invar36 alloy prepared by LPBF, the texture strength of 0° , 45° and 90° samples can be calculated as 2.46, 2.90 and 2.61, respectively. The texture index and the texture strength of Invar 36 alloy prepared by LPBF process are greater than 1 in the directions of 0°, 45° and 90°, indicating that the microstructure of the material shows obvious anisotropy.

Itsstress-strain curves of Invar36 alloy manufactured by LPBF in different building directions were tested. Obviously, the three samples exhibit different mechanical properties: sample 90° has a yield strength of 364MPa, while samples 0° and 45° show higher 392MPa and 401MPa. And the tensile strength of each sample followed this trend, with values of 397MPa, 485MPa, and 496MPa of 90° , 0° , and 45° . Finally, the elongation measurement shows that the elongation of 90° is 62.70% indicating that Invar 36 alloy prepared by LPBF has a good application prospect.

Fig.3 provides a more complete explanation anisotropy of microstructure in alloys manufactured by LPBF. For 90°, the temperature gradient G between the molten pool and the solidified solid is significantly larger, which is conducive to the formation of columnar grains in the direction of heat flux. For 0° samples, heat flows from the molten pool center to both sides, resulting in a smaller G. Therefore, it is easier to form equiaxed grains. In addition, the geometric relationship of the microstructure of 45° sample is shown in Fig. 3 (c). The observed surface is equivalent to the surface obtained by cutting the 90° sample with a 45° tangent, and the projection of the 0°sample. Therefore, both 0° and 45° samples exhibit equiaxial morphology, but the latter exhibits elongation.

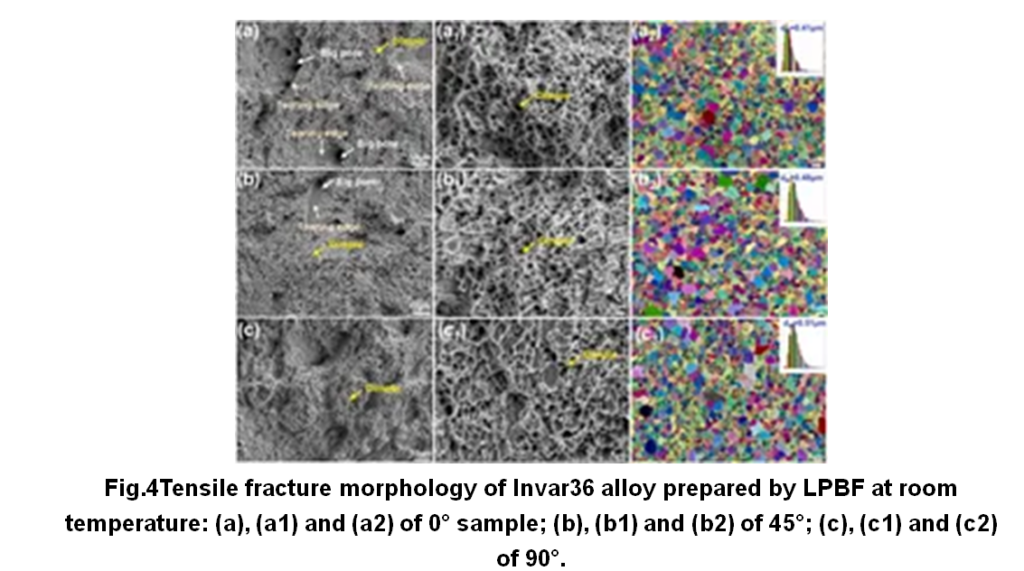

Fig. 4 shows the tensile fracture morphology of 0°, 45° and 90° samples at room temperature, revealing the tensile failure mode. In the 0° and 45° samples, there are large pores, which may be attributed to the formation of weak regions with damaged metallurgical bonding. During the tensile test, the weak area shows preferential fracture, resulting in the generation of tearing edges. In contrast, the 90° sample does not exhibit large voids and exhibits excellent elongation, which is consistent with the tensile test results.

After some tests and analysis by Truer for Invar36 alloys which were prepared by fusion of laser powder beds, we concluded, at different build orientations of 0°, 45° and 90°,the microstructure and mechanical properties of Invar36 alloy prepared by LPBF show obvious anisotropy in three directions. And the specimens at 90° direction showed columnar grain growth in multiple pools. However, structures manufactured at 0° and 45° directions exhibit equiaxed grains. The mechanical properties of Invar36 alloy prepared by LPBF are sensitive to the microstructure and therefore show obvious anisotropy. Invar36 alloy prepared by LPBF showed ductile fracture, and the sample prepared in the 90° direction had the largest dimple size and better elongation (62.70%).

This work provides valuable insights and a solid foundation for manufacturing Invar36 alloy by LPBF and also Invar 36 powders.